Crescentmage

New Member

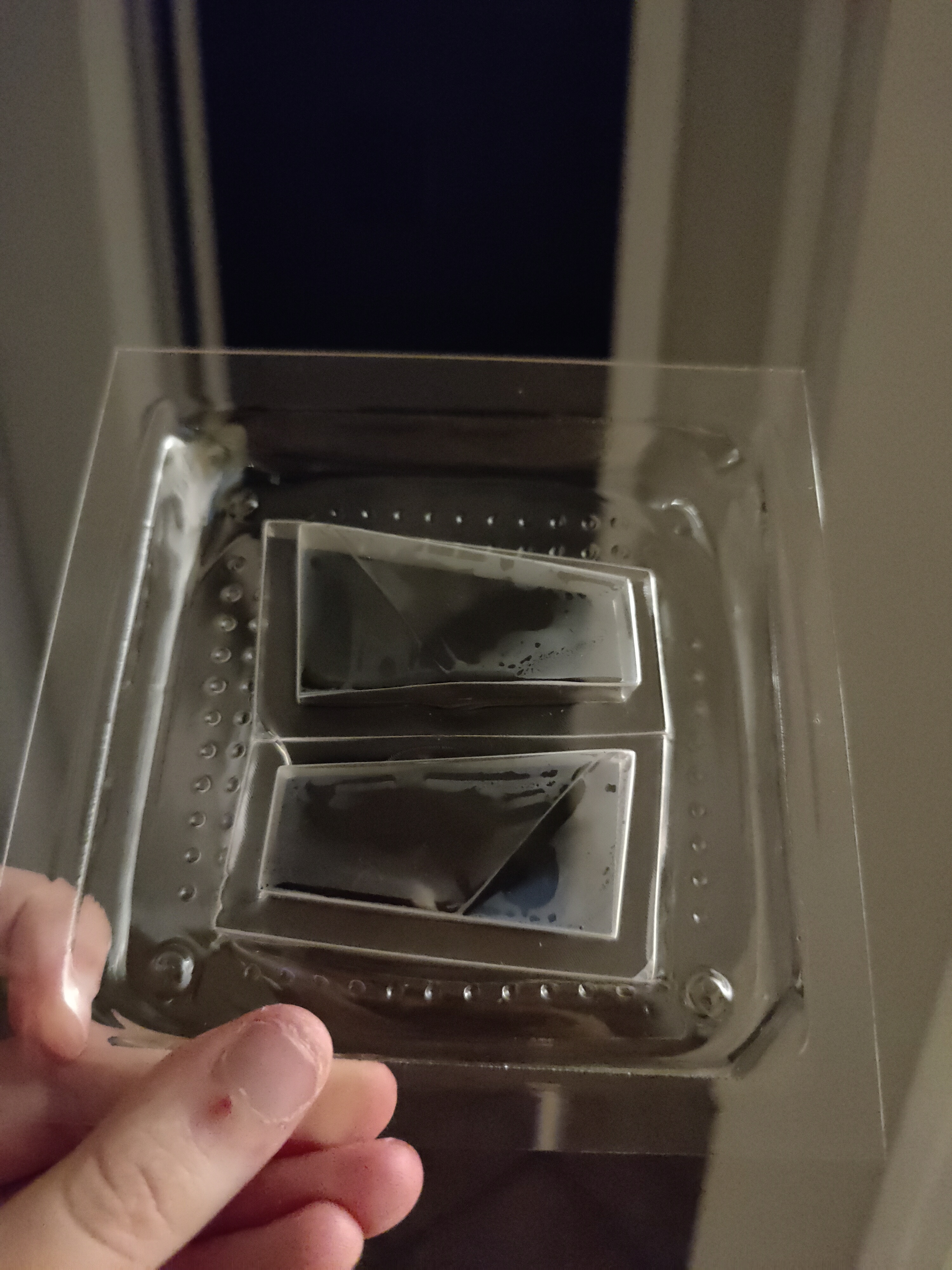

I'm trying to vacuuform some lenses for a Madness Combat mask I'm working on. The bucks are resin printed, and originally the thermoplastic would pick up the print lines when I'd do pulls, so I decided to sand out the print lines on the bucks to a glasslike finish. Upon attempting to vacuuform the lenses again, a new issue occured; the pulls now develop a cloudy film(?) on them, which compromises their use as lenses. Could someone help me figure out what's going on here? I suspected it may be moisture, but I wasn't having this issue before I removed the print lines.