You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ANH Motorised stunt Saber experiments (& blades) Part 1

- Thread starter Mouse Vader

- Start date

Mouse Vader

Sr Member

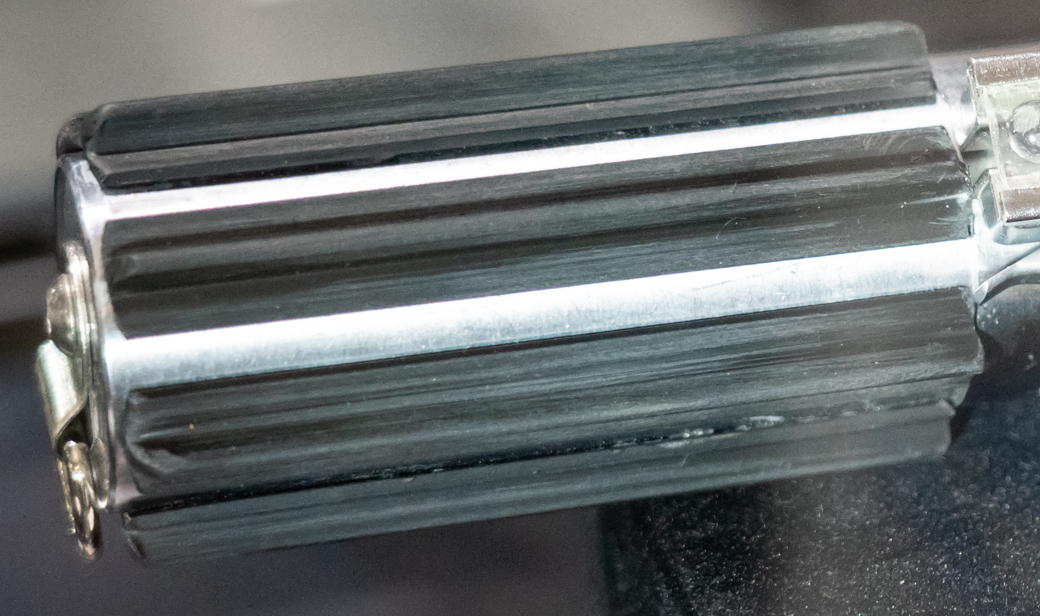

It's a single metric knurl 1mm pitch. I did a direct measure with calipers on my Romans red button to come up with that so imperial equivalent would be 24 or 25 TPI.

Mouse Vader

Sr Member

Thanks DP - like the end plate it was an itch I had to scratch. I can now concentrte on fitting the core to the main tube. Wish me luke... or luck, there's Freudian slip if ever there was one !

Mouse Vader

Sr Member

The main tube for the MK1b , as with all previous ones, is a length of 1 1/2 inch diam stainless steel exhaust repair tube. The 1st one was nicely polished - the second polished but not so nicely. This one wasn't at all & had a slightly flattened seam. Neither of these pics really shows how much difference there was but there was no real comparison it was just raw stock metal surface.

Before throwing in the towel I decided to see if a whizz in the lathe with file & emery would be any use. It was.

Previous (squiffy one) & the current one on the right.

Wrapped up in my latest template. (This actually printed fine at 100% - fits best if you cut off the overlap part.)

Lining up the bottom center line of the core (glass eye hole) with the center line on the tube, then marking up the center line of the grub screw onto the main tube. Did it this way rather than by direct measure from the core to compensate for the different diameters of the tubes (radial difference). Then extended that line onto the template, double checking where the core would be in relation to the bottom of the 'S' curve. (Remembered to use the small angle length to provide the ruler - see prev posts.)

All that measuring paid off. Got the glass eye centered & level.

Couldn't have hit the old hole any better. There are some traces of the old thread just visible but the the meatier thread has done what I wanted & overwritten cleanly the old stuff. Glass eye fits well & is a good secure fixing for the core.

There was a cost though. As usual I forgot the remove the motor from the core before machining & as expected once done the new thread had cast up burrs from the underside of the s/s tube preventing me pushing out the core normally. I had use a drift & soft face hammer & no I wasn't an idiot & hammered directly on the bottom of the of motor I used some sturdy Ally tubing that fitted around the motor so I was in direct contact with the core sleeve. Made no difference. The inertia of the motor armature (if you don't know that's the bit in the middle with all the copper windings & actually does the spinning) meant it wanted to stay still while the core/tube moved when I hit it. This proved too much for the crimp on the end of the motor (& the drive gear fitted on the motor drive shaft) & I ended up with a pile of bits. I might have been able to reassemble this but one of the ferite magnets had broken too.

