You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oblivion Drone Scratch build

- Thread starter niart17

- Start date

patrickivan

Sr Member

Very cool... If you're interested, I came across a front pic of the prop being moved on a forklift here: http://www.scalemodeladdict.com/SMF/index.php?topic=10001.0

It's about 2/3rd down the page.

It's about 2/3rd down the page.

Awesome work man. Are you lighting this guy up?

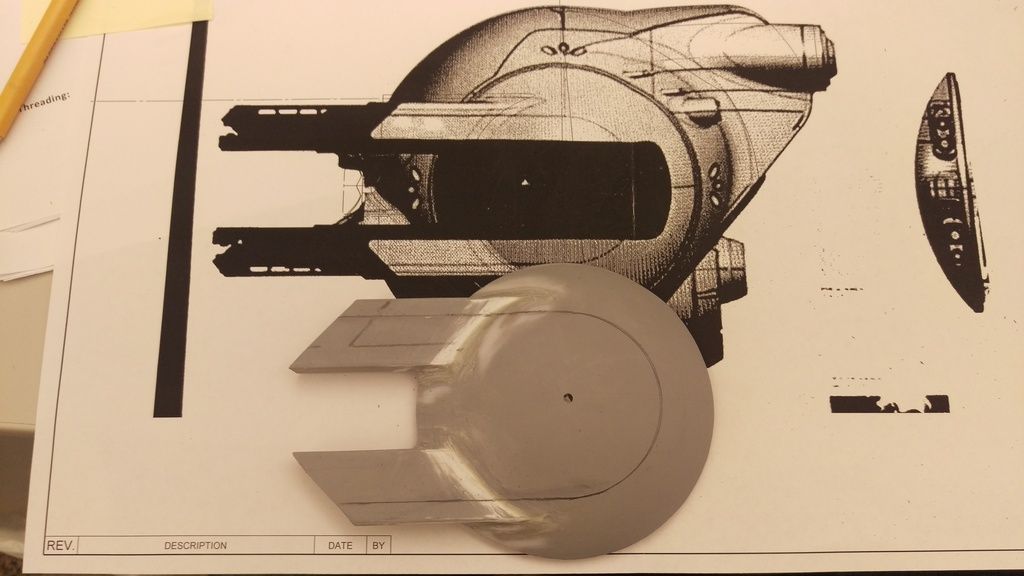

This is the best reference I've been able to find for the thruster.

View attachment 599114

Thanks for the kind words. I only hope I can live up to the task.

I'm at the very least planning on making it easy to add lights later IF I don't incorporate them as I build. I've never tried to light anything and this seems simple enough as there aren't many lights on it. I don't know about engines etc...but the eye and the scanner shouldn't be too hard. It would be really cool to go all out and try to somehow install a blue laser line generator in it, but I'm not brave enough to mess with that stuff without knowing more about it and risk burning out someone's retinas.

Thank you for the pic as well. I did have the 2 on the left, but they were much lower res than what you posted. And the shot on the right definitely helps add a piece to the puzzle. Thanks!

Bill

Thanks! I did actually have that shot of it on the fork lift. The two areas I'm finding most challenging in finding resources for are the inside of the main engine bell and what the detail is like on the drone side when the gun pods are open. I found good shots of the inside face of the gun pods, but nothing showing all the detail of the other face. In some shots you can tell there is much more there than the smooth clean face that all of the real prop pics show. It may be just that it was added digitally post production, but that really wouldn't make sense to put so much detail elsewhere and leave that bare. If anyone has anything else it would be very much appreciated.Very cool... If you're interested, I came across a front pic of the prop being moved on a forklift here: http://www.scalemodeladdict.com/SMF/index.php?topic=10001.0

It's about 2/3rd down the page.

Thanks again guys for all the kind words of encouragement.

Bill

I've looked thoroughly as well in all kinds of places and haven't found any good shots inside the gun pods you're looking for. The guns and arms just hide too much from any angle it's shot from. All I can make out is a thin ring around the outermost perimeter on which the small hydraulic struts attach. I get the sense they didn't do much detailing in there on the built drone and maybe didn't go nuts on the vfx model either.

As far as detailing it, I've thought about possibly copying some of the shapes and detail from the exterior of the 't-800' stripped down version and slapping them in there, maybe have some wire harness or hoses coming from the center hole to little boxes around it. Here's a nice shot of it from the press tour:

As far as detailing it, I've thought about possibly copying some of the shapes and detail from the exterior of the 't-800' stripped down version and slapping them in there, maybe have some wire harness or hoses coming from the center hole to little boxes around it. Here's a nice shot of it from the press tour:

Great pic.That would be a real challenge to build the stripped down version. But I'm not that brave or skilled...yet.

I wonder where the original props ended up? Surely the full size drone is still around somewhere. It would be great if I could find someone that could go shoot that area for me. I've found one screen shot from the attack outside the stadium that I can't seem to locate again that shows there is definitely some intricate detail going on under the pods. Its just not clear enough to make out any details

Bill

I wonder where the original props ended up? Surely the full size drone is still around somewhere. It would be great if I could find someone that could go shoot that area for me. I've found one screen shot from the attack outside the stadium that I can't seem to locate again that shows there is definitely some intricate detail going on under the pods. Its just not clear enough to make out any details

Bill

Its looking good....now if there was only a way to make it actually hover....

I'm sure it's in a studio warehouse somewhere gathering dust - so much amazing art built for films that either gets scrapped or stored forever without access.

I briefly looked into maglev devices - seems you'd have to get something custom to have any hope of floating a sphere with any weight to it an appreciable height. Crealev makes some good (expensive) ones but the levitation height just isn't enough to make it worthwhile.

In the initial shots of the captured drone it seems to be magically floating (it's powered off) with cables coming out the bottom. This might be an interesting solution, to use steel wire and dress it as a cable snaking backwards out the bottom.

Another possibility if you're one for the floating look (and more of a diorama) is to strap it up with all the guylines as when Jack powers it up at the Scav base.

edit: There's also the rig the stripped down drone is suspended from in the tower lab. Kind of a fork that comes over the top and locks into the scanning circles in the middle of the turrets.

I briefly looked into maglev devices - seems you'd have to get something custom to have any hope of floating a sphere with any weight to it an appreciable height. Crealev makes some good (expensive) ones but the levitation height just isn't enough to make it worthwhile.

In the initial shots of the captured drone it seems to be magically floating (it's powered off) with cables coming out the bottom. This might be an interesting solution, to use steel wire and dress it as a cable snaking backwards out the bottom.

Another possibility if you're one for the floating look (and more of a diorama) is to strap it up with all the guylines as when Jack powers it up at the Scav base.

edit: There's also the rig the stripped down drone is suspended from in the tower lab. Kind of a fork that comes over the top and locks into the scanning circles in the middle of the turrets.

Last edited:

I've looked around as well into the thought of levitating it. There are a few blue tooth speakers out there that float and if I had unlimited resources I'd try to figure out a way to put one in the bottom of this thing. That would be pretty cool with the ability to play drone sounds, or music. But that's a bit expensive for me. There is a guy who levitated a modified Hot Toys Iron-man. It came out looking pretty cool.

I've starting playing around with lighting ideas. I found a red LED that was mounting in a metal casing, I think from an industrial control panel, and it seems to fit the bill. I mounted it to a cheap flashlight reflector to see how it would look. It doesn't have the mechanical rotatable look of the real eye, but I think it's pretty convincing if I can't come up with something better. This will have to have a curved lens in front of it and I'll want to find a better reflector that's not chipped up but here is what I have so far. It's just loosely placed in the eye socket for now. (ignore the rough fillet around the face structure, that will all have to be built up and smoothed in)

Bill

[/quote]

Bill

[/quote]

youngtiger1

Member

Pretty cool subject. Will follow with great interest!

