Another Early Morning Update!

Let's start with the awesome! This arrived yesterday - a HUGE THANKS to Wavey for carrying the weight of this transaction!

We've got seats! These are VERY close to the original seats used in the full scale MF prop!

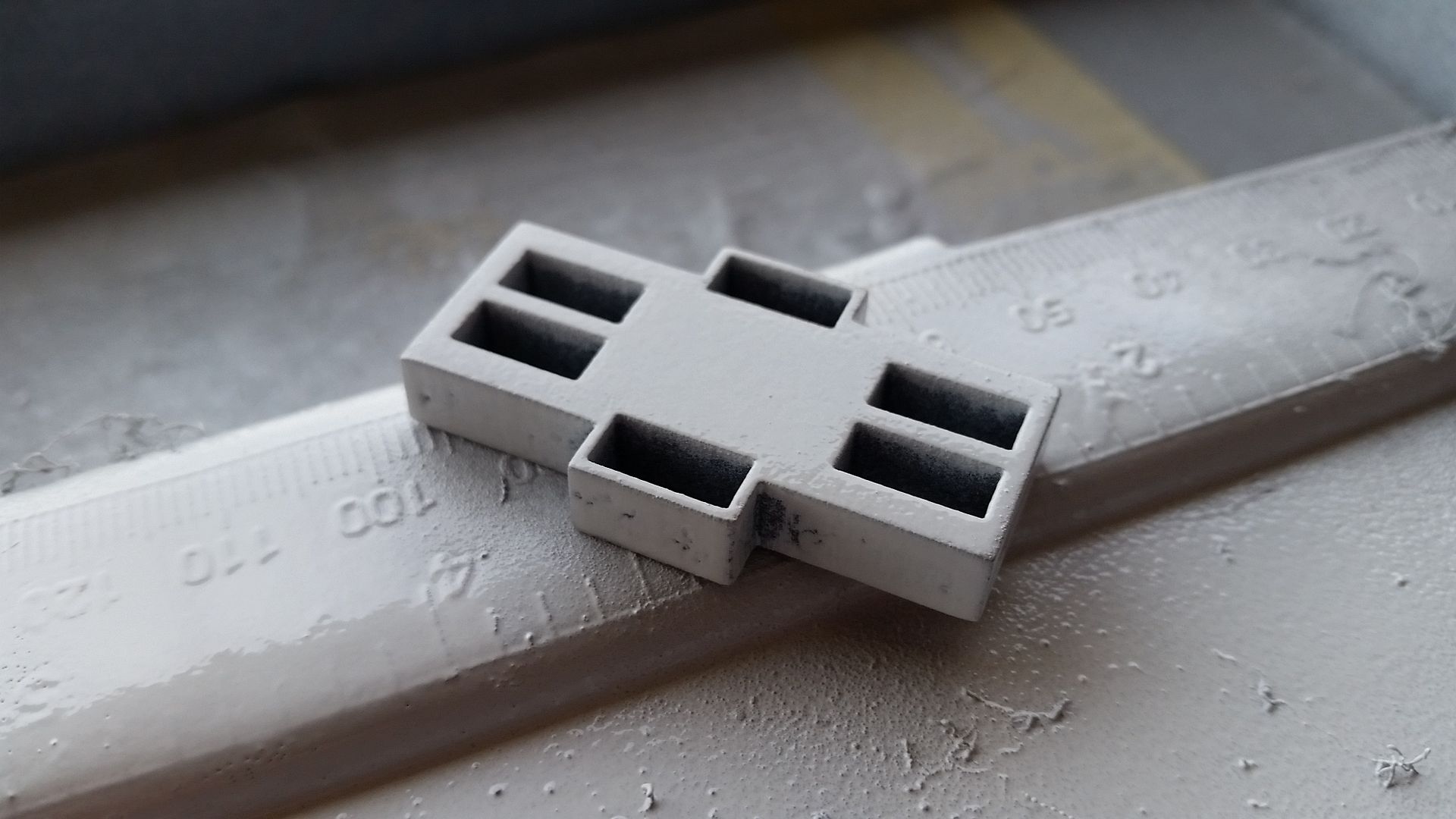

Also tucked away in the box... another Volvo Panel greeblie!

SWEET! Thank you again, Wavey! I am forever grateful for all your continued efforts!

