You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My new HAL 9000

- Thread starter rogerrabt

- Start date

rogerrabt

Active Member

The screen-used HAL had the top of the aluminium frame slightly beveled. The part, in the middle, over the grill was flat. Neil (3Dsf here on the RPF) made an extensive and most excellent research on that prop.

There are definitely a few aspects I would do, but I either have no idea how to do them, or just want to keep the build somewhat reasonable. I know, I know... perfection! I wish I had access to a bulbous glass like the original. I have no idea how to make the lettering on the lens bezel. I could add that at a later date. I did follow 3Dsf's post on undercutting the frame though which he wasn't able to do, but it sure worked out well. I just noticed the part about a 5° chamfer on the inside of the bezel. Without holding an original, it'd sure be difficult to spot that in the film.

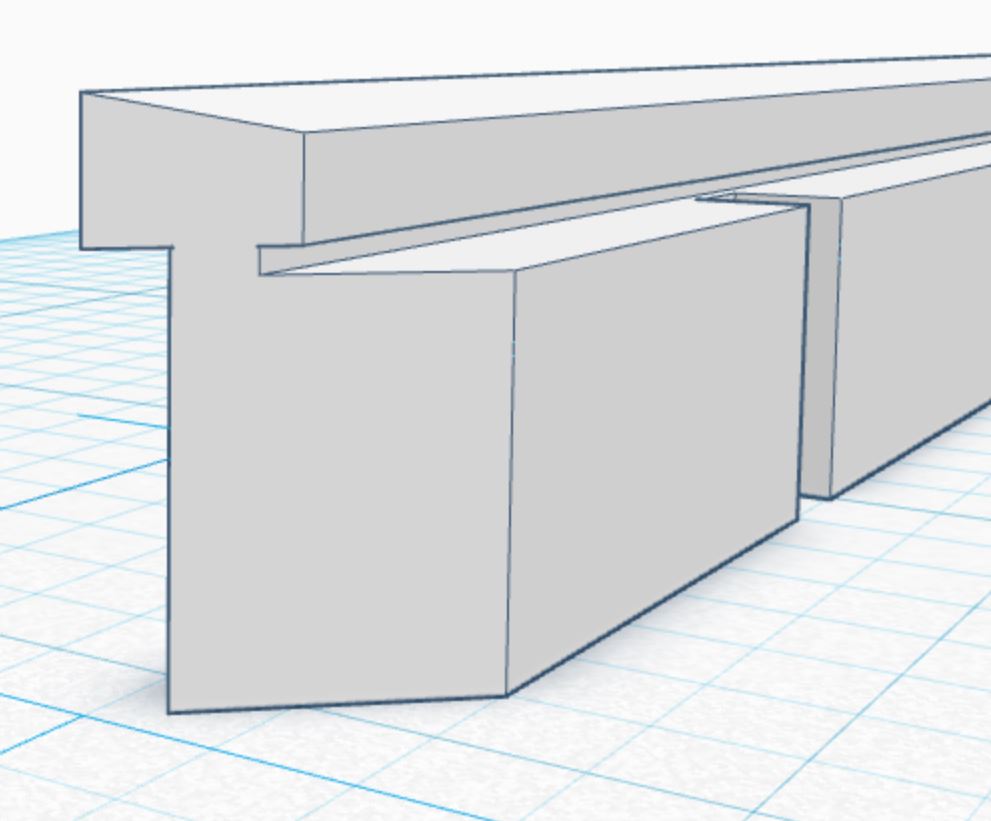

Sketch-Up profile of the frame with proposed 5° chamfer.

One thing that I'm not sure about doing is the color on the grill. In this shot, it's quite dark.

