You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

USS Cygnus 1/700 - The Black Hole

- Thread starter szarchie

- Start date

-

- Tags

- black hole cygnus

szarchie

Sr Member

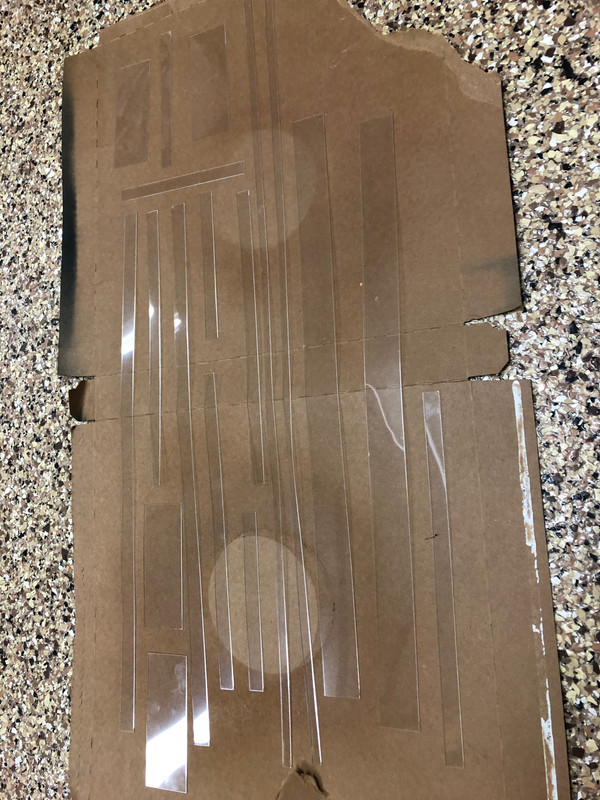

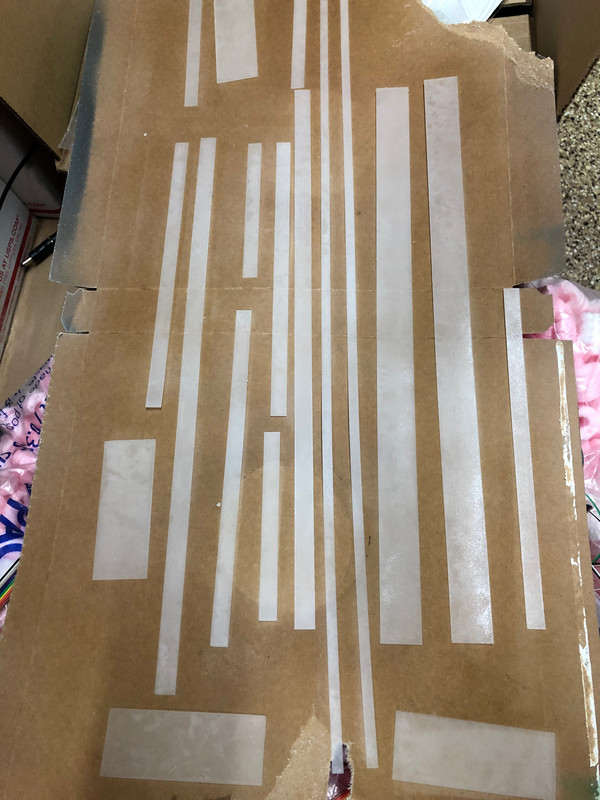