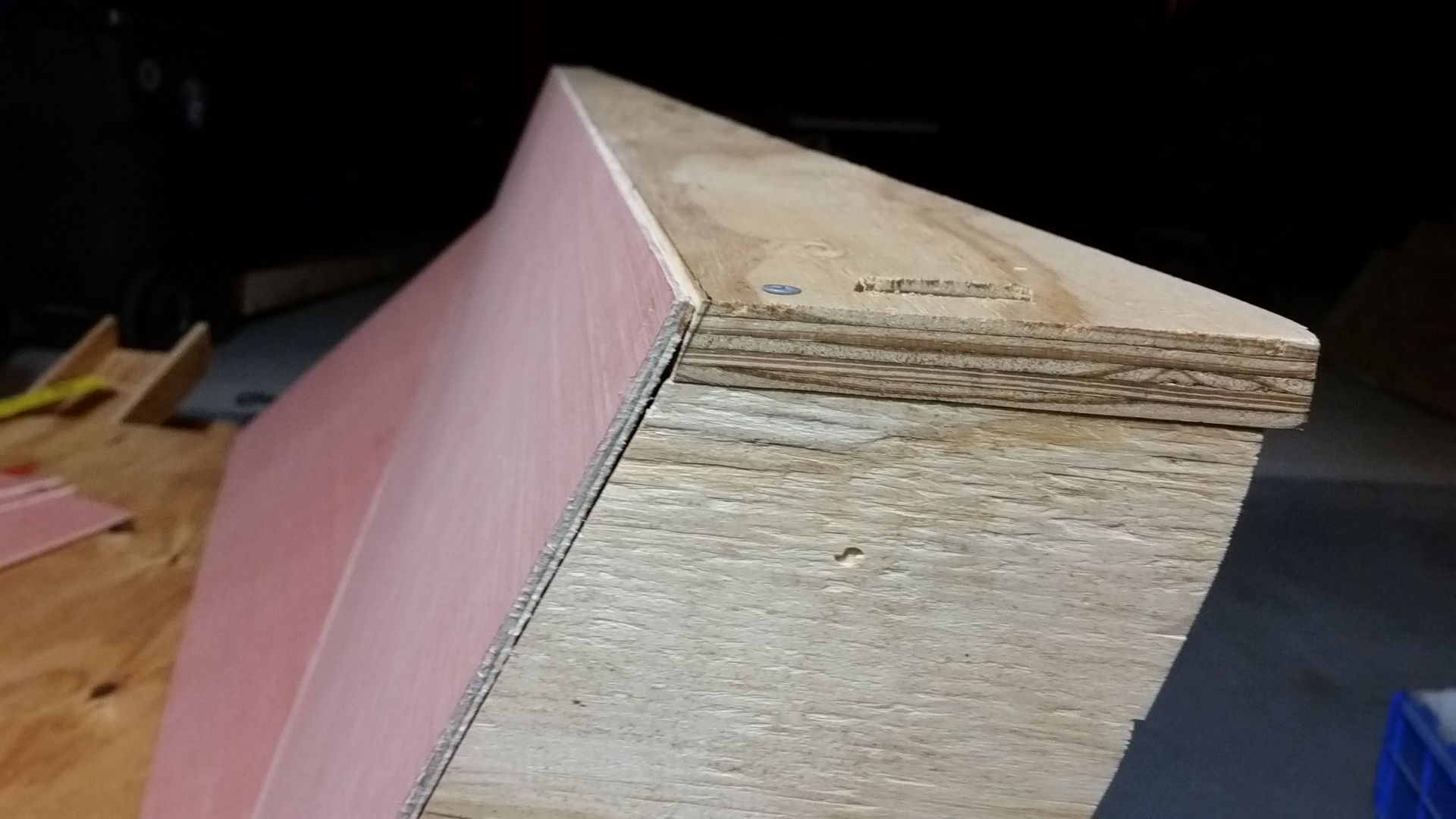

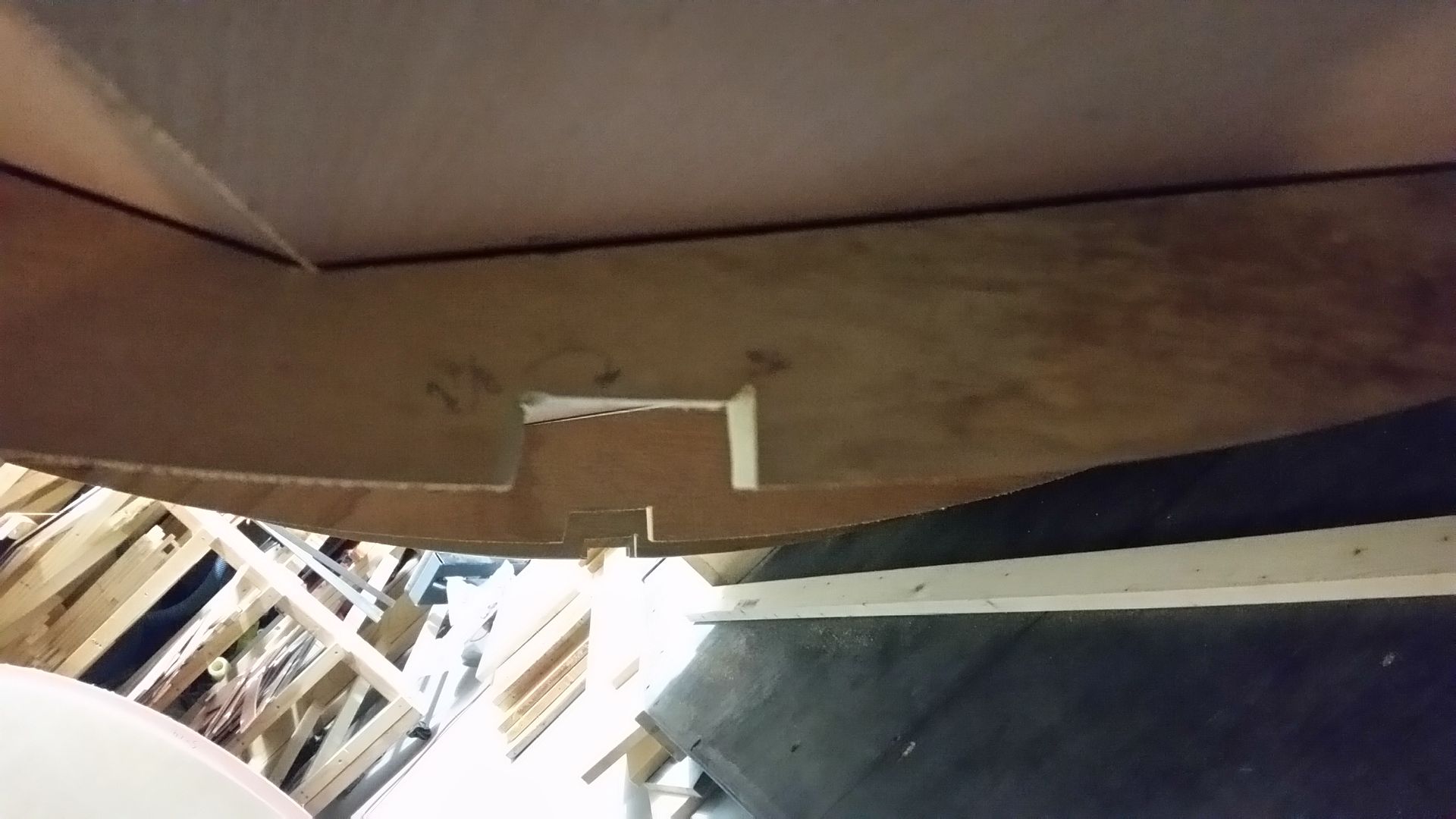

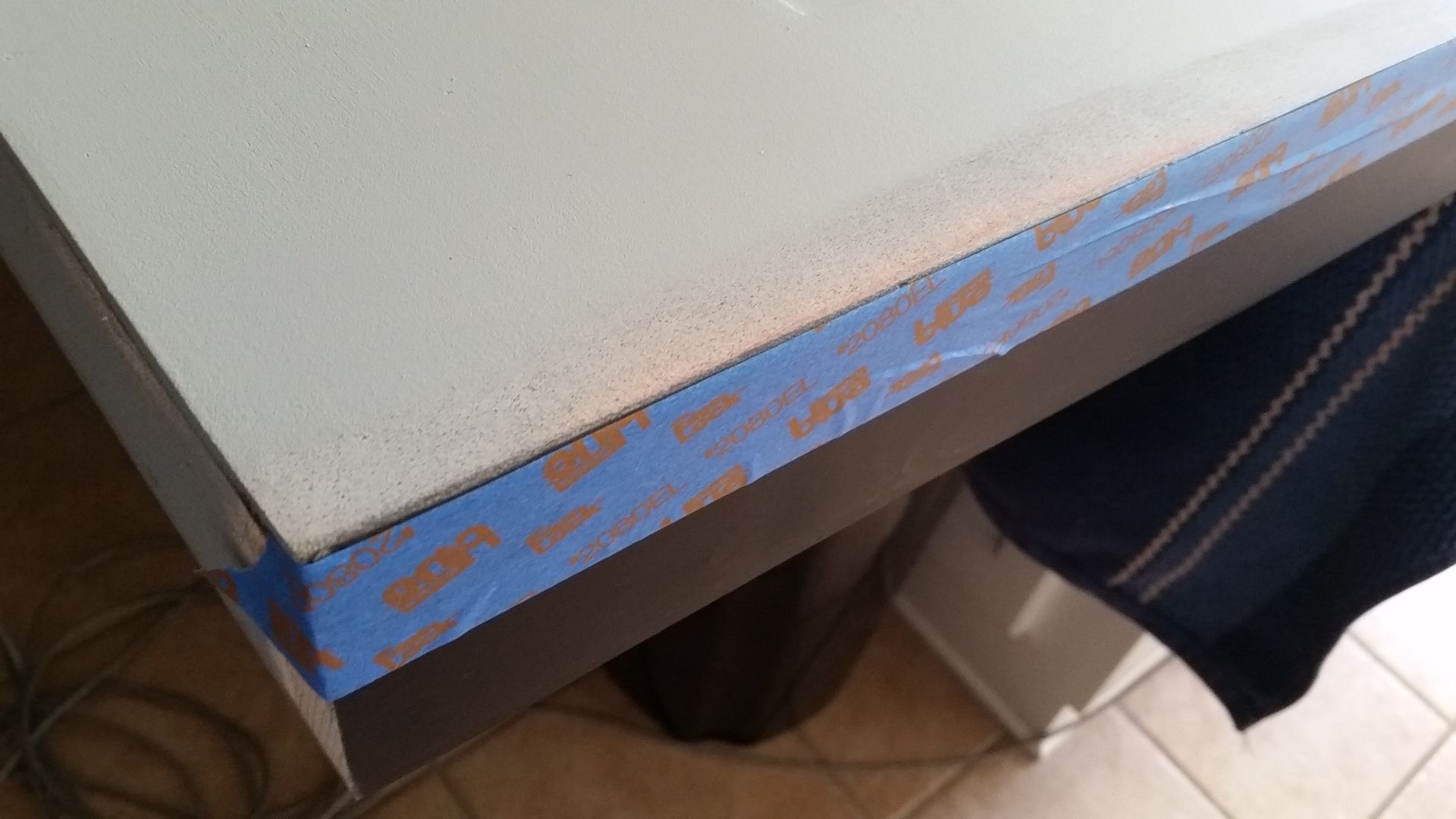

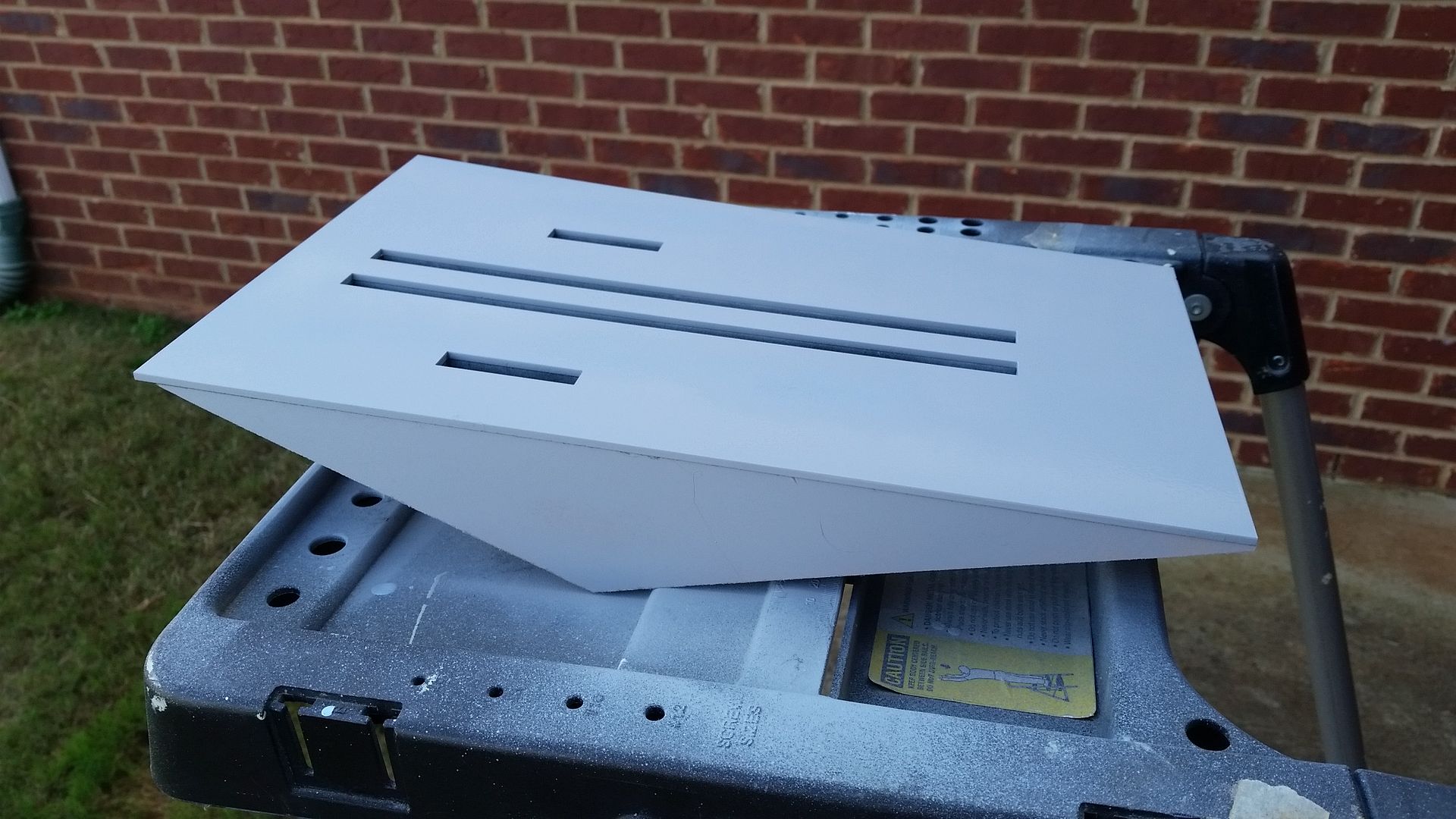

Tough to see anything here - added 1/2" ply and more supports to the nav chair platforms. This changes the overall dimensions by 1/2" so I have to remove 1/2" of material from the new riser panels (that sit just on top of the nav chair platforms) UGH