Fortunately there is some recompense. I've now got the a primary drive gear free which I can now try & fit to the big red motor I bought a while ago - more on this next time.

Before throwing in the towel I decided to see if a whizz in the lathe with file & emery would be any use. It was.

Previous (squiffy one) & the current one on the right.

Wrapped up in my latest template. (This actually printed fine at 100% - fits best if you cut off the overlap part.)

Lining up the bottom center line of the core (glass eye hole) with the center line on the tube, then marking up the center line of the grub screw onto the main tube. Did it this way rather than by direct measure from the core to compensate for the different diameters of the tubes (radial difference). Then extended that line onto the template, double checking where the core would be in relation to the bottom of the 'S' curve. (Remembered to use the small angle length to provide the ruler - see prev posts.)

All that measuring paid off. Got the glass eye centered & level.

Couldn't have hit the old hole any better. There are some traces of the old thread just visible but the the meatier thread has done what I wanted & overwritten cleanly the old stuff. Glass eye fits well & is a good secure fixing for the core.

There was a cost though. As usual I forgot the remove the motor from the core before machining & as expected once done the new thread had cast up burrs from the underside of the s/s tube preventing me pushing out the core normally. I had use a drift & soft face hammer & no I wasn't an idiot & hammered directly on the bottom of the of motor I used some sturdy Ally tubing that fitted around the motor so I was in direct contact with the core sleeve. Made no difference. The inertia of the motor armature (if you don't know that's the bit in the middle with all the copper windings & actually does the spinning) meant it wanted to stay still while the core/tube moved when I hit it. This proved too much for the crimp on the end of the motor (& the drive gear fitted on the motor drive shaft) & I ended up with a pile of bits. I might have been able to reassemble this but one of the ferite magnets had broken too.

Fortunately there is some recompense. I've now got the a primary drive gear free which I can now try & fit to the big red motor I bought a while ago - more on this next time.

Last edited:

Mouse Vader

Sr Member

Here's the salvaged primary gear & compared to the Big red motor's. The other motor is a 310 which I tried to pull one off. It was on so tight I was in danger of wrecking it so gave up on getting one off. Careful what you wish for eh?

The red motor is too long ( as just the motor is as long as the others are with the gear box attached). To be any use on either the MK1b or MK2 as I'd need to shorten the cores to get it to miss the switch, so I'll be in no hurry to mess about with it. Maybe on the Vader or Kenobi.

There is a motor combo I am pursuing. If you recall in post #170 I had the voltage set too high & the higher RPM was giving good spin on the wooden dowel. The higher rpm put me in mind of the black motor I'd bought (see above). At the same 6V & with the same gearbox it was delivering 900 rpm - 50% more than the other 370's even thought it also a 370. I thought if I could put a higher ratio gearbox on it then I should be getting more torque. Calc'd ratio required is 14.5 : 1. As I can't get these gearboxes on their own I needed to look for a (sliver) 370 motor/gearbox claiming to give app. 380 rpm (270 for the 310 motor). Unfortunately there aren't any but they do do a 280 rpm (370 motor) which I calc to have a ratio of about 20 : 1. Ring any bells? John Bunker recalled (with a ?) them using a 20 : 1 gearbox. So one of these on the black motor (running 8 - 9V) should deliver 600 rpm on a 20 : 1 box.

I have one on order & intend to try this on the MK1b.

The red motor is too long ( as just the motor is as long as the others are with the gear box attached). To be any use on either the MK1b or MK2 as I'd need to shorten the cores to get it to miss the switch, so I'll be in no hurry to mess about with it. Maybe on the Vader or Kenobi.

There is a motor combo I am pursuing. If you recall in post #170 I had the voltage set too high & the higher RPM was giving good spin on the wooden dowel. The higher rpm put me in mind of the black motor I'd bought (see above). At the same 6V & with the same gearbox it was delivering 900 rpm - 50% more than the other 370's even thought it also a 370. I thought if I could put a higher ratio gearbox on it then I should be getting more torque. Calc'd ratio required is 14.5 : 1. As I can't get these gearboxes on their own I needed to look for a (sliver) 370 motor/gearbox claiming to give app. 380 rpm (270 for the 310 motor). Unfortunately there aren't any but they do do a 280 rpm (370 motor) which I calc to have a ratio of about 20 : 1. Ring any bells? John Bunker recalled (with a ?) them using a 20 : 1 gearbox. So one of these on the black motor (running 8 - 9V) should deliver 600 rpm on a 20 : 1 box.