In this shot, it's quite a bit lighter. Chalk it up to lighting I suppose. I'm thinking BW Casey Aluminum Black and see how that looks.

alensatemybuick

Active Member

Would love to see that…I’ve modelled the Nikkor lens in 3D - just redone it for higher resolution printing. I’ve included the engraved lettering, traced from an original lens. You can use white paint to fill it in like the original. It’s not cheap to print, though.

rogerrabt

Active Member

I hope to see that someday!I’ve modelled the Nikkor lens in 3D - just redone it for higher resolution printing. I’ve included the engraved lettering, traced from an original lens. You can use white paint to fill it in like the original. It’s not cheap to print, though.

rogerrabt

Active Member

About time to wrap this project up.

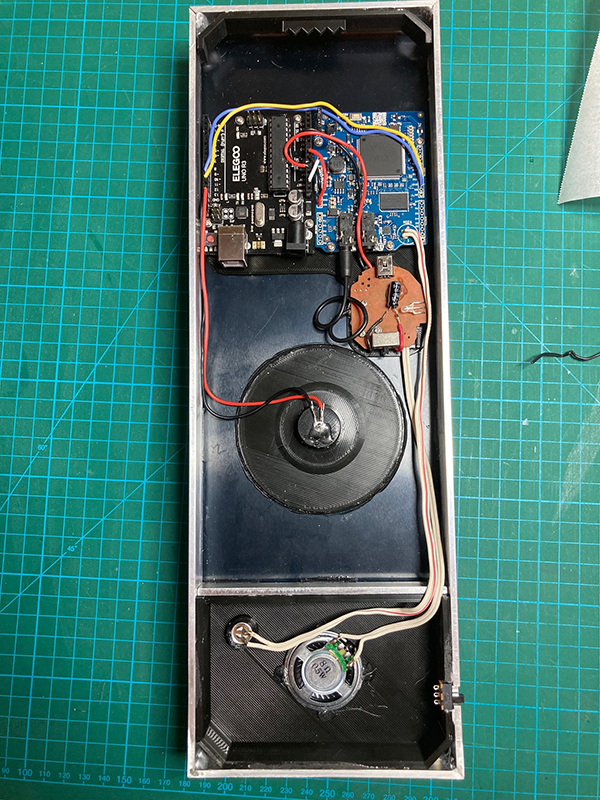

I decided to move away from a 9v battery that I showed on Oct 31. The run time with an arduino and movi is quite short on it. So, here's the new board support.

Got all the wiring in place. The brightness of the LED can be controlled by the Arduino. I imagine i'll just ask HAL to turn up or down the brightness. I desoldered the microphone from the Movi and moved it down to the grill. The one thing I may change in the future is to turn on and off the amplifier when it's not in use. It should just be a transister or darlington pair to do that.

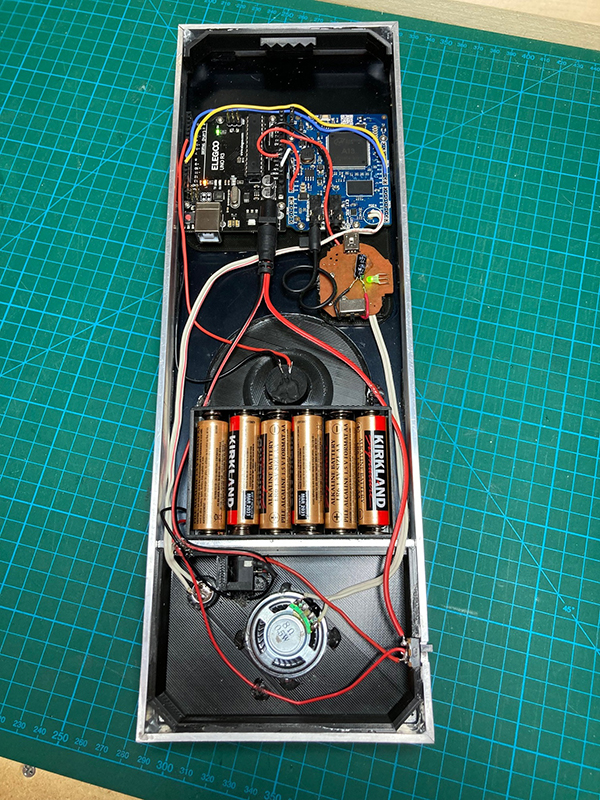

I ordered a 6 AA battery carrier from Robotshop. This should give me loads of power. Approx 2000 vs 450 mAH.