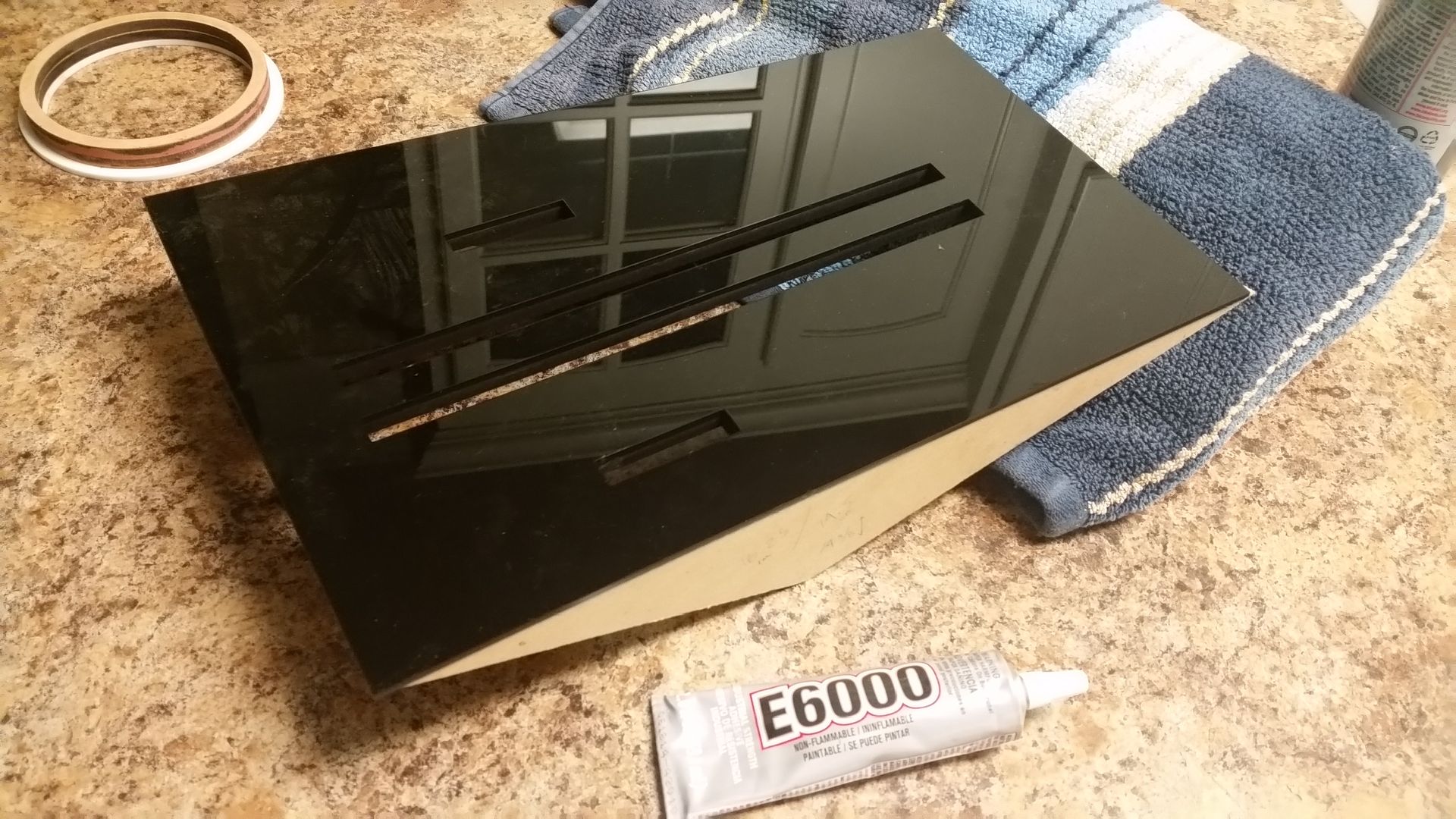

Finally finished the door

Painted the mounting hardware

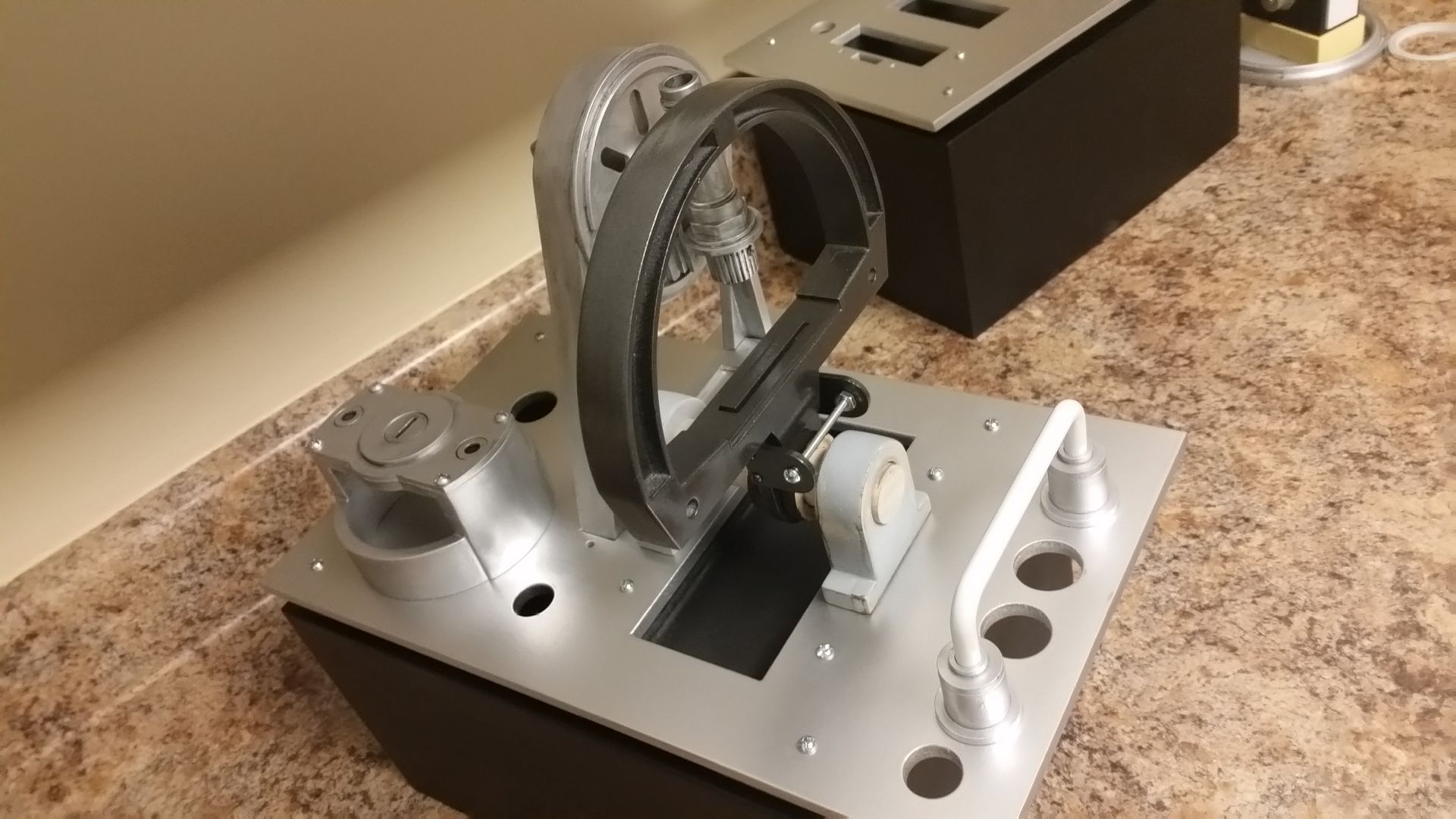

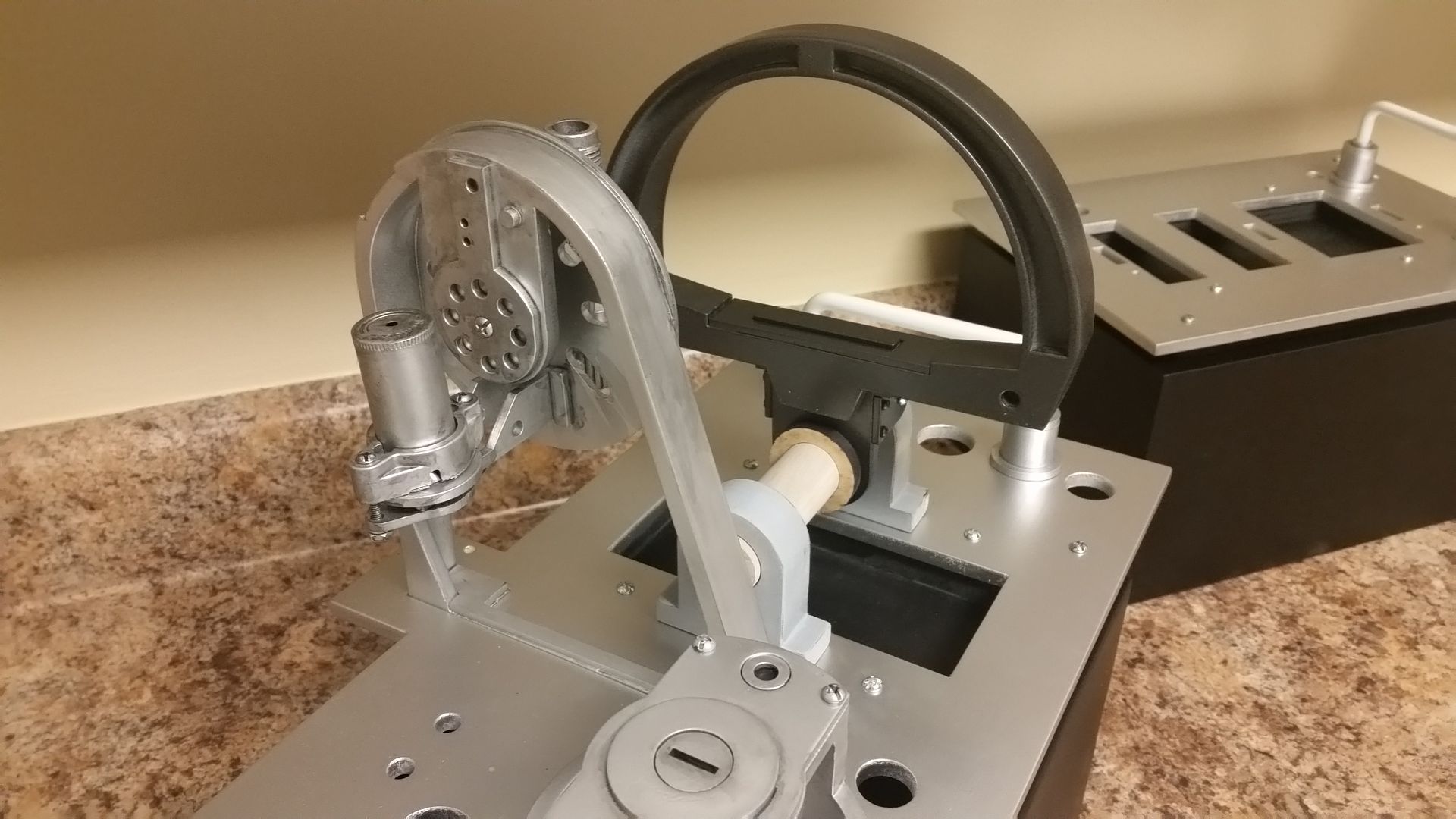

Applied several layers of primer