My normal go-to for 3D printing and model kits is normally ships and vehicles. But over the last year, I have been trying to expand my skill set starting with an IG-88 and Mandolorian build I did a while back. I have a vinyl Rancor kit I picked up on eBay a while back and so I have been looking for some 'creatures' to practice with before I dive into that kit. My putty skills are pretty terrible so I thought this kit would also be a good place to attempt to hone those a bit.

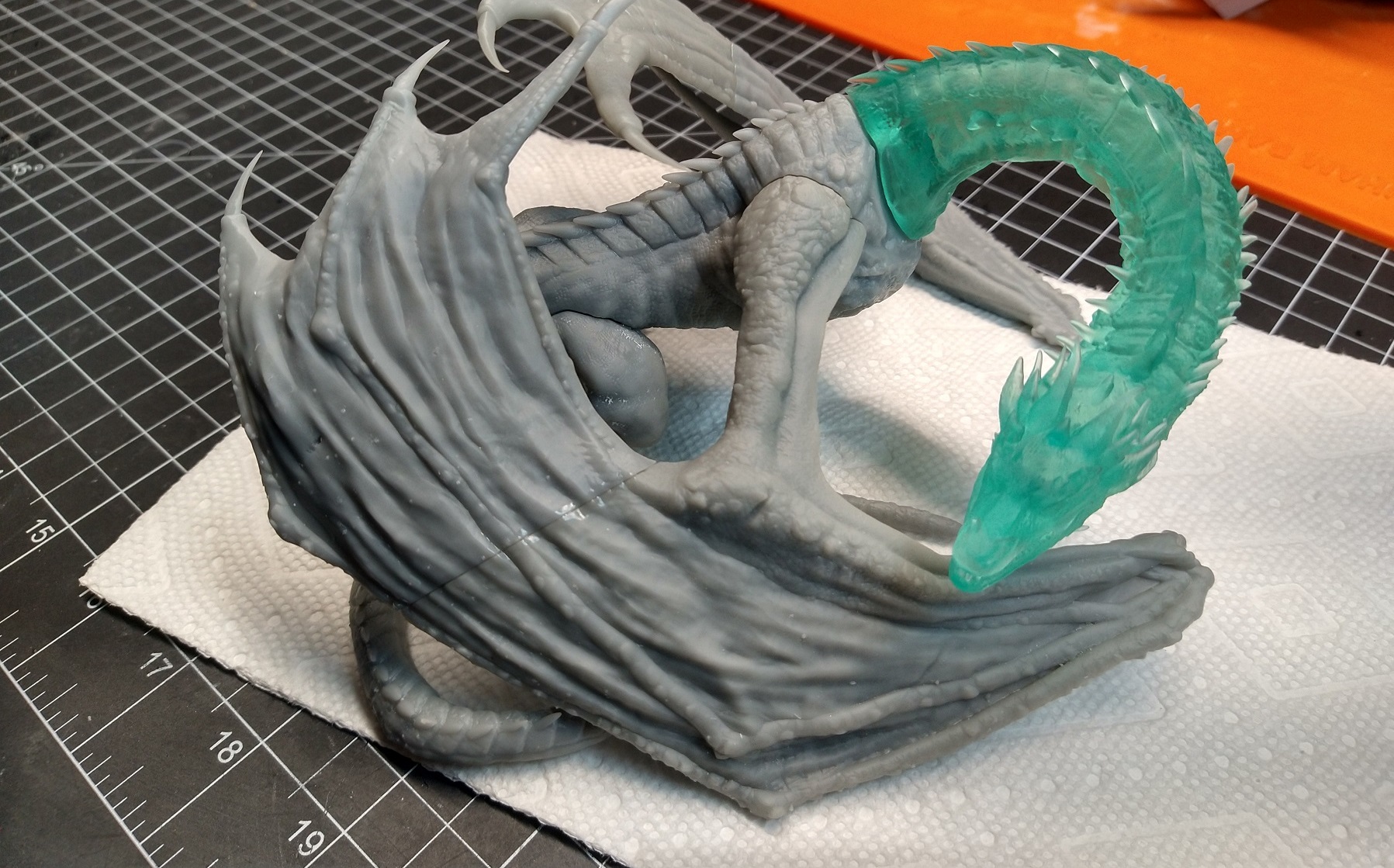

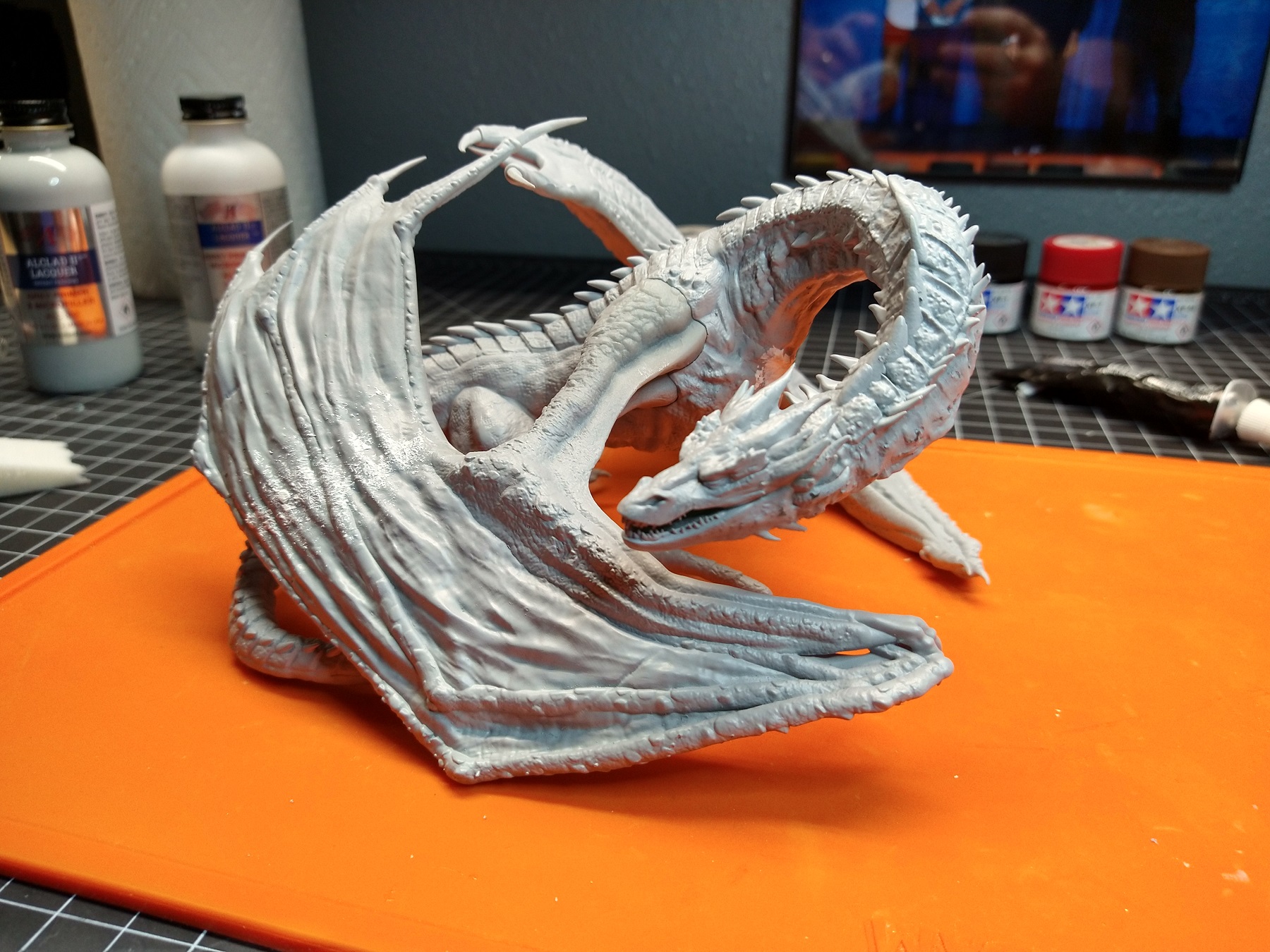

Other than Star Wars, one of my favorite series is the Lord of the Rings (and to a lesser degree The Hobbit). My daughter is a huge Hobbit fan so I decided to pick up these files from Gambody and give them a try. I did not like the base that came with the kit and thought the mighty Smaug could use something a bit more substantial.

These were all printed on my Mars Pro with several resins from Sirya Tech. If you have not tried out their "Blu" resin it's basically amazing. It takes much longer to print with (unless you have a heated vat) but the strength is pretty incredible. The parts I print with the Blu are much more durable than even my PLA prints. My son and I had fun throwing parts at the cement and trying to break some of them, they almost never broke. This is a HUGE departure from the water washable resins I was using up until now from Elegoo, I found those to be very brittle.

Enjoy

Other than Star Wars, one of my favorite series is the Lord of the Rings (and to a lesser degree The Hobbit). My daughter is a huge Hobbit fan so I decided to pick up these files from Gambody and give them a try. I did not like the base that came with the kit and thought the mighty Smaug could use something a bit more substantial.

These were all printed on my Mars Pro with several resins from Sirya Tech. If you have not tried out their "Blu" resin it's basically amazing. It takes much longer to print with (unless you have a heated vat) but the strength is pretty incredible. The parts I print with the Blu are much more durable than even my PLA prints. My son and I had fun throwing parts at the cement and trying to break some of them, they almost never broke. This is a HUGE departure from the water washable resins I was using up until now from Elegoo, I found those to be very brittle.

Enjoy