Thanks!

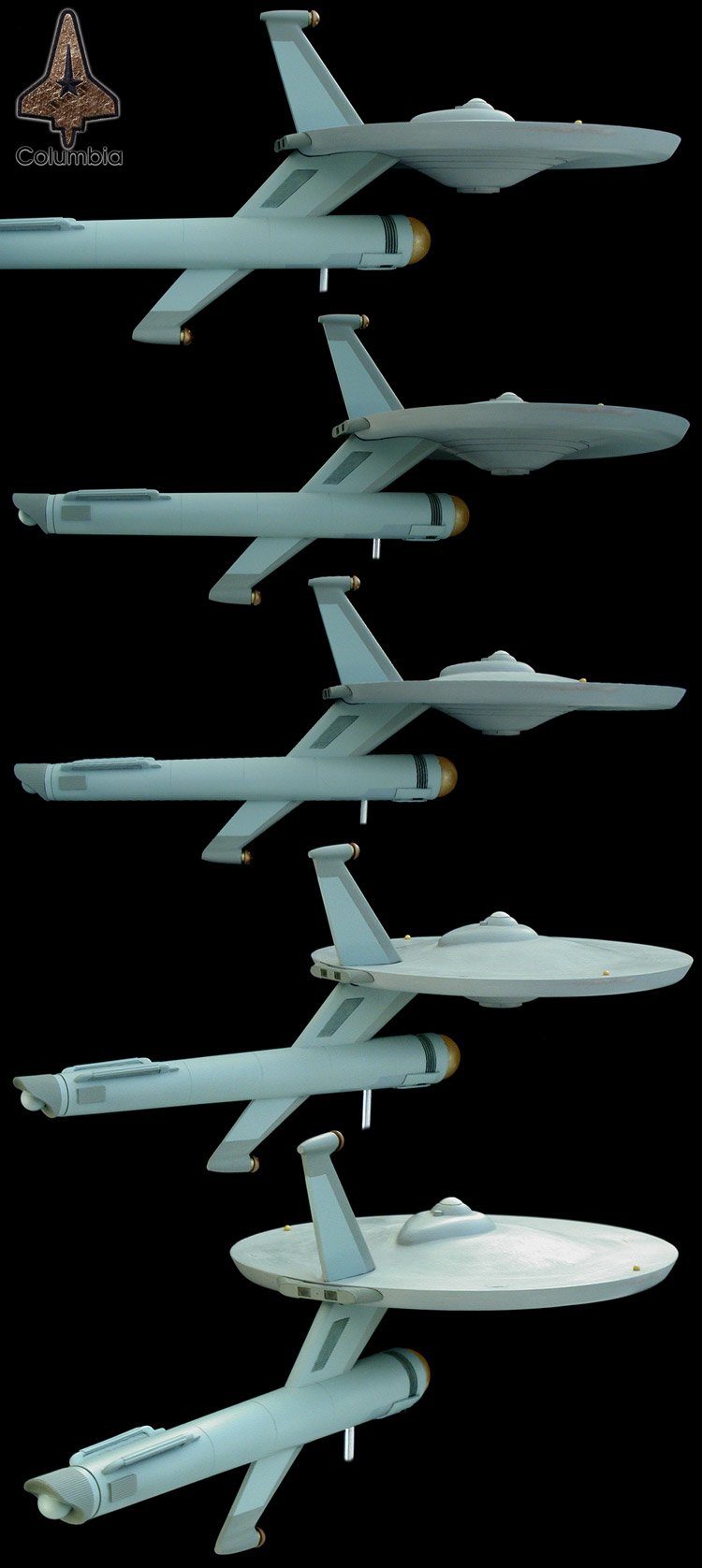

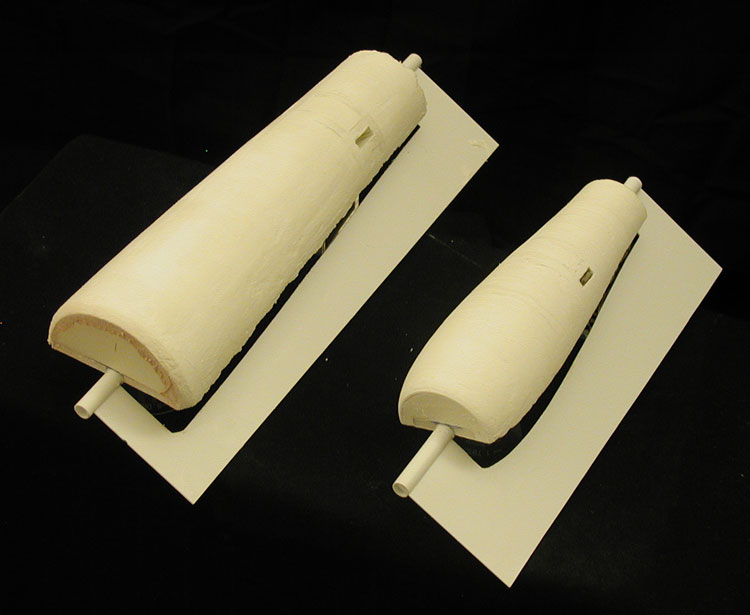

I'd love to see a 1/2500 version! I'll be putting together a more complete set of plans for her, but the main difference from the one I posted is that I made the sensor pods larger (which will also help at 1/2500 scale). The main thing to note is that the sensor masts are about half as thick as the dorsal.

I look forward to see what you come up with. I'm always impressed with how much detail I've seen people get out of their 1/2500 builds.