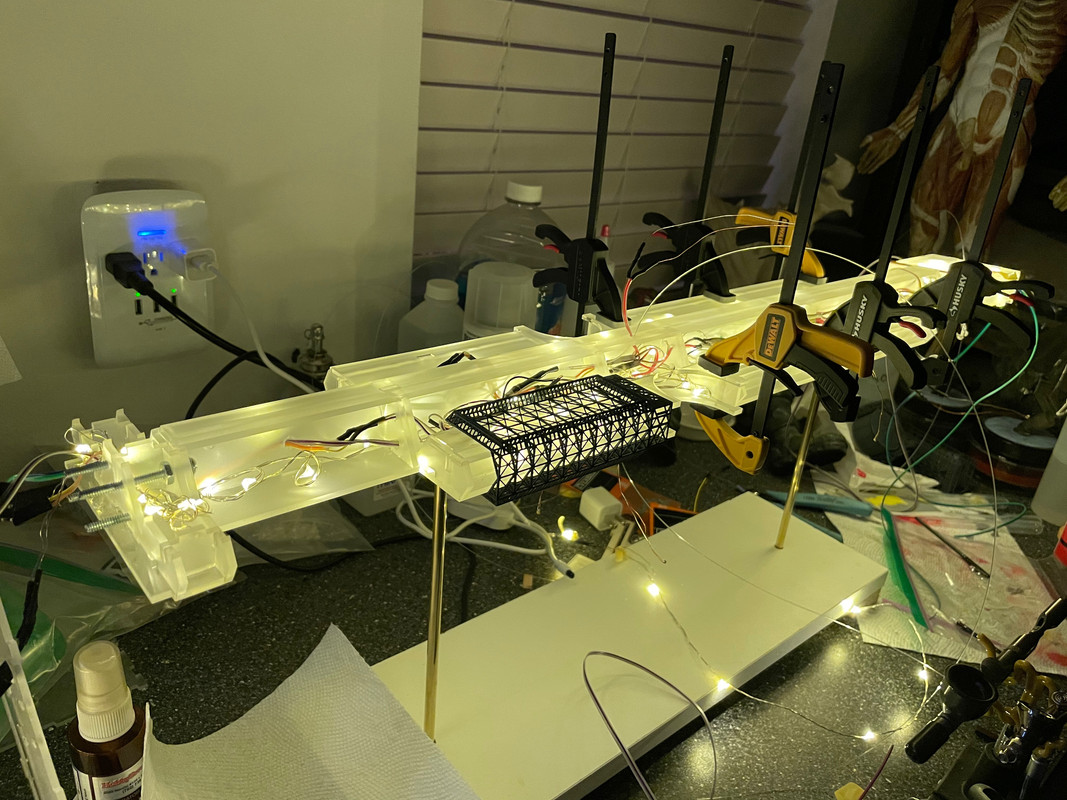

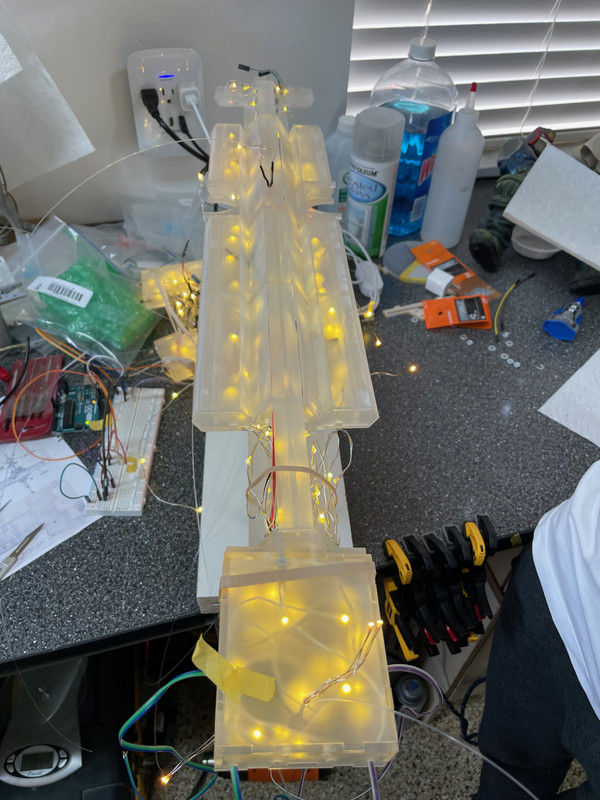

Started prepping some of the smaller armature parts. Wanted to make them hazy but transparent so the lighting is diffused. I used Rustoleum Frosted Glass for this which worked pretty well.

