zjunlimited

Sr Member

Internal Mount Support

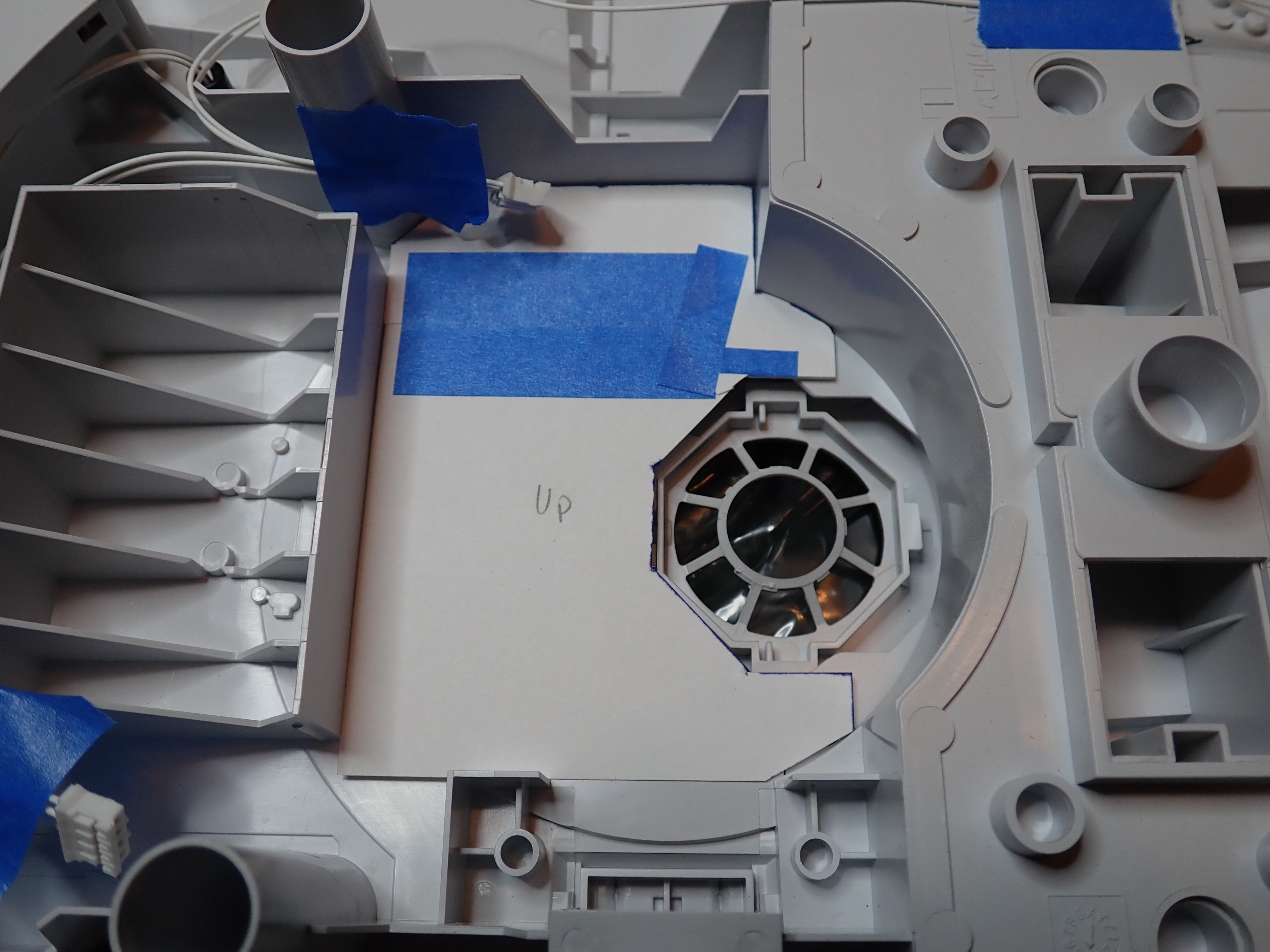

This consists of two sections....the mounting plate and connecting rod support. First up, the mounting plate.

