Firefox3D

Well-Known Member

No problem, the distortions should not be there, the resin is flexing on the supports, combination of give and the resin shrinks slightly in the plane of the bed when curing.

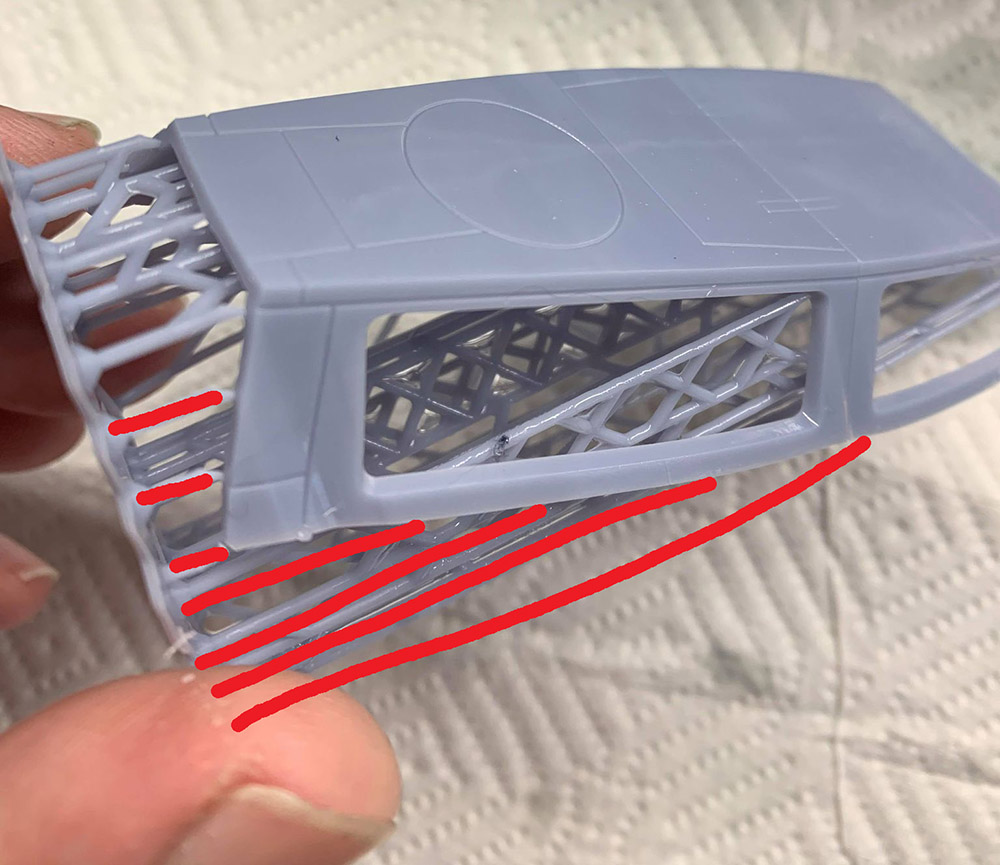

Try thicker supports with 2 times larger contact points, and add some more from the bottom edge of the canopy, like this

Try thicker supports with 2 times larger contact points, and add some more from the bottom edge of the canopy, like this