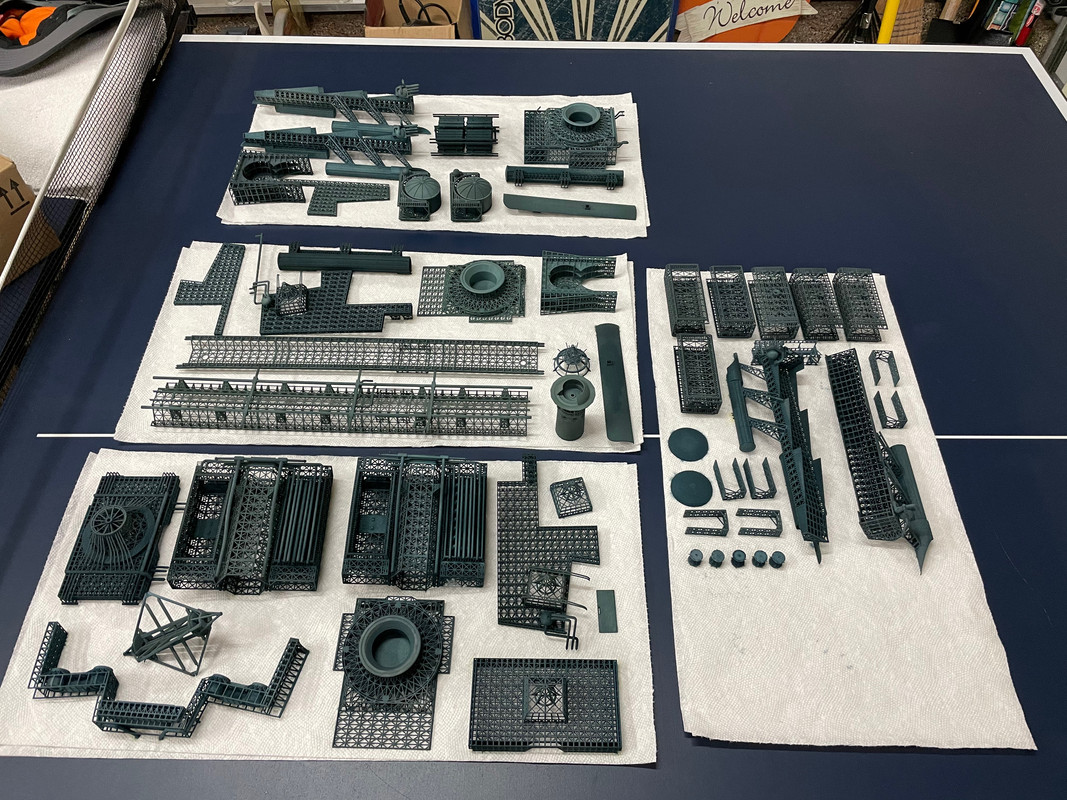

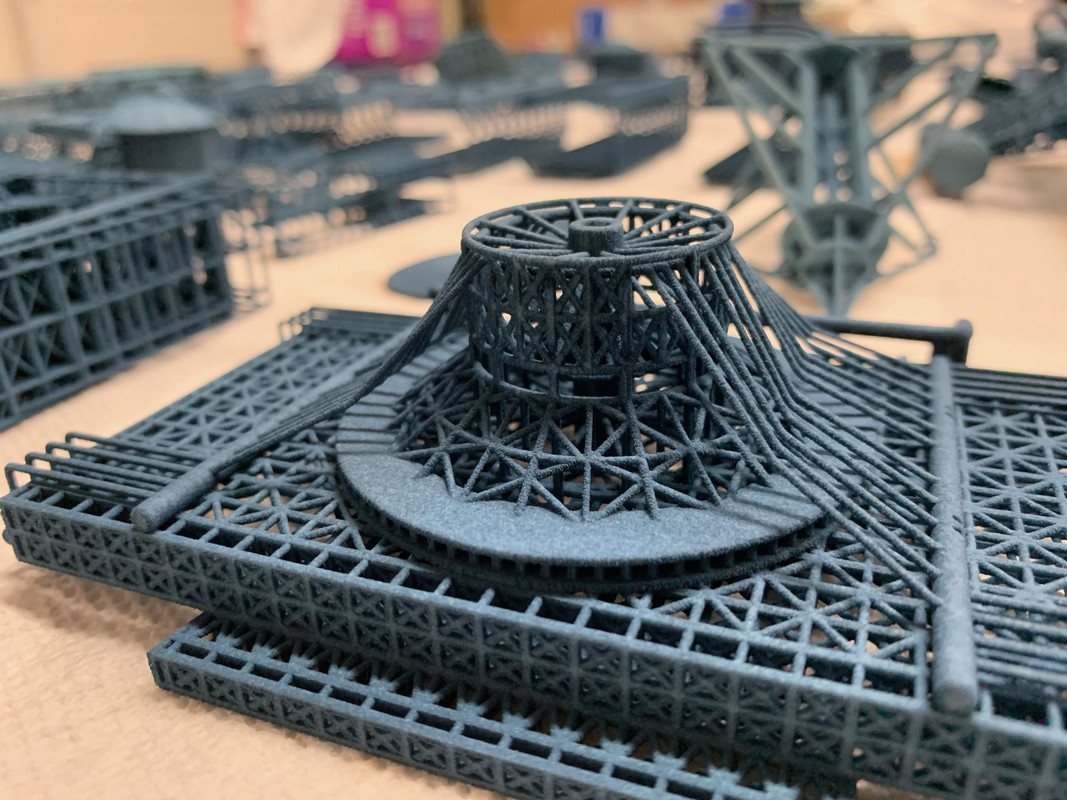

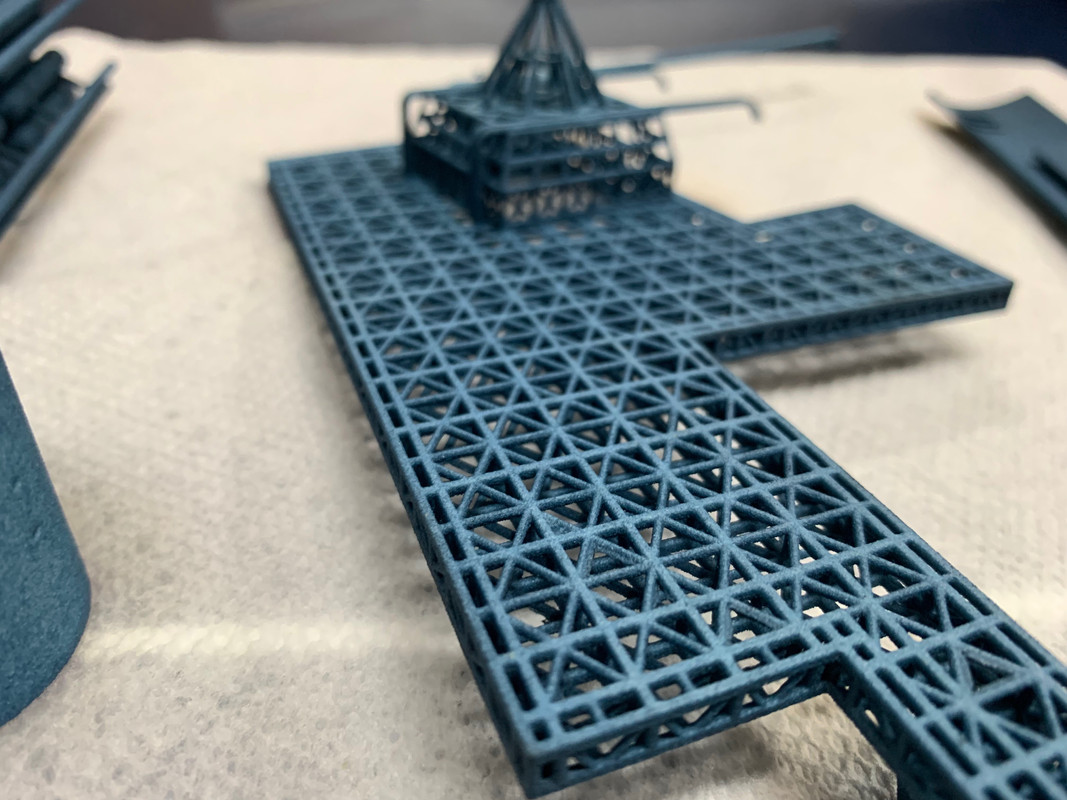

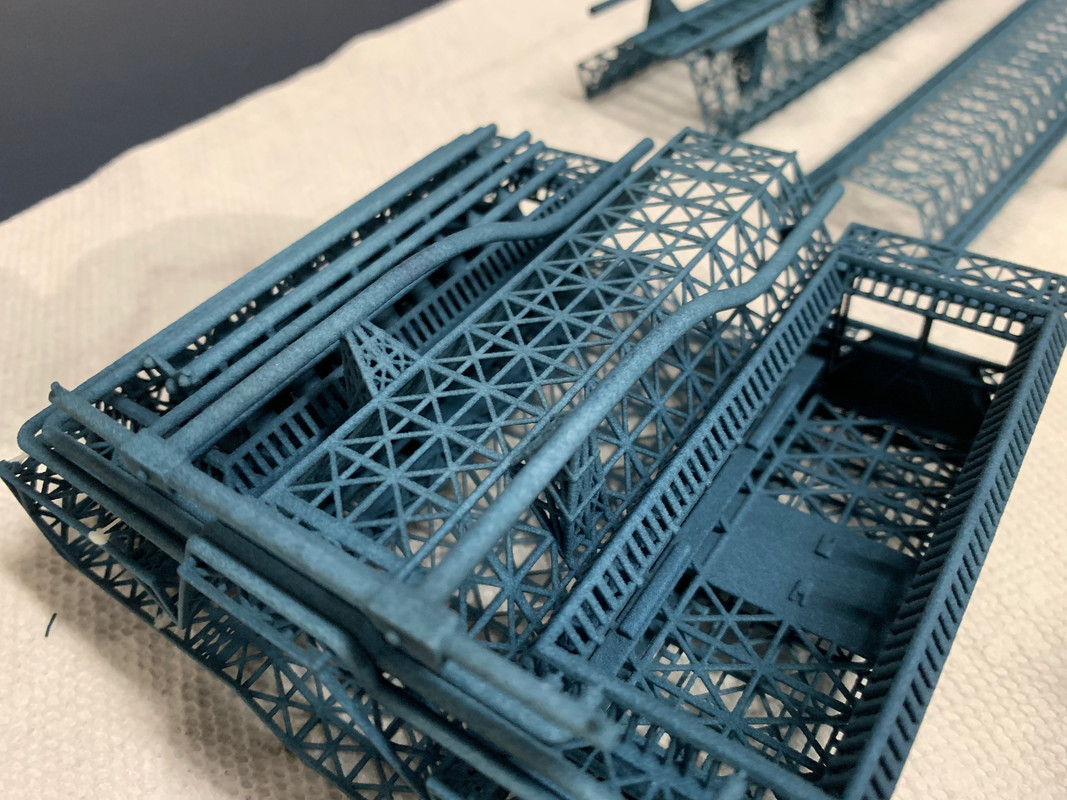

I was really scratching my head on how to paint these complex parts. I was contemplating spraying from a can but was concerned that I would deposit too much paint and some areas are really tricky to access. My son suggested using some sort of dye so we ended up doing with Rit fabric dye. You have to heat up the dye to about 90 celsius and then immerse for 5-10 mins, which worked great. The parts were nicely colored and there was no accumulation of paint. The dye is absorbed into the material so all the details are preserved. Very happy with how that worked out.

