Carson Dyle

Sr Member

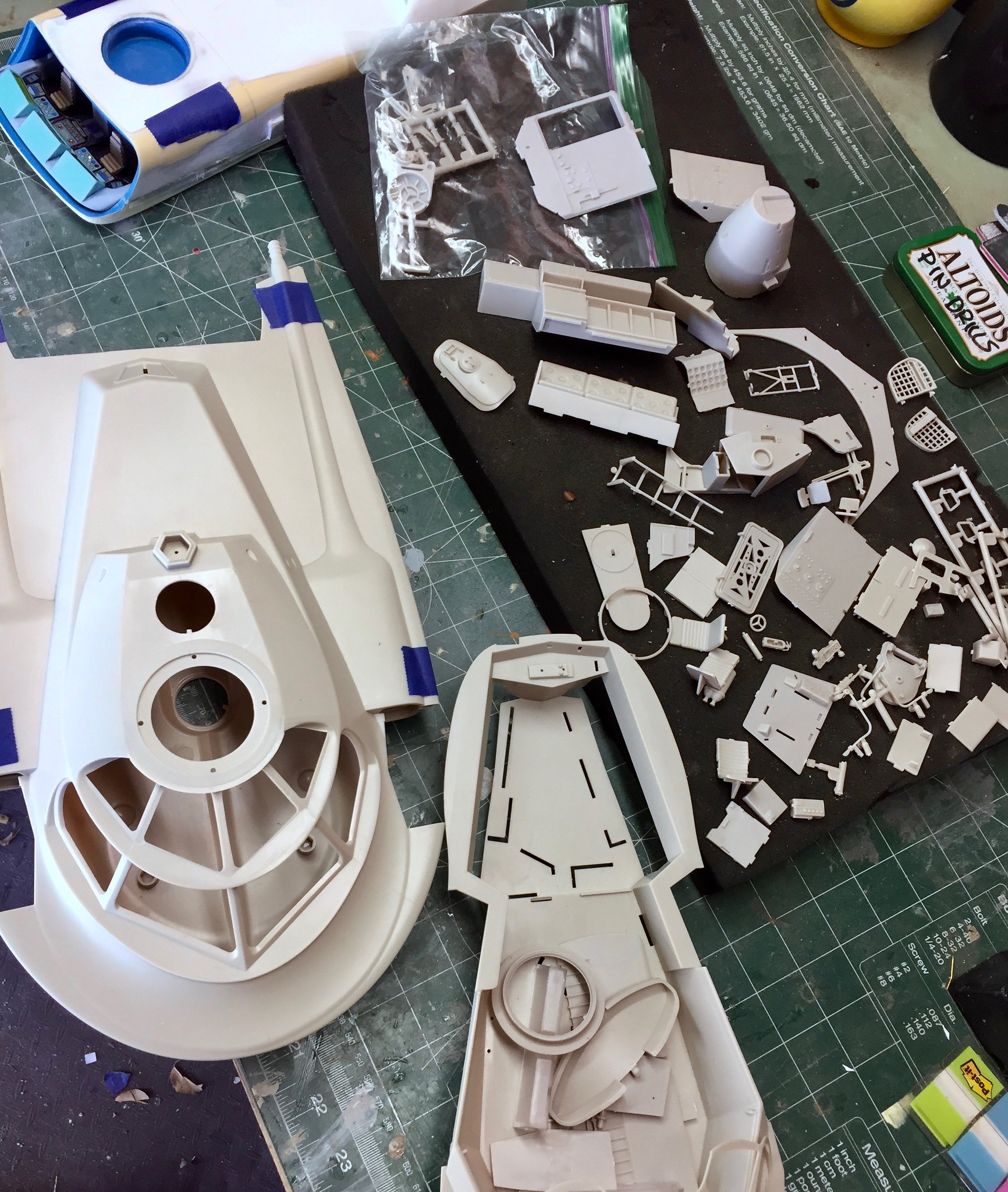

This thread will chronicle my efforts to build the Moebius Proteus kit. I had the privilege of helping to make this model a reality, and I’m grateful to Frank and Dave for providing me with an advance “test shot” of the parts.

Having built a couple very fine Garage Kits of this subject I hafta say it’s WONDERFUL to finally be working in injection-moulded styrene!

1 by Carson Dyle, on Flickr

1 by Carson Dyle, on Flickr

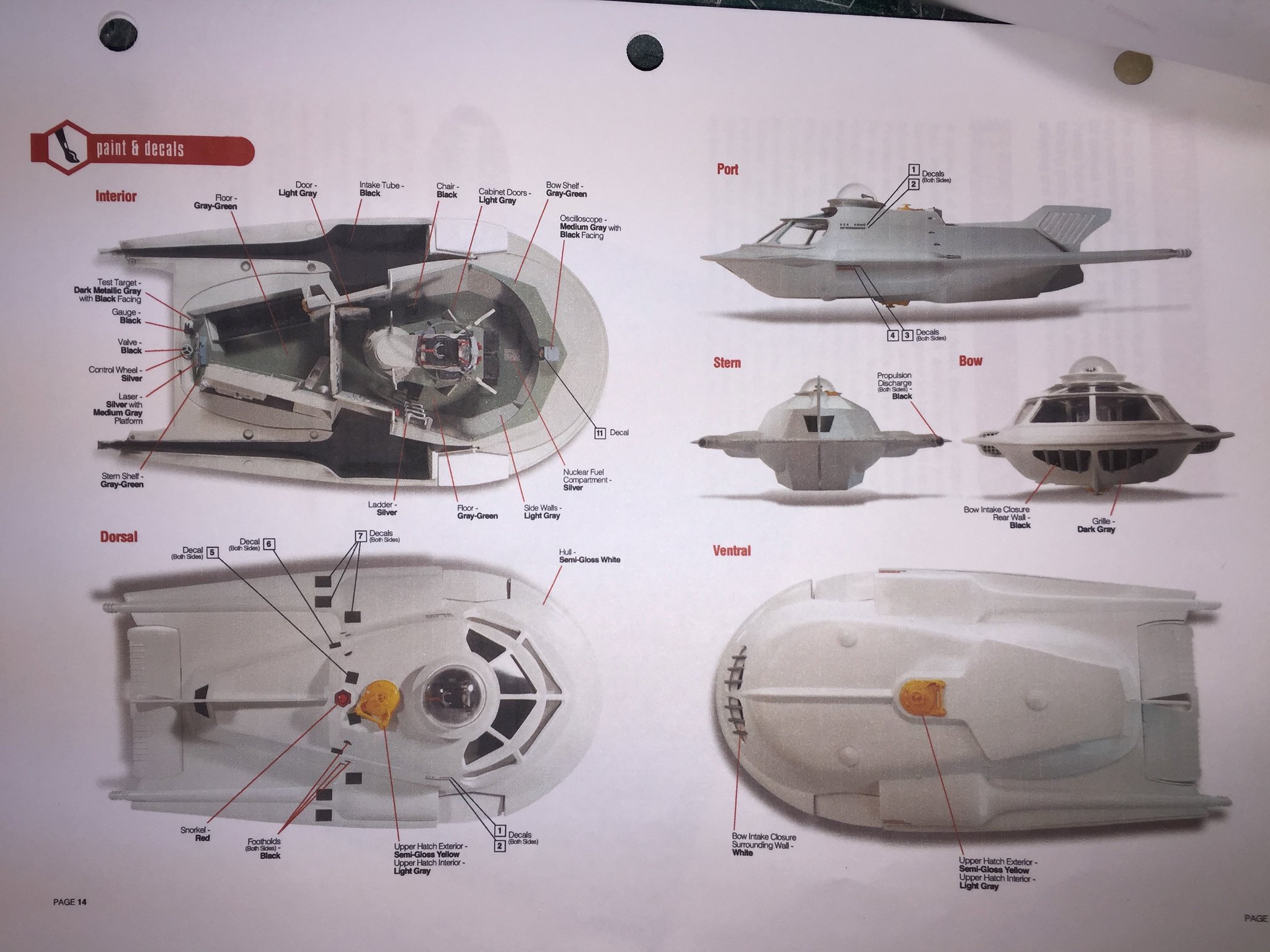

The instructions are well laid-out, and are accompanied by pix of Moebius’s test build.

2 by Carson Dyle, on Flickr

2 by Carson Dyle, on Flickr

3 by Carson Dyle, on Flickr

3 by Carson Dyle, on Flickr

So let’s get started!

