No worries. If you find a solenoid with a convincing throw at a decent price, please let me know. I'm thinking along the same lines for other projects, but anything with a push throw of more than about 18mm gets crazy pricey and takes a butt-load of power. I do hope to find a happy compromise though.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dredd 2012 Lawgiver II functional build

- Thread starter Nicodema

- Start date

seekerofgiants

Active Member

This is looking awesome! Can't wait to see the finished lawgiver!

Time for an update.

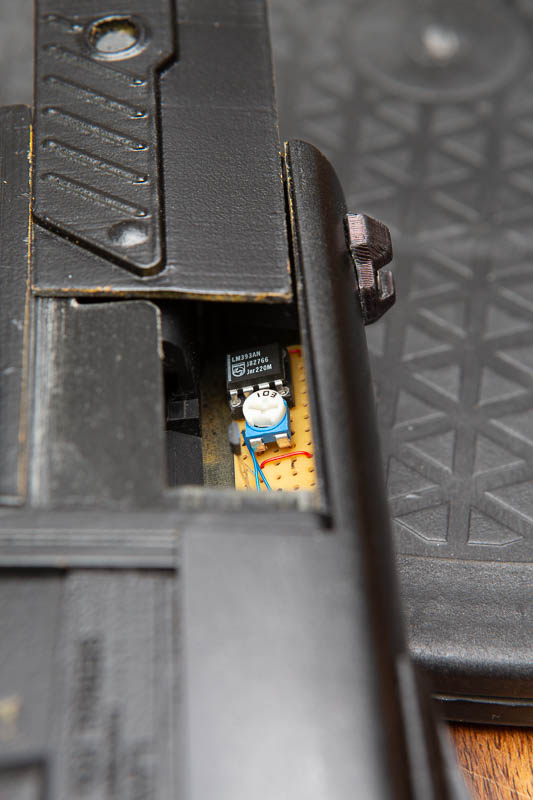

First up, counting the ammo down...

A rare earth magnet on VHB taped to the slide and a Hall effect sensor and comparator to drive the Cortex. The sensor is a bit hard to make out, looking like a super slim transistor.

A quick aside. The yellow filler primer is showing through in some of these photos, so I've gone over with some black acrylic and will be sealing the finished piece to avoid this wear. I could really do with finding some black and maybe some grey filler primers in the UK. The yellow stuff from Halfords is probably fine when used for automotive repairs, but most props will be taking a much thinner build up of paint than I would use for a car.

The slide tail piece I had to reshape in Meshmixer. There was no way to get the original to fit the slide without basically hogging away and rebuilding with epoxy putty or similar. No fun in that when I can do it in software. The hex screw you can see is what holds it onto the slide. I actually modelled a replacement back cap for the G17 slide. It has a countersunk hole at a useful angle to grab the main body of the tail piece. A nice, two part solution.

The tail piece in place. Annoyingly the top part is wrong, the rectangular section should be recessed rather than flush.

