Kwally89

Well-Known Member

Here is the mini-tutorial that everyone has been asking for!

MOLDING WITH SILICONE CAULK

Ok, so you are poor and want to make a quick mold of your sculpt/prop. What do you do? You use silicone caulk. Yes the same stuff that you use in the bathroom around sinks and showers.

Some people will tell you to mix in some glycerin or paint. Others say that you need to put some plaster in it. My method is A LOT easier and works just as well if not better. Ok, silicone caulk cures with water. When you squirt it out of the tube, it instantly begins reacting with the moisture in the air to become solid when cured. People have used plaster mixes to speed this process up because the silicone caulk produces acetic acid while curing. Acetic acid mixed with the mild base (usually a carbonate) in certain kinds of plaster produces water and a salt. This is obvious to anyone who has taken a general chemistry course...like I already stated, this is true, but is only need if you are casting something with the silicone caulk. In a simple mold, it is unnecessary.

MATERIALS

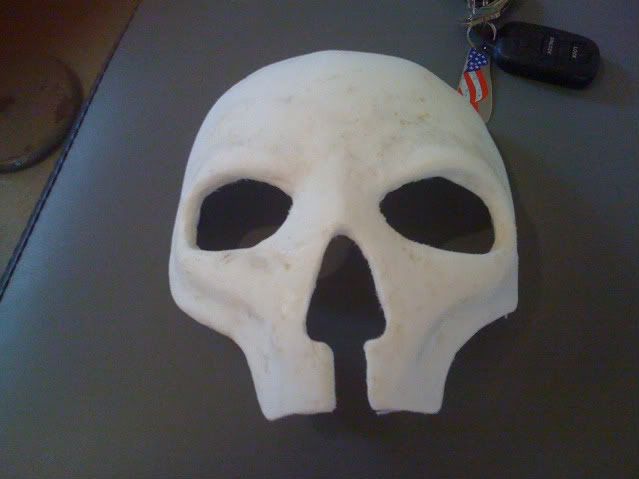

100% Silicone Caulk: I prefer the use GE Silicone 1 TRANSPARENT. I usually get two tubes, but it will differ depending on the size of your piece. In this tutorial, I used white silicone because they were in the transparent bin at Wal-Mart so I thought I bought transparent!

A medium to large bucket

Some dish soap

a fairly sharp knife

silicone/grout dispensing gun

Procedure

First, you need to take your trusty bucket and fill it with luke warm water. As the water is coming out of the faucet, squirt about...idk...the volume of a golf ball or more dish soap into the stream. This just makes the dish soap mix and gets the suds going.

Next, place the bucket next to your sculpt. Cut the ends of the silicone tubes off.

It is beneficial to do this because it is hard to get a smooth surface if you squeeze all the silicone out in little snakes.

Squeeze ALL the silicone into the bucket. Stick your hands in the water and get them soapy and wet before working the silicone. The soap acts as a nice release from your sculpt and your hands. The only problem is the silicone has a hard time sticking to itself. Hence, my suggestion to cut off the ends so you don't have a bunch of little silicone snakes.

Work the silicone A BIT under the water. You don't need to play with it though it is fun. Grab the big glob out of the water and get it into a ball or pancake shape. Make sure the surface of the silicone is fairly flat. You don't want to capture any air bubbles.

Push the silicone over the sculpture making sure that you work it into the undercuts and detail areas.

If I had looked closer at Wal-Mart, I would have used transparent. You really need to use transparent so you can accurately judge the thickness of the mold. Generally, a thickness of 1/4" will work just fine. I actually don't even make mother molds when the silicone is thick enough because it will hold its shape. With that being said, that means that the silicone doesn't have the ability to stretch very much before it rips.

You should be able to demold anywhere from 24-48 hours though it will dispel the acidic gas for 1-2 weeks. I usually get really excited and demold in 24 hours. If you got enough water in there and it isn't too thick, you should be just fine.

Any questions....feel free to ask!!!

HAVE FUN!!!

Kody

MOLDING WITH SILICONE CAULK

Ok, so you are poor and want to make a quick mold of your sculpt/prop. What do you do? You use silicone caulk. Yes the same stuff that you use in the bathroom around sinks and showers.

Some people will tell you to mix in some glycerin or paint. Others say that you need to put some plaster in it. My method is A LOT easier and works just as well if not better. Ok, silicone caulk cures with water. When you squirt it out of the tube, it instantly begins reacting with the moisture in the air to become solid when cured. People have used plaster mixes to speed this process up because the silicone caulk produces acetic acid while curing. Acetic acid mixed with the mild base (usually a carbonate) in certain kinds of plaster produces water and a salt. This is obvious to anyone who has taken a general chemistry course...like I already stated, this is true, but is only need if you are casting something with the silicone caulk. In a simple mold, it is unnecessary.

MATERIALS

100% Silicone Caulk: I prefer the use GE Silicone 1 TRANSPARENT. I usually get two tubes, but it will differ depending on the size of your piece. In this tutorial, I used white silicone because they were in the transparent bin at Wal-Mart so I thought I bought transparent!

A medium to large bucket

Some dish soap

a fairly sharp knife

silicone/grout dispensing gun

Procedure

First, you need to take your trusty bucket and fill it with luke warm water. As the water is coming out of the faucet, squirt about...idk...the volume of a golf ball or more dish soap into the stream. This just makes the dish soap mix and gets the suds going.

Next, place the bucket next to your sculpt. Cut the ends of the silicone tubes off.

It is beneficial to do this because it is hard to get a smooth surface if you squeeze all the silicone out in little snakes.

Squeeze ALL the silicone into the bucket. Stick your hands in the water and get them soapy and wet before working the silicone. The soap acts as a nice release from your sculpt and your hands. The only problem is the silicone has a hard time sticking to itself. Hence, my suggestion to cut off the ends so you don't have a bunch of little silicone snakes.

Work the silicone A BIT under the water. You don't need to play with it though it is fun. Grab the big glob out of the water and get it into a ball or pancake shape. Make sure the surface of the silicone is fairly flat. You don't want to capture any air bubbles.

Push the silicone over the sculpture making sure that you work it into the undercuts and detail areas.

If I had looked closer at Wal-Mart, I would have used transparent. You really need to use transparent so you can accurately judge the thickness of the mold. Generally, a thickness of 1/4" will work just fine. I actually don't even make mother molds when the silicone is thick enough because it will hold its shape. With that being said, that means that the silicone doesn't have the ability to stretch very much before it rips.

You should be able to demold anywhere from 24-48 hours though it will dispel the acidic gas for 1-2 weeks. I usually get really excited and demold in 24 hours. If you got enough water in there and it isn't too thick, you should be just fine.

Any questions....feel free to ask!!!

HAVE FUN!!!

Kody

Last edited: