Joy

Member

New member here, with a question for the more experienced.

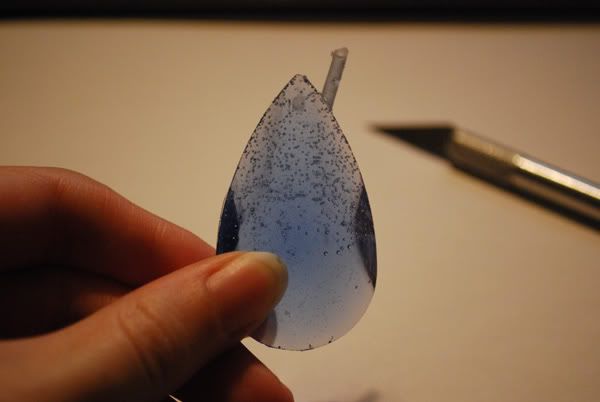

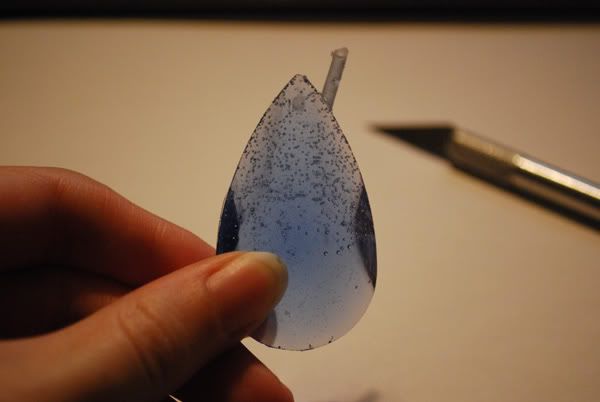

I'm working on a small part of a larger batch of replicas for someone, a tear shaped crystal from Final Fantasy 13, and I ran into a problem in the casting process.

This resin is not degassing as it should (it advertizes high self-degassing). I'm still a low-end propmaker, and lack a vacuum chamber, nor can I really afford one now. Is there anything I can do to minimize these cursed bubbles? Or is there another clear resin that works better than this cheap mess that doesn't require I have a crazy ventillation system?

What's being used:

Easy Cast clear epoxy

Castincraft transparent dye

Rebound 25 Silicon mold, with a pour channel and a vent channel

I'm working on a small part of a larger batch of replicas for someone, a tear shaped crystal from Final Fantasy 13, and I ran into a problem in the casting process.

This resin is not degassing as it should (it advertizes high self-degassing). I'm still a low-end propmaker, and lack a vacuum chamber, nor can I really afford one now. Is there anything I can do to minimize these cursed bubbles? Or is there another clear resin that works better than this cheap mess that doesn't require I have a crazy ventillation system?

What's being used:

Easy Cast clear epoxy

Castincraft transparent dye

Rebound 25 Silicon mold, with a pour channel and a vent channel