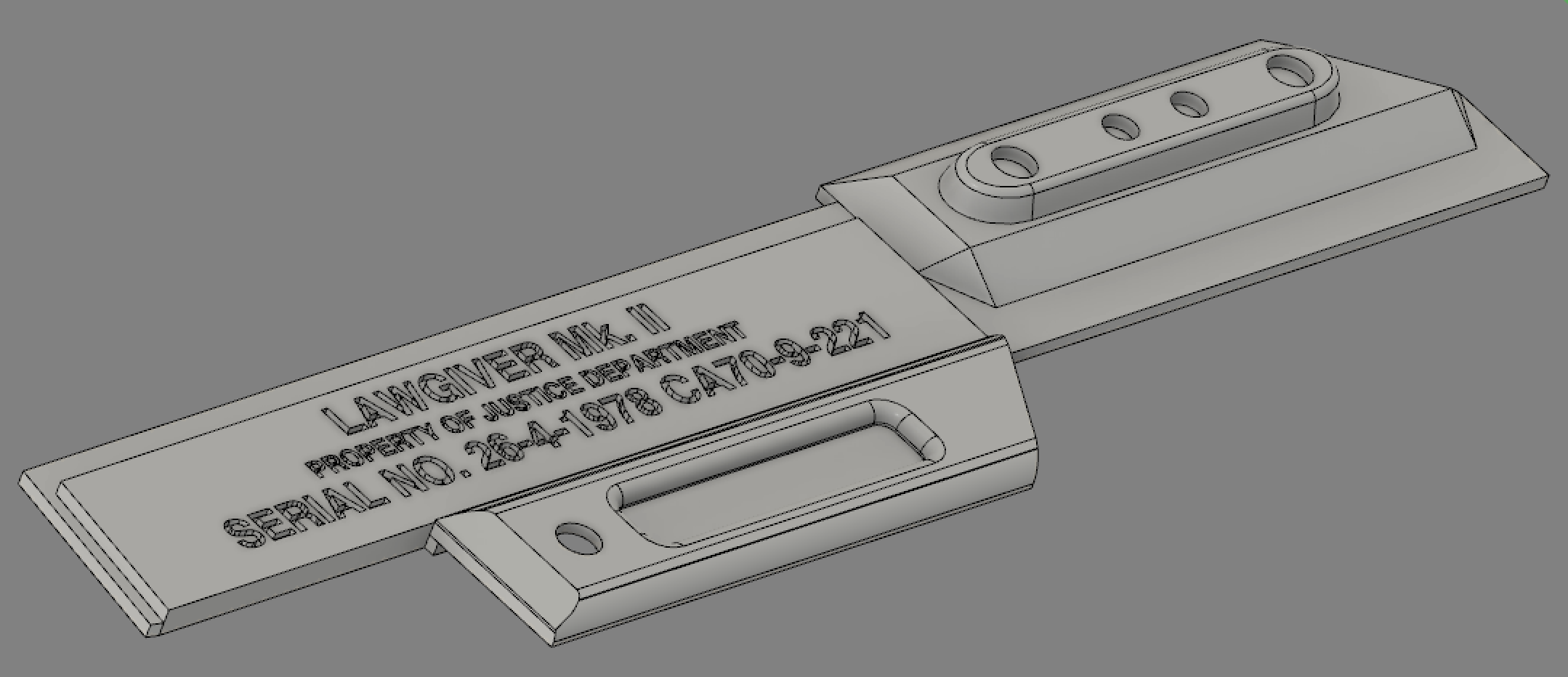

I had intended to print the name plate on the Form 1+ but it was a complete failure. The Form 1+ peel mechanism is far less reliable than the Form 2 it seems. So I decided to try printing at high res on the S5, after modelling the plate again from scratch, this time with a void to take a switch and wiring. The little dirty brown button is visible on the lower part of the plate, in front of the dummy front-mag release button.

The S5 did a great job with the text. Not perfect, but better than the lumpy resin soup that the Form "printed".

The barrel and top covers I've tried to slightly metallicize with the lightest touch of RubnBuff. It looks better in daylight than the flash here, but I will also be revisiting the finish. I intend to do a full weathering treatment before I'm done, so there will be much more "metal scuff" detailing to provide the right contrast which is lacking at present.

Next up, swapping over to the blue screen, thanks to Joatrash for making my mind up to go blue.

First up, counting the ammo down...

A rare earth magnet on VHB taped to the slide and a Hall effect sensor and comparator to drive the Cortex. The sensor is a bit hard to make out, looking like a super slim transistor.

A quick aside. The yellow filler primer is showing through in some of these photos, so I've gone over with some black acrylic and will be sealing the finished piece to avoid this wear. I could really do with finding some black and maybe some grey filler primers in the UK. The yellow stuff from Halfords is probably fine when used for automotive repairs, but most props will be taking a much thinner build up of paint than I would use for a car.

The slide tail piece I had to reshape in Meshmixer. There was no way to get the original to fit the slide without basically hogging away and rebuilding with epoxy putty or similar. No fun in that when I can do it in software. The hex screw you can see is what holds it onto the slide. I actually modelled a replacement back cap for the G17 slide. It has a countersunk hole at a useful angle to grab the main body of the tail piece. A nice, two part solution.

The tail piece in place. Annoyingly the top part is wrong, the rectangular section should be recessed rather than flush.

I had intended to print the name plate on the Form 1+ but it was a complete failure. The Form 1+ peel mechanism is far less reliable than the Form 2 it seems. So I decided to try printing at high res on the S5, after modelling the plate again from scratch, this time with a void to take a switch and wiring. The little dirty brown button is visible on the lower part of the plate, in front of the dummy front-mag release button.

The S5 did a great job with the text. Not perfect, but better than the lumpy resin soup that the Form "printed".