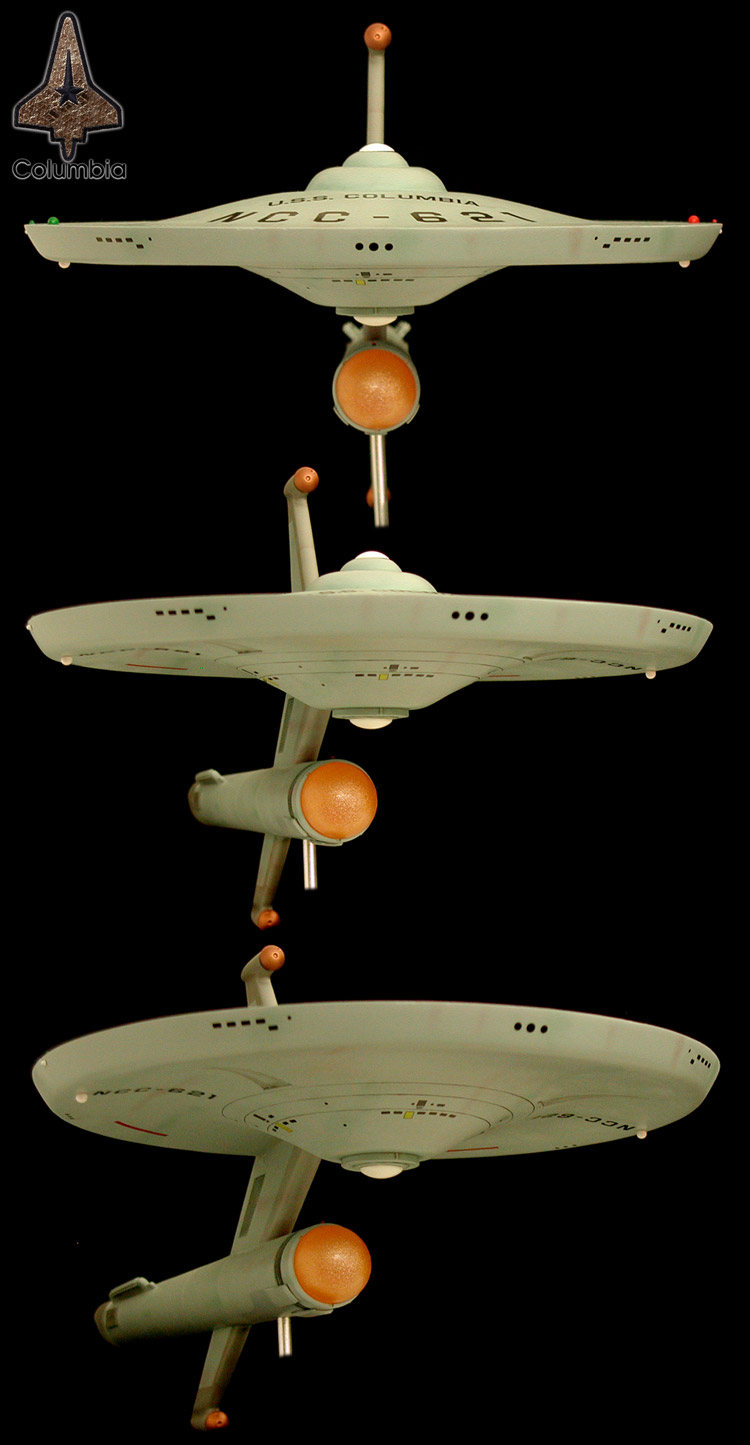

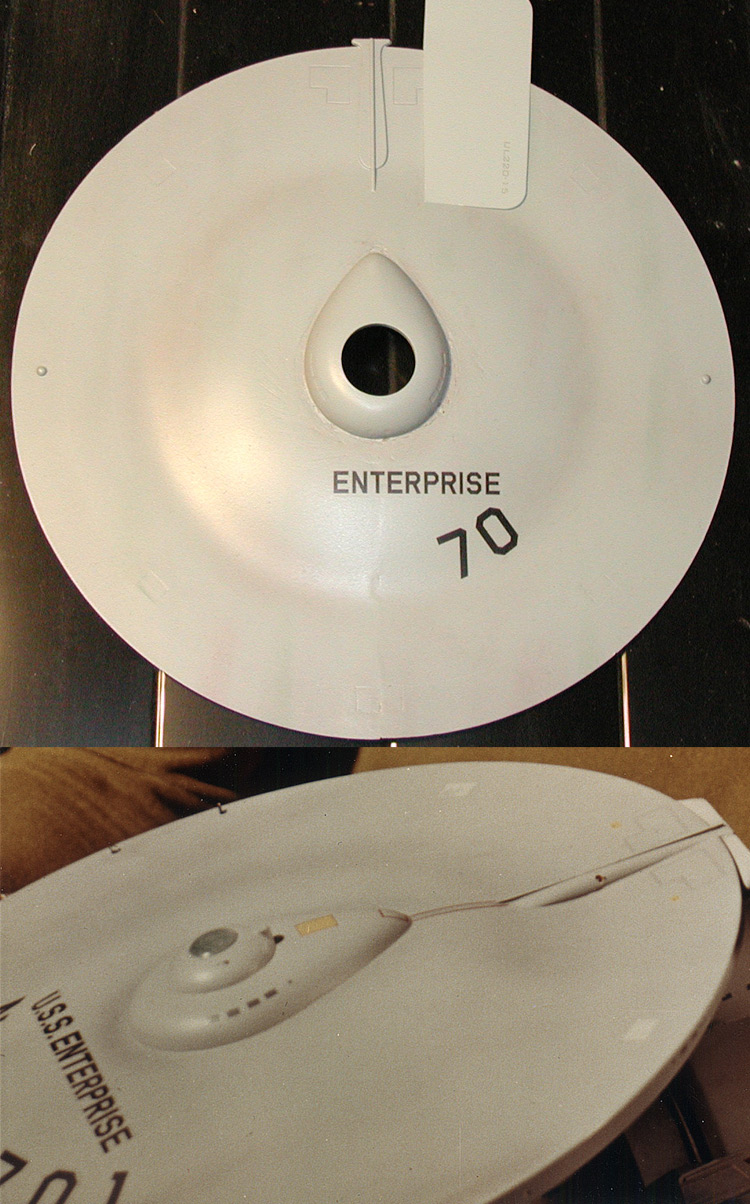

The docking hatch is recessed a small amount, so even if you can't see the decals because of a glare on the surface, the physical circle would still show. The decal for the door is from the Phase II Enterprise decal sheet, but the target ring decal was made for the Columbia. I figured this modification was during the Phase II era.

I always felt that with the scout/destroyer configuration the dorsal spaces would be mostly devoted to engineering, so the only windows I put on the dorsal were directly across from the docking hatch for the receiving area. Engineers don't need windows.