PHASE 1

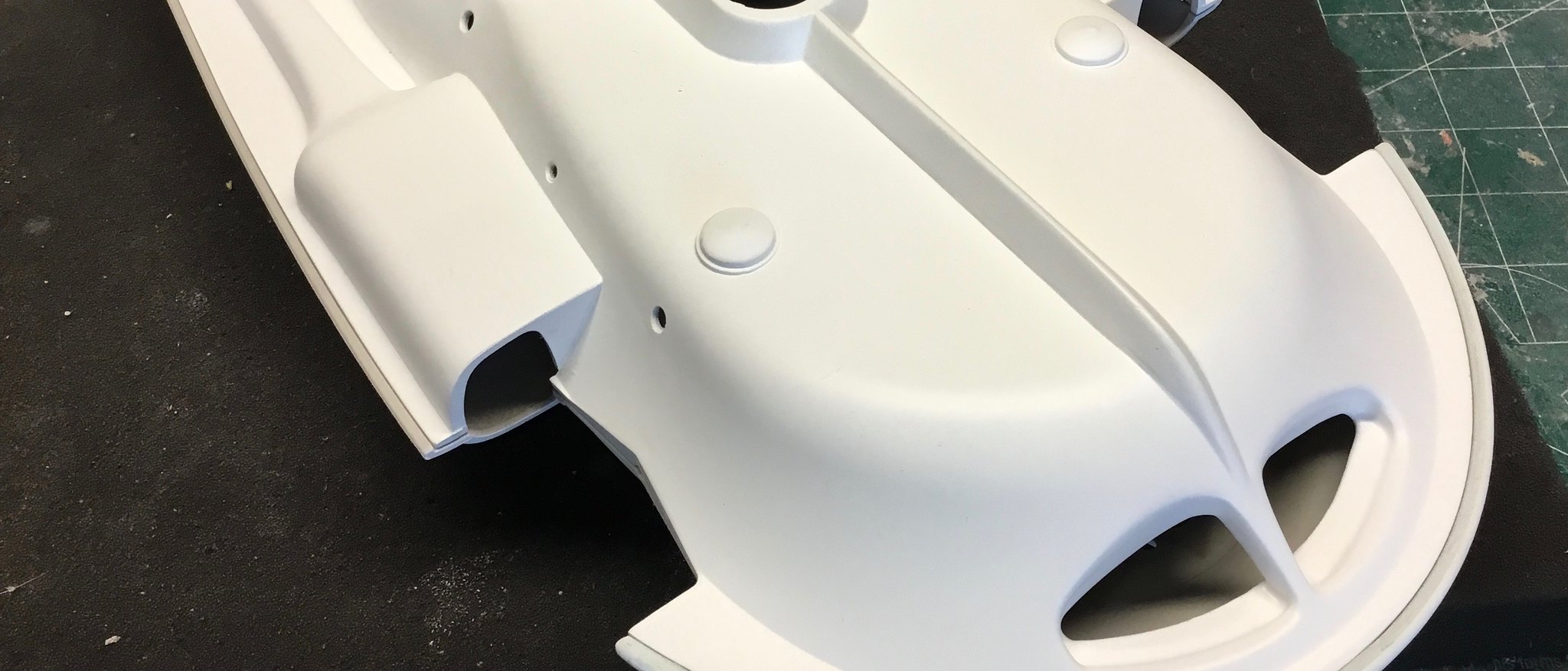

The first order of business was making a few modifications to the upper and lower hull halves. It’s important to note that none of these tweaks are required, and the modeler is free to either emulate or ignore them. I should also note that this kit (which I’m building for a friend) will not be lit. I’ll save that ad-on for my own Proteus build.

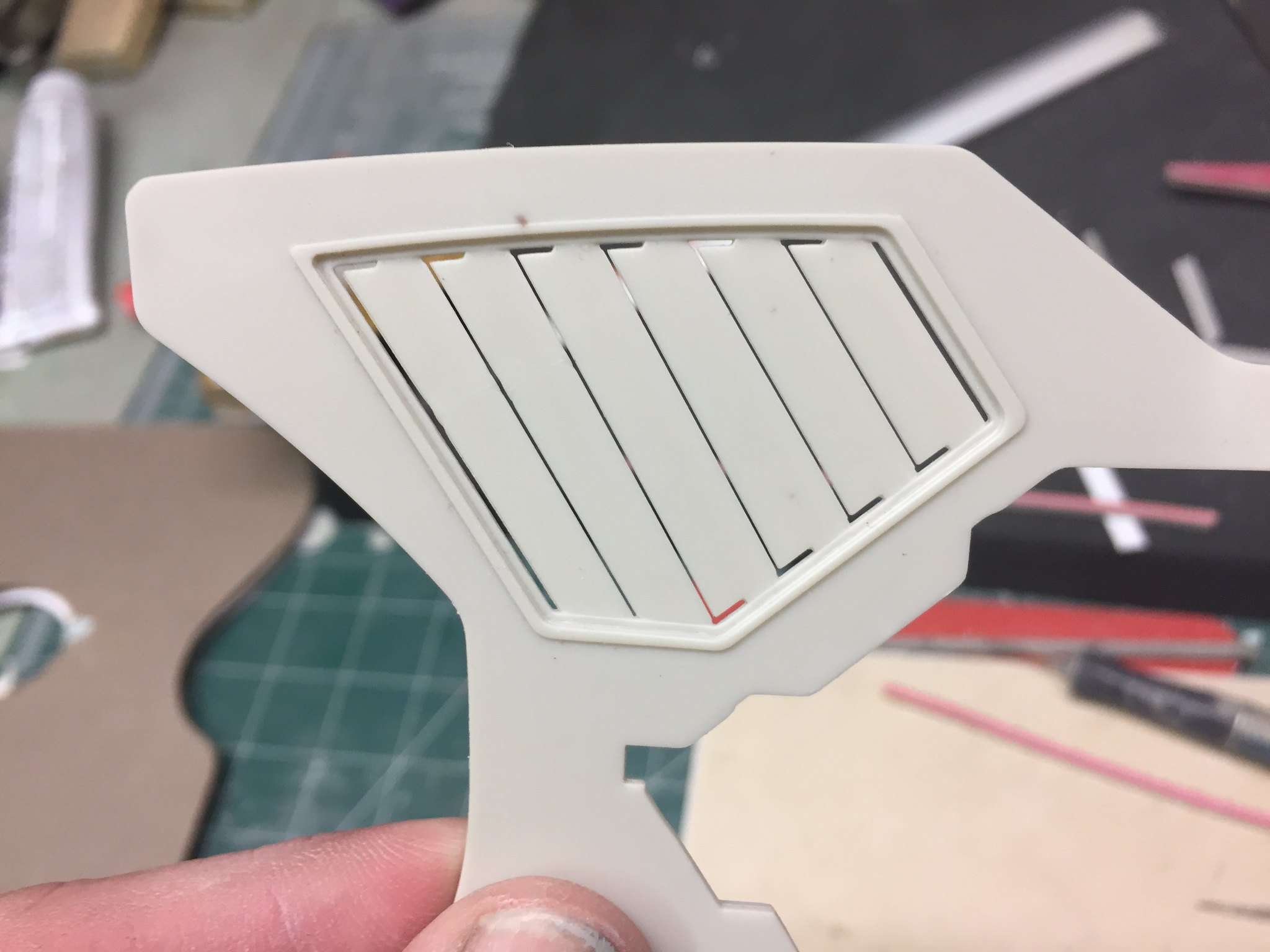

The large intakes below the windows have always posed a bit of a dilemma for Proteus modelers. On both the full-scale mockup and hero FX miniature the intakes are simply a pair of scooped-out cavities painted to create an illusion of depth. In the film the area just goes dark, but for my purposes I decided to add a pair of scratch-built styrene inner-grills. This required me to Dremmel out two openings in the intake part to accommodate the grills (the model comes with the six outer-grills moulded in place. I removed these, and will replace them later with sections of styrene T-bar).

4 by Carson Dyle, on Flickr

4 by Carson Dyle, on Flickr

On my test shot the intake part did not seat well against the interior of the hull. The part has since been corrected, but the poor fit required a bit of puttying before it would blend seamlessly into the lower hull.

7 by Carson Dyle, on Flickr

7 by Carson Dyle, on Flickr

8 by Carson Dyle, on Flickr

8 by Carson Dyle, on Flickr

9 by Carson Dyle, on Flickr

9 by Carson Dyle, on Flickr

The custom grills, designed to be inserted after the hull is finished, are just dropped temporarily into place here, but you get the idea. The surrounding area will eventually be airbrushed in progressively darkening tones to recreate the transition from white to black seen in the film.

10 by Carson Dyle, on Flickr

10 by Carson Dyle, on Flickr

- - - Updated - - -

As with any model kit, certain inaccuracies crop up. In this case the factory in China failed to properly recreate the sub’s keel, and the goof wasn’t discovered in time to correct (I’ll take the heat for that one). On both the full-scale mock-up and hero miniature the bottom of the keel should be even with the bottom of the lower hull where the two areas meet just forward of the lower hatch. This is where putty comes in handy.

11 by Carson Dyle, on Flickr

11 by Carson Dyle, on Flickr

A strip of styrene was glued into place along the bottom of the keel. The sides were then built up with putty. It may seem like a lot of work, but it took less than an hour to complete (I use Evercoat sanding putty, which makes tasks like this a lot easier).

