I'll have a go polishing them. I agree that the buttons should be matte, certainly look that way on the reference photos.Absolutely polish before anodizing. The anodizing will not polish, so if you want the pieces to look shiny I would polish. The buttons will likely want to be matte.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NASA ACES suit disconnects

- Thread starter antarusfree

- Start date

-

- Tags

- aces disconnects nasa replica suit

Here's a first go at some polishing.

Bearing ring polished, rest of the assembly had some scotch-brite used on it to clean up some of the machining marks.

As far as I'm concerned it was successful, I will only polish the visible surfaces, seem a bit pointless to polish something that will be covered up.

Bearing ring polished, rest of the assembly had some scotch-brite used on it to clean up some of the machining marks.

As far as I'm concerned it was successful, I will only polish the visible surfaces, seem a bit pointless to polish something that will be covered up.

I am now planning on polishing before anodising. Where do you think the radius should be larger?We finish everything to mirror finish before anodizing. You will also want a much bigger radius on the clam ring.

The suit / fabric clamp ring, OD. (I can't see the ID)I am now planning on polishing before anodising. Where do you think the radius should be larger?

One thing I have learned from making this hardware, is the edge radii are always larger than they look.

antarusfree

Well-Known Member

Yeah, Imgill is reffering to the mounting ring. The OD and ID are the same. From the looks I would also suggest to make the radius larger. Maybe 2x larger than in my model.I am now planning on polishing before anodising. Where do you think the radius should be larger?

Yeah, Imgill is reffering to the mounting ring. The OD and ID are the same. From the looks I would also suggest to make the radius larger. Maybe 2x larger than in my model.

The suit / fabric clamp ring, OD. (I can't see the ID)

One thing I have learned from making this hardware, is the edge radii are always larger than they look.

Many Thanks both

I have done some work to make the radius larger as suggested, definitely improved.

A polishing update, I've purchased a better buffing compound, certainly improved the process.

Indeed, made the process a lot quicker and improved the finish.Yep, there's a notable difference with that new compound

A polishing update only one main part to go.

antarusfree

Well-Known Member

WOW

Thank youThose are gorgeous!!!

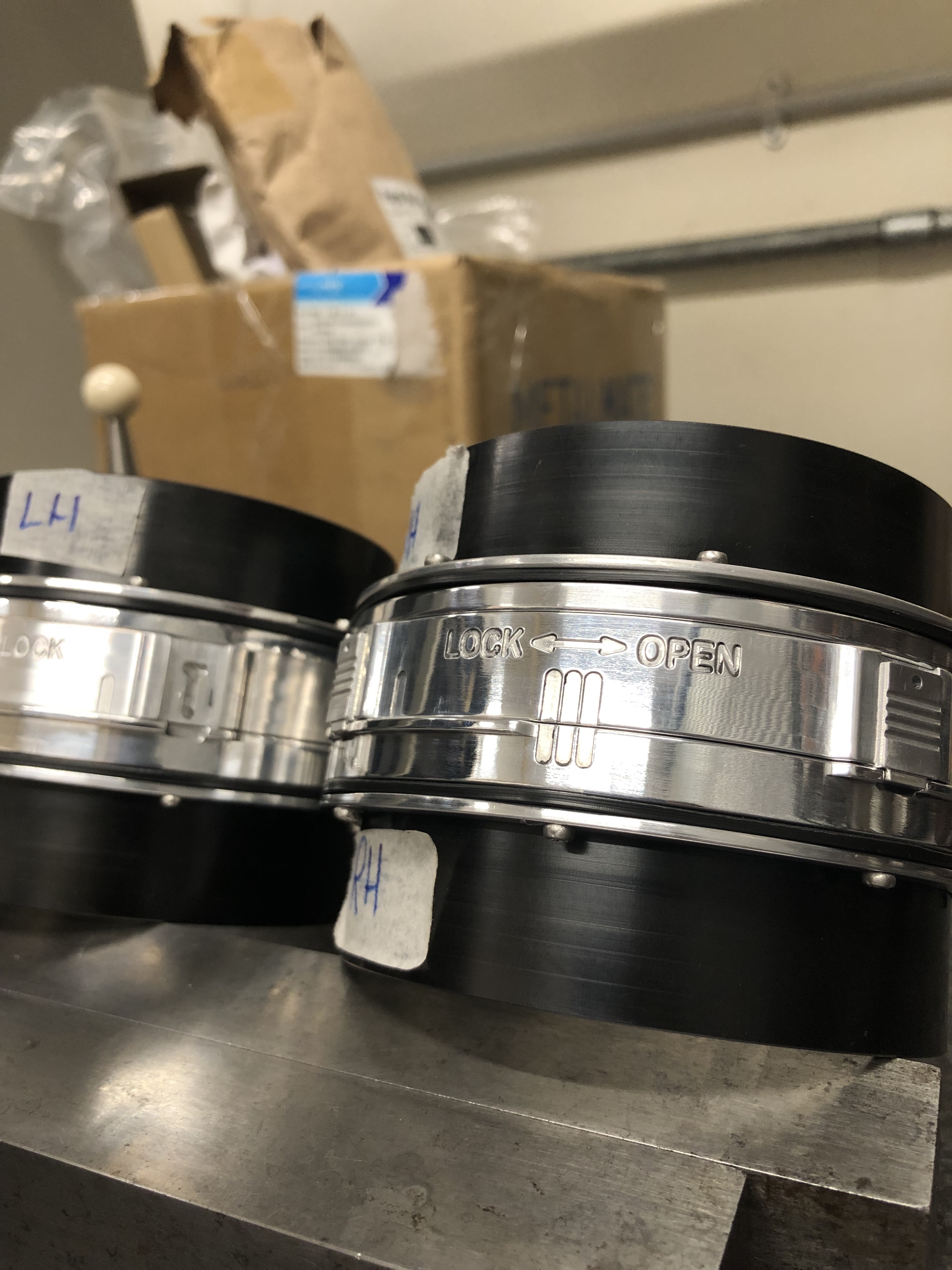

Polishing is now finished, some areas to improve, however I think they turned out well.