Started off with a template using notecards. Needed something stiffer than regular paper.

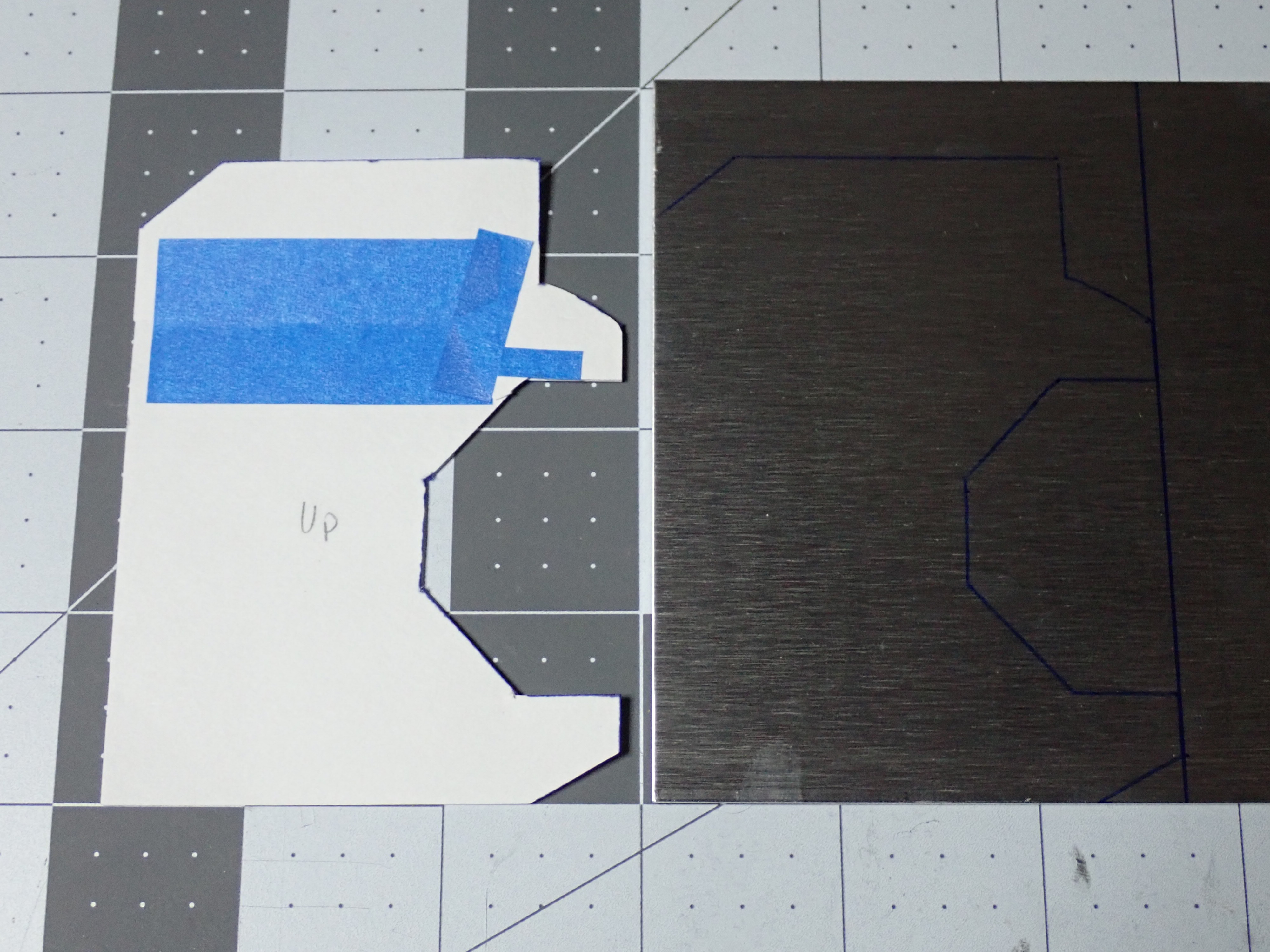

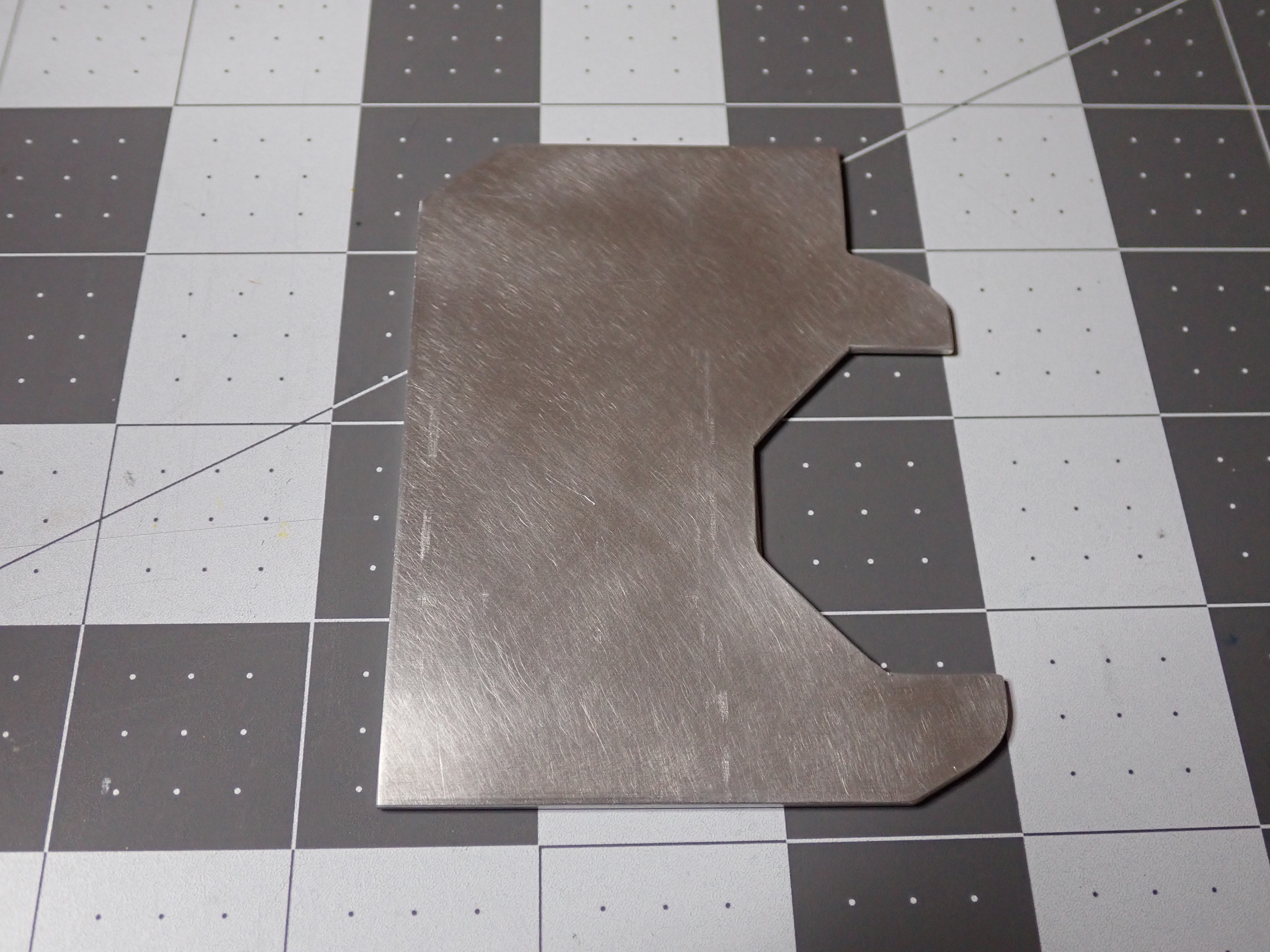