12 by Carson Dyle, on Flickr

12 by Carson Dyle, on Flickr

13 by Carson Dyle, on Flickr

13 by Carson Dyle, on Flickr

14 by Carson Dyle, on Flickr

14 by Carson Dyle, on Flickr

15 by Carson Dyle, on Flickr

15 by Carson Dyle, on Flickr

16 by Carson Dyle, on Flickr

16 by Carson Dyle, on Flickr

17 by Carson Dyle, on Flickr

17 by Carson Dyle, on Flickr

- - - Updated - - -

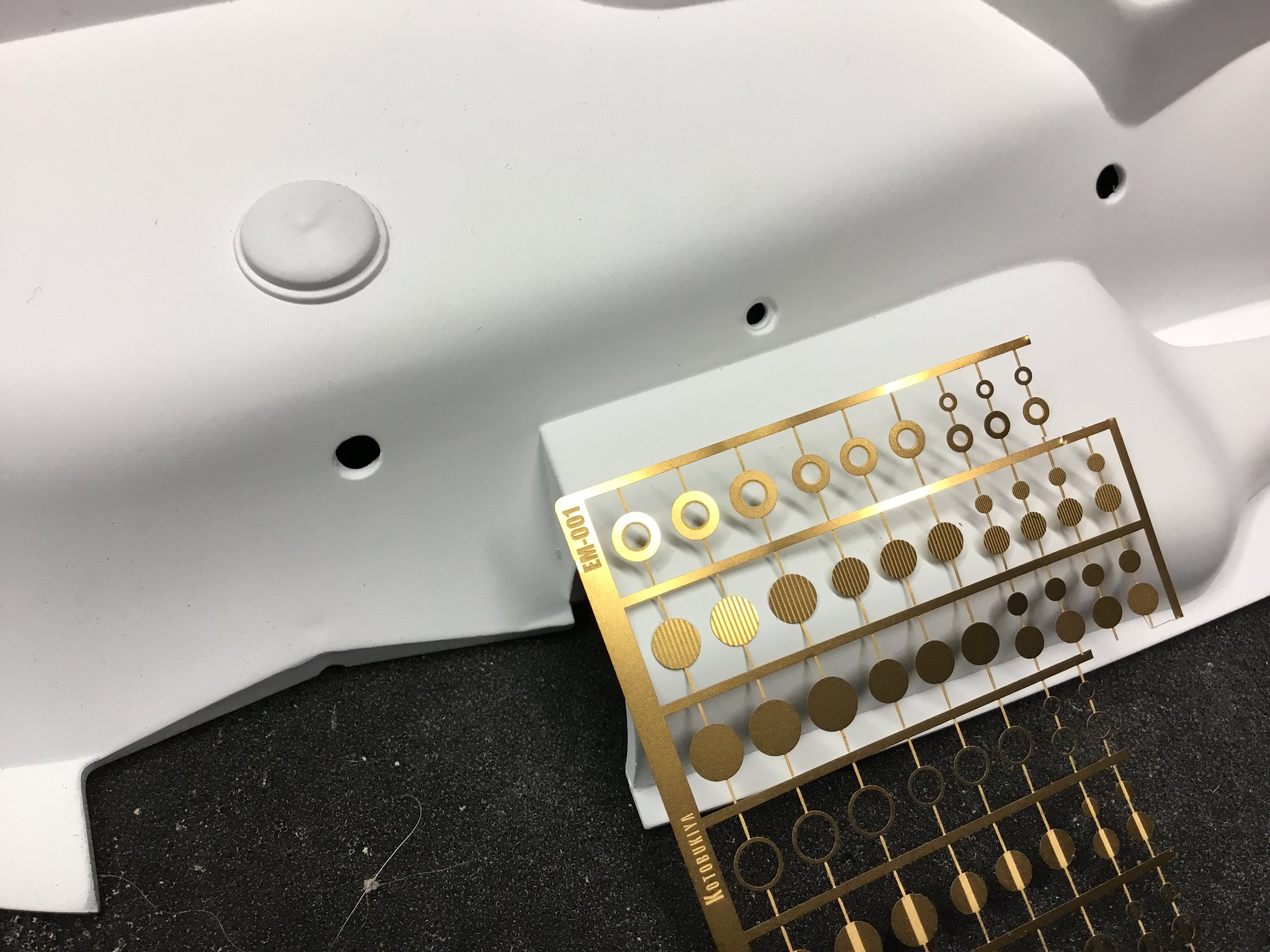

The model comes with ballast vents moulded into the hull. The detail is a little soft, so I removed the details in question. Eventually they’ll be replaced with either parts built from scratch, or aftermarket photo-etch (the etch shown here is just some stuff I had on hand).

18 by Carson Dyle, on Flickr

18 by Carson Dyle, on Flickr

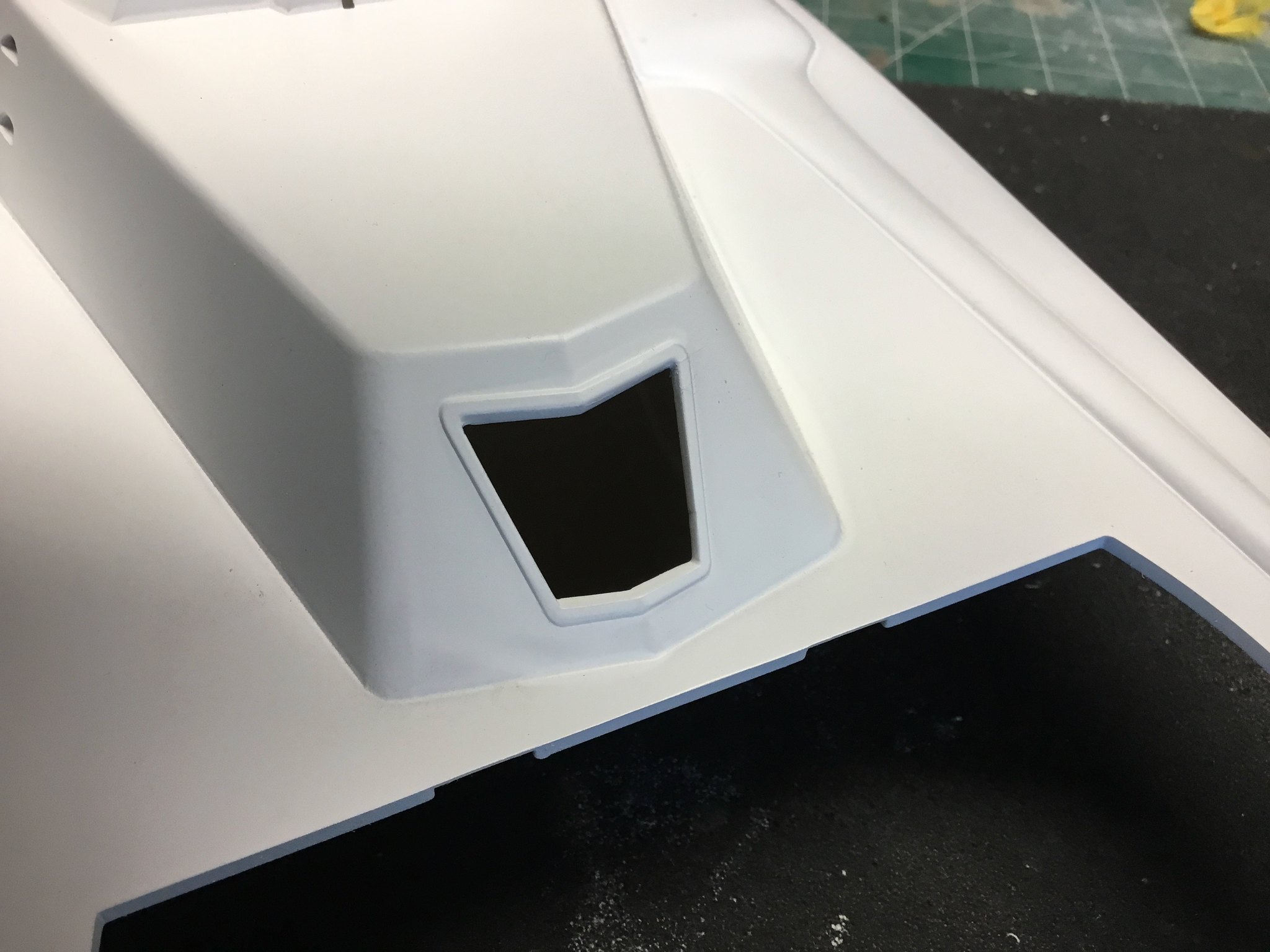

The model comes with the rear windows sealed (which is how they appear in the film). I chose to open them up, and will add clear styrene windows later.