I have one on order & intend to try this on the MK1b.

Mouse Vader

Sr Member

Fitting the red button. This was a real PITA. It's such a shallow blind hole I can't really do it with a descent size drill. Had to start with the a center drill then progressively larger end mills which aren't designed for this sort of thing. They dont cut in the middle hence having to use increasing diam's they tend to produce chatter & vibration to gen giving oversize cuts. Tapped fairly well but I had trouble getting the red button to pick up on the thread. All in all 2 - 3 hours work.

Refitting the template to mark the red button & 'S' curve.

( & switch & wire hole, with faint marks for the T-track spacing. Checking these are in line with some Ally angle.)

As usual burrs on the S/s tube meant I had to knock the core out with a drift giving these deep scores marks.

Refitting the template shows I'm close enough. ( Checking latter I found my mill cross slide was moved - from vibration? - & I'm actually about 5 thou out laterally. This is just at the periphery of being detectable to the unaided eye so you have to look hard to spot it.)

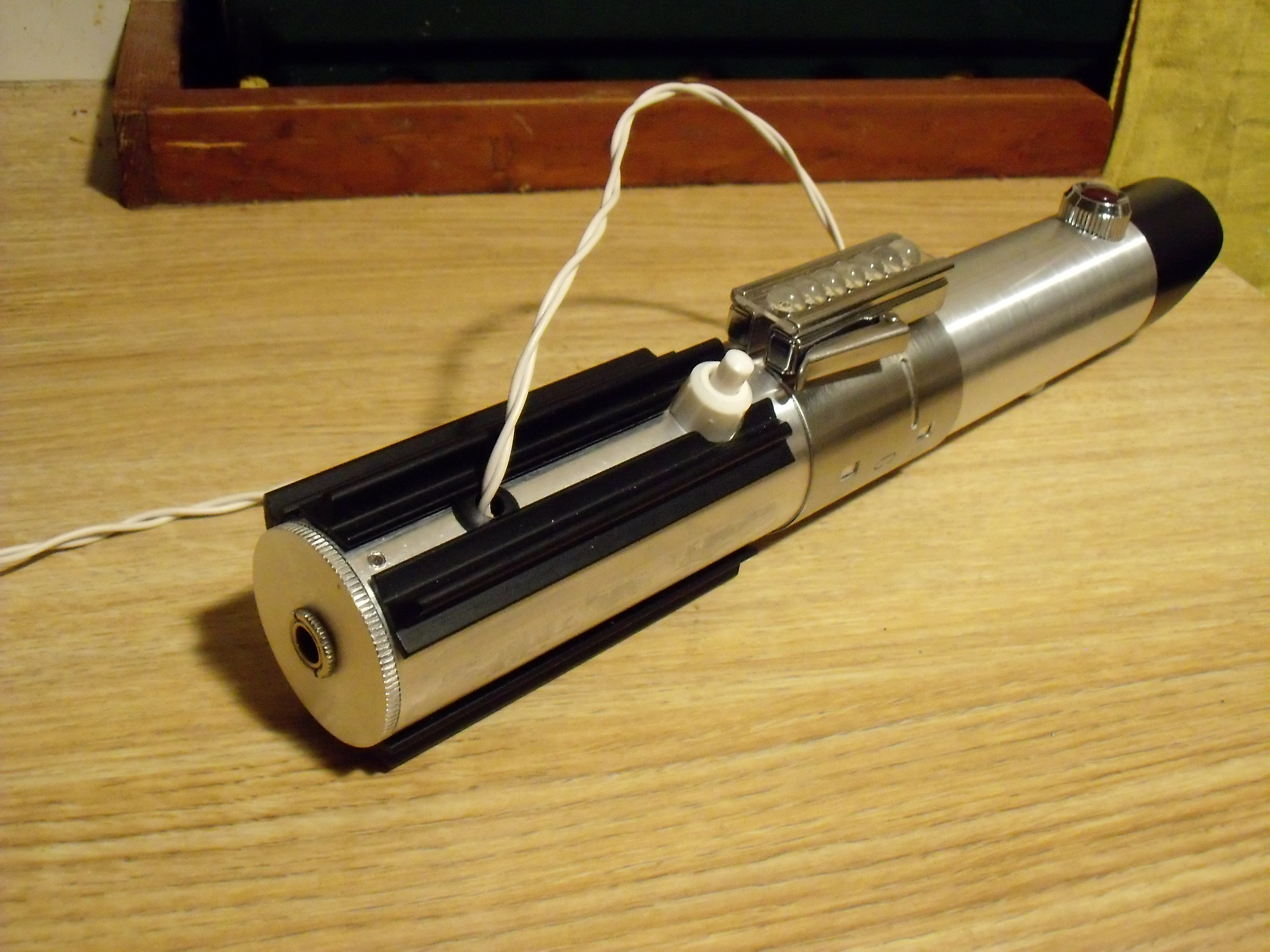

Cleaned up & working. The dark patch at the bottom is the roller bearing housing.

The additional holes drilled. Template shows these are on target. Yea no serious balls ups! The wires hole is over size as I'm going off piste here & putting in a 3.5mm jacklpug socket. The one thing I find annoying with the Mk2 is all that spaghetti hanging out of it. I'm also trying sort out a layout for an internal battery pack.

At the right angle light reflects in the clear red button. Because the curve at he top acts like a lens this appears to be a light deep in the interior of the hilt. (Doesn't show very well without stereo vision.)

I've had to add some tape 'shims' to the core sleeve as this replacement s/s tube is either a fraction larger than the last one or is more circular (I had to squash the other tube into round). Probably a bit of both.

Cutting the 'S' curve (& my hand - stainless produces some nasty burrs).

Finished off with a half round file. I used only the scribed mark from my template, When I compared this to the MK2 profile I could see no difference.

(Need to polish up the inside surface of that glasseye !)

Refitting the template to mark the red button & 'S' curve.

( & switch & wire hole, with faint marks for the T-track spacing. Checking these are in line with some Ally angle.)

As usual burrs on the S/s tube meant I had to knock the core out with a drift giving these deep scores marks.

Refitting the template shows I'm close enough. ( Checking latter I found my mill cross slide was moved - from vibration? - & I'm actually about 5 thou out laterally. This is just at the periphery of being detectable to the unaided eye so you have to look hard to spot it.)