I was really scratching my head on how to paint these complex parts. I was contemplating spraying from a can but was concerned that I would deposit too much paint and some areas are really tricky to access. My son suggested using some sort of dye so we ended up doing with Rit fabric dye. You have to heat up the dye to about 90 celsius and then immerse for 5-10 mins, which worked great. The parts were nicely colored and there was no accumulation of paint. The dye is absorbed into the material so all the details are preserved. Very happy with how that worked out.

I was really scratching my head on how to paint these complex parts. I was contemplating spraying from a can but was concerned that I would deposit too much paint and some areas are really tricky to access. My son suggested using some sort of dye so we ended up doing with Rit fabric dye. You have to heat up the dye to about 90 celsius and then immerse for 5-10 mins, which worked great. The parts were nicely colored and there was no accumulation of paint. The dye is absorbed into the material so all the details are preserved. Very happy with how that worked out.

View attachment 1462620

View attachment 1462621

View attachment 1462622

View attachment 1462623

View attachment 1462624

Brilliant solution for coloring the delicate parts!

NakedMoleRat

Legendary Member

gorgeous! I had such fond memories of that movie. Then I watched it again on Disney +. But the ship is awesome.

big F

New Member

This is an awesome build so far. The primative Dave build of this has been on my To be built list for too long.

The dyeing of parts..... gonna give that a test on some other projects.

Just wondering is that nylon or PLA, or ABS.

Back in the day I used a dye to colour gears for my 1/10th RC stuff and thats mostly nylon. If memory serves, and Tamiya only did bright colours like neon pink etc.

So looking forward to progress on this.

The dyeing of parts..... gonna give that a test on some other projects.

Just wondering is that nylon or PLA, or ABS.

Back in the day I used a dye to colour gears for my 1/10th RC stuff and thats mostly nylon. If memory serves, and Tamiya only did bright colours like neon pink etc.

So looking forward to progress on this.

Last edited:

A very nice bit of 3D printing news here!

New technique 'breaks the mold' for 3D printing medical implants

Instead of making the bioscaffolds directly, the team 3D printed molds with intricately-patterned cavities then filled them with biocompatible materials, before dissolving the molds away.

Using the indirect approach, the team created fingernail-sized bioscaffolds full of elaborate structures that, until now, were considered impossible with standard 3D printers.

Lead researcher Dr. Cathal O'Connell said the new biofabrication method was cost-effective and easily scalable because it relied on widely available technology.

PERFECT for Cygnus...which is really Galactus' stent, right?

Tough graphene

Superflimsy graphene turned ultrastiff by optical forging

Model glue

Scientists make powerful underwater glue inspired by barnacles and mussels

The birth of a subnanometer-sized soccer ball

New technique 'breaks the mold' for 3D printing medical implants

Instead of making the bioscaffolds directly, the team 3D printed molds with intricately-patterned cavities then filled them with biocompatible materials, before dissolving the molds away.

Using the indirect approach, the team created fingernail-sized bioscaffolds full of elaborate structures that, until now, were considered impossible with standard 3D printers.

Lead researcher Dr. Cathal O'Connell said the new biofabrication method was cost-effective and easily scalable because it relied on widely available technology.

PERFECT for Cygnus...which is really Galactus' stent, right?

