zanderwitaz

Well-Known Member

I saw this little guy in the trailer and had to make one. I originally made about a third of it at a scale of 14" long, didn't like the size, and scrapped it. I started again, this time at 15.5" long.

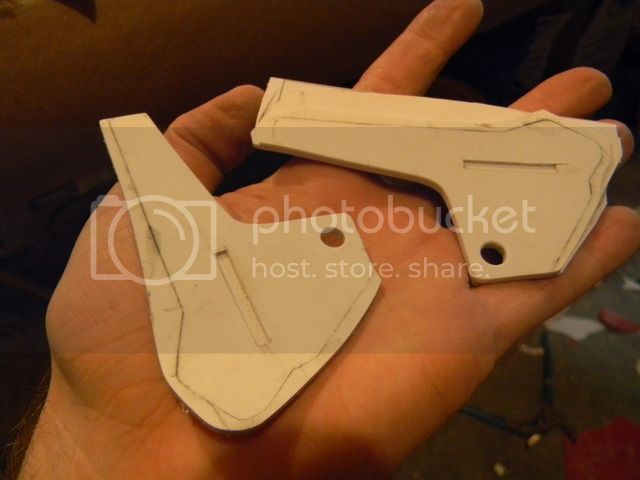

I cut out the general shape of the receiver, and a cavity for the magazine.

Then I glued down some styrene on each side of the cavity, and the grips on top of that.

The magwell plate is a few layers of MDF and Styrene.

Some beveled paneling around the trigger area.

The little foregrip is simple enough.

Testing out the thickness of some side panels near the front.

I used some styrene rod for the trim, but sometimes use sanded wooden dowels as well.

Looking good. I made the front shroud as well. A little too rounded in my opinion. This is where I scrapped the thing and re-made it again using the same techniques.

All right, V2. all of these parts are now about 13 percent larger. I made the rounded front shroud more pointy this time.

I used some carefully cut PVC to offset the thickness as well as provide a guide for installing the barrel bits down the road.

Here's the original antenna module.

Well, I didn't want to re-make that again so I simply beefed up the walls with styrene. Same with the magazine. I also added a strip of MDF in there to increase the length.

Back to the barrel shroud. It got its plating installed.

Next up, the panels behind the shroud. Carefully cut and layered styrene.

I didn't want to glue those in place until I had the receiver made. This way I could account for the angles better. Its hard to explain.I started on the receiver.

The rails are simply cast weaver mounts.

Finally coming together. The inset triangle details are all cut with an exacto at about 30 degrees or so. Very tedious and very difficult. A small Bojack horseman marathon was required to finish those.

I messed up the stock a little too.

For some reason, I thought there was a step down in the back of the stock.

I had no idea there wasn't and came close to finishing the back.

Ended up re-doing it.

Some silver colored fiddlybit goes in the front of the stock.

The layering for the stock tip was done in a different direction, and had to be a separate piece, grafted on at the end.

Did I say the end? I lied. There's more to the stock. The connector was simplified and thickened a bit. This was going to be a pour spout area, and I don't want problem areas or it to break off.

It lines up perfectly though.

The connector sits too low and hides all of the details. Even now. I'll fix it later.

With the big stuff done, its on to the fiddlybits. This is the mount by the flex cable.

Some fiddlbits on the front sight too.

The folded charging handle. It has a slider on it. Maybe I'll make it move someday.

Sides of the rear sight body.

I got about 80% done, then found a better reference and scrapped it. Widened it an 8th of an inch, and re-did all of the top details. No WIP progress the second time around though. Here's the old one.

This part was tricky. I cut this out of a handle. It was an old cheapie engraving tool. It was the perfect diameter and thickness.

I got lucky again and found an acrylic rod that sleeved the inside nicely. Then I did the remaining parts on carefully cut MDF on the scroll saw. (Like everything else)

The flex cable was all done in styrene, carefully cut with an exacto. Ready for molding!

I'll update once I start molding. build time, about 10 days including some screw ups and a partial re-make. Thanks guys!

I cut out the general shape of the receiver, and a cavity for the magazine.

Then I glued down some styrene on each side of the cavity, and the grips on top of that.

The magwell plate is a few layers of MDF and Styrene.

Some beveled paneling around the trigger area.

The little foregrip is simple enough.

Testing out the thickness of some side panels near the front.

I used some styrene rod for the trim, but sometimes use sanded wooden dowels as well.

Looking good. I made the front shroud as well. A little too rounded in my opinion. This is where I scrapped the thing and re-made it again using the same techniques.

All right, V2. all of these parts are now about 13 percent larger. I made the rounded front shroud more pointy this time.

I used some carefully cut PVC to offset the thickness as well as provide a guide for installing the barrel bits down the road.

Here's the original antenna module.

Well, I didn't want to re-make that again so I simply beefed up the walls with styrene. Same with the magazine. I also added a strip of MDF in there to increase the length.

Back to the barrel shroud. It got its plating installed.

Next up, the panels behind the shroud. Carefully cut and layered styrene.

I didn't want to glue those in place until I had the receiver made. This way I could account for the angles better. Its hard to explain.I started on the receiver.

The rails are simply cast weaver mounts.

Finally coming together. The inset triangle details are all cut with an exacto at about 30 degrees or so. Very tedious and very difficult. A small Bojack horseman marathon was required to finish those.

I messed up the stock a little too.

For some reason, I thought there was a step down in the back of the stock.

I had no idea there wasn't and came close to finishing the back.

Ended up re-doing it.

Some silver colored fiddlybit goes in the front of the stock.

The layering for the stock tip was done in a different direction, and had to be a separate piece, grafted on at the end.

Did I say the end? I lied. There's more to the stock. The connector was simplified and thickened a bit. This was going to be a pour spout area, and I don't want problem areas or it to break off.

It lines up perfectly though.

The connector sits too low and hides all of the details. Even now. I'll fix it later.

With the big stuff done, its on to the fiddlybits. This is the mount by the flex cable.

Some fiddlbits on the front sight too.

The folded charging handle. It has a slider on it. Maybe I'll make it move someday.

Sides of the rear sight body.

I got about 80% done, then found a better reference and scrapped it. Widened it an 8th of an inch, and re-did all of the top details. No WIP progress the second time around though. Here's the old one.

This part was tricky. I cut this out of a handle. It was an old cheapie engraving tool. It was the perfect diameter and thickness.

I got lucky again and found an acrylic rod that sleeved the inside nicely. Then I did the remaining parts on carefully cut MDF on the scroll saw. (Like everything else)

The flex cable was all done in styrene, carefully cut with an exacto. Ready for molding!

I'll update once I start molding. build time, about 10 days including some screw ups and a partial re-make. Thanks guys!

Attachments

Last edited: