So, I really want to hash out more on how the ROTJ MoM DV6 (whatever) Vader saber is held together.

To do this, I think it would be good to consolidate discussion on this topic in general. The DV6 was originally an ESB Luke hilt, one way or another. Which means certain things. The sabers we know of that were built this way include:

1 ANH Luke pipe with bolts

Barbican Saber*

*Vader Severed Hand cast

Luke ESB Graflex (maybe multiples, maybe just 1)*

*Vader DV6

Vader MPP (Maybe multiples, maybe just 1)

*1 ANH Motorized Luke pipe without black bolts, just a small grub screw seen in warehouse*

any more?

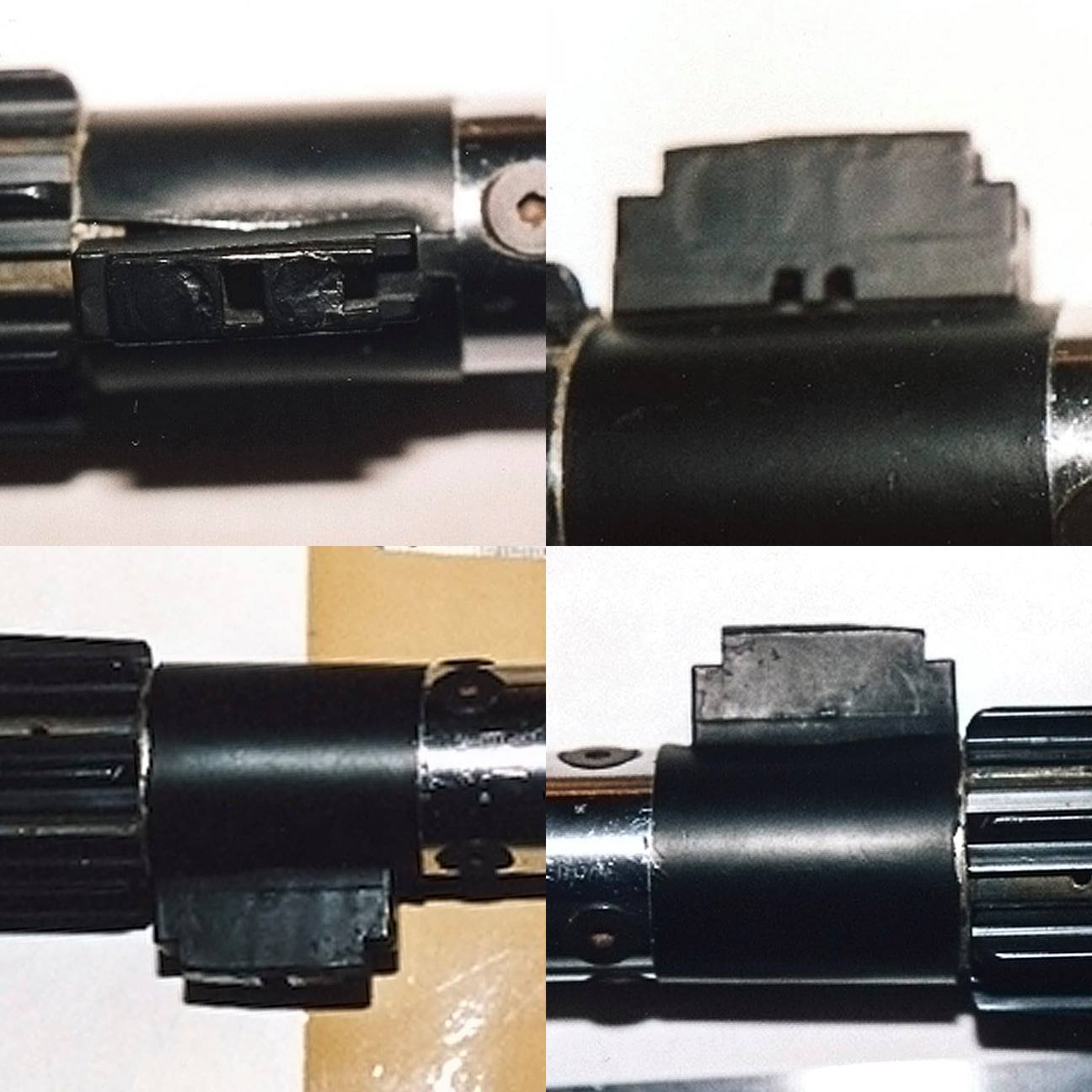

The main item inside the hilt is an aluminum slug. I am 99% sure they did not extend through the entire hilt, it would be too back heavy. A front-half core balances the saber in your hand, I've done this at home. Black M6 bolts, countersunk, held the core in the tube. The Barbican and the "pipe" stunt had 4 bolts and a solid front-half core.