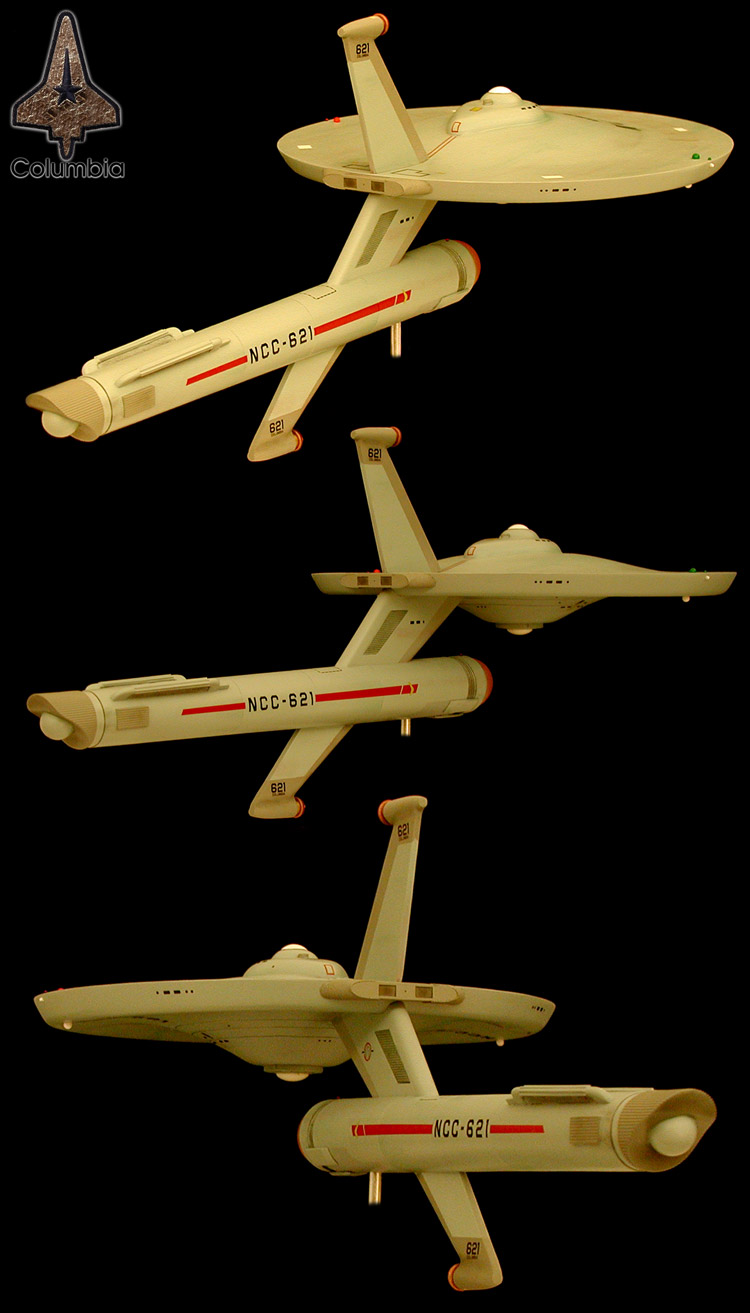

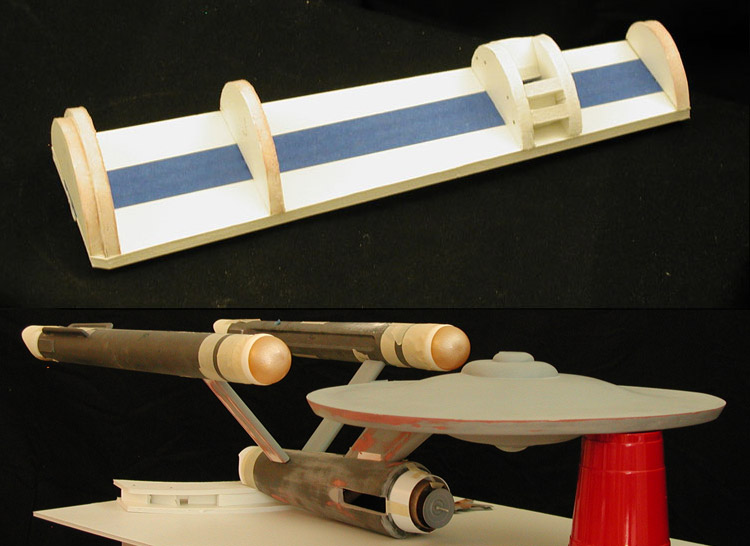

Speaking of the Phase II Enterprise, I thought I'd share a few shots of the Columbia with the Enterprise as both are at 1/500 scale...

I'll inspect the decals on the Columbia today and if they are all good I'll start in on the clear coats. After that, a few small details and I'll start taking beauty shots of her.