GlennTech

Active Member

Foreword

Quote: You can't leave something behind you, if you loved it.

I pulled the plug out of all my previous threads. Sorry STEALTH for been rude and sorry community to delete all my files. I also deleted the master files which I had. Sad but lets leave it alone.

I hope you guys grant me a fresh start. This time I don't associate me with costume building. Now I'll be more focussing on electronics. Since this is a huge time consumption of my life. I'm an electronic student and worked on other electronic projects in the past. So I've a bit background in the electronics world.

I want to cover various problems when been at a event that could easily be solved by using 'smart' electronic circuits.

This thread is divide in several chapters. Since I'm working on my Senior Paper for my last year of school I'll also cover technical knowledge to it. So other electronic hobbyists can guide me or can help making things simpler.

The technical content is written in Italic. Just ingnore it if you don't understand it.

Speech Amplifier Circuit (S.A.C.)

Oh man I still remember my first day on a cosplay convention. I was wearing a Halo 3 peped costume (first pep costume I've ever made). The helmet I was wearing was TOO much padded. I couldn't understand the people which I was having a conversation nor did they understand me...

Some people solves this mechanical (drilling a few holes around the ear). But that would take away the looks and accuracy.

Stormtrooper's have already a solution using 2 way headsets that are modified and other things. I wanted something 'original' something that was very versatile and economic!

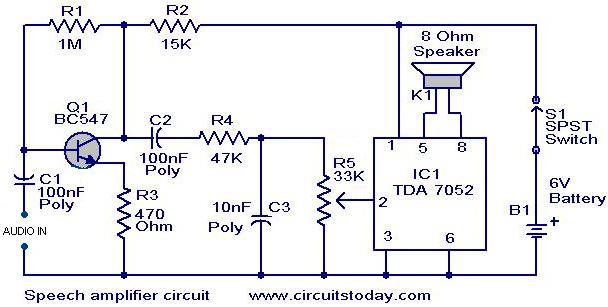

This circuit is originally from Speech amplifier circuit.

You'll need two of these. One for outside sound to your ears and one for your voice to the outside. This circuit pick ups your voice and amplify it to the outside. Very good for crowded places. After all the analysing is done through-hole PCBs will come available and also SMD PCBs.

Something I learned after using many circuits is test them before using!

I study at a school with many components. Problem is: the components aren't organised. I used values that were about the same as the original components used on the schematic.

Analysing

The circuit can be divided into 3 huge parts; Pre-amplify, RC-circuit (Low Pass Filter), final amplify stage to sound.

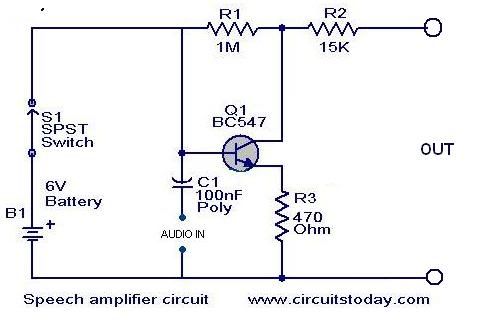

Pre-amplify

The schematic uses a BC547 (datasheet). Since the voltage produced by speaking is very low we'll want a pre-amplification. The transistor is connected as a Common Emitter Configuration. The pro's of a Common Emitter Configuration are: voltage amplify, current amplify, power amplify, average input impedance, average output impedance, very common used.

The C1 capacitor (bipolar) is used to block the direct current (you want produce DC when speaking but it's better to prevent then heal the damage)

There's also a voltage divider as you can see they used a high ohms resistor and a average ohms resistor. I'm still analysing why they did it I think to create a high impedance to prevent voltage drop.

I'm using an old analogue frequency generator, because the digital frequency generator can't send in such low voltages. They got only a -20dB button and the analogue has a -40dB button. A digital oscilloscope was also used.

Measurements will be available for download after I finished them.

RC-circuit

The RC-circuit is also called a Low-Pass filter. It's used to filter a signal and block certain frequencies and passing others.

The capacitor C2 has the same function as C1. It's there to block DC signal input.

I determined the cutoff frequency using the formula fc = 1 / (2.PI.R.C) Hz. The result was about 338Hz. When my input signal reaches about 338Hz the higher frequency will decrease logarithmic. This is RC-circuit also to avoid the Larsen's effect. The effect occurs if the microphone picks up the speaker output and causes howls, also called audio feedback). The pot-meter (variable resistance) is used as a volume controller.

Final amplify stage

The IC TDA 7052 (datasheet) is a "1W BTL (Bridge-Tied Load) mono audio amplifier" . This IC is very often used in many audio devices.

Still doing measurements.

Quote: You can't leave something behind you, if you loved it.

I pulled the plug out of all my previous threads. Sorry STEALTH for been rude and sorry community to delete all my files. I also deleted the master files which I had. Sad but lets leave it alone.

I hope you guys grant me a fresh start. This time I don't associate me with costume building. Now I'll be more focussing on electronics. Since this is a huge time consumption of my life. I'm an electronic student and worked on other electronic projects in the past. So I've a bit background in the electronics world.

I want to cover various problems when been at a event that could easily be solved by using 'smart' electronic circuits.

This thread is divide in several chapters. Since I'm working on my Senior Paper for my last year of school I'll also cover technical knowledge to it. So other electronic hobbyists can guide me or can help making things simpler.

The technical content is written in Italic. Just ingnore it if you don't understand it.

Speech Amplifier Circuit (S.A.C.)

Oh man I still remember my first day on a cosplay convention. I was wearing a Halo 3 peped costume (first pep costume I've ever made). The helmet I was wearing was TOO much padded. I couldn't understand the people which I was having a conversation nor did they understand me...

Some people solves this mechanical (drilling a few holes around the ear). But that would take away the looks and accuracy.

Stormtrooper's have already a solution using 2 way headsets that are modified and other things. I wanted something 'original' something that was very versatile and economic!

This circuit is originally from Speech amplifier circuit.

You'll need two of these. One for outside sound to your ears and one for your voice to the outside. This circuit pick ups your voice and amplify it to the outside. Very good for crowded places. After all the analysing is done through-hole PCBs will come available and also SMD PCBs.

Something I learned after using many circuits is test them before using!

I study at a school with many components. Problem is: the components aren't organised. I used values that were about the same as the original components used on the schematic.

Analysing

The circuit can be divided into 3 huge parts; Pre-amplify, RC-circuit (Low Pass Filter), final amplify stage to sound.

Pre-amplify

The schematic uses a BC547 (datasheet). Since the voltage produced by speaking is very low we'll want a pre-amplification. The transistor is connected as a Common Emitter Configuration. The pro's of a Common Emitter Configuration are: voltage amplify, current amplify, power amplify, average input impedance, average output impedance, very common used.

The C1 capacitor (bipolar) is used to block the direct current (you want produce DC when speaking but it's better to prevent then heal the damage)

There's also a voltage divider as you can see they used a high ohms resistor and a average ohms resistor. I'm still analysing why they did it I think to create a high impedance to prevent voltage drop.

I'm using an old analogue frequency generator, because the digital frequency generator can't send in such low voltages. They got only a -20dB button and the analogue has a -40dB button. A digital oscilloscope was also used.

Measurements will be available for download after I finished them.

RC-circuit

The RC-circuit is also called a Low-Pass filter. It's used to filter a signal and block certain frequencies and passing others.

The capacitor C2 has the same function as C1. It's there to block DC signal input.

I determined the cutoff frequency using the formula fc = 1 / (2.PI.R.C) Hz. The result was about 338Hz. When my input signal reaches about 338Hz the higher frequency will decrease logarithmic. This is RC-circuit also to avoid the Larsen's effect. The effect occurs if the microphone picks up the speaker output and causes howls, also called audio feedback). The pot-meter (variable resistance) is used as a volume controller.

Final amplify stage

The IC TDA 7052 (datasheet) is a "1W BTL (Bridge-Tied Load) mono audio amplifier" . This IC is very often used in many audio devices.

Still doing measurements.

Last edited: