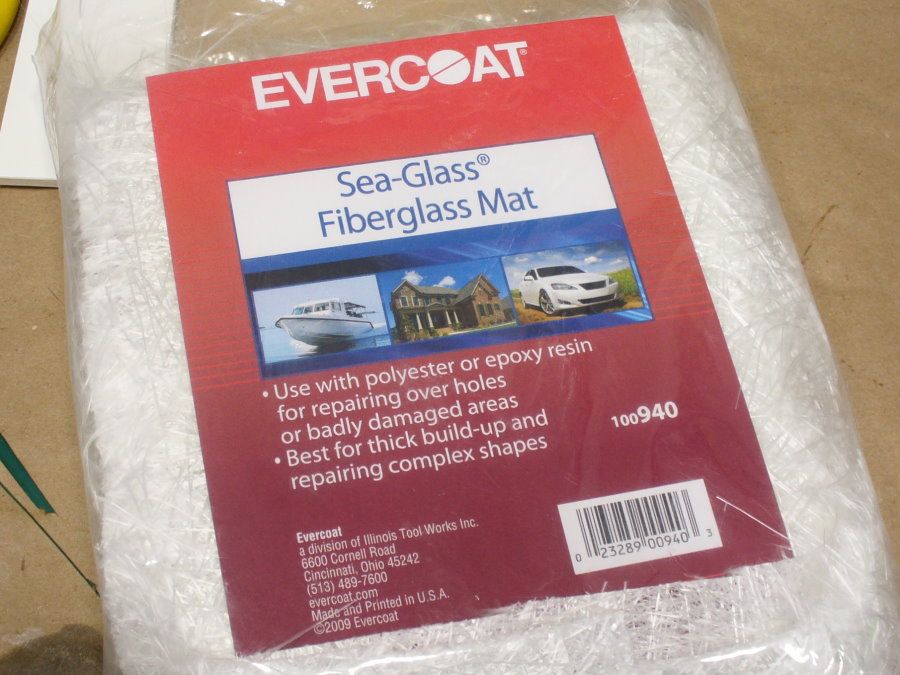

Quick question for those who have experience with this. I've always stuck with polyester, because despite the smell, it's cheap and easy to use. However, I recently picked up some epoxy resin along with some powder bound mat to use with it, thinking I'd see if it was worth the extra. So far, I've found that the resin is almost too thick to properly wet out the mat, and getting it to follow the mould shape can be quite challenging. Despite my best efforts (and I never have this problem with polyester), air bubbles seem to pop up under the mat, separating it from the surface beneath. It probably doesn't help that I picked the fast set resin (doh!), and it's starting to gel before I'm really done, even when using quite small amounts of resin.

I'm using a 300gm mat, which I think roughly equates to 1oz. for the US folks, which isn't really that heavy at all. I've never really used the cloth, is that a better option with epoxy resin? Are there any other techniques that will help?

Any suggestions appreciated!

I'm using a 300gm mat, which I think roughly equates to 1oz. for the US folks, which isn't really that heavy at all. I've never really used the cloth, is that a better option with epoxy resin? Are there any other techniques that will help?

Any suggestions appreciated!