RevMarx

New Member

I am in the midst of making a couple of props for an upcoming steampunk larp game at Origins. Among them is a deep sea diving helmet. I have never made something like this before, but I have read a few blog from others who have. I am mostly making it up as I go along, and could use any advice that is offered.

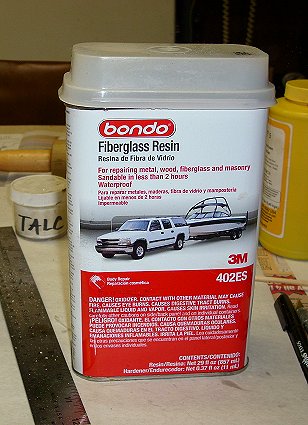

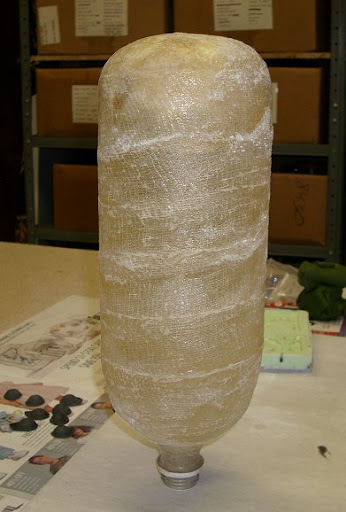

To start with, I covered an inflatable beach ball with petroleum jelly (so it can be removed later), and then covered it with paper-mâché (not very thick, because I hate working in paper-mâché). That was not going to be strong enough, so I decided that I should try covering it with fiberglass.

I have only ever used fiberglass once before, and it was a mess. Anyway, to save on bulk and cost, I thought that I could maybe substitute the fiber mat with cheesecloth, since I don't really need it to be super strong, and I thought the cheese cloth would give the resin strength just like the glass mat would, for super cheap. I did a little digging on the web and did find some evidence of cheese cloth being used with fiberglass resin by a couple of artists, but no details of the process.

My main question is this; has anyone ever used cheese cloth with fiberglass resin? If so, how did it turn out? Does anyone have any pointers on this technique? Just to be clear, I am talking about what Americans call cheese cloth (like gauze) , not what people form the UK call cheese cloth which, as I hear, is something else.

I've worked on two pieces so far, and it has not been as easy to work with as I imagined. For my next test piece, I am using spray glue to adhere the cheese cloth to the object first, then adding the resin. Adhering the cheese cloth with the glue went much smoother than it did applying it directly to the base coat of wet resin, but I have yet to see what happens when the resin is brushed on (tomorrow's goal).

If anyone has used this technique, or has any general fiberglass tips, or really and advice at all for this project, I would love to hear it.

-Rev. Marx

To start with, I covered an inflatable beach ball with petroleum jelly (so it can be removed later), and then covered it with paper-mâché (not very thick, because I hate working in paper-mâché). That was not going to be strong enough, so I decided that I should try covering it with fiberglass.

I have only ever used fiberglass once before, and it was a mess. Anyway, to save on bulk and cost, I thought that I could maybe substitute the fiber mat with cheesecloth, since I don't really need it to be super strong, and I thought the cheese cloth would give the resin strength just like the glass mat would, for super cheap. I did a little digging on the web and did find some evidence of cheese cloth being used with fiberglass resin by a couple of artists, but no details of the process.

My main question is this; has anyone ever used cheese cloth with fiberglass resin? If so, how did it turn out? Does anyone have any pointers on this technique? Just to be clear, I am talking about what Americans call cheese cloth (like gauze) , not what people form the UK call cheese cloth which, as I hear, is something else.

I've worked on two pieces so far, and it has not been as easy to work with as I imagined. For my next test piece, I am using spray glue to adhere the cheese cloth to the object first, then adding the resin. Adhering the cheese cloth with the glue went much smoother than it did applying it directly to the base coat of wet resin, but I have yet to see what happens when the resin is brushed on (tomorrow's goal).

If anyone has used this technique, or has any general fiberglass tips, or really and advice at all for this project, I would love to hear it.

-Rev. Marx