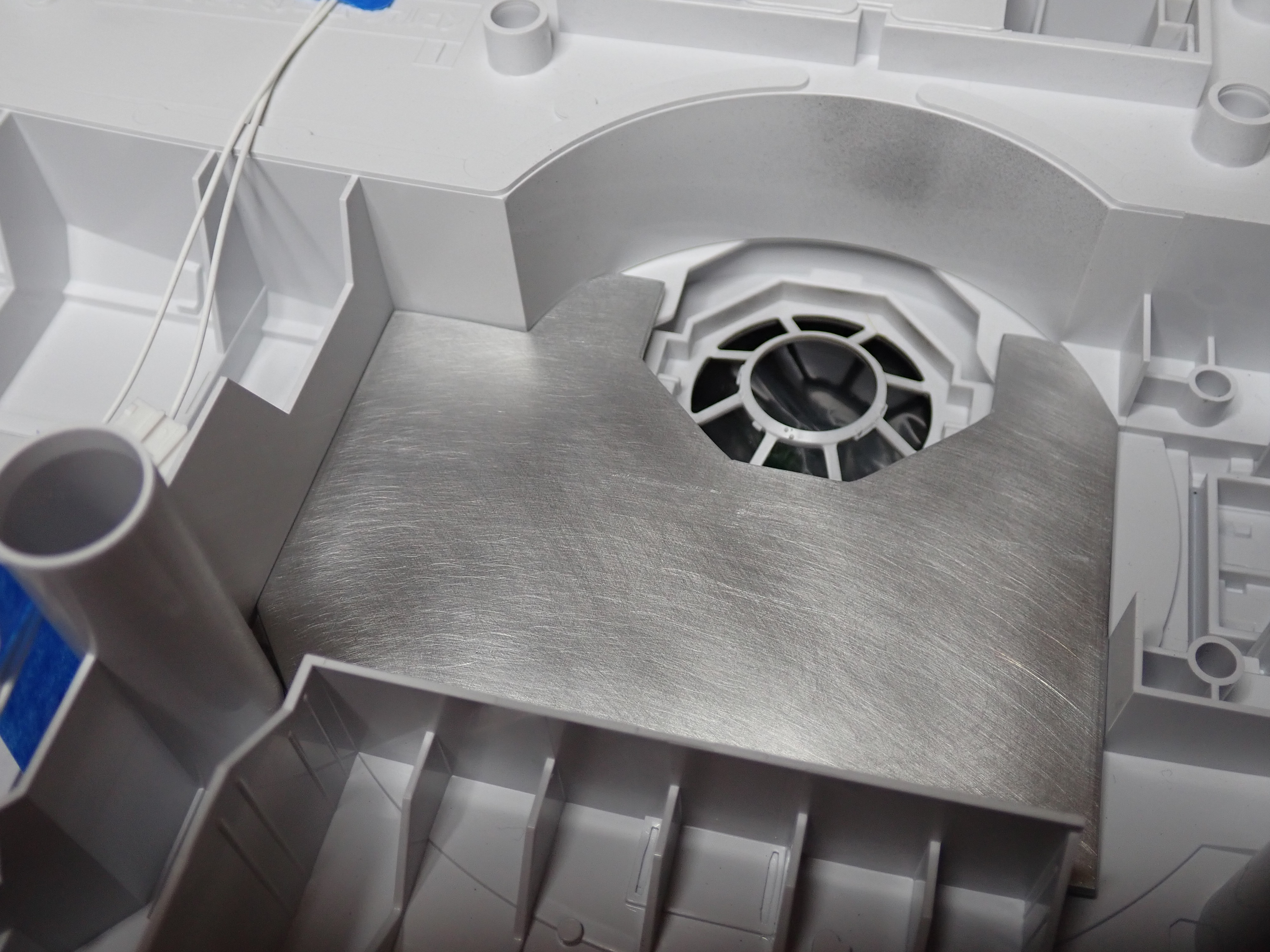

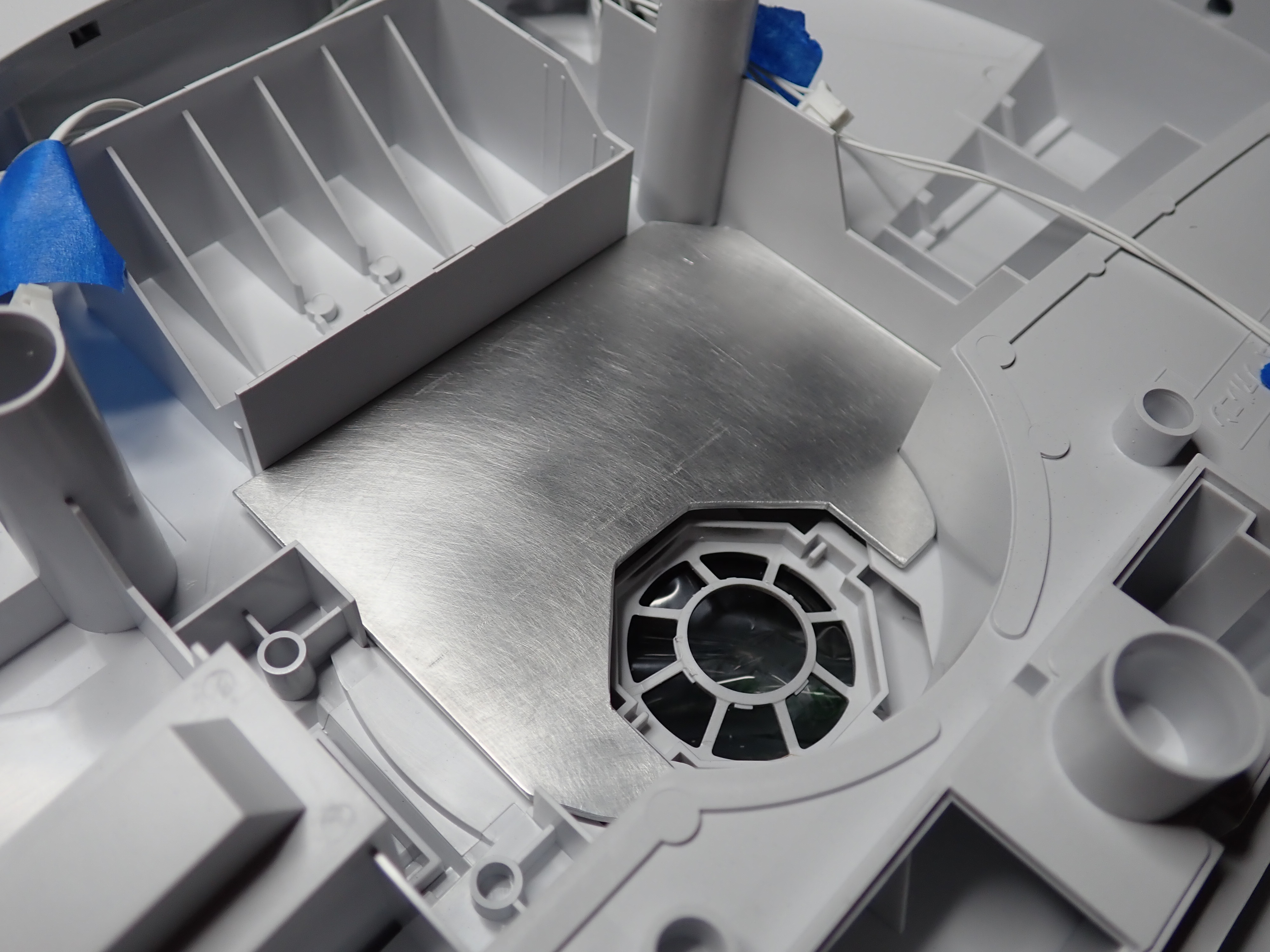

Transferred that to some aluminum sheet and cut out using a dremel.