Cleaned up & working. The dark patch at the bottom is the roller bearing housing.

The additional holes drilled. Template shows these are on target. Yea no serious balls ups! The wires hole is over size as I'm going off piste here & putting in a 3.5mm jacklpug socket. The one thing I find annoying with the Mk2 is all that spaghetti hanging out of it. I'm also trying sort out a layout for an internal battery pack.

At the right angle light reflects in the clear red button. Because the curve at he top acts like a lens this appears to be a light deep in the interior of the hilt. (Doesn't show very well without stereo vision.)

I've had to add some tape 'shims' to the core sleeve as this replacement s/s tube is either a fraction larger than the last one or is more circular (I had to squash the other tube into round). Probably a bit of both.

Cutting the 'S' curve (& my hand - stainless produces some nasty burrs).

Finished off with a half round file. I used only the scribed mark from my template, When I compared this to the MK2 profile I could see no difference.

(Need to polish up the inside surface of that glasseye !)

Last edited:

Mouse Vader

Sr Member

I discovered I needed a spacer on the switch to stop the terminals interfering with the battery pack. I did one in red acrylic but it didn't look right.

So did one in stainless, complete with thin knurl band , to compliment the red button. I used the red one as an internal contour filler. Much happier with this looks wise but it's a real PITA to fit & this will only get worse once it has leads.

I've also discovered more %^%(*&^g problems with the power supply on the MK2 - the jack plug isn't staying put in the socket. I checked all the diferent jack plug / sockets I have & all combinations do the same. I also can't tell by looking which prospective online replacements are good quality & which are just cheap ones at high prices. I also discovered there's an outside possibility of a short circuit if a mono jack is inserted into a socket wired for a stereo jack & I don't want that when using lipo's. So I can't / won't use jacks.

As the problems I had with the 5.5mm connections was with the inline female ones & dug out some panel mount ones that seem a good grippy fit ( one seen in above pic's). There is a benefit in that they don't intrude so far into the tube. I've some others on order that may look better & / or be easier to fit.

So did one in stainless, complete with thin knurl band , to compliment the red button. I used the red one as an internal contour filler. Much happier with this looks wise but it's a real PITA to fit & this will only get worse once it has leads.