The Graflex, at least, had a second core replacing the upper section of the socket, while the slug replaced the lower section of the socket leaving the middle. The MPP.... we are not sure, there seem to be wires suggesting a socket piece, but it also would be easier to run a solid core.

The countersinking was not well done, I have NO idea why there are 7 bolts in the Vader DV6, after drilling 1... maybe 2.... properly, a core is stuck solid.

Anyway, the other feature is a steel tang stuck in the core, with a lathed ring for the blade collar set screws. I'm not 100% sure where the grub screw for these are in the hilt. The pipe stunt may have one where the red button used to go, there is a threaded hole there. The others? I can only assume a threaded hole is drilled into the core somewhere, with a grub screw lowered flush with the surface, so it can slide into the tube. This might explain why people kept chopping the tang with a hacksaw instead of pulling it out like the V3, the screw might not have been accessible...covered by the bolted handle

Back to the DV6 this means we can start our brainstorming standing on a few facts. We can't see any tang grub screw (with the Vader parts on the flash at least). The core extends from the side ports to.... at least.... to the 3 bolts side-by-side on the back of the saber. I doubt it goes much further, I think it is the Luke core and I have been told they don't extend much further than the front half of the flash. ala, this photo, look on the sofa

So now begs the question how the heck is the rear of the Vader saber held on so well it can be hung upside down!? It is able to twist.. which maybe means only a couple screws attach it. I see black empty space behind the control box, actually two where there should be 1 (the bayonet lock slot). People who can do 3D stuff, I would love to hear your thoughts.

To do this, I think it would be good to consolidate discussion on this topic in general. The DV6 was originally an ESB Luke hilt, one way or another. Which means certain things. The sabers we know of that were built this way include:

1 ANH Luke pipe with bolts

Barbican Saber*

*Vader Severed Hand cast

Luke ESB Graflex (maybe multiples, maybe just 1)*

*Vader DV6

Vader MPP (Maybe multiples, maybe just 1)

*1 ANH Motorized Luke pipe without black bolts, just a small grub screw seen in warehouse*

any more?

The main item inside the hilt is an aluminum slug. I am 99% sure they did not extend through the entire hilt, it would be too back heavy. A front-half core balances the saber in your hand, I've done this at home. Black M6 bolts, countersunk, held the core in the tube. The Barbican and the "pipe" stunt had 4 bolts and a solid front-half core.

The Graflex, at least, had a second core replacing the upper section of the socket, while the slug replaced the lower section of the socket leaving the middle. The MPP.... we are not sure, there seem to be wires suggesting a socket piece, but it also would be easier to run a solid core.

The countersinking was not well done, I have NO idea why there are 7 bolts in the Vader DV6, after drilling 1... maybe 2.... properly, a core is stuck solid.

Anyway, the other feature is a steel tang stuck in the core, with a lathed ring for the blade collar set screws. I'm not 100% sure where the grub screw for these are in the hilt. The pipe stunt may have one where the red button used to go, there is a threaded hole there. The others? I can only assume a threaded hole is drilled into the core somewhere, with a grub screw lowered flush with the surface, so it can slide into the tube. This might explain why people kept chopping the tang with a hacksaw instead of pulling it out like the V3, the screw might not have been accessible...covered by the bolted handle

Back to the DV6 this means we can start our brainstorming standing on a few facts. We can't see any tang grub screw (with the Vader parts on the flash at least). The core extends from the side ports to.... at least.... to the 3 bolts side-by-side on the back of the saber. I doubt it goes much further, I think it is the Luke core and I have been told they don't extend much further than the front half of the flash. ala, this photo, look on the sofa

So now begs the question how the heck is the rear of the Vader saber held on so well it can be hung upside down!? It is able to twist.. which maybe means only a couple screws attach it. I see black empty space behind the control box, actually two where there should be 1 (the bayonet lock slot). People who can do 3D stuff, I would love to hear your thoughts.