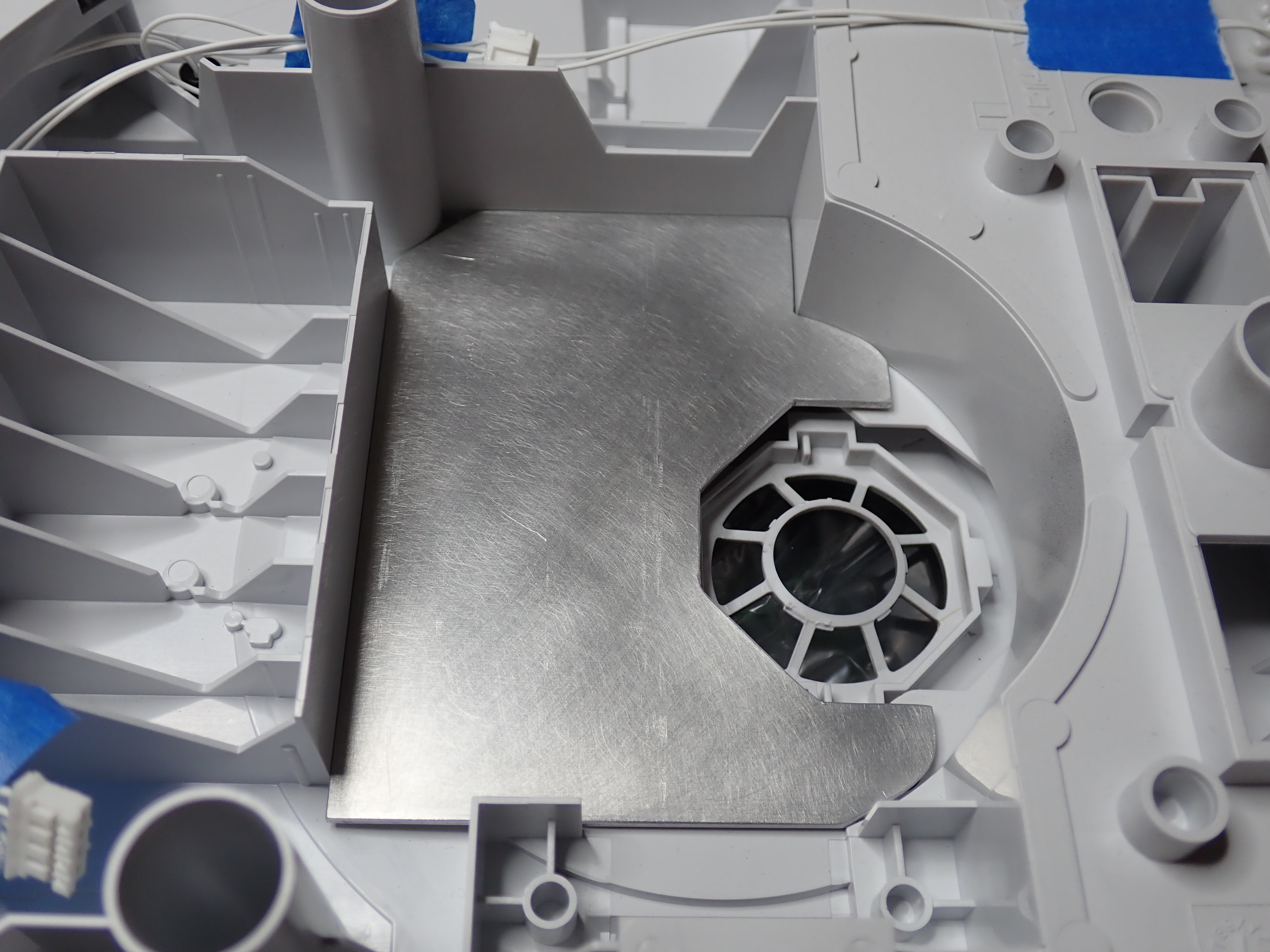

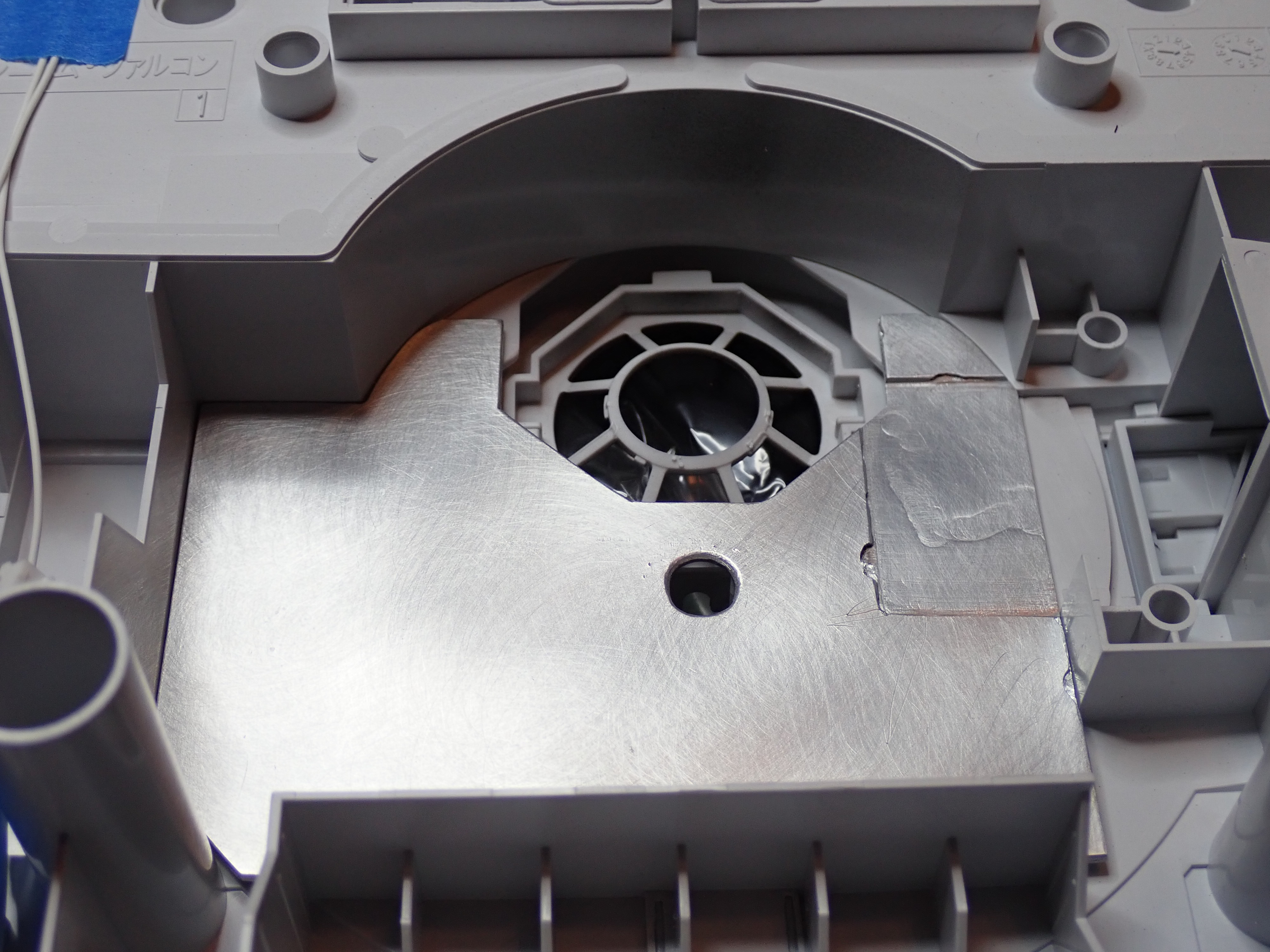

Test fit is good. Now in hindsight I would have made the opening around the gun windows slightly larger. As it is, I can not remove them after the plate is installed. Likely not a big deal since once everything is close, you're not going to remove anything but just something to note.