The barrel and top covers I've tried to slightly metallicize with the lightest touch of RubnBuff. It looks better in daylight than the flash here, but I will also be revisiting the finish. I intend to do a full weathering treatment before I'm done, so there will be much more "metal scuff" detailing to provide the right contrast which is lacking at present.

Next up, swapping over to the blue screen, thanks to Joatrash for making my mind up to go blue.

seekerofgiants

Active Member

Your lawgiver looks ready to deliver some justice!

Hot glue to the rescue.

The new, blue OLED is now installed and the bezel re-bonded to the side of the prop. All the trailing wires are hot glued down for longevity.

With the top covers and sights reattached it's time for a video of the cycling.

Also a clip of the transition from "Ammunition Low" to "Empty" as our intrepid judge runs out of Hi-Ex!

The new, blue OLED is now installed and the bezel re-bonded to the side of the prop. All the trailing wires are hot glued down for longevity.

With the top covers and sights reattached it's time for a video of the cycling.

Also a clip of the transition from "Ammunition Low" to "Empty" as our intrepid judge runs out of Hi-Ex!

seekerofgiants

Active Member

Absolutely incredible!! This is the best lawgiver I've seen!

Gah! I forgot to sort out the connection from the battery in the front mag to the electronics. Need to sort that out before weathering, otherwise I just know I'm going to smudge or break something.

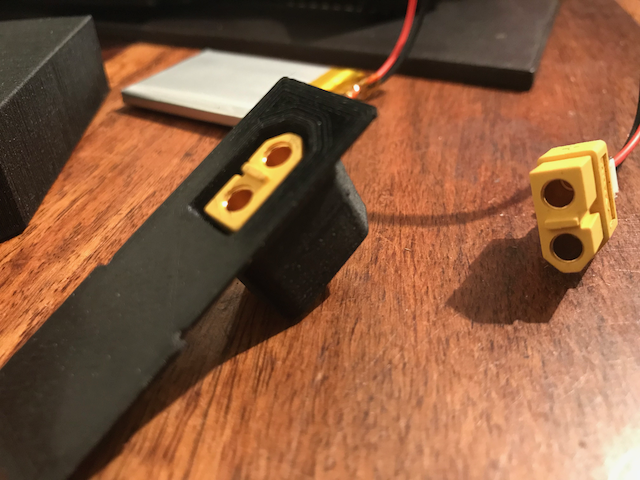

So I modelled a box and a lid, where the lid has a receptacle for the XT60 female. It's a click fit that locks into the rectangular grip wells on the connector. (Earlier in the build I said I was using XT30 - wrong, they're 60s - overkill, but what I have)

These parts are printed in ABS and interestingly, the thin walls of the box, which ends up with a single skin and a wiggle filling, ended up very rough. Not a major problem, as the ABS is much easier to sand than the PLA, but something to remember for next time.

One connector locked in, the other for reference.

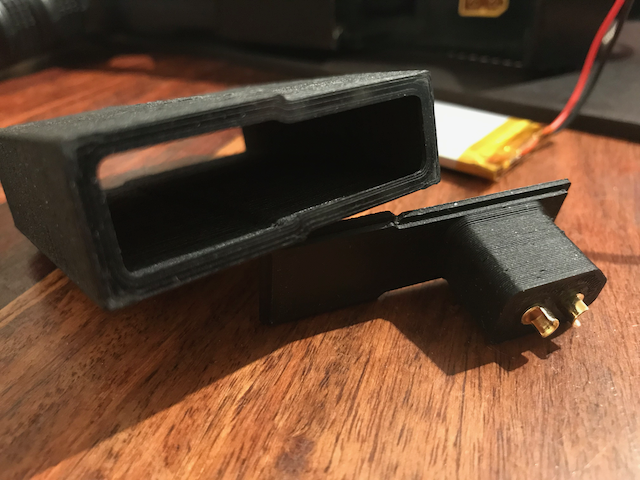

The box has an opening in the base to allow access to the battery if needed. The walls are much thinner than this view shows. What you can see here is an internal flange for stiffness and bed adhesion. The walls are only 1mm thick.

Aww Snap! Test fitting and disassembly saw just about everything break.

The 1mm walls were too thin and so was the well around the plug.

Try again. Back to Fusion 360 and beef up the failed areas. Walls go to 1.5mm, Some fillets added to strength in the base. Well walls thickened too.