Here's some photo showing the installation of the spring and grub screws into the locking tabs, a little fiddly but not as bad as I expected the worst part was tapping the M2 thread in the locking tab, I didn't enjoy doing that, thankfully the parts were all okay.

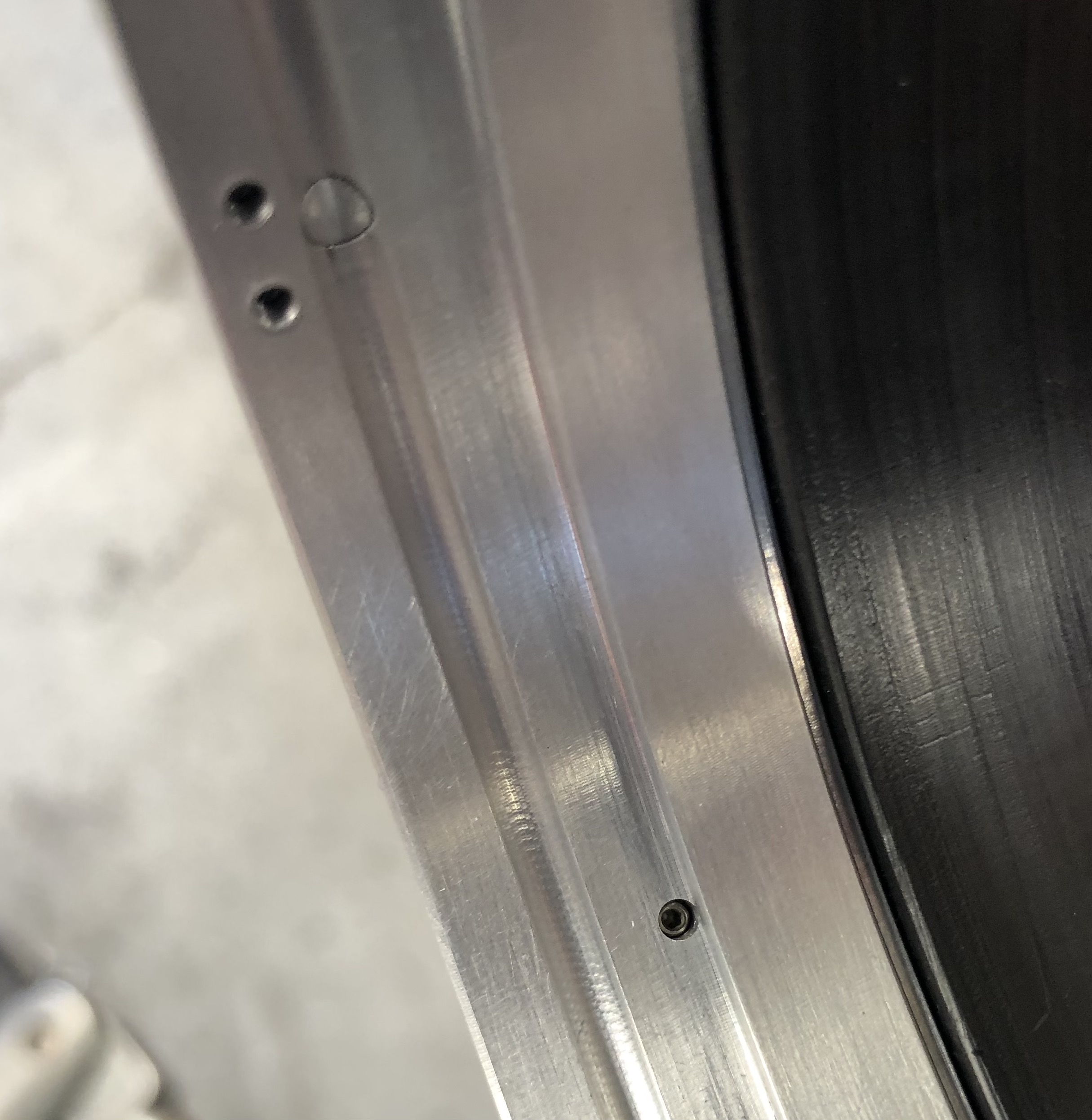

Step 1 insert the grub screw the place the spring into the slot keeping the grub screw below the surface.

Step 2 slide the locking tab into position with the hole and the grub screw are in line.

Step 3 tighten the grub screw so that the locking tab slides freely and doesn't fowl on the bottom of the slot.

Here from the inside you can just make out the grub screw visible.

Whole setup works really well, once again many thanks to antarusfree for his excellent CAD modelling without whom this wouldn't have been possible.

Step 1 insert the grub screw the place the spring into the slot keeping the grub screw below the surface.

Step 2 slide the locking tab into position with the hole and the grub screw are in line.

Step 3 tighten the grub screw so that the locking tab slides freely and doesn't fowl on the bottom of the slot.

Here from the inside you can just make out the grub screw visible.

Whole setup works really well, once again many thanks to antarusfree for his excellent CAD modelling without whom this wouldn't have been possible.

Similar threads

- Replies

- 15

- Views

- 901

- Replies

- 24

- Views

- 1,667