Le Chuck

New Member

I've lurked this forum for a while and am finally tackling a project that I thought I should share and that I could get some great help and advice on.

I'm in the early stages of building a ride on 74-Z speeder that is being build on the frame of an old SEGA Super Hang-On ride on machine. When complete the build will allow one to play Star Wars Trilogy Arcade and Star Wars Racer by leaning and controlling the speeder.

As such everything I'm building has to be extremely durable as it is being made to be used. I'm not going for 100% screen accuracy but am trying to execute more along the lines of what one would find in an arcade.

The build will be a steel frame on a fiberglass body with metal and plastic accents. My biggest challenge thus far is figuring out the speeder handles. Specifically, can they be created from found objects or do I need to have them fabricated? I think I'm going to just have to bite the bullet and have them milled but thought I'd put it out to all of you builders first.

The link to my build thread on BYOAC can be found in my signature under New Republic Flight Trainer but here are a few pics for those who don't feel like clicking.

This is my promo teaser art

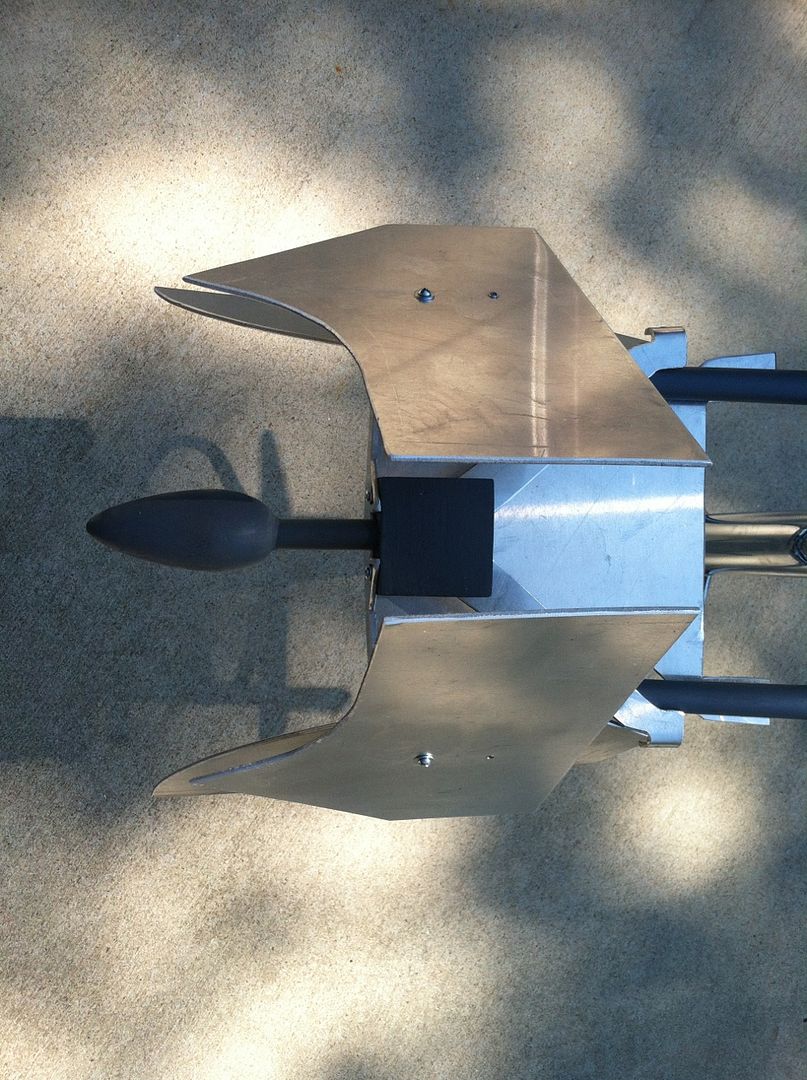

This is the sacrificial frame

Anyway, thanks for looking and thanks for all the help!

I'm in the early stages of building a ride on 74-Z speeder that is being build on the frame of an old SEGA Super Hang-On ride on machine. When complete the build will allow one to play Star Wars Trilogy Arcade and Star Wars Racer by leaning and controlling the speeder.

As such everything I'm building has to be extremely durable as it is being made to be used. I'm not going for 100% screen accuracy but am trying to execute more along the lines of what one would find in an arcade.

The build will be a steel frame on a fiberglass body with metal and plastic accents. My biggest challenge thus far is figuring out the speeder handles. Specifically, can they be created from found objects or do I need to have them fabricated? I think I'm going to just have to bite the bullet and have them milled but thought I'd put it out to all of you builders first.

The link to my build thread on BYOAC can be found in my signature under New Republic Flight Trainer but here are a few pics for those who don't feel like clicking.

This is my promo teaser art

This is the sacrificial frame

Anyway, thanks for looking and thanks for all the help!