19 by Carson Dyle, on Flickr

19 by Carson Dyle, on Flickr

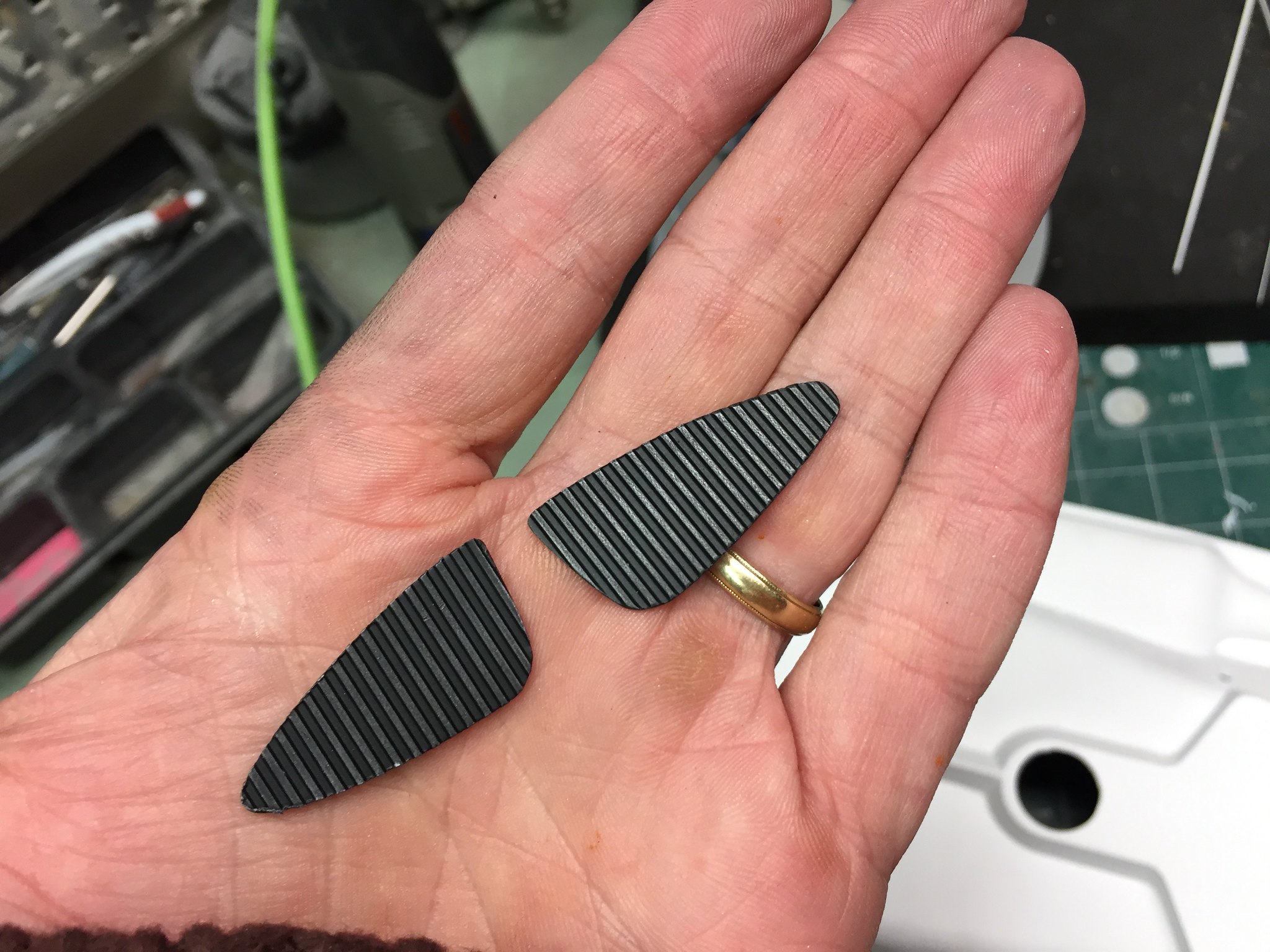

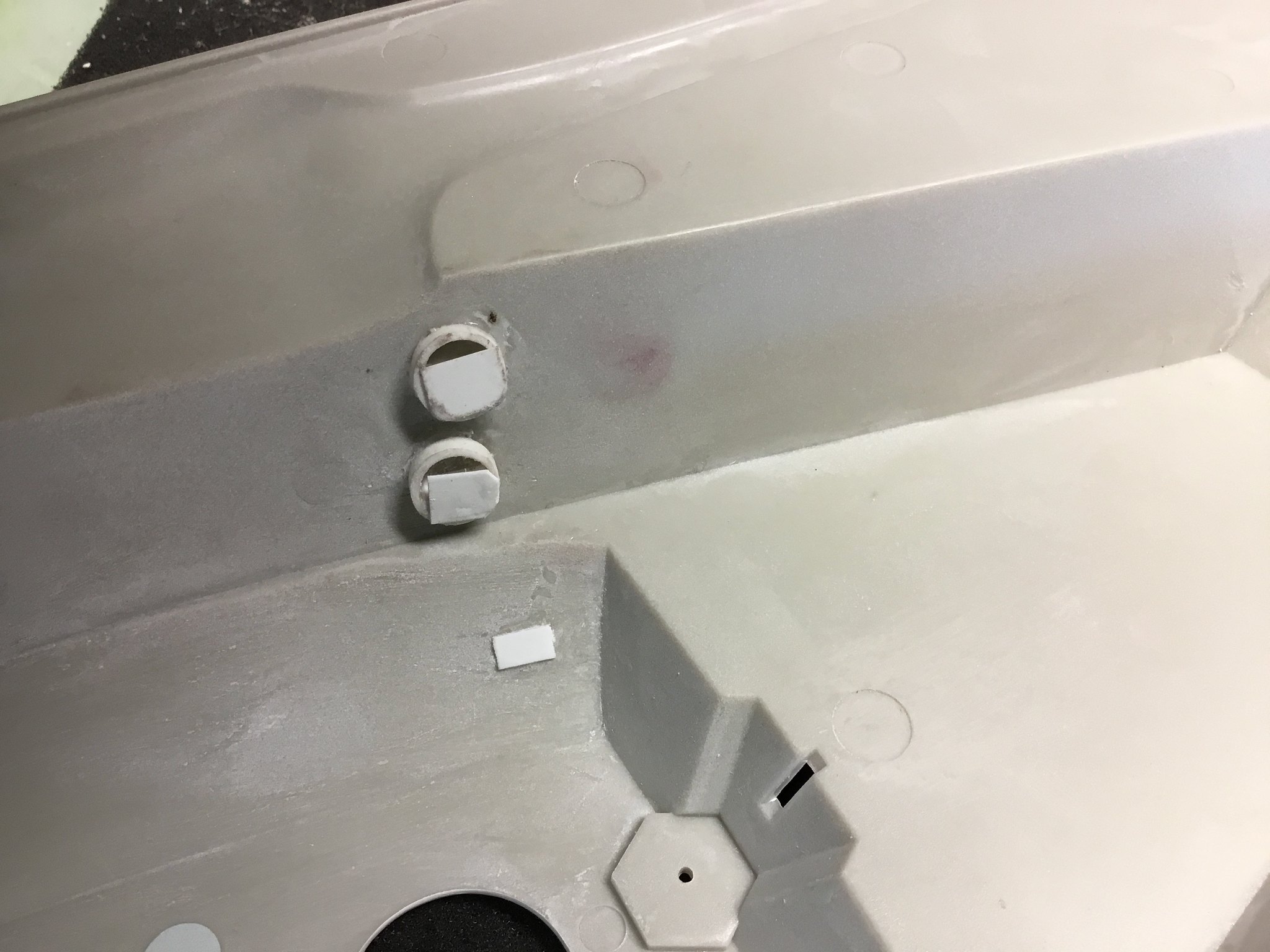

The sunken footholds looked a tad soft and shallow to me, so I opened them up, reshaped them, and fashioned simple backings, which were then bonded to the interior.

20 by Carson Dyle, on Flickr

20 by Carson Dyle, on Flickr

21 by Carson Dyle, on Flickr

21 by Carson Dyle, on Flickr

22 by Carson Dyle, on Flickr

22 by Carson Dyle, on Flickr

- - - Updated - - -

The next addition is more a matter of personal taste than screen accuracy; I added a thin strip of styrene to the leading edge of the prow. The intension is to create a more streamlined profile, but as you can see the effect is subtle.

