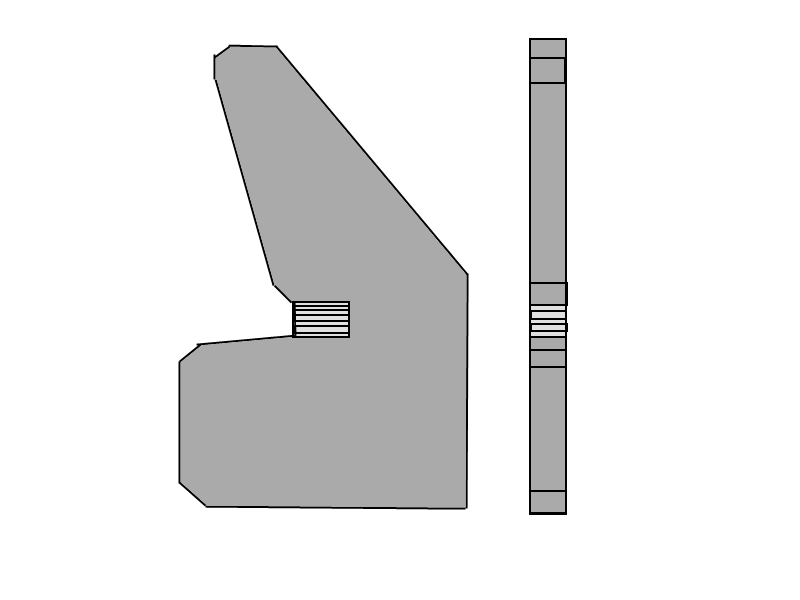

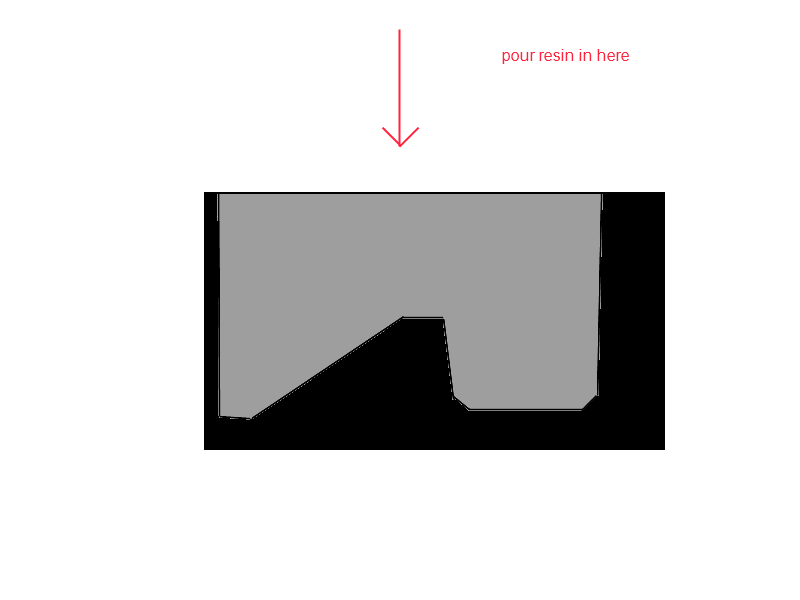

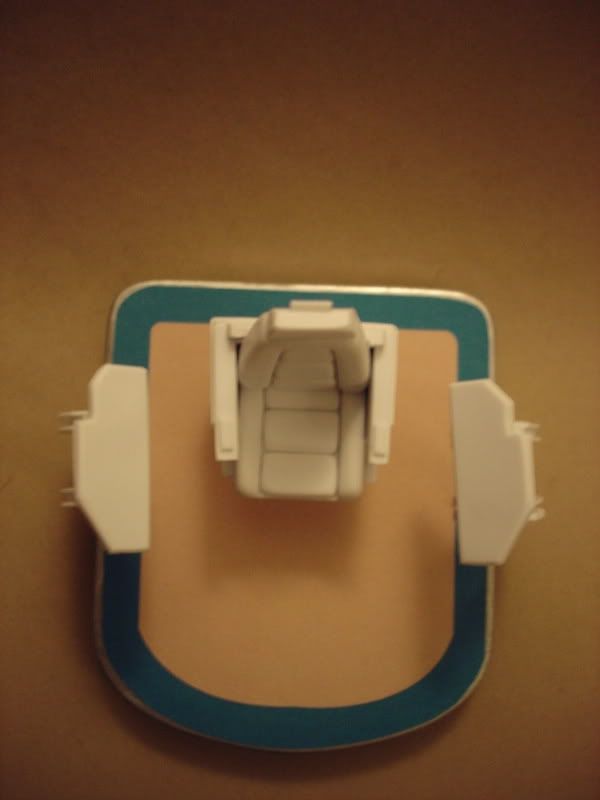

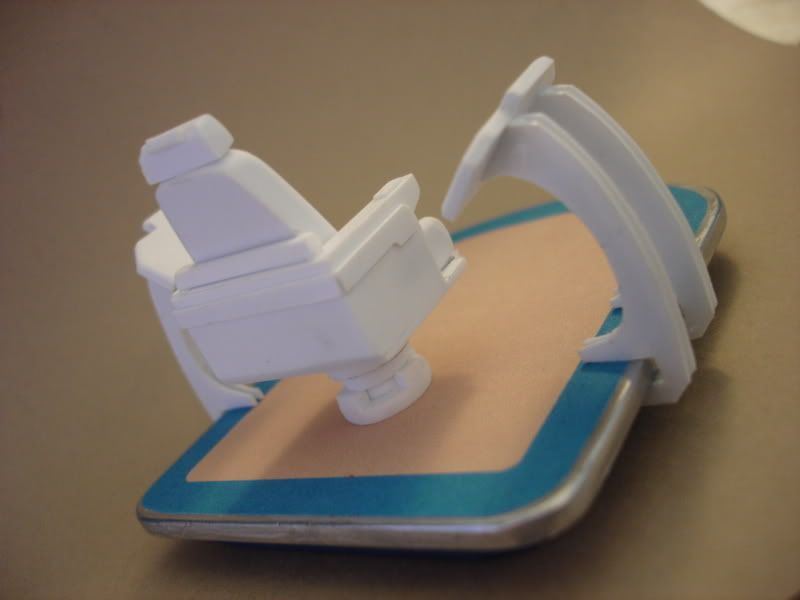

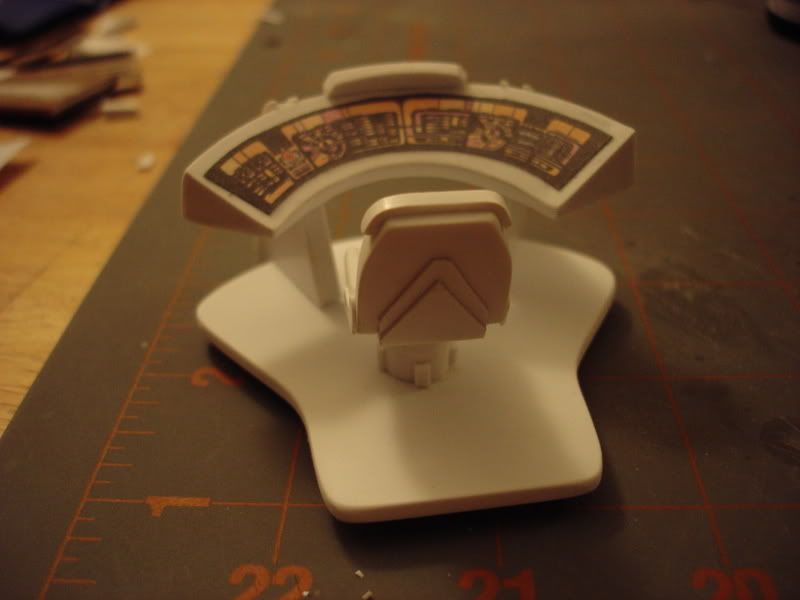

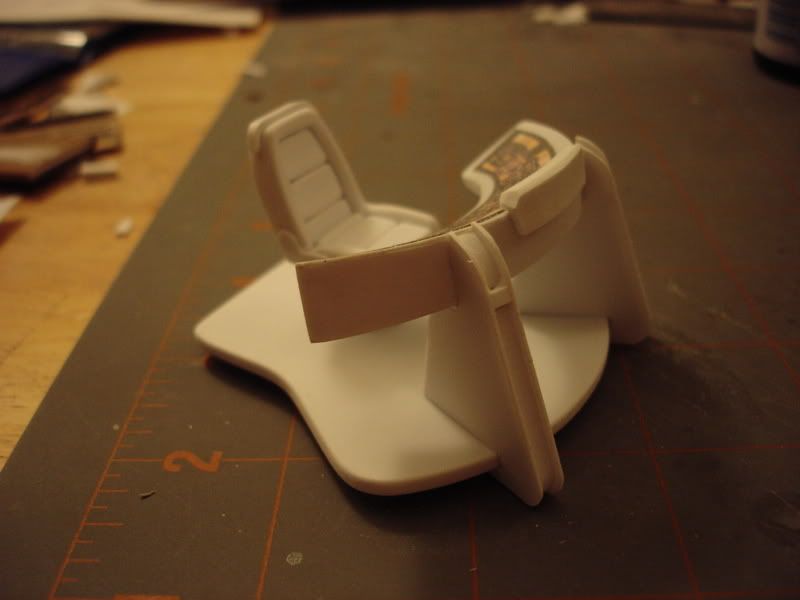

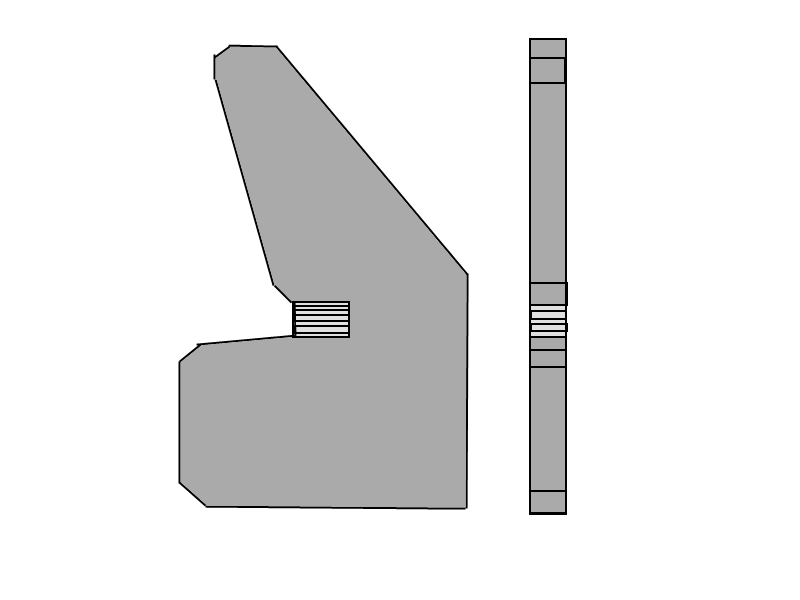

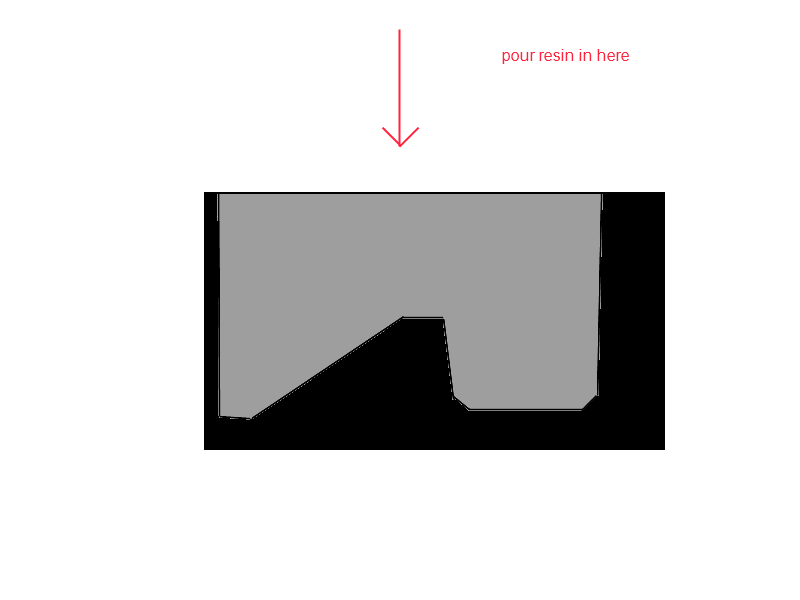

I want to scratch build this wall section in styrene and resin cast duplicates from a single mold since I need to make 8 total. These will be about 7” – 8” tall and maybe 1/2” thick. The right side (in the picture) will be unseen so I was wondering if I could use it as an open pour point and make a single cast mold. (see pic 2) With this method there should be no undercuts, just a lot of material.

Is my item too big to cast like this? Will it destroy the mold taking it out so I can’t have multiple pulls from the same mold, even with mold release? It only has to last through 8 pourings.

Is my item too big to cast like this? Will it destroy the mold taking it out so I can’t have multiple pulls from the same mold, even with mold release? It only has to last through 8 pourings.