You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/144th Prometheus scratch build

- Thread starter TheNylonGag

- Start date

Ello,

Well, what can i say.

Squeezed a few hours in

Had to adapt a few things,

But

I made some progress

Ready, is everyone in, this is a small update, about 10,1/2 hours at the bench

Lets go

During my sick time i spent some dough

10" Bench top pillar drill, 18 pcs hole saw set including arbour, 3 piece step drill set from 1/16" to 3/4" in 1/16" steps, including delivery.

Guess, go on guesss.

$93, thats 58 quid, for the lot.

Then i tidied up the cave

Then it was back to the Prometheus

Engines build up.

Cut out all pieces for the bottom nozzel assembly

Had to use sizzors instead of a knife

Did three sets

Top rings

Sides and top ring fitted and trimmed

Three done

Fiddled with this for a night and managed to fit the front wing

Outer nozzel covers

Rough Trimmed

Inners glued and basic shaped

Action shots

Thats about the story so far.

Just wanted to thenk all the people who supported me though my wrist malfunction

Your support and kind words ment alot to me.

Thank you friends

Gag

Tony

Toe

Well, what can i say.

Squeezed a few hours in

Had to adapt a few things,

But

I made some progress

Ready, is everyone in, this is a small update, about 10,1/2 hours at the bench

Lets go

During my sick time i spent some dough

10" Bench top pillar drill, 18 pcs hole saw set including arbour, 3 piece step drill set from 1/16" to 3/4" in 1/16" steps, including delivery.

Guess, go on guesss.

$93, thats 58 quid, for the lot.

Then i tidied up the cave

Then it was back to the Prometheus

Engines build up.

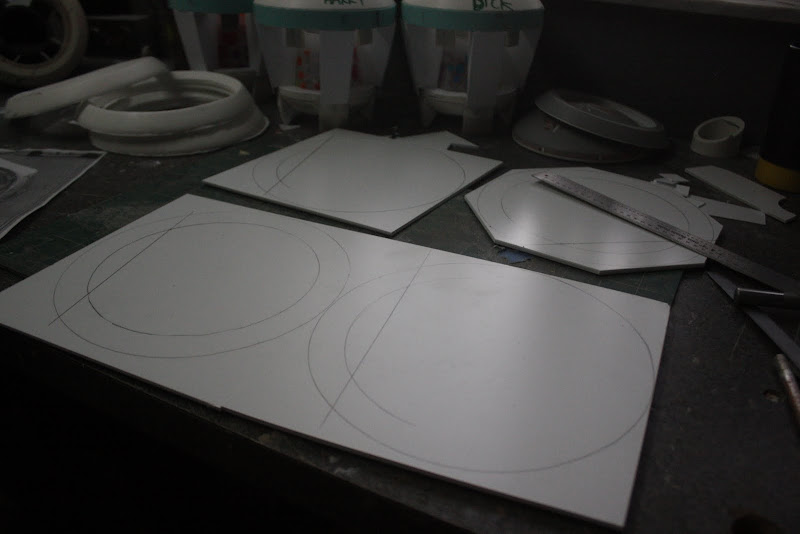

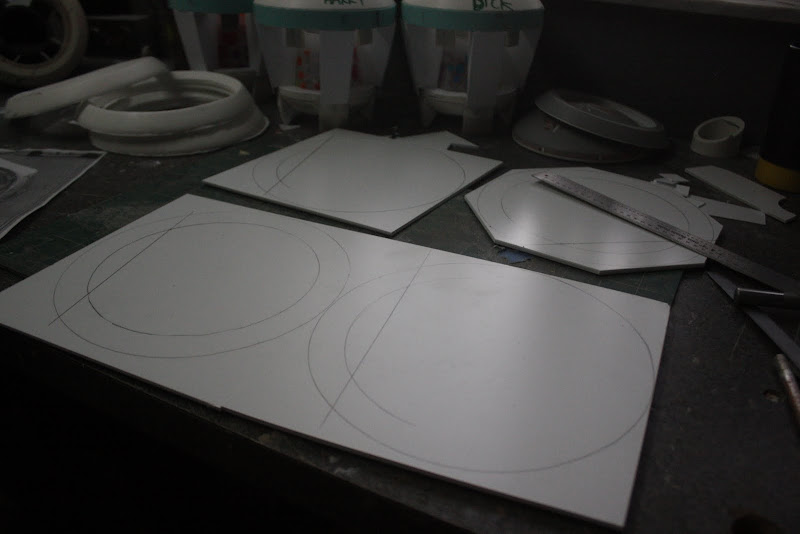

Cut out all pieces for the bottom nozzel assembly

Had to use sizzors instead of a knife

Did three sets

Top rings

Sides and top ring fitted and trimmed

Three done

Fiddled with this for a night and managed to fit the front wing

Outer nozzel covers

Rough Trimmed

Inners glued and basic shaped

Action shots

Thats about the story so far.