23 by Carson Dyle, on Flickr

23 by Carson Dyle, on Flickr

23a by Carson Dyle, on Flickr

23a by Carson Dyle, on Flickr

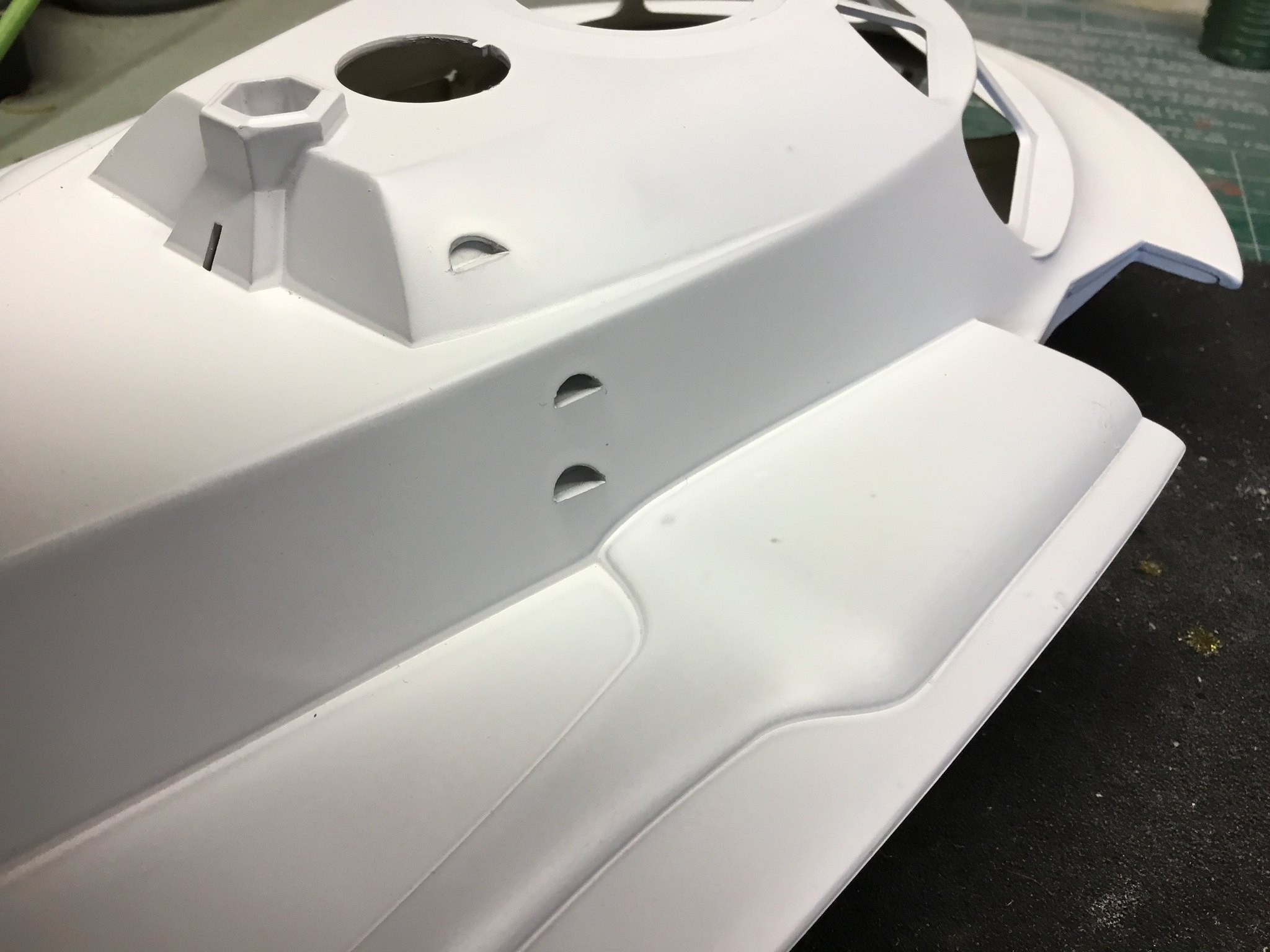

The propulsion nozzles are, unfortunately, moulded into the upper and lower hull halves (a cost-cutting choice). To avoid alignment problems later, I decided to carefully saw the nozzles away from the hull halves and assemble them separately. The parts will eventually be filled with putty, the thruster openings will be drilled out, and small locator pins will be attached for bonding the parts to the completed hull.

23b by Carson Dyle, on Flickr

23b by Carson Dyle, on Flickr

23c by Carson Dyle, on Flickr

23c by Carson Dyle, on Flickr

Other than the issue with the keel, my biggest regret is the tail. Owing to another factory error that wasn’t caught in time (blame me) the shape of the inner rudder frame is off. As a result, the six slats which comprise the rudder are irregular in shape. It’s subtle, but it’s there. Hopefully this flaw will be corrected for later editions of the kit, and in any case some modelers will no doubt decide to live with tail the way it is. It’s one of those things that drives me crazy, so eventually I will either scratch an all new replacement tail, or modify the existing part to accommodate aftermarket photo-etch (hurry up, Paul!). (-:

