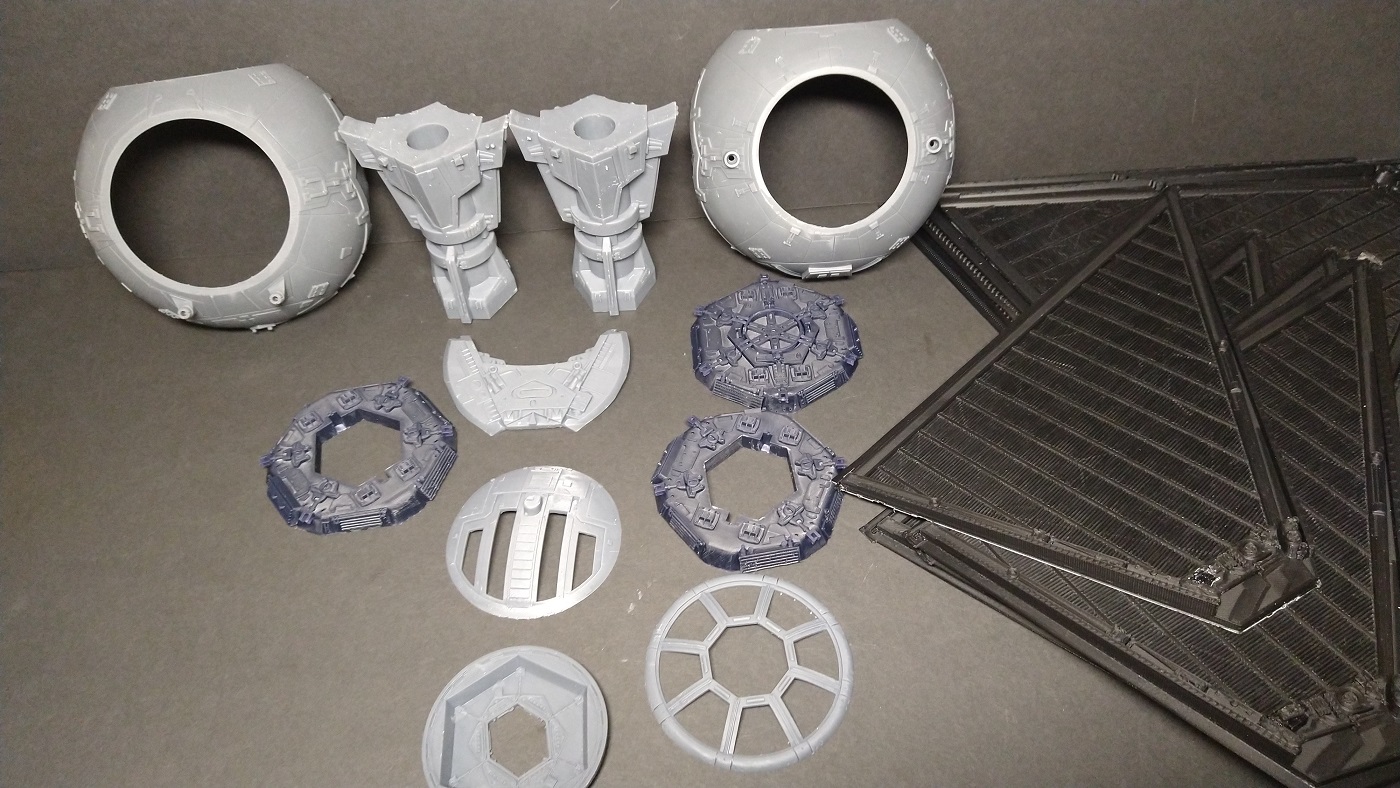

There have been some new editions to my family of printers, a Neptune 3 Plus and the new Elegoo Mars 12K Ultra. So, what can you do with 5 printers going full out for 10 days, well, one option is to really put them through paces and print both a 1/24th Scale X-Wing and TIE, which is exactly what I did

Technically, the TIE is not all the way printed as I am still running through the wings as there are 24 panels that need to be printed and only one of my printers is large enough for that. There are at least 3 or 4 more full days to finish those up.

I plan to light both kits and build up some custom bases.

About 3 years ago when I first got into 3D printing my first project was a 1/24th scale X-Wing which ended up with an okay paint job (it's posted here). That kit was all PLA with no resin parts. This time round I plan to print resin where it makes sense and PLA for the rest. I really like the way both of these files turned out as they both have a very 'model kit' feel to them as all the small parts are separate.

Well, let's see what I have learned over the last few years and get these things built!

Technically, the TIE is not all the way printed as I am still running through the wings as there are 24 panels that need to be printed and only one of my printers is large enough for that. There are at least 3 or 4 more full days to finish those up.

I plan to light both kits and build up some custom bases.

About 3 years ago when I first got into 3D printing my first project was a 1/24th scale X-Wing which ended up with an okay paint job (it's posted here). That kit was all PLA with no resin parts. This time round I plan to print resin where it makes sense and PLA for the rest. I really like the way both of these files turned out as they both have a very 'model kit' feel to them as all the small parts are separate.

Well, let's see what I have learned over the last few years and get these things built!