TI-6212

New Member

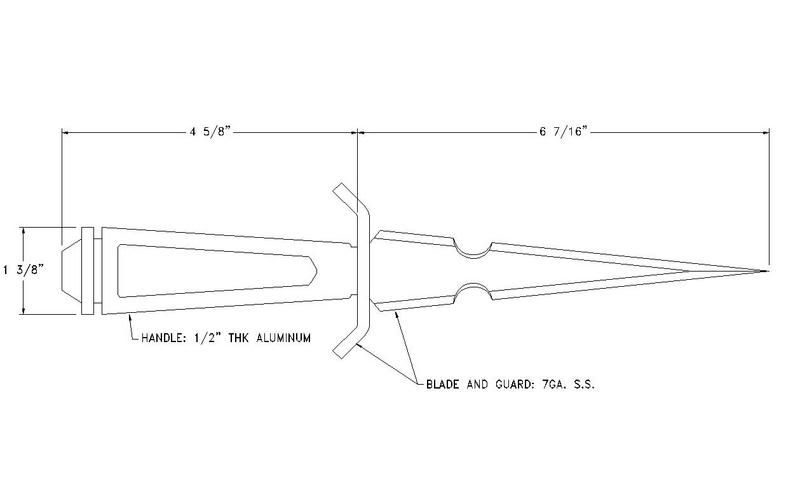

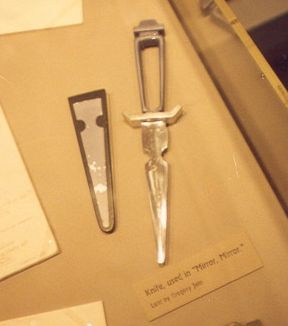

Tiberius Kirk has inspired me. After fifteen years (I saw the original on display at the Smithsonian back in '92) I've decided to try my hand at this. Here's a rough mock-up of mine.

The finished handle will be machined from 1/2" thick Aluminum.

The blade and guard are 7 gage (3/16" Thk) Stainless Steel.

The blade will have a partial tang that fits inside the handle.

My thanks to NeilO for his generous technical advice on this project.

Wish me luck!

Todd H.

The finished handle will be machined from 1/2" thick Aluminum.

The blade and guard are 7 gage (3/16" Thk) Stainless Steel.

The blade will have a partial tang that fits inside the handle.

My thanks to NeilO for his generous technical advice on this project.

Wish me luck!

Todd H.