Risu

Master Member

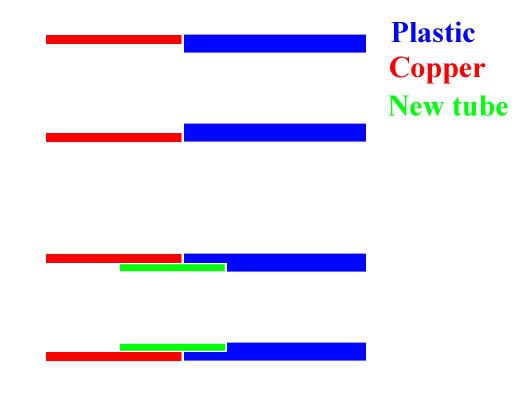

I've got this prop I'm working on that consists of a series of tubes. There's one point where a plastic tube meets a copper tube, the exterior diamaters are the same and the interior diameter of the plastic tube is smaller than that of the copper tube. Another tube fits inside this point and just barely fits. What is the best way to permanently attach these two pieces without adding any thickness to the inside wall of the plastic tube? Thanks in advance for any and all help. The whole piece relies completely on finding a way to solve this problem.