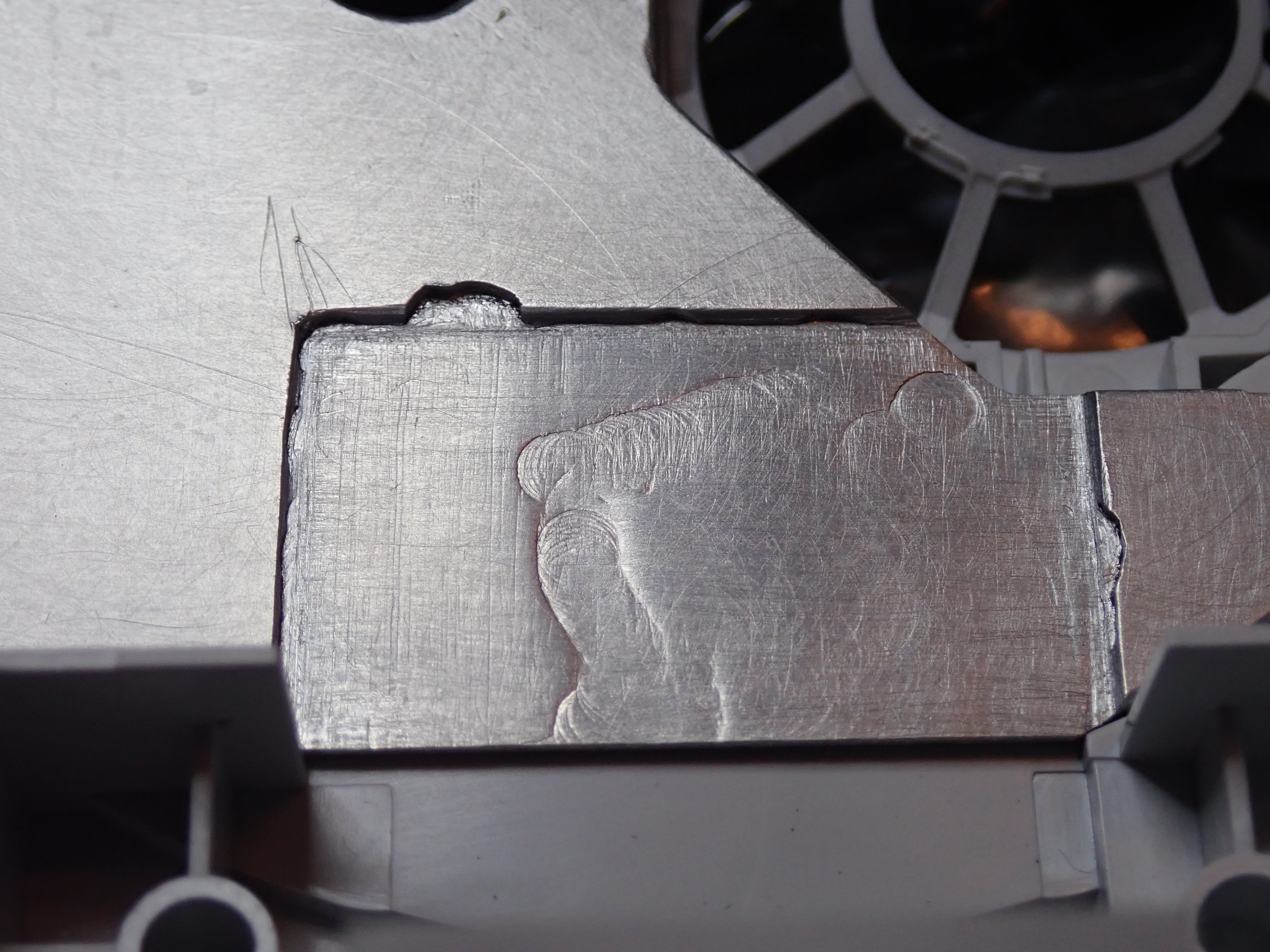

Since I wanted to use the ramp corridor as well the metal plate was a tad too thick. So I milled out a section using my drill press and some milling bits and some creativity....lol. A few mistakes and slips here and there but got the job done.

The second part to come....connecting rod support.

This consists of two sections....the mounting plate and connecting rod support. First up, the mounting plate.

Started off with a template using notecards. Needed something stiffer than regular paper.

Transferred that to some aluminum sheet and cut out using a dremel.

Test fit is good. Now in hindsight I would have made the opening around the gun windows slightly larger. As it is, I can not remove them after the plate is installed. Likely not a big deal since once everything is close, you're not going to remove anything but just something to note.

Since I wanted to use the ramp corridor as well the metal plate was a tad too thick. So I milled out a section using my drill press and some milling bits and some creativity....lol. A few mistakes and slips here and there but got the job done.

The second part to come....connecting rod support.