Just wanted to thenk all the people who supported me though my wrist malfunction

Your support and kind words ment alot to me.

Thank you friends

Gag

Tony

Toe

CyberGolem

Active Member

Yessssss!!

SmilingOtter

Master Member

Even in their early stages, the engines look awesome.

Glad you're recovering well, and I look forward to more progress shots.

Glad you're recovering well, and I look forward to more progress shots.

So glad to see an update! I like your new toys, can't wait to see what you do with them.

Caretaker10

Active Member

It's good to see you back at work Gag...

Nice progress as usual.

How's the wrist?

Nice progress as usual.

How's the wrist?

Vacformedhero

Sr Member

Welcome back, a wrist injury for an artist is a serious problem, and you are creating art......glad your at it again

the DOCTOR

Sr Member

Phew! All is right with the world, Gag's back in his cave!

Last edited:

yuumi2891103

Master Member

What a wonderful world!!

Your golden hands are recovered!!

I can see you work again.

YOU ARE NUMBER ONE!!

I really wish all the best things happen to you.

katsu

ps. I wanna one of those drill.:eek

Your golden hands are recovered!!

I can see you work again.

YOU ARE NUMBER ONE!!

I really wish all the best things happen to you.

katsu

ps. I wanna one of those drill.:eek

Welcome back old boy. So glad to see you here. How's the wrist holding up? All good?

Thank you everyone so much for your comments and for visiting

Still have pain, but, by cricky we are gunna finish this thing with or without pain.

The wrist has its limitations but i am adapting well to my new situation.

But

On ward my friends

PIX

Hope you have all recovered from my action shots.

Filled with bondo......

Three, everything is three at the mo......

Sanded......

Three........main engine bodies

Covered the outsides and sanded all nice like

Started molding the outer rings, inner and outer are the same

Now we're doin eights

Marked

Rough cut

Four, yes four inner walls

Glued inner wall to outer inside ring, i think.....only one this time......to test

Cut bottom bit off

Moved on next to the inner workings of the engine, lights and sum such.....

1,000,000 watt LED spot light, i plan to use a dimmer.....i think.

Cut hole in tube with cap to hold 1,000,000 watt LED bulb

So......

1 million watts, watch your eyes people

Dry fit in the main engine body

Cut support for outer wall

dry fit.......again

Very rough sketch of detail positions

Dry fit.............again

Hole saw action

Hole by saw

Final Dry fit

Thats the story so far

Definately more to come

Still making it up as i go

Hope you are having as much fun as me

Its good to be back in the groove baby

Gagster

OUT

Still have pain, but, by cricky we are gunna finish this thing with or without pain.

The wrist has its limitations but i am adapting well to my new situation.

But

On ward my friends

PIX

Hope you have all recovered from my action shots.

Filled with bondo......

Three, everything is three at the mo......

Sanded......

Three........main engine bodies

Covered the outsides and sanded all nice like

Started molding the outer rings, inner and outer are the same

Now we're doin eights

Marked

Rough cut

Four, yes four inner walls

Glued inner wall to outer inside ring, i think.....only one this time......to test

Cut bottom bit off

Moved on next to the inner workings of the engine, lights and sum such.....

1,000,000 watt LED spot light, i plan to use a dimmer.....i think.

Cut hole in tube with cap to hold 1,000,000 watt LED bulb

So......

1 million watts, watch your eyes people

Dry fit in the main engine body

Cut support for outer wall

dry fit.......again

Very rough sketch of detail positions

Dry fit.............again

Hole saw action

Hole by saw

Final Dry fit

Thats the story so far

Definately more to come

Still making it up as i go

Hope you are having as much fun as me

Its good to be back in the groove baby

Gagster

OUT

CyberGolem

Active Member

This is exciting, inspiring and overwhelming ... all at once.

Constantine

Well-Known Member

Luv the ingenuity and dedication, great work!

yuumi2891103

Master Member

One of the most exciting scene would be seen soon.

GAG! your work makes mine a toy stuff! :facepalm

katsu

GAG! your work makes mine a toy stuff! :facepalm

katsu