Plus I can drive it off a wall wart; the socket is positioned right next to the microphone.

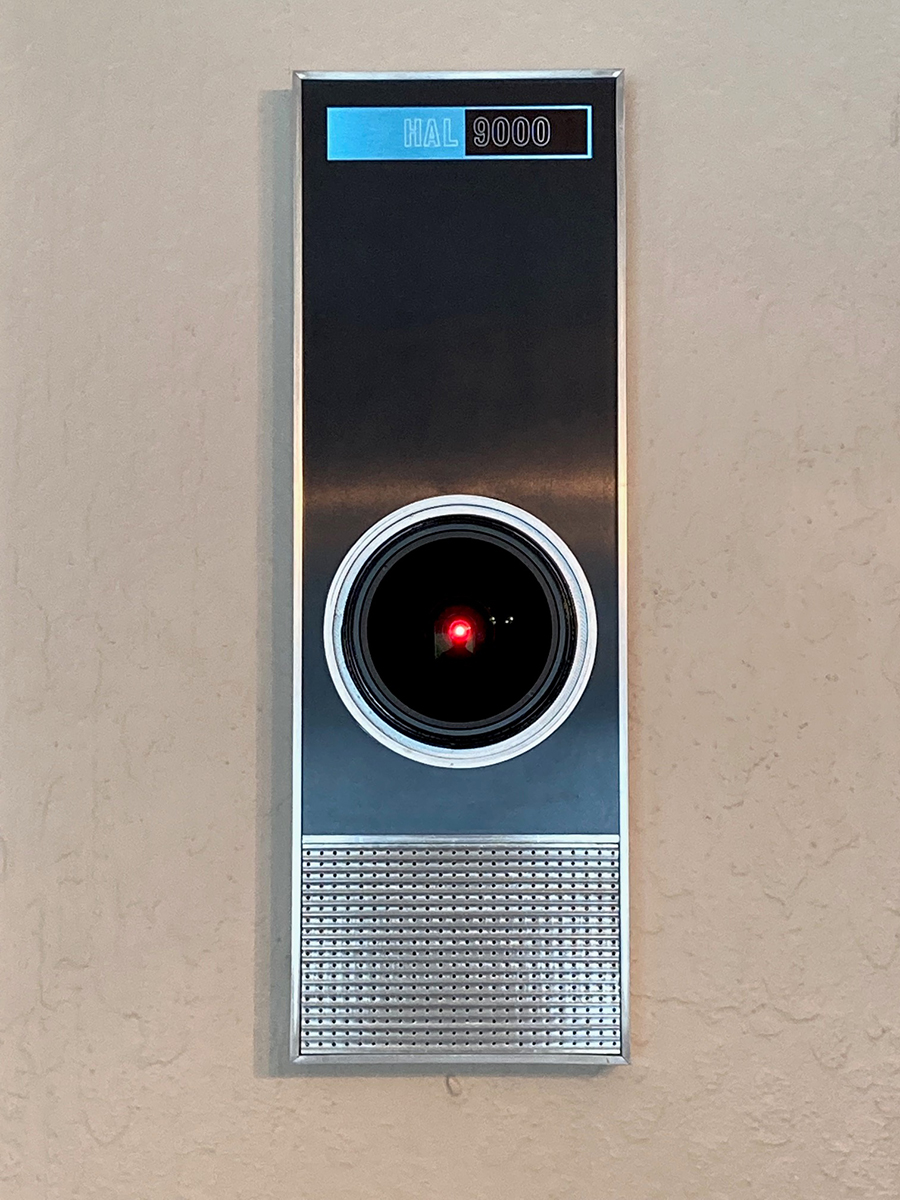

Once the holidays are over, I'll find a shop to anodize the grill in gray. For now, HAL looks pretty sharp.

