ScoobiJohn

Active Member

Started this a while back,

its my favourite sword from destiny (original - no really cool swords in destiny 2) was very satisfying running up and uppercutting bosses (usually dying in the process but it felt very heroic) it was a grind to get it in the game and the real world is proving no different, my quest started with the magic crystal, my first attempt started trying to make one out of clay but never having done much sculpting i tried to do it in 2 halves but as it dried it warped bah long story short by the time i had the second half glued on it was crumbling and cracking and bending, it was an unmitigated disaster.....onto plan b i found the game model online and while much of the texture was missing from the 3d mesh i printed it out and then using an epoxy modelling putty added the missing details and then came my first mold - there is a thread on here somewhere to help me through teething process in the end i got this

this was my first attempt and i put in 2 much mica powder and its completely opaque so i did a second one that much more transparent but it was full of bubbles despite giving it an even more through vacuum degassing anyway resin being expensive i decided to make the best of and ground away the worst of the bubbles and then washed it thoroughly to get the dust out of the little holes and then i sprayed it with laquer which filled the worst of the holes and left it with a nice shiney surface - more on this later

anyway resin being expensive i decided to make the best of and ground away the worst of the bubbles and then washed it thoroughly to get the dust out of the little holes and then i sprayed it with laquer which filled the worst of the holes and left it with a nice shiney surface - more on this later

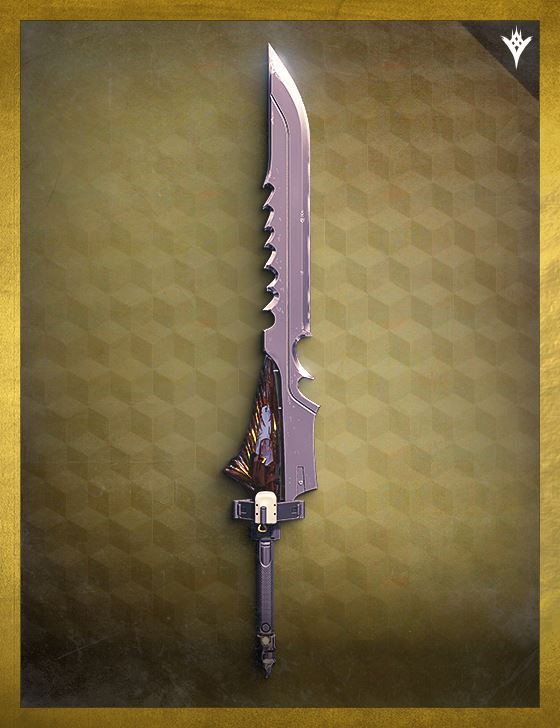

with the crystal largely done (wishful thinking) i started on the blade now using the image up top i traced the outline in ps elements and enlarged it to life sized and printed it out stuck it down on a sheet of 3mm aluminium and cut it out with a jigsaw and i was left with this

now i realised that my low res image and the subsequent enlargement had left me with very thick lines and the sword is too fat! anyway some more time with the jigsaw, angle grinder, files and a little grindy burr type thing for my dremmel for which i made a little collet type thing on my mini lathe so it could run along a guide

and i had this

now starting to look not bad but close up on the grove....argh not great still trying to work out how to get that nice and smooth - might try electro etching but its a big bit of metal to try that for the first time on

anyway back to that crystal i thought was done..... well it was about this time i started to ask how do i attach it to the blade and realised it wasn't gonna work as things stood. i had an idea to fix it and have started to implement it but not taken any pics yet so that can wait until tomorrow

its my favourite sword from destiny (original - no really cool swords in destiny 2) was very satisfying running up and uppercutting bosses (usually dying in the process but it felt very heroic) it was a grind to get it in the game and the real world is proving no different, my quest started with the magic crystal, my first attempt started trying to make one out of clay but never having done much sculpting i tried to do it in 2 halves but as it dried it warped bah long story short by the time i had the second half glued on it was crumbling and cracking and bending, it was an unmitigated disaster.....onto plan b i found the game model online and while much of the texture was missing from the 3d mesh i printed it out and then using an epoxy modelling putty added the missing details and then came my first mold - there is a thread on here somewhere to help me through teething process in the end i got this

this was my first attempt and i put in 2 much mica powder and its completely opaque so i did a second one that much more transparent but it was full of bubbles despite giving it an even more through vacuum degassing

with the crystal largely done (wishful thinking) i started on the blade now using the image up top i traced the outline in ps elements and enlarged it to life sized and printed it out stuck it down on a sheet of 3mm aluminium and cut it out with a jigsaw and i was left with this

now i realised that my low res image and the subsequent enlargement had left me with very thick lines and the sword is too fat! anyway some more time with the jigsaw, angle grinder, files and a little grindy burr type thing for my dremmel for which i made a little collet type thing on my mini lathe so it could run along a guide

and i had this

now starting to look not bad but close up on the grove....argh not great still trying to work out how to get that nice and smooth - might try electro etching but its a big bit of metal to try that for the first time on

anyway back to that crystal i thought was done..... well it was about this time i started to ask how do i attach it to the blade and realised it wasn't gonna work as things stood. i had an idea to fix it and have started to implement it but not taken any pics yet so that can wait until tomorrow