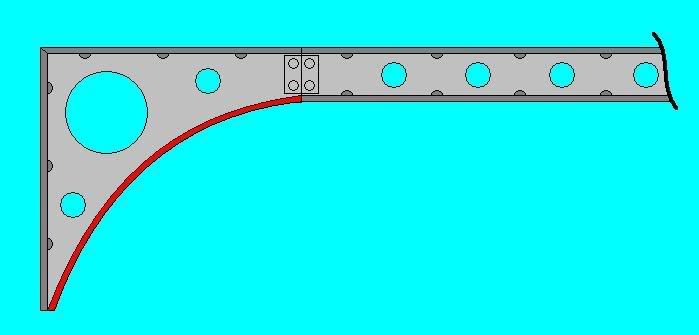

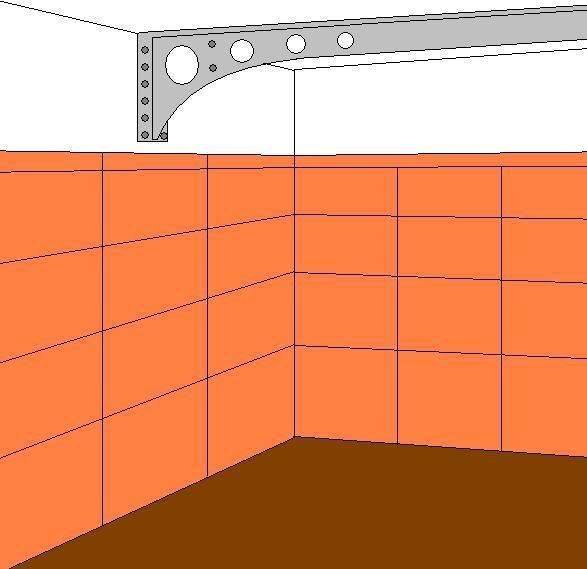

i think i might know what you mean.....like where the straight parts of the I beam intersect isn't a sharp 90 degree corner, but more beveled like this

what i would do is build the I beam out of wood then get a piece of flat plastic (like styrene, but more towards the thicker side like .060 or .080) make sure the edge of the plastic is a perfect 90 degrees (and make sure your I beam is pretty perfect too) then cut out the negative shape of how you want your bevel/transition to be, then get some bondo, smear it along the corner, and scrape your plastic template over that to shape it

some tips/pointers:

to save time and money if the bevel is more than .25", glue a strip of wood in the corner to take up some of the space so you don't have to fill the entire area with bondo

bondo kicks pretty fast so do smaller sections instead of trying to do it all at once

maybe have a spray bottle with acetone handy, apply your bondo, swipe it with the plastic, clean off the plastic, then give the bondo and the plastic a fine mist of acetone and re-drag the plastic to get a smoother finish (note: too much acetone will leave the surface of the bondo a little tacky but its not a big deal)

you can also mix up your bondo, throw it in a sturdy ziplock bag, shake it until it gathers in the corner of the bag, then snip the tip of the corner off and use it like a pastry/icing bag to apply the bondo faster and more consistently before you swipe it

be careful, some types of plastic disolve with acetone, and some will even get a little soft with continued exposure to the resin in bondo

hope that helps......and if you were talking about something completely different then i just wasted my time