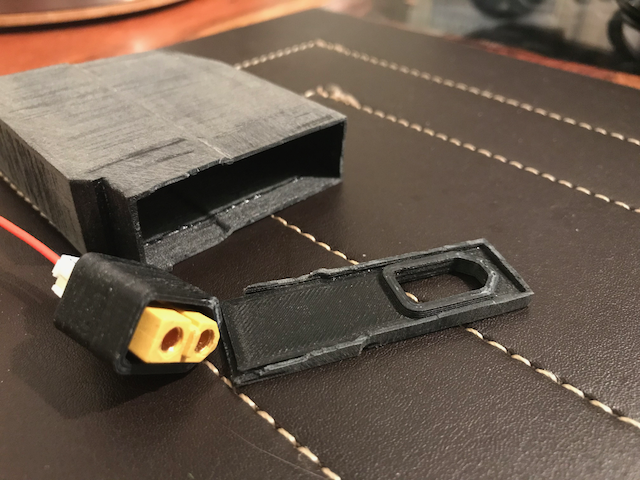

LiPo pack wrapped in craft foam sits happily in the box.

Top view of the assembled box showing the connector. Just needs a bead of CA to close it up then push it home into the front mag.

Then weathering...

So I modelled a box and a lid, where the lid has a receptacle for the XT60 female. It's a click fit that locks into the rectangular grip wells on the connector. (Earlier in the build I said I was using XT30 - wrong, they're 60s - overkill, but what I have)

These parts are printed in ABS and interestingly, the thin walls of the box, which ends up with a single skin and a wiggle filling, ended up very rough. Not a major problem, as the ABS is much easier to sand than the PLA, but something to remember for next time.

One connector locked in, the other for reference.

The box has an opening in the base to allow access to the battery if needed. The walls are much thinner than this view shows. What you can see here is an internal flange for stiffness and bed adhesion. The walls are only 1mm thick.

Aww Snap! Test fitting and disassembly saw just about everything break.

The 1mm walls were too thin and so was the well around the plug.

Try again. Back to Fusion 360 and beef up the failed areas. Walls go to 1.5mm, Some fillets added to strength in the base. Well walls thickened too.

LiPo pack wrapped in craft foam sits happily in the box.

Top view of the assembled box showing the connector. Just needs a bead of CA to close it up then push it home into the front mag.

Then weathering...

Yeah, I think a Form 2 would have had no problem with the part. The Form 1+, with possibly slightly tired grey resin just made a disaster. Everything ended up stacked tightly on the build window. Took a while to clean it off, at which point my patience to try again was gone. I was very happily surprised how well the S5 did with the text detail.

The original part had some mesh issues around the serial number text, which opened fine in some software but not others. When I decided to remodel from scratch, I had to track down to the font and it turned out to be just a standard Helvetica Bold.

The original part had some mesh issues around the serial number text, which opened fine in some software but not others. When I decided to remodel from scratch, I had to track down to the font and it turned out to be just a standard Helvetica Bold.

I have a Form 2 and while my machine is (thankfully) performing well, so I haven't had to do a lot of fixing, your situation sounds similar to some I've read where the laser was worn out. The F2 would have zero issues with a part like that. I've printed details not much thicker than a cat's whisker on it! The next Lawgiver buildup I do will be printed almost entirely on the F2. (Well, at least the outer chassis will be.) If you use the pro-grade resins, the parts are fairly durable too.Yeah, I think a Form 2 would have had no problem with the part. The Form 1+, with possibly slightly tired grey resin just made a disaster. Everything ended up stacked tightly on the build window.

Interesting. Yes, the 1+ at Makespace could have laser troubles, I'll see if anyone else has had problems recently. I suspect also the resin I used was some fairly old stuff, looking at the version number. The sliding peel mechanism on the 2 makes so much more sense than the tilting / tearing mechanism on the 1+. Basically the part just tore off and I ended up with a fair amount of support tree on the build surface and a gummy plastic slab stuck to the tank window. At some point I'll probably just get a Form 2 (or 3 if and when), but I need to make some space first.

oswaldkefo

New Member

This is one of the most amazing props I have ever seen. Absolutely fantastic, great work Nicodema

EasternBloc

Active Member

Drokking yeah! Thanks for sharing; really cool project! Is it easy to take out perps on Slo-mo?

AndoShinobi

Member

Amazing functional prop. Have you thought about adding voice control? Something like the SpeakUp Click may work.

However, it looks like your out of actual space inside for electronics.

However, it looks like your out of actual space inside for electronics.

Similar threads

- Replies

- 13

- Views

- 315

- Replies

- 9

- Views

- 2,450