24 by Carson Dyle, on Flickr

24 by Carson Dyle, on Flickr

- - - Updated - - -

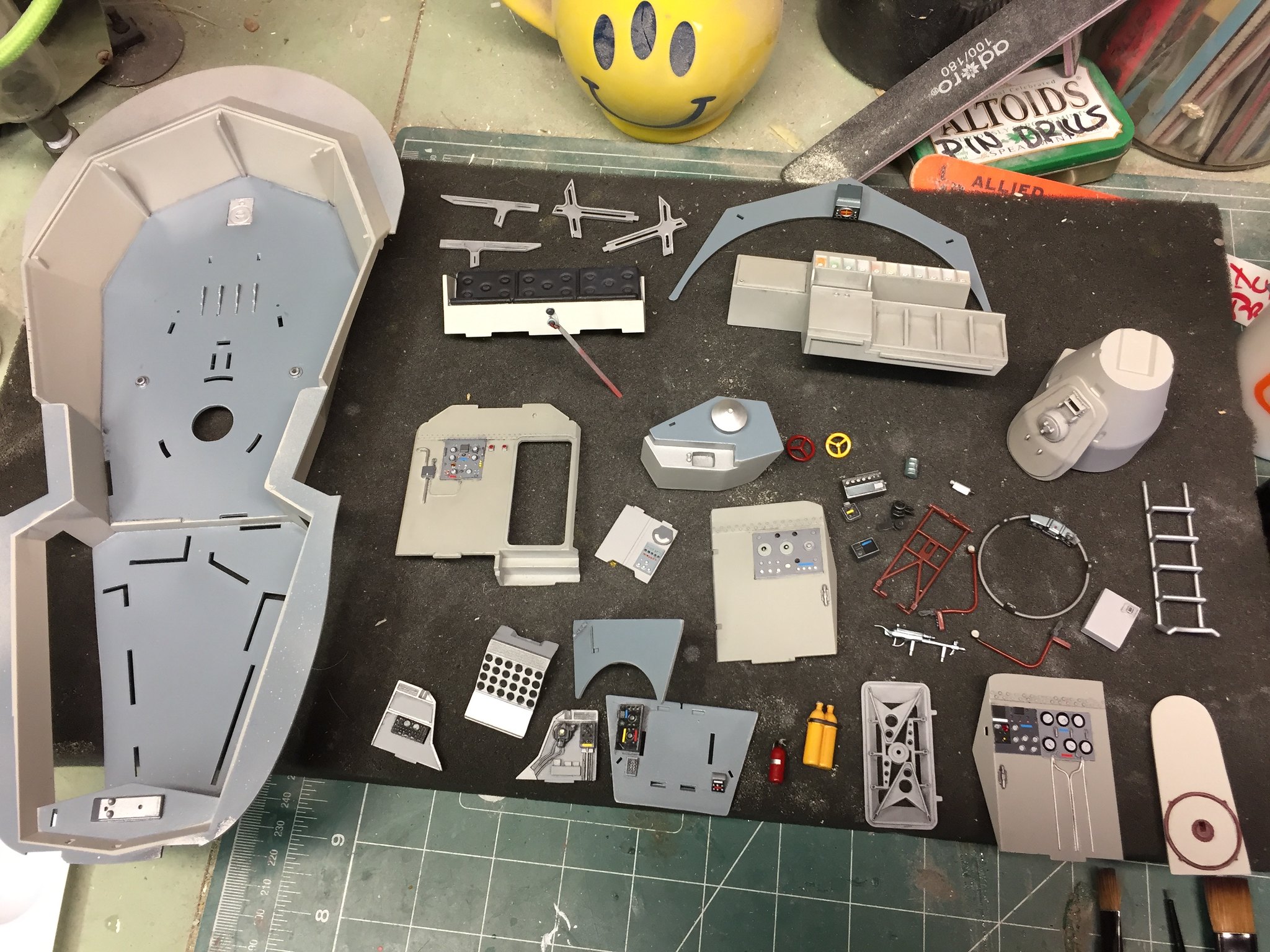

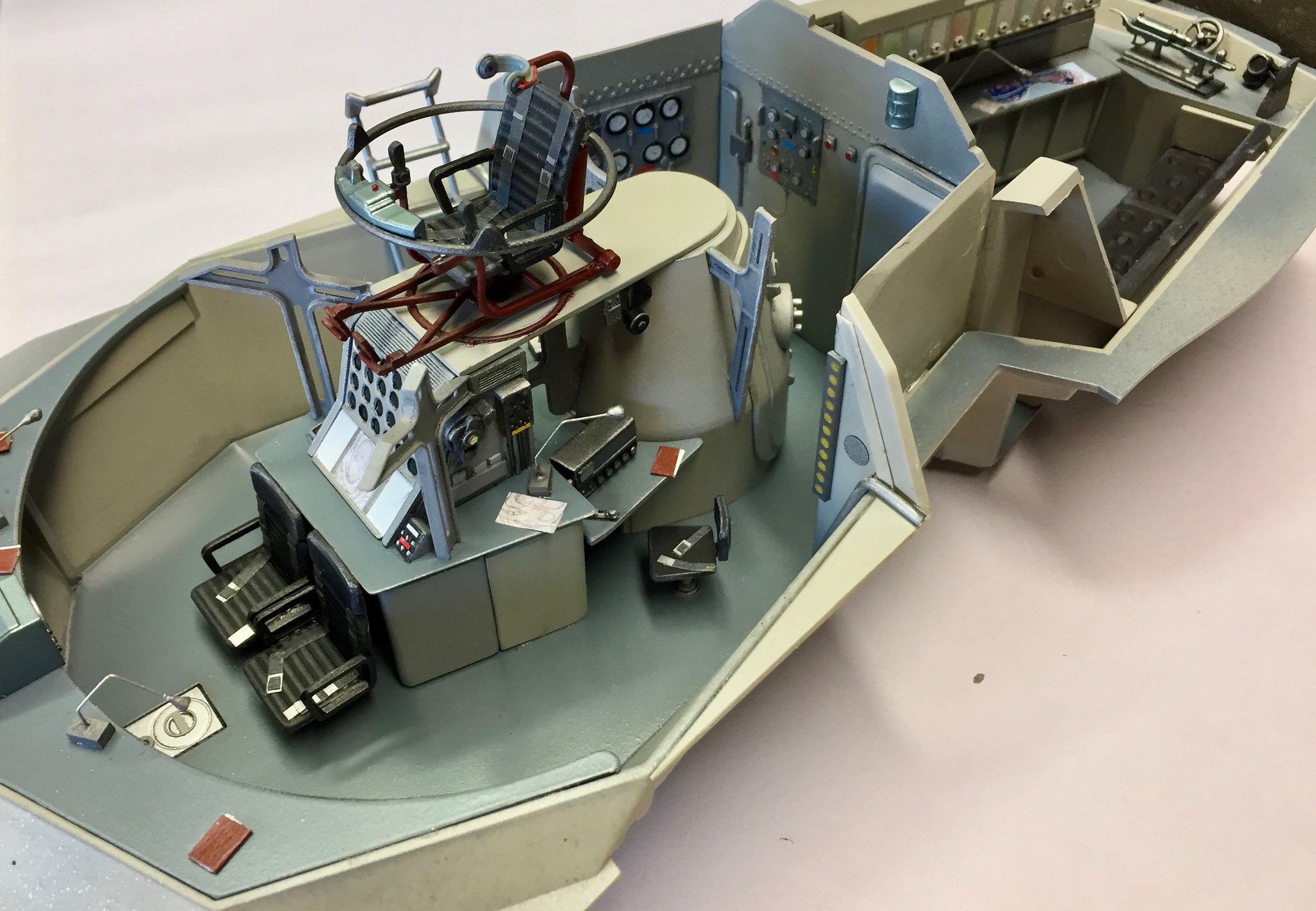

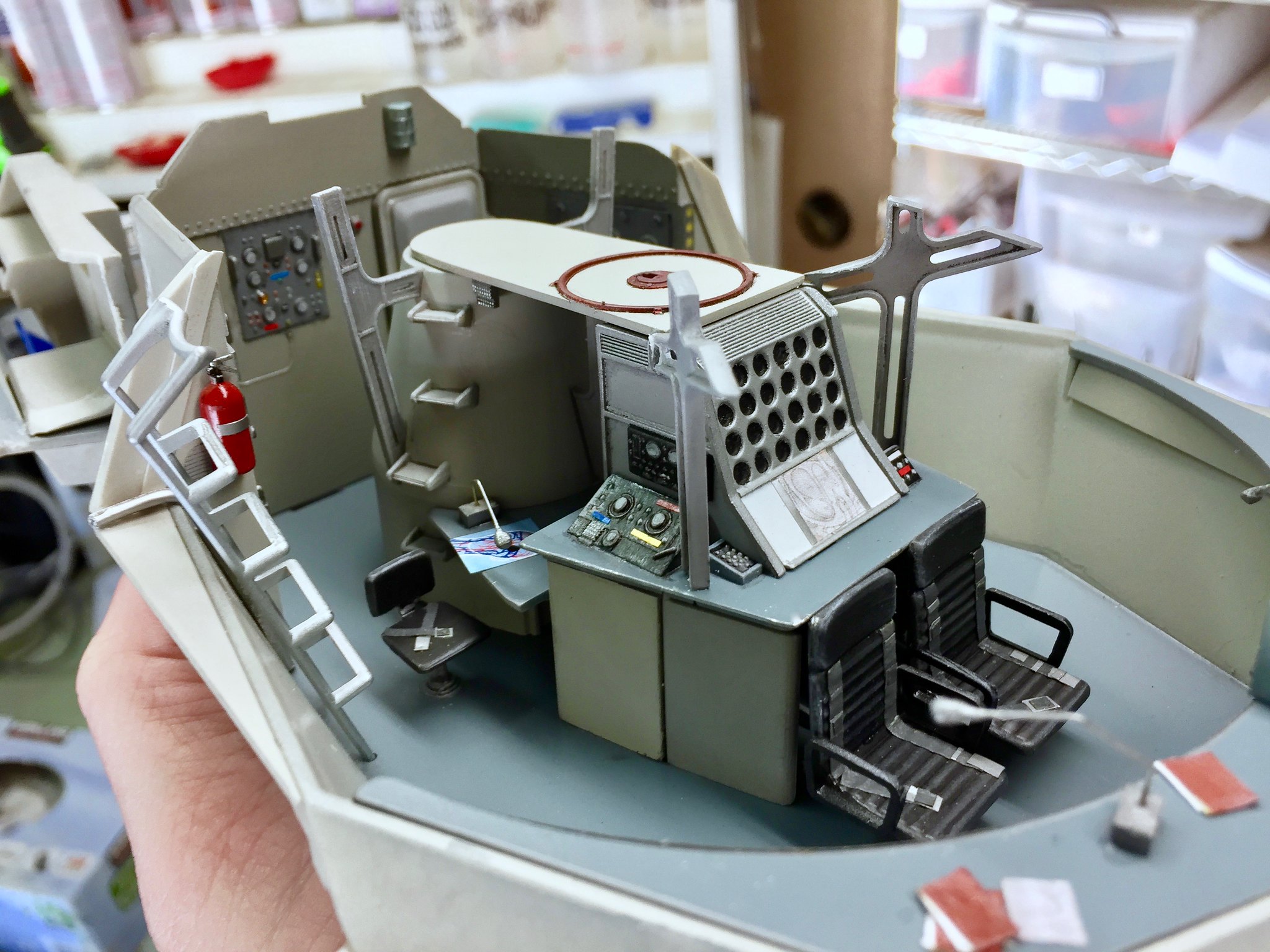

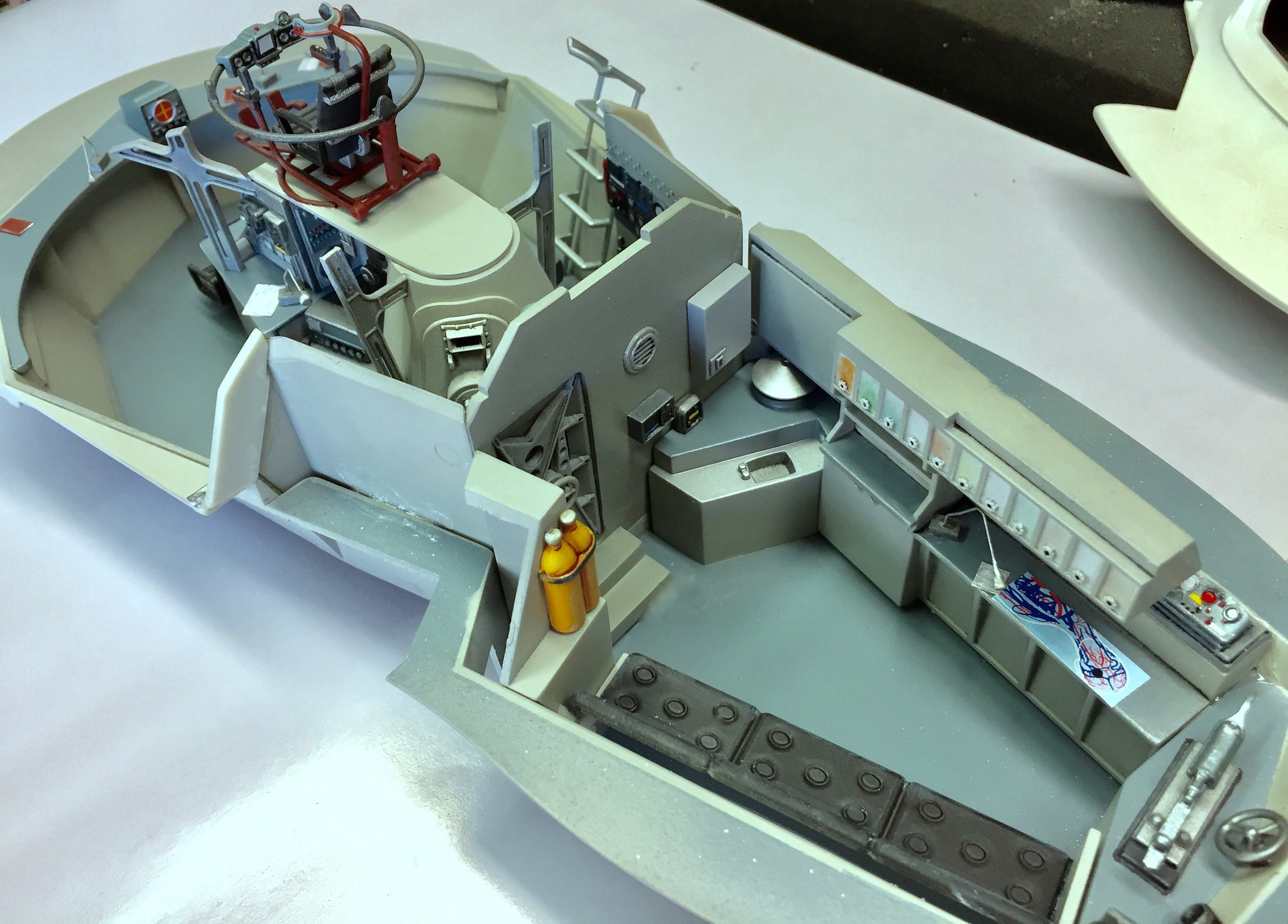

On to the interior. I’m always surprised by how many parts there are inside the Proteus. I tend to think of the interior as being rather simple, but it’s actually filled with detail. Per my usual approach to this sort of assembly, I pre-painted all the parts.

25 by Carson Dyle, on Flickr

25 by Carson Dyle, on Flickr

The only reference we have for the interior color scheme of the Proteus comes from the film itself (the miniaturizer room sequence is the most helpful owing the the relatively neutral ambient lighting). Lunadude’s CMDF site is a great resource for frame grabs, for those who don’t have a DVD of Fantastic Voyage.

Please note that the images I’m posting here have not been color-timed, so the grays I used are reading much greener than they appear to the naked eye. For the most part I've attempted to recreate the look of the film, I did take some liberties here and there (blue-grey floor instead of slate green, and so forth). Point being, please don’t mistake the images here as being the last word in screen accuracy… I just went with what I thought would look good.