Plus programming work to do. Get rid of the confirmation beep. Listen more actively. Play lines without getting the prompts 100% perfectly accurate.

I decided to move away from a 9v battery that I showed on Oct 31. The run time with an arduino and movi is quite short on it. So, here's the new board support.

Got all the wiring in place. The brightness of the LED can be controlled by the Arduino. I imagine i'll just ask HAL to turn up or down the brightness. I desoldered the microphone from the Movi and moved it down to the grill. The one thing I may change in the future is to turn on and off the amplifier when it's not in use. It should just be a transister or darlington pair to do that.

I ordered a 6 AA battery carrier from Robotshop. This should give me loads of power. Approx 2000 vs 450 mAH.

Plus I can drive it off a wall wart; the socket is positioned right next to the microphone.

Once the holidays are over, I'll find a shop to anodize the grill in gray. For now, HAL looks pretty sharp.

Plus programming work to do. Get rid of the confirmation beep. Listen more actively. Play lines without getting the prompts 100% perfectly accurate.

How did we arrive 5° for the chamfer. I do agree there's a chamfer just that it looks more like 30°. Just asking as I'll need to order an end mill.

We didn't. I'm one of the few people who's done the bevel, and I did so because I believe it's the only way the frame could appear in many of the photos of the actual props.

I experimented with a few angles, and 5 worked for me - it's enough to show different brightness levels at some angles, but it's definitely not as much as 30°, because that would appear much more obvious. (ie: the frame looks flat in most photos)

But either way, it's conjecture.

Think you're right on the 5°. Thanks so much for getting back to me. If only one had servived. Lights on a set leave little room for shadows. There is so little material to work with on the sides. So if the frame is 1/8" and taking a 1/16" or less from the outside lower part to form the outer rim doesn't leave much. If the plan is to cut a slot on the inside for the black faceplate and speaker grill to sit under well that might be a problem. Might make something like the drawing below. Might make it out of 1/4" stock instead of 1/8" for some extra room.

In the picture below the reveal looks to be in the 1/8" to 1/4" range and it looks like the faceplate is even with the surrounding casework. Do you have any hard data on that measurement? The speaker grill seems to be at the same depth, maybe. It may be a bit before I start the actual build. I'm picking brains (hope that didn't hurt) and making a list of things I'll need. Sure would be nice if we could get Peter to open up his to have a look see on the inside. Thanks again for the 5° tip.

In the picture below the reveal looks to be in the 1/8" to 1/4" range and it looks like the faceplate is even with the surrounding casework. Do you have any hard data on that measurement? The speaker grill seems to be at the same depth, maybe. It may be a bit before I start the actual build. I'm picking brains (hope that didn't hurt) and making a list of things I'll need. Sure would be nice if we could get Peter to open up his to have a look see on the inside. Thanks again for the 5° tip.

That's an interesting approach. But it does seem to me to be overcomplicating things a bit. If you machine the side pieces in a kind of T shape you won't have all the additional complexity of the lower bit extending out, and machining in the slot, etc. I just put high density MDF blocks underneath the brushed panel and the grille, with the side screws holding them in place.

The Randall/Jackson prototype faceplate appears to have a similar construction, only with a heavier aluminium block inside. Judging by the Adam Savage video, anyway.

Your design is great I think I may have to steal it if you don't mind. Both would be relatively easy to make with the proper equipment. I just through something together I thought might work. I think starting with angle aluminum would simplify the process. In my opinion the real issue is not how to make it but what the dimensions should be. It's pretty much been determined the exposed frame has a face on width of 1/8". So as far as we know the remaining measurements of the profile of this part remain unknown at this point.

I watched 2010 again last night and although I liked the movie the quality of the movie and props are no where close to those of 2001.

Thanks again for the help.

I watched 2010 again last night and although I liked the movie the quality of the movie and props are no where close to those of 2001.

Thanks again for the help.

Similar threads

- Replies

- 3

- Views

- 1,562