I've also discovered more %^%(*&^g problems with the power supply on the MK2 - the jack plug isn't staying put in the socket. I checked all the diferent jack plug / sockets I have & all combinations do the same. I also can't tell by looking which prospective online replacements are good quality & which are just cheap ones at high prices. I also discovered there's an outside possibility of a short circuit if a mono jack is inserted into a socket wired for a stereo jack & I don't want that when using lipo's. So I can't / won't use jacks.

As the problems I had with the 5.5mm connections was with the inline female ones & dug out some panel mount ones that seem a good grippy fit ( one seen in above pic's). There is a benefit in that they don't intrude so far into the tube. I've some others on order that may look better & / or be easier to fit.

Last edited:

I'm really impressed by how clean your threads and knurling turn out.

I have a diamond knurling bit and one is always slightly straying out of alignment. Hardly noticeable but something that really irks me. Threading is something I've yet bothering to do. I have a cheap-o mini-lathe that I've been modifying and retrofitting, and exchanging the gears just to even attempt threading would mean I'd have to refit each gear I need to set it up with.

I have a diamond knurling bit and one is always slightly straying out of alignment. Hardly noticeable but something that really irks me. Threading is something I've yet bothering to do. I have a cheap-o mini-lathe that I've been modifying and retrofitting, and exchanging the gears just to even attempt threading would mean I'd have to refit each gear I need to set it up with.

Mouse Vader

Sr Member

Thanks. I'm not sure it's deserved though. I have good experience with screw turning & having a decent lathe with a decent screw turning gearbox helps. As for knurling - well 80% of what I've ever done is here on this thread & I think photography is helping me out here. Trying out a new macro extension tube on my proper camera you can see the knurl skipped out of index on both the red button & glasseye. Only the spacer is 'perfect'. Not trying to knurl under the motor power & turning the chuck by hand has been a big step in my technique. I'm also knurling onto a raised band which is keeping the edges neat & concentrates the pressure I'm applying from the cross slide. Still a bit of praise is always a nice thing  .

.

Mouse Vader

Sr Member

Got round to doing a machined end cap for the MK2. I got the center counter bore a little wide so had to make a spacer/washer. Whole thing took about 50min inc knurling & fitting - if you discount the 2 days wait for a new 3mm tap for the grub screws (I dropped the first one on the workshop floor & it bounce who knows where?) Made from 38mm (1 1/2 inch) solid bar stock.

With the jack socket installed.

Did all this before I reattach the T-track, so I wouldn't knock them off again when holding in the drill vice to do the grub screws. Also remembered to take the core out before doing the grub screw holes so I could push the end cap off if burs made it stick (they did). I don't think the original had the knurling but I wanted to see what it would look like with, just to be sure and , less importantly, to see if knurling ally was any easier than stainless (is a bit but not by as much as I thought it might). Is useful in fitting & removal.

Installed .

With the jack socket installed.

Did all this before I reattach the T-track, so I wouldn't knock them off again when holding in the drill vice to do the grub screws. Also remembered to take the core out before doing the grub screw holes so I could push the end cap off if burs made it stick (they did). I don't think the original had the knurling but I wanted to see what it would look like with, just to be sure and , less importantly, to see if knurling ally was any easier than stainless (is a bit but not by as much as I thought it might). Is useful in fitting & removal.

Installed .

Mouse Vader

Sr Member

NO promises here, but just gauge 'demand'. Anyone interested in a MK2, to whatever level of completion, can you PM me. I've still no idea of cost or of what to do about blades. This is as much about offsetting costs I've incurred so far than anything & knowing what it's like to see 'unavailable' goodies that I'm not in a position to make for myself.

Be aware that even if I do make some it's unlikely to be quick (months or even yrs) as my time is limited & and unpredictable.

Be aware that even if I do make some it's unlikely to be quick (months or even yrs) as my time is limited & and unpredictable.

Mouse Vader

Sr Member

Some pic's of the MK2 with jack plug attached. For strict 2 handed use it looks viable...

...but as soon as you go to waving it about with one hand or at angles it's clearly sticking out & would be quite obvious.

Compare to where the side wire set up is. It's right at the heel of my hand in pretty much every position one or two handed. I think the jack plug was the original set up & the side wire (& possibly the switch as well) was added once the jack plug was found too obvious.

edit:

Forgot say the 280rpm 370 motor arrived yesterday. Gear box works out as 21.29 : 1 which is slightly closer to 20:1 than I was expecting.. Have fitted it to the black motor without prob's, tests next time.