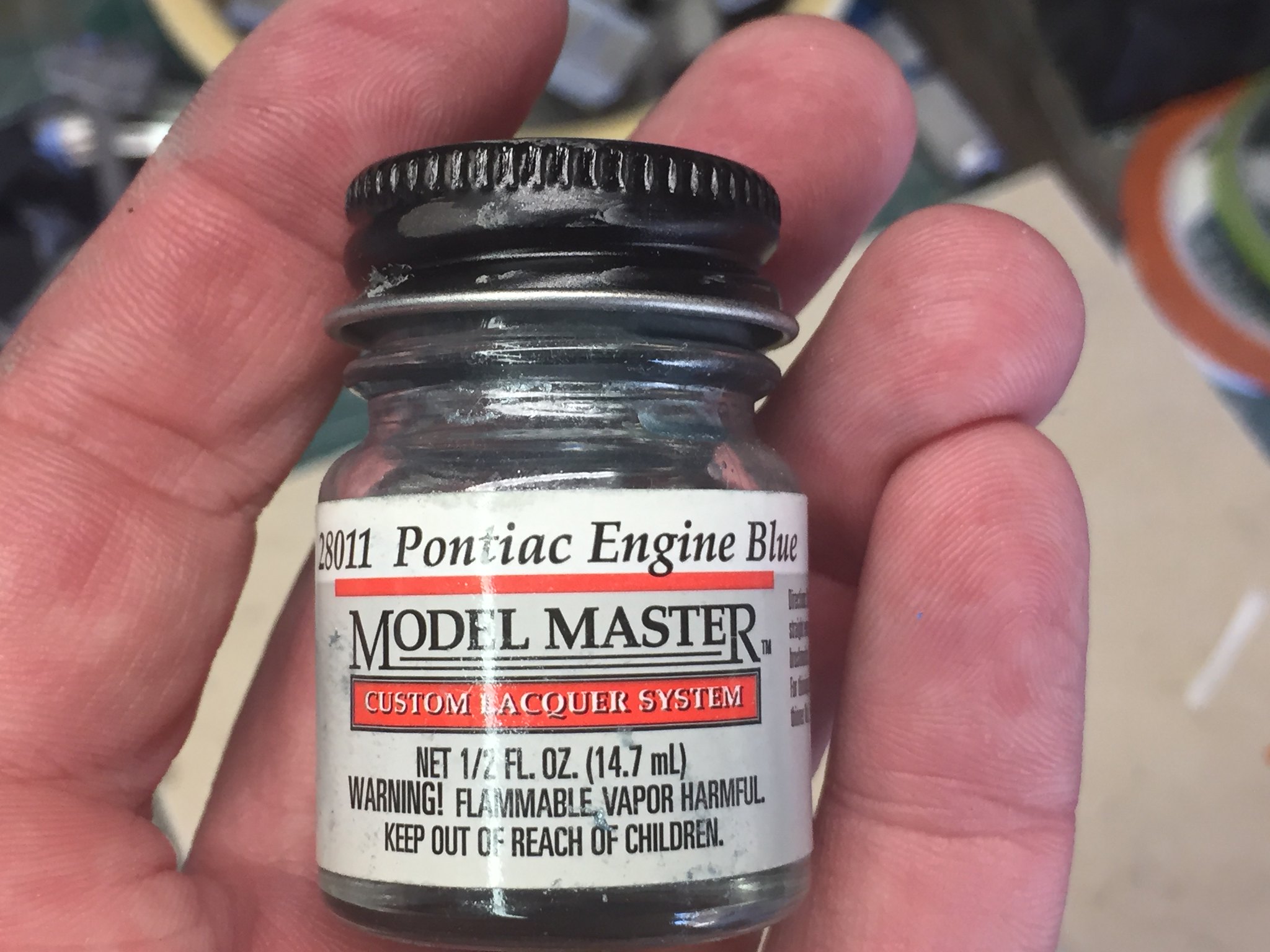

As I mentioned up-thread, this model will not be lit, so most of this detail will never be visible once the model is complete. My next Proteus model will be lit, so this was my opportunity to mess around with different techniques to see what worked. That said, here are a few paints that came in handy…

26 by Carson Dyle, on Flickr

26 by Carson Dyle, on Flickr

26b by Carson Dyle, on Flickr

26b by Carson Dyle, on Flickr

27 by Carson Dyle, on Flickr

27 by Carson Dyle, on Flickr

Model Master no longer makes Pontiac Engine Blue in lacquer (grrr), but I believe it’s still available in enamel and acylic. I mention it because that particular shade of silver-blue appears throughout Fantastic Voyage, as well as in many of Irwin Allen’s shows (it shows up inside the Planet of the Apes spaceship too). Fox must have had a ton of the stuff on hand, LOL.

28 by Carson Dyle, on Flickr

28 by Carson Dyle, on Flickr

29 by Carson Dyle, on Flickr

29 by Carson Dyle, on Flickr

30 by Carson Dyle, on Flickr

30 by Carson Dyle, on Flickr

31 by Carson Dyle, on Flickr

31 by Carson Dyle, on Flickr

A hole-punch came in handy for creating small paint masks for the chart table (I still need to find something suitable scale-wise to use as protruding charts; suggestions welcome!).