Tough graphene

Superflimsy graphene turned ultrastiff by optical forging

Model glue

Scientists make powerful underwater glue inspired by barnacles and mussels

The birth of a subnanometer-sized soccer ball

szarchie

Sr Member

Hi Jeff, That would have been a great way to go. I wasn't sure what the best approach should be and I was also worried about hot spots. I think your way may be the better solution to make sure there is better diffusion.I think I actually just painted the inside of the clear armature white--that transmits the light very evenly with no hot spots and still allows for a lot of brightness.

szarchie

Sr Member

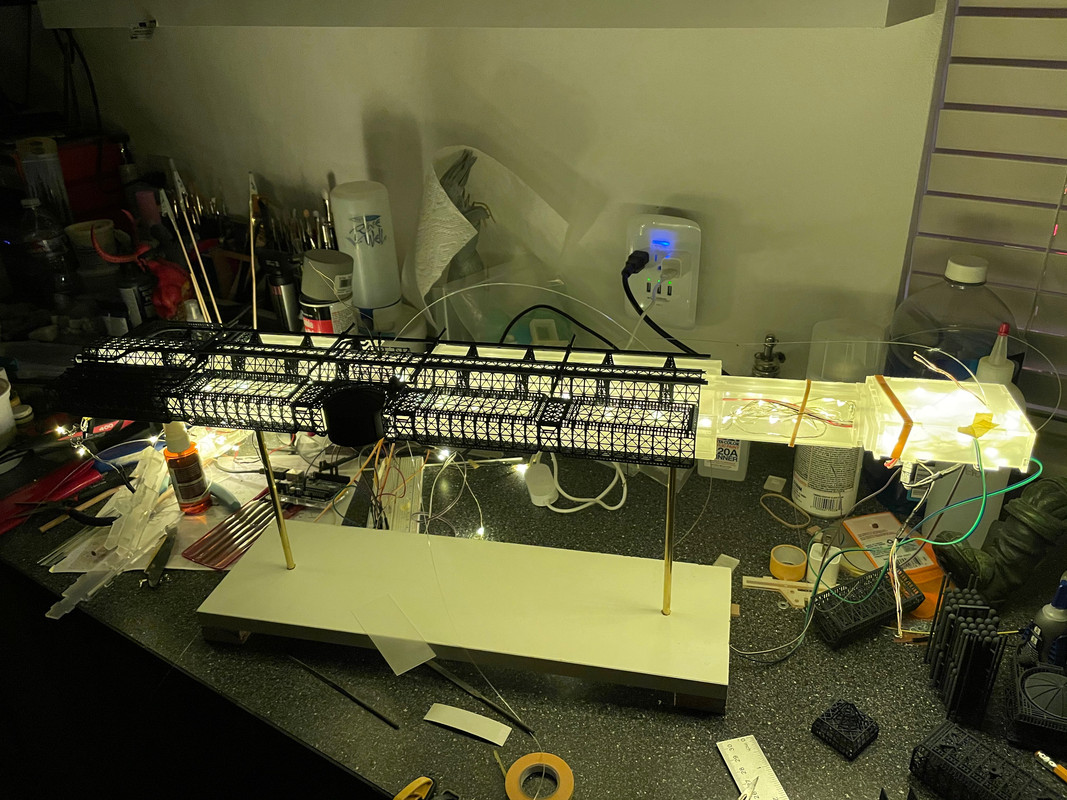

Not much to report. Making slow progress on the armature and adding strips that enclose the lighting. So hoping I got all the wiring right as going back in well not be easy. Also temporarily added some of the parts just to see how they look. It starts to look like the Cygnus pretty quickly once they are added.

szarchie

Sr Member

These were printed in White Natural Versatile Plastic by Shapeways. I believe it's nylon material and the parts seem pretty porous so they absorbed the dye very well. I did have to get a replacement part much later and the material was the same but seems less porous. I did absorb the dye but it took much longer. So not sure if they have improved the printing process or materials but definitely was not as easy to color.This is an awesome build so far. The primative Dave build of this has been on my To be built list for too long.

The dyeing of parts..... gonna give that a test on some other projects.

Just wondering is that nylon or PLA, or ABS.

Back in the day I used a dye to colour gears for my 1/10th RC stuff and thats mostly nylon. If memory serves, and Tamiya only did bright colours like neon pink etc.

So looking forward to progress on this.

Similar threads

- Replies

- 183

- Views

- 18,084

- Replies

- 3

- Views

- 505

- Replies

- 7

- Views

- 1,646