...but as soon as you go to waving it about with one hand or at angles it's clearly sticking out & would be quite obvious.

Compare to where the side wire set up is. It's right at the heel of my hand in pretty much every position one or two handed. I think the jack plug was the original set up & the side wire (& possibly the switch as well) was added once the jack plug was found too obvious.

edit:

Forgot say the 280rpm 370 motor arrived yesterday. Gear box works out as 21.29 : 1 which is slightly closer to 20:1 than I was expecting.. Have fitted it to the black motor without prob's, tests next time.

Last edited:

Mouse Vader

Sr Member

I have yet to see a set screw hole near the endcap on any of these, but its the only way to hold one in without threading!

Exactly. I think I made a small mistake in placing the grub screws where I did but I was honestly not expecting them to be so obvious. On the other hand I've so few pic's of sufficient quality that would show them up even if they are that obvious. The one from ESB training with Mark H resting his hand on the pommel I think is good enough that they'd show if in either of the 2 gaps between T-track. I'm fairly sure they'd have used 2 as this is common on the other hilts.

If they used blacked steel ones going through the T-track then I think they'd be invisible but that seems a little too refined considering the light switch & wires. They would help keep the T-track attached though... now there's an idea !

The other option, of course is the penny washer style set up onto a push in plastic end cap as i did top of last page. Nothing to see on the outside there.

One other observation while I'm here. That endcap has been on for a few days now & the hilt on the coffee table (or in my hand). That ring locknut is really quite well camouflaged in most lighting conditions & angles. It is not common though (at least on fleabay). Another option is they threaded it direct into the endcap. The thread on my 'vintage' (mono) sockets is 9 x 1mm* but I also bought some new (stereo) ones that are threaded 3/8 x 32 ME (Model Engineering) which looks like a reasonably common thread. Certainly something I'd expect in a props Dept. I think I may need to do a penny washer threaded to take the jack socket as a comparison (it will certainly be quicker than the machined one).

*Edit: Actually 9 x 0.75mm. serves me right for not using a proper thread gauge.

Last edited:

Mouse Vader

Sr Member

Black motor with 21:1 G/b in the Mk1b core & using the heavy suffer d/shaft. This was fitted into the s/s outer tube for rpm testing with full length

un-tapered beech dowel.

Starting at 7V & going to 11V in 1/2V increments , a short video of each then frame counting & calc. rpm.

9.0V gave 558rpm, 9.5V gave 618rpm. Splitting the dif. for 9.25V gave 580rpm which is bang on for the (true) rpm seen in the film of 576. I usually aim for 600 as that's easy to frame count. Flat out at 11V (the 3cell lipo needed charging) gave 720rpm.

Here it is running 9.25V. It is noticeably noisier than the silver 370's.

So is it any good ? Yes it is! I thrashed this as hard as I could in my kitchen to the point of endangering light fittings & could barely notice any change in pitch of the motor/gearbox noise.

Other points to note: I can easily turn a 9.6:1 g/box output shaft (370 motor) by hand. When the 280rpm (21:1) 370 motor combo arrived I could turn it in the same way but it was bordering on difficult , actually about the same as the black motor with a 9.6:1 g/box. The black motor with 21:1 g/box is impossible to turn with just finger power, need pliers to move it ( I can turn it when there's a blade on as there's more to grip).

So what you may ask? well I think it will inhibit the 'pendulum' swing encountered in posts #64 & 65 pg 4 & as seen in that cantina clip. I'll have to test to be sure but this may indicate that a 20:1 g/box was not used on the Kenobi hilt ( given 20:1 g/box requires a high rev motor - like the black one - to give the 580-600rpm we see in the duel).

un-tapered beech dowel.

Starting at 7V & going to 11V in 1/2V increments , a short video of each then frame counting & calc. rpm.

9.0V gave 558rpm, 9.5V gave 618rpm. Splitting the dif. for 9.25V gave 580rpm which is bang on for the (true) rpm seen in the film of 576. I usually aim for 600 as that's easy to frame count. Flat out at 11V (the 3cell lipo needed charging) gave 720rpm.

Here it is running 9.25V. It is noticeably noisier than the silver 370's.