filler to the yoke body 3D print

Just a teeny tiny bit more filler

First round of sanding

Still lots of work to do

Throttle housing got some filler and primer

More filler

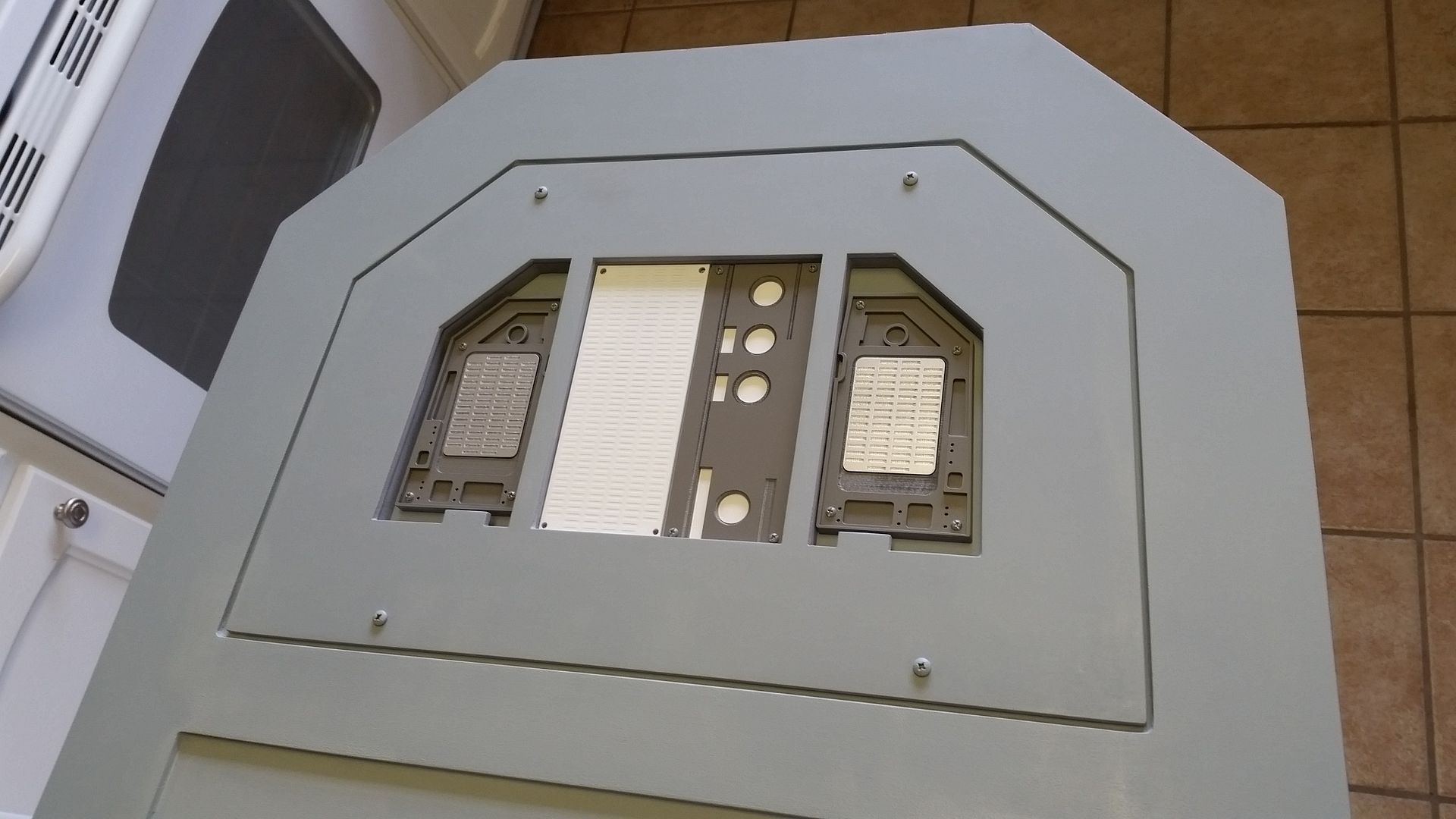