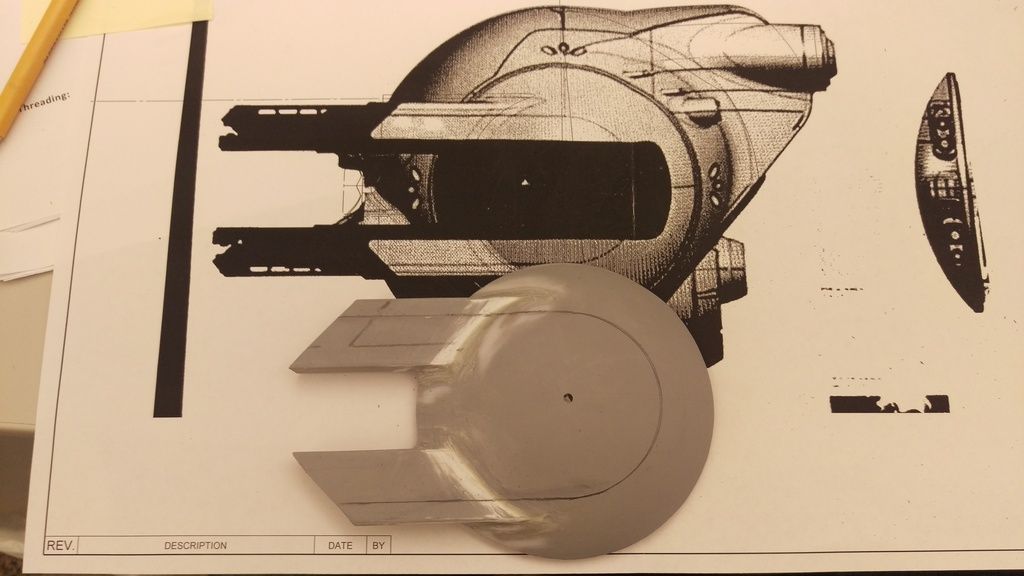

Thanks guys. Slowly getting there. Almost done smoothing everything out and scribing the main body. I still need to figure if I want to cast the gun pod or try to make another by scratch. Surprisingly it was possibly the most difficult part of the build so far getting the guns blended and lined up evenly. I really would prefer to make a mold. Here is what I have so far.

Suggestions, critiques and comments are welcome!

Bill

Suggestions, critiques and comments are welcome!

Bill

Speaking of casting, this is a question about rotocasting I'd posted on a couple of forums and haven't gotten an answer yet, maybe you guys could help me out.

I am thinking about taking a shot at rotocasting some parts. They aren't huge parts, about 4" diamter and only about .75" tall, but it would be a lot of extra resin and therefor unwanted weight and money if I cast them solid. I've been reading a little bit about it and I think I understand the concept for the most part, but I haven't seen much about any differences in the mold material. Can a simple 2-piece mold that would be used to make a solid cast be used just as effectively, provided that I block it in to keep it straight, as the ones that have flexible silicon covered with a plaster shell that I see most people use on large rotocastings? I have plenty of the Alumilite rubber mold material that I can use and I was planning on just buying some smooth-on smooth cast 65D. These aren't complicated parts so I am planning on just hand spinning them. Should this work?

Just for a frame of reference, this is the part I'm wanting to cast. Before it's molded I will scribe the pencil lines that are drawn on and I'll even out the length and cap off the ends of the gun sleeves. Other than that, it's pretty much ready to be made.

Any help would be appreciated.

Bill

I am thinking about taking a shot at rotocasting some parts. They aren't huge parts, about 4" diamter and only about .75" tall, but it would be a lot of extra resin and therefor unwanted weight and money if I cast them solid. I've been reading a little bit about it and I think I understand the concept for the most part, but I haven't seen much about any differences in the mold material. Can a simple 2-piece mold that would be used to make a solid cast be used just as effectively, provided that I block it in to keep it straight, as the ones that have flexible silicon covered with a plaster shell that I see most people use on large rotocastings? I have plenty of the Alumilite rubber mold material that I can use and I was planning on just buying some smooth-on smooth cast 65D. These aren't complicated parts so I am planning on just hand spinning them. Should this work?

Just for a frame of reference, this is the part I'm wanting to cast. Before it's molded I will scribe the pencil lines that are drawn on and I'll even out the length and cap off the ends of the gun sleeves. Other than that, it's pretty much ready to be made.

Any help would be appreciated.

Bill

Your standard mold practice is fine for rotocasting, all you need is a good way to plug the pour hole and make sure the seam line stays closed. That said, that part seems a tad small for rotocasting, only in that you wont really be saving that much material once you've got a thick enough uniform wall built up, but that's not definitive by any means... maybe if you were making 100 of em... your long thin arm boxes could have trouble filling as well, unless you've got plans to solidify the arms.

You might look into fillers like urefil 15 to save on resin as an alternative. my .02

You might look into fillers like urefil 15 to save on resin as an alternative. my .02

Generalurko

Sr Member

So are you going to be offering this as a resin kit for sale? Would definitely be interested if you do.

Thanks, and great work!

Chris

Thanks, and great work!

Chris

Similar threads

- Replies

- 3

- Views

- 904

- Replies

- 1

- Views

- 1,234

- Replies

- 6

- Views

- 1,666