helix_3

Well-Known Member

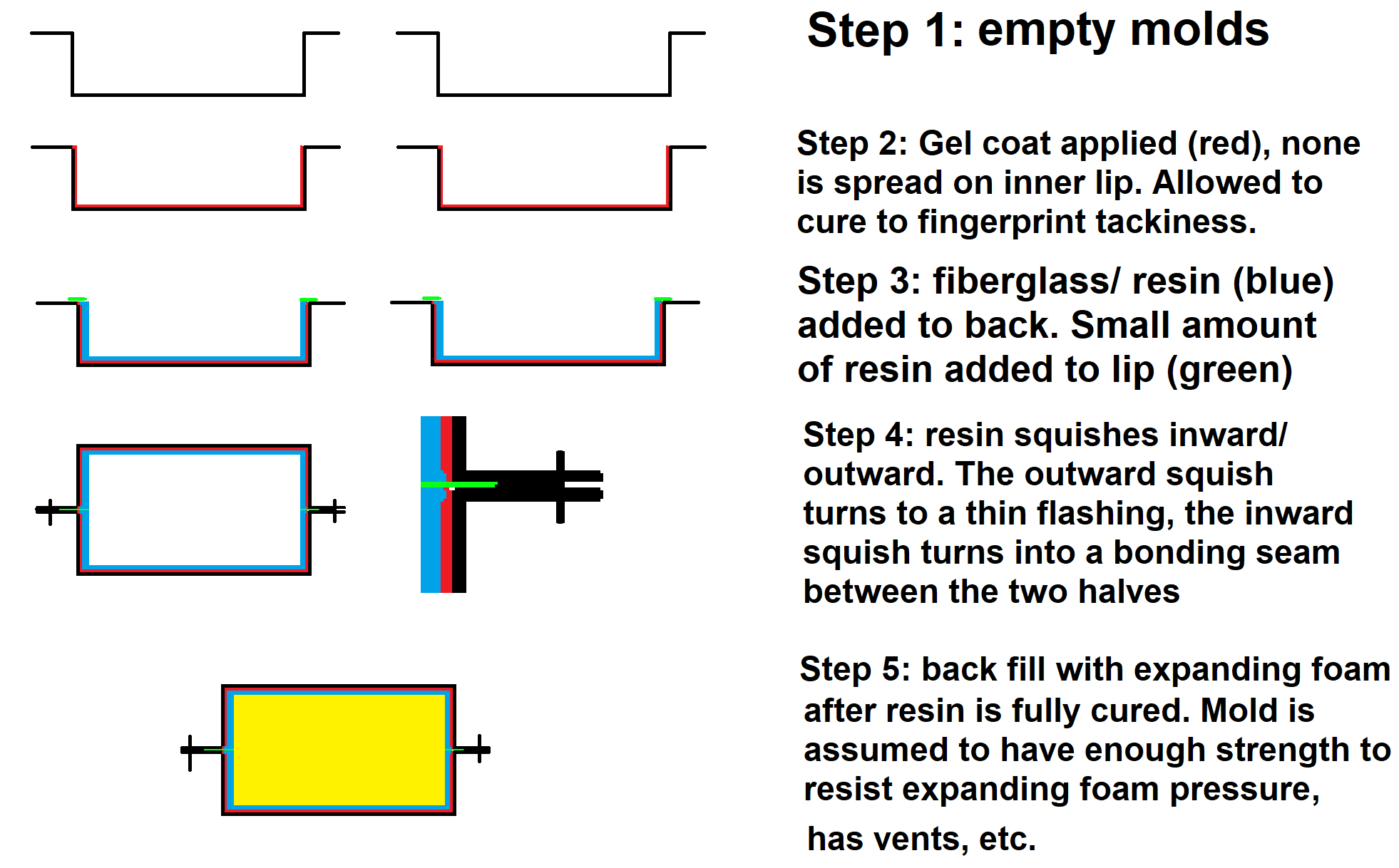

I have a hypothetical two part mold, with geometry that prevents the user from being able to reach inside and hand-apply fiberglass at the seam. Assume it's a large mold, 24"+ wide, etc.

I'm assuming the foam backing is necessary because the green resin is creating a resin-only seam between two knife-edges of stronger fiberglass material, and represents a major weak point in the piece.

Does this method make sense? Is there any better way to do this?

I'm assuming the foam backing is necessary because the green resin is creating a resin-only seam between two knife-edges of stronger fiberglass material, and represents a major weak point in the piece.

Does this method make sense? Is there any better way to do this?