Console greeblie finally getting painted

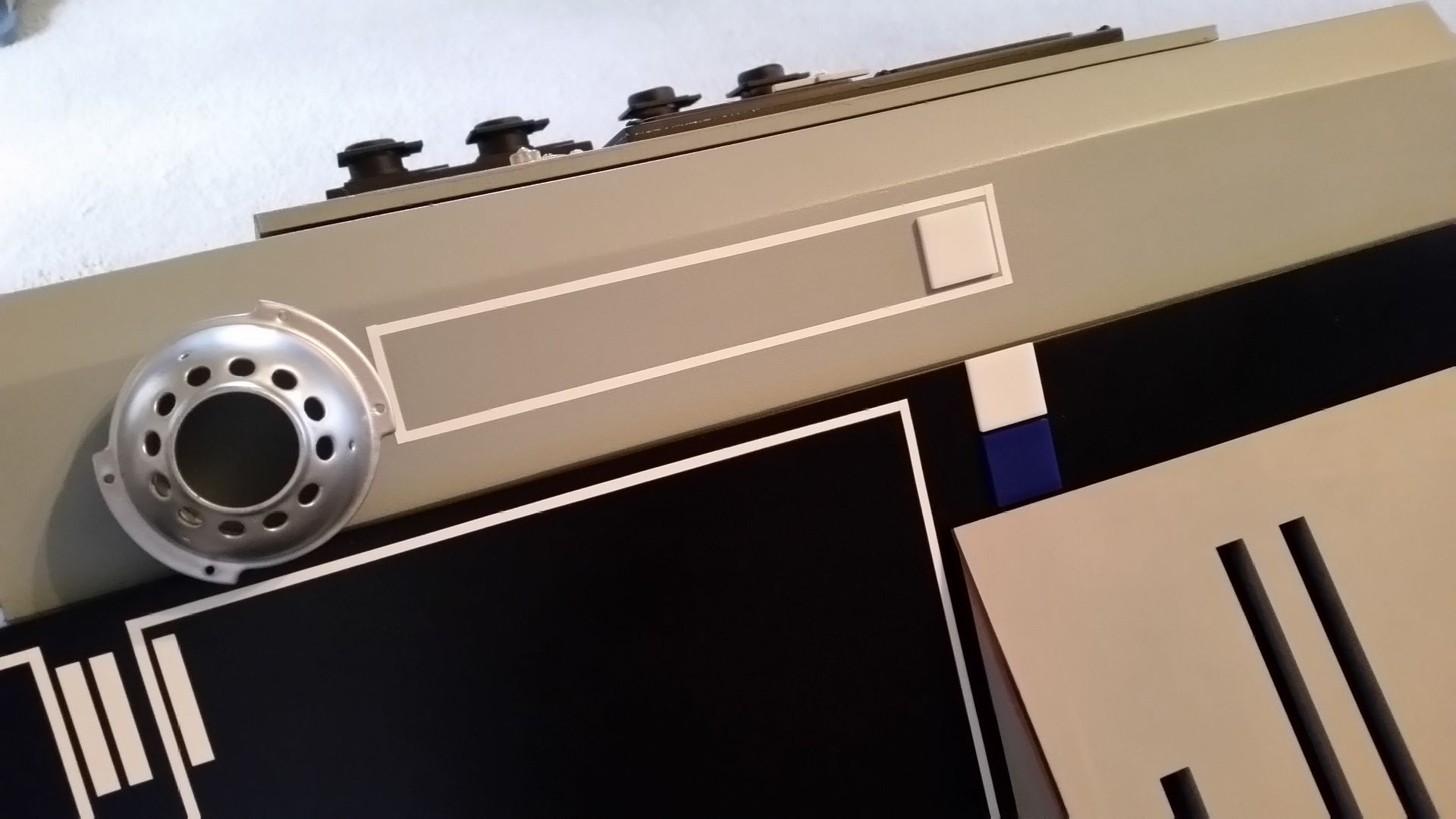

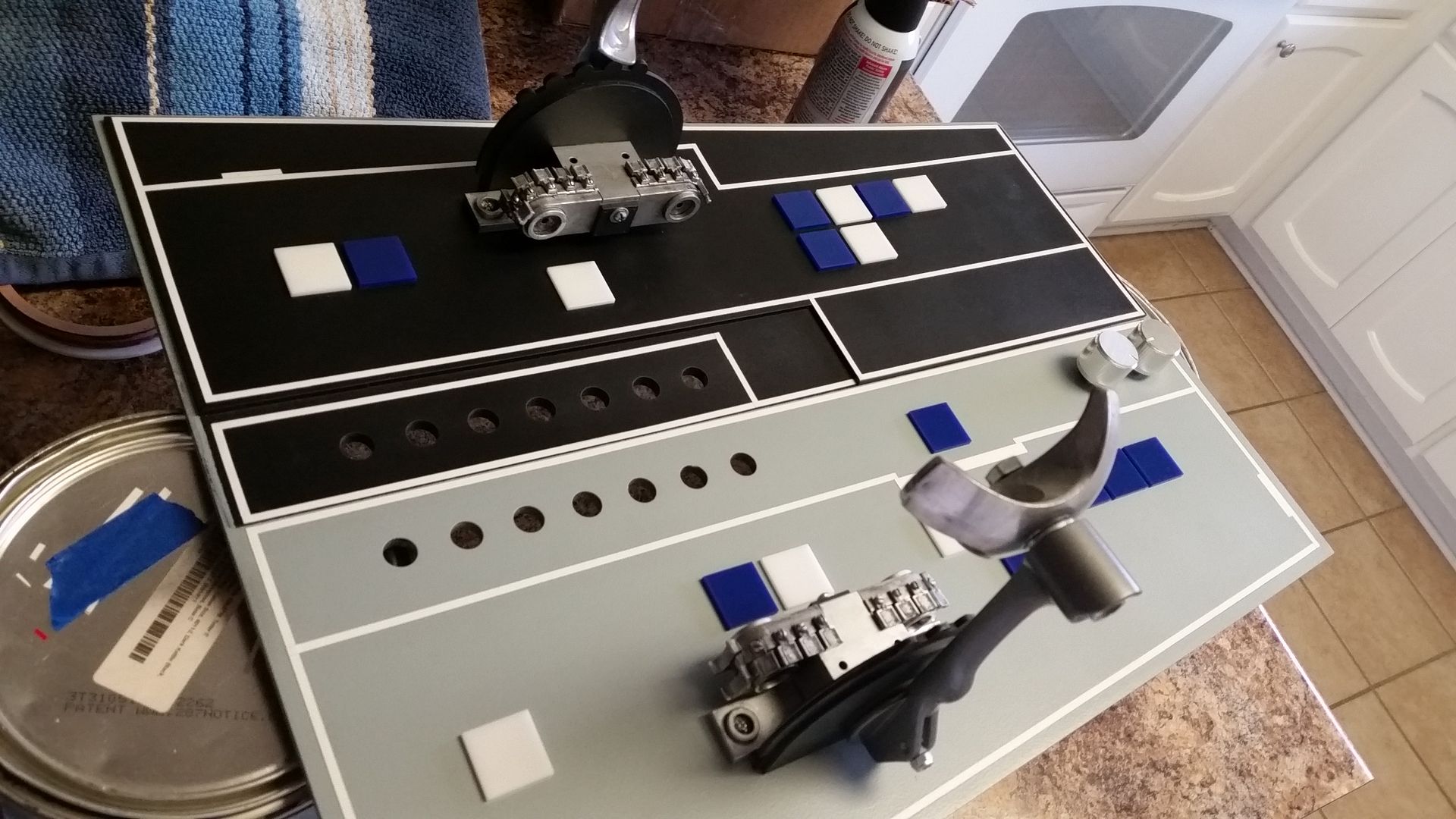

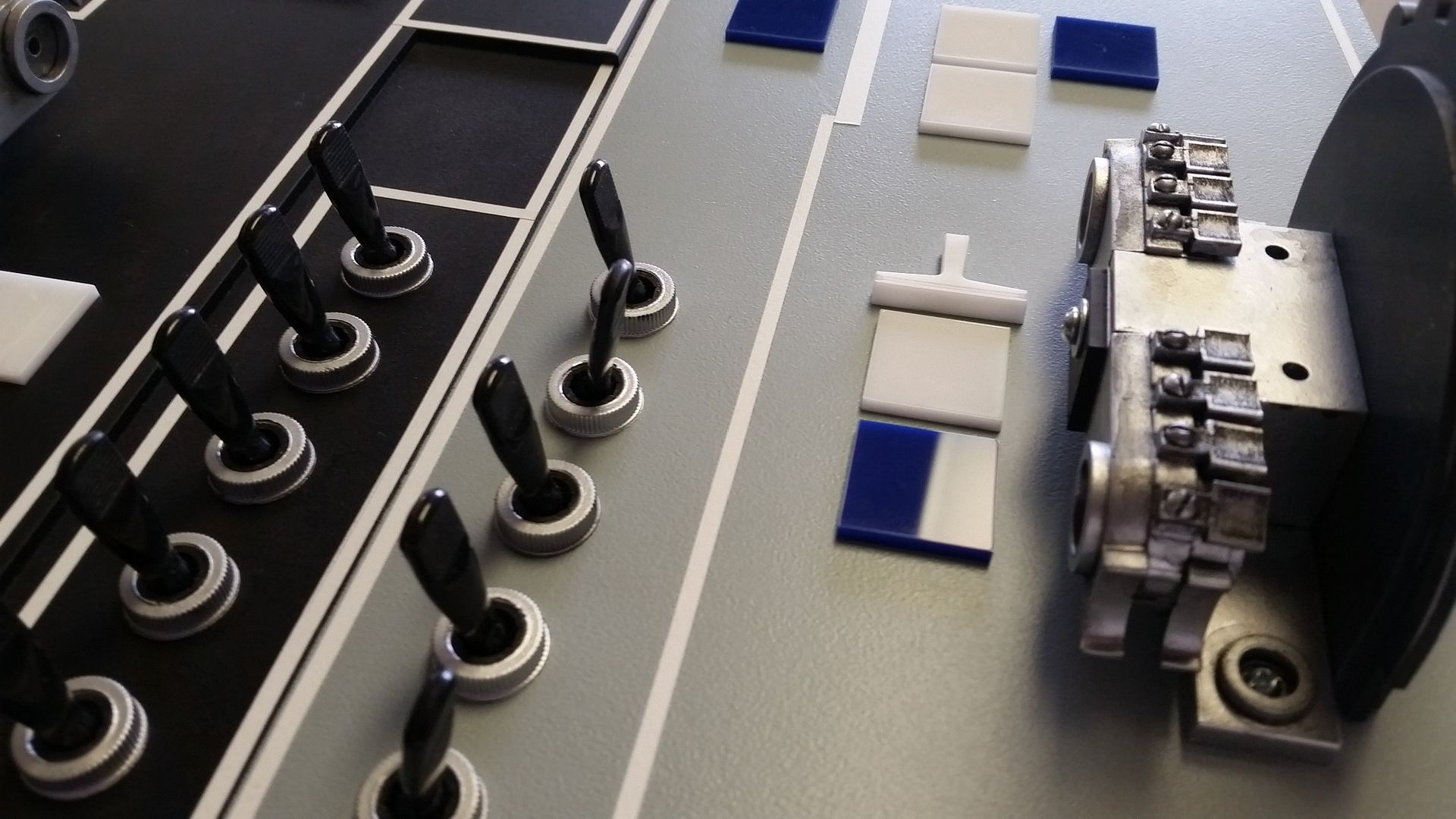

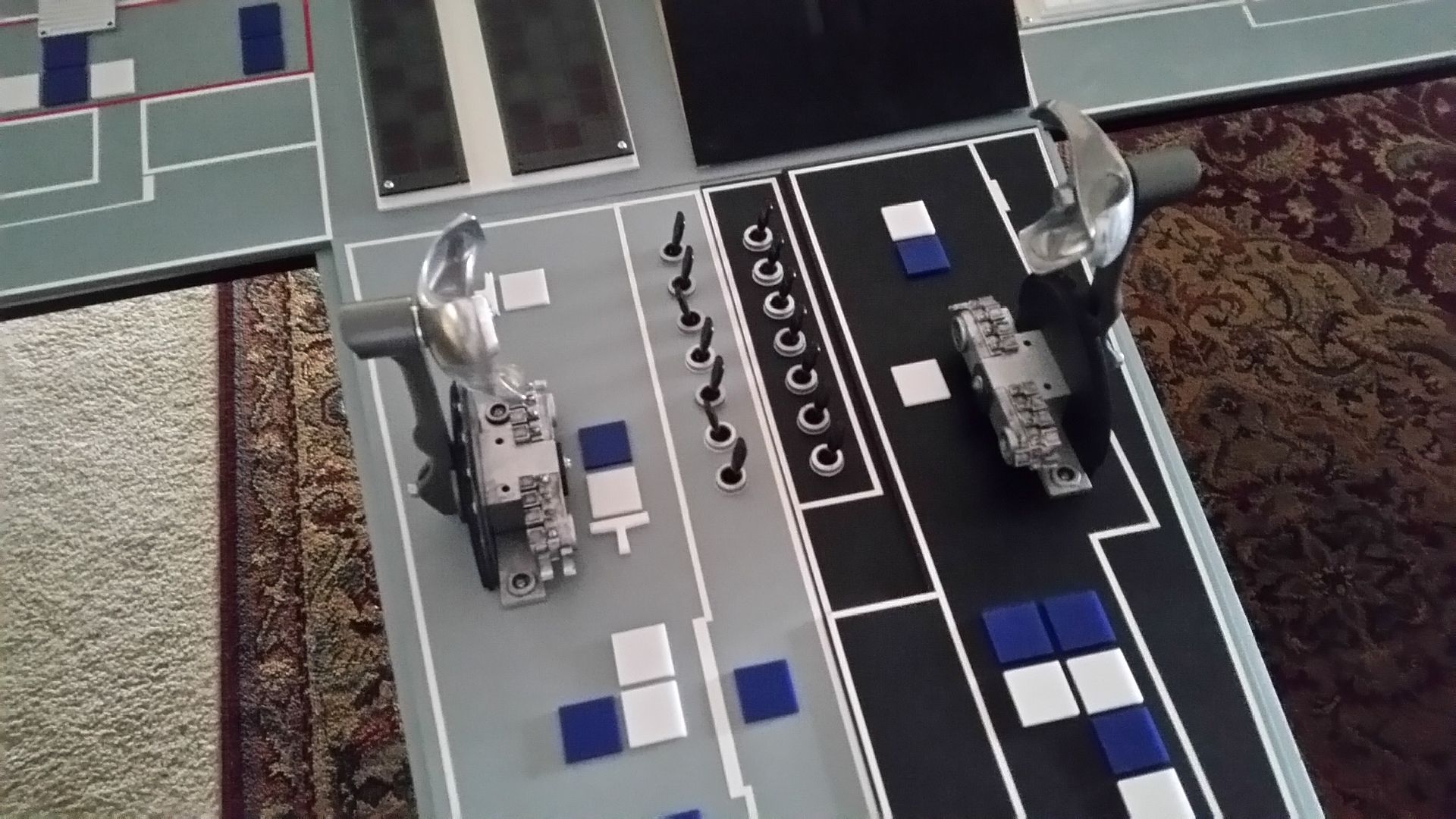