So is it any good ? Yes it is! I thrashed this as hard as I could in my kitchen to the point of endangering light fittings & could barely notice any change in pitch of the motor/gearbox noise.

Other points to note: I can easily turn a 9.6:1 g/box output shaft (370 motor) by hand. When the 280rpm (21:1) 370 motor combo arrived I could turn it in the same way but it was bordering on difficult , actually about the same as the black motor with a 9.6:1 g/box. The black motor with 21:1 g/box is impossible to turn with just finger power, need pliers to move it ( I can turn it when there's a blade on as there's more to grip).

So what you may ask? well I think it will inhibit the 'pendulum' swing encountered in posts #64 & 65 pg 4 & as seen in that cantina clip. I'll have to test to be sure but this may indicate that a 20:1 g/box was not used on the Kenobi hilt ( given 20:1 g/box requires a high rev motor - like the black one - to give the 580-600rpm we see in the duel).

Mouse Vader

Sr Member

Here's me thrash testing the black motor at 9.3V (app 590rpm) in the MK1b part finished hilt. This doesn't look anywhere near the level of thrash I was putting in. This is about the 7th take as I think I was overloading the battery with the amp draw due to the thrashing & it was just cutting out as it did this time too at the end. There was no noticeable slow down otherwise. I'd at least got some decent footage in - perhaps I was getting tired. I was certainly getting hot.

Mouse Vader

Sr Member

Glued the T-track back onto the MK2 last Friday. One with UHU the other with Bostik. Both give the glue 'seam' seen on the Terry Christian Graffy he tried to sell recently.

Christian.

UHU.

Bostik.

Yes I know it's been said he made it recently as part of his proposed repo scheme then tried to pass it off as period but in this respect it doesn't matter as he made either/both irrespective & his 'repro's' were proposed exact copies even down to method, so presuming same type of glue. As I said previously I remember both these glues from the '70's. The recently bought stuff looks & smells just as I remember. I had 1st thought that the UHU would be most likely as it's clear & the Bostik is yellowy & cloudy but you can't tell much dif. once applied.

UHU left, Bostik rt.

When I took that glue comparison pic I first tried putting some on some scrap T-track but the dif wasn't really visible so I wiped the glue off. I noticed the Bostik had dissolved the surface of the plastic!

I did the UHU 1st. This took a long time to set. 24hrs later there was still some slight movement but it was set enough to handle & not change position. The Bostik was much quicker. It was the same firmness as the UHU after only a couple of hours. It's now 3 days set & I tried hard swings with a dowel in place, as I did when they 1st came off, & both have stayed putt with no hint of failure.

So for me, I have to recommend Bostik (all purpose) for an effective & possibly correct T-track adhesive. (Araldite aside). Dries reasonably quickly - over night seemed quite solid - & looks about right & is easier than epoxy. Well see how both stack up during subsequent testing.

Christian.

UHU.

Bostik.

Yes I know it's been said he made it recently as part of his proposed repo scheme then tried to pass it off as period but in this respect it doesn't matter as he made either/both irrespective & his 'repro's' were proposed exact copies even down to method, so presuming same type of glue. As I said previously I remember both these glues from the '70's. The recently bought stuff looks & smells just as I remember. I had 1st thought that the UHU would be most likely as it's clear & the Bostik is yellowy & cloudy but you can't tell much dif. once applied.

UHU left, Bostik rt.

When I took that glue comparison pic I first tried putting some on some scrap T-track but the dif wasn't really visible so I wiped the glue off. I noticed the Bostik had dissolved the surface of the plastic!

I did the UHU 1st. This took a long time to set. 24hrs later there was still some slight movement but it was set enough to handle & not change position. The Bostik was much quicker. It was the same firmness as the UHU after only a couple of hours. It's now 3 days set & I tried hard swings with a dowel in place, as I did when they 1st came off, & both have stayed putt with no hint of failure.

So for me, I have to recommend Bostik (all purpose) for an effective & possibly correct T-track adhesive. (Araldite aside). Dries reasonably quickly - over night seemed quite solid - & looks about right & is easier than epoxy. Well see how both stack up during subsequent testing.

Last edited:

Mouse Vader

Sr Member

As I'm not able to do much practically at the moment I've added a table of contents at the start of the thread post #1, something I've been meaning to do for a while. Hopefully it will prove useful in the future.

Similar threads

- Replies

- 4

- Views

- 915

- Replies

- 15

- Views

- 2,751

- Replies

- 63

- Views

- 5,550