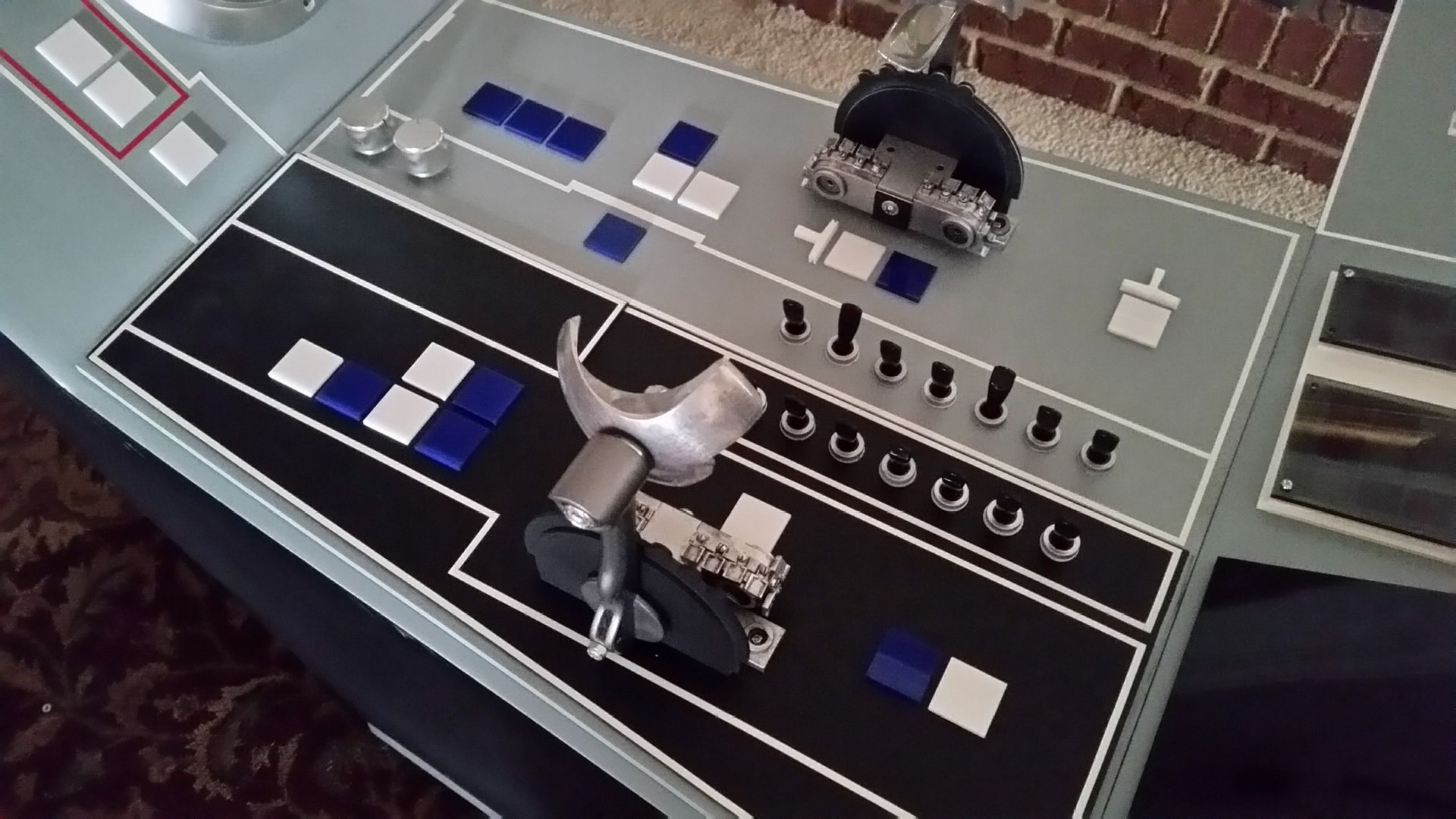

Adding more details/greeblies to the new center console

Bolted the Vickers Vents into place

The other vent has a black surround / housing that I have to design

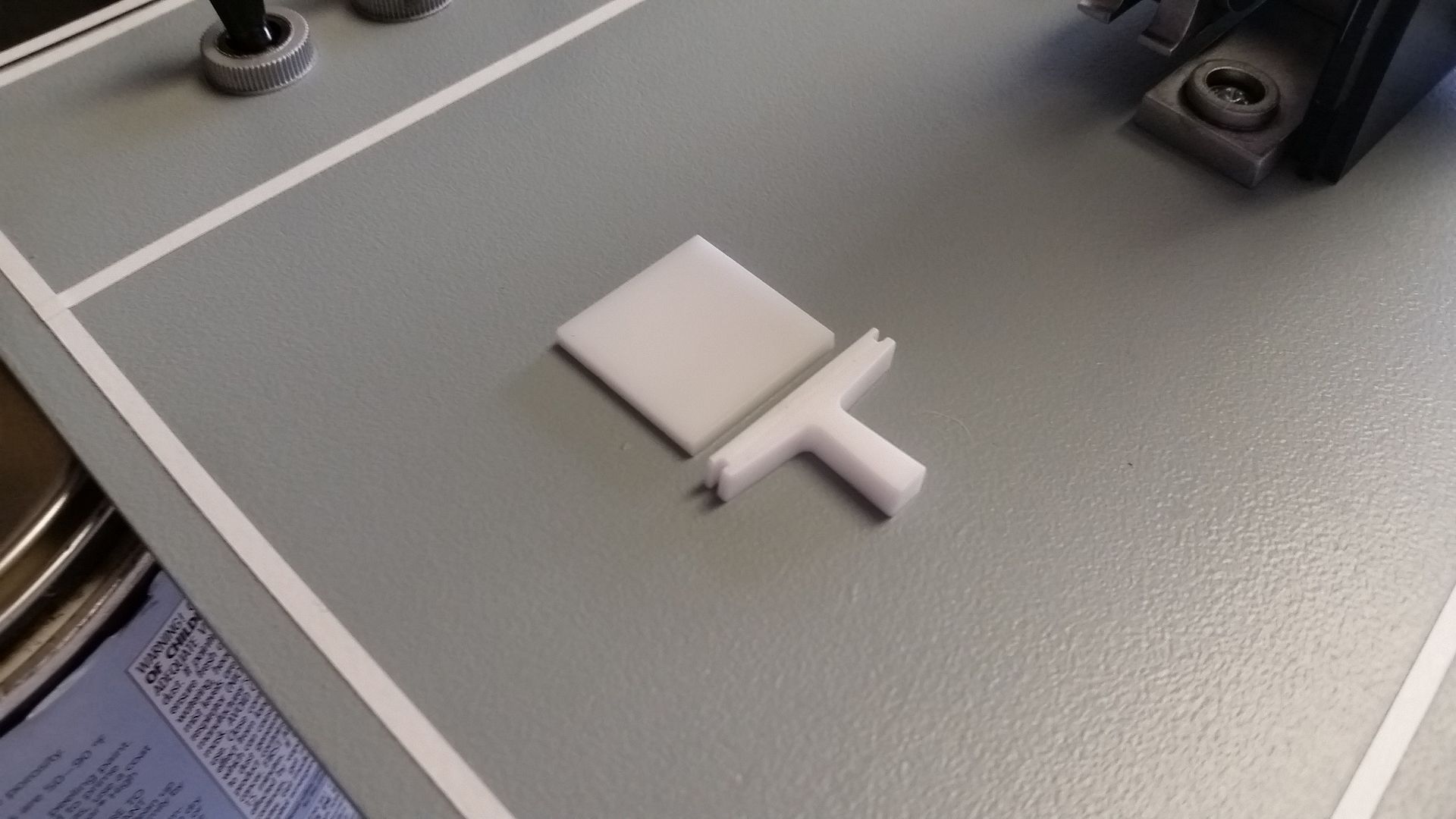

Finally applied the 1" tiles

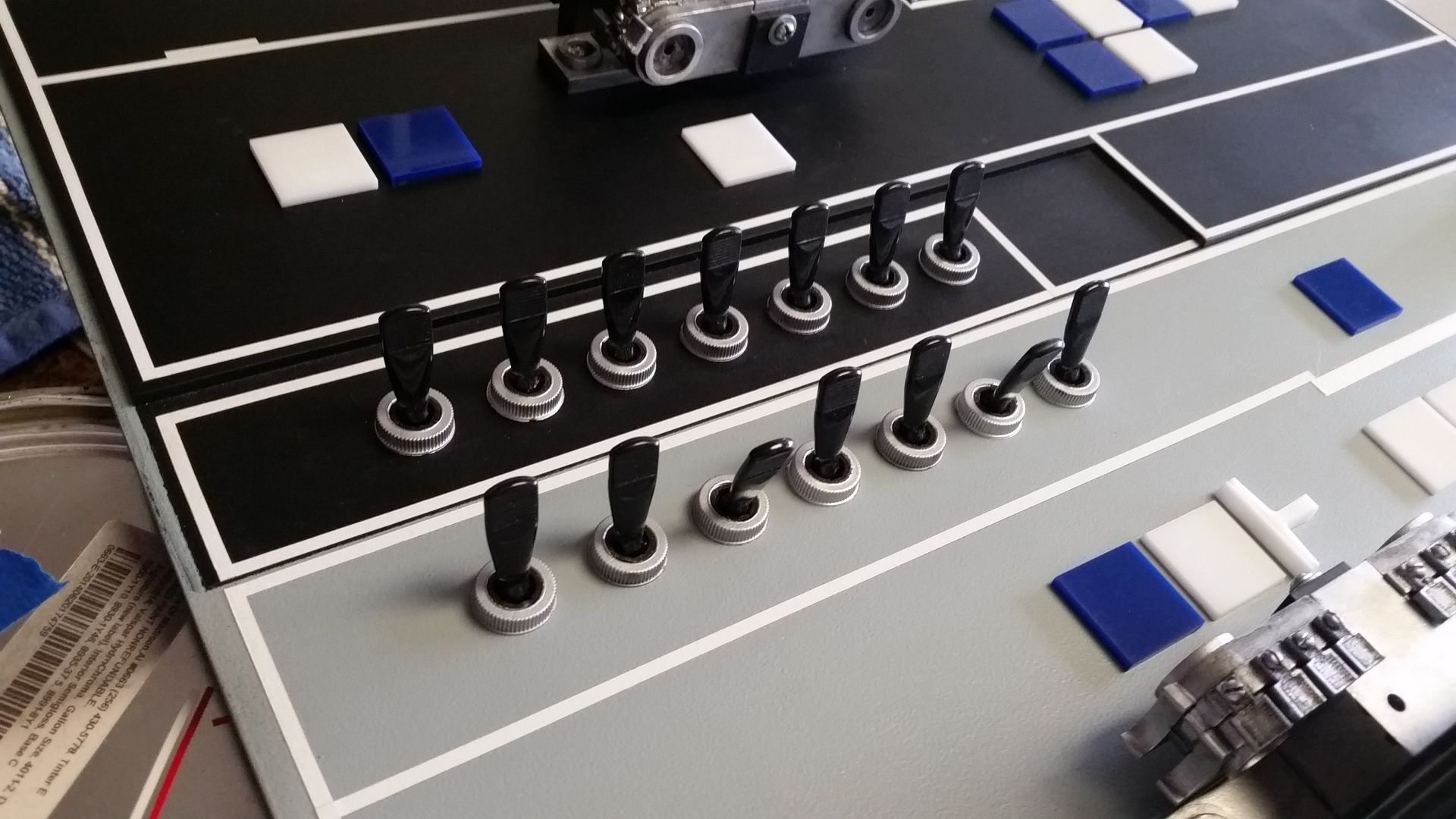

Then switches

Final details

We've got rain the next few days so we'll see what happens next! Stay Tuned!

Got all 3 done!