32 by Carson Dyle, on Flickr

32 by Carson Dyle, on Flickr

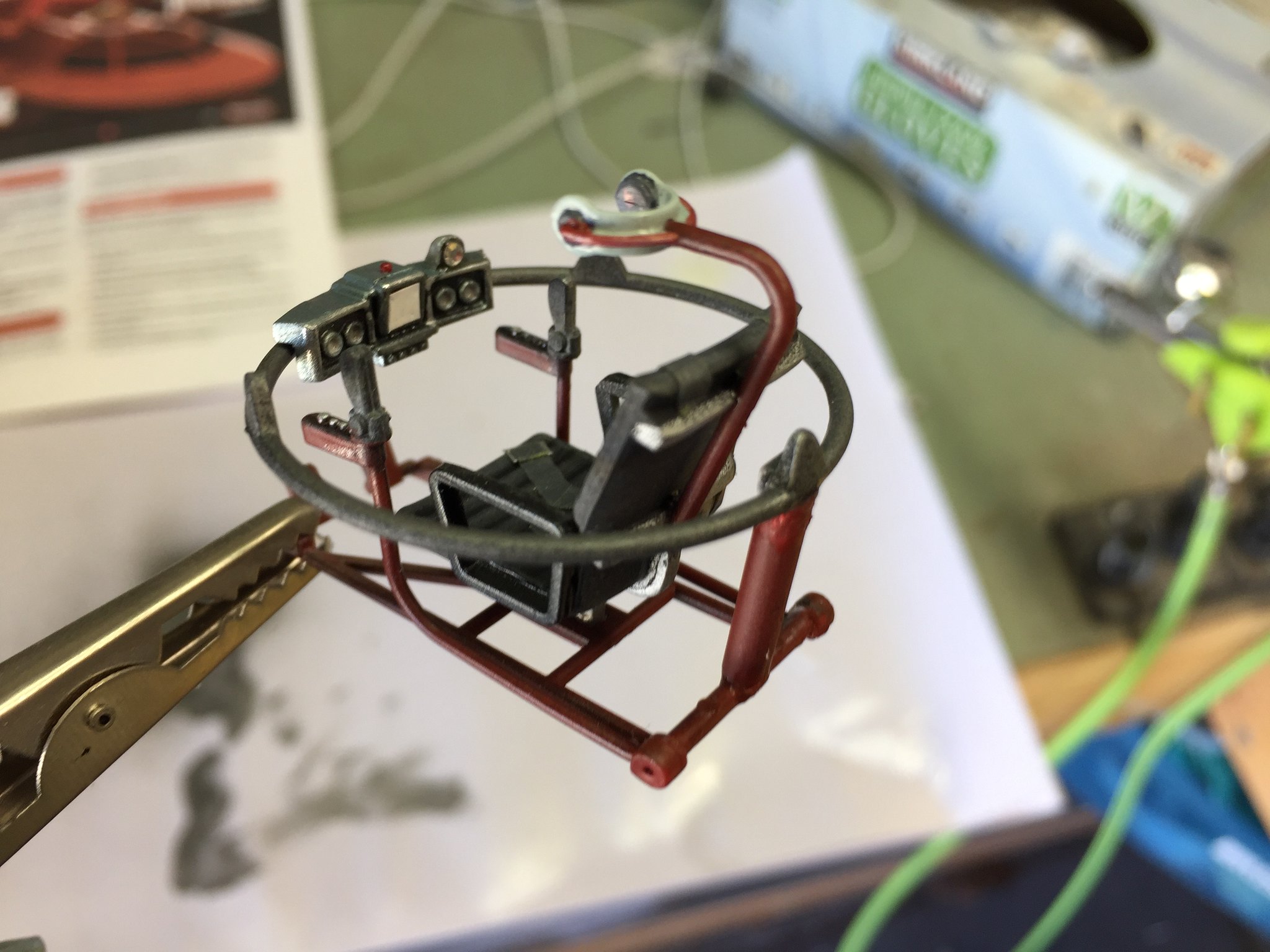

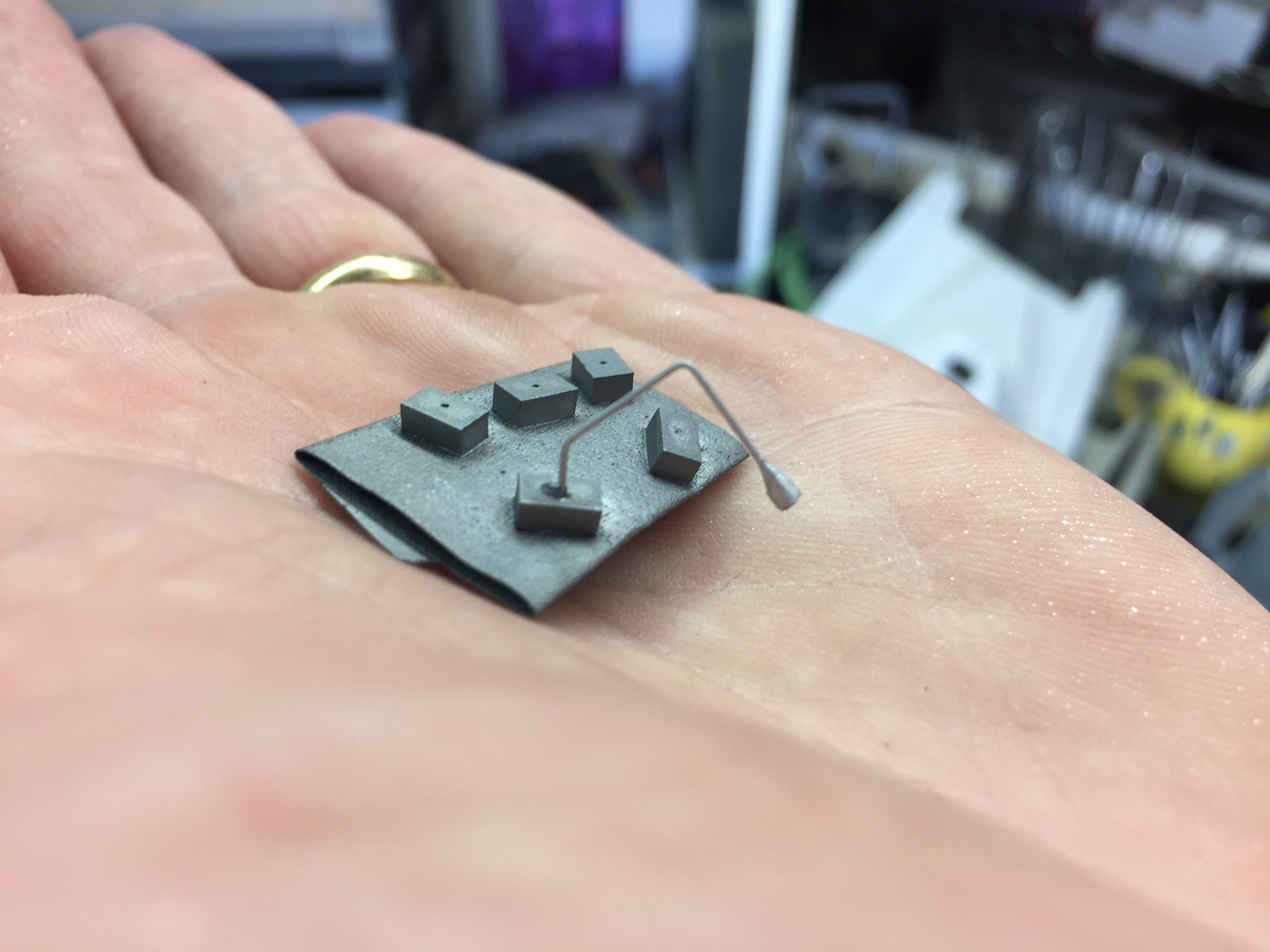

There are five reading lamps inside the Proteus. These are not included as parts, but they are easily recreated with a little wire and styrene chip. A drop of thick crazy glue promptly accompanied by a spritz of accelerator was used to fashion the shades.

33 by Carson Dyle, on Flickr

33 by Carson Dyle, on Flickr

- - - Updated - - -

Semi-accurate seat-belts were made from from Tamiya masking tape, along with bits of silver pin-striping tape. The circular air vents, accidentally omitted from the kit, were fashioned from aftermarket etch I had laying around. The vertical bar of “elevator lights” (also omitted from the kit) was similarly added, along with random print-outs, charts, file-folders, etc.

34 by Carson Dyle, on Flickr

34 by Carson Dyle, on Flickr

35 by Carson Dyle, on Flickr

35 by Carson Dyle, on Flickr

36 by Carson Dyle, on Flickr

36 by Carson Dyle, on Flickr

Test-fit of the interior assembly mated with the upper hull (the inner window frame is not yet attached, hence the gap between the inner bulkhead and the support braces).

37 by Carson Dyle, on Flickr

37 by Carson Dyle, on Flickr

The windows come moulded as a single piece, which, when mated with the inner window frame, nests perfectly against the inside of the upper hull. This will no doubt be completely acceptable for 90% of Proteus modelers. For those wishing a more scale-appropriate glass thickness, the clear styrene window part can be trimmed into four separate panes, which may then be used as scribing templates for the creation of replacement panes (I used a suitably thin gage of clear styrene sheet, carefully scribing around the edges of the template parts to get the correct shape).

38 by Carson Dyle, on Flickr

38 by Carson Dyle, on Flickr

The most visually important feature of this kit (IMO) is the window assembly. One's eye goes right to that area, so a crisp, clean look is highly desirable. Fortunately, because of the way the upper and lower hull halves are engineered to fit together (with the seam semi-hidden along the lower hull’s flange), it should be possible to completely paint the upper hull prior to installing the windows. Not only is this is a HUGE time saver in terms of window masking (none required!), it also means that if the builder takes his time to install the windows carefully, avoiding glue smears, the windows should set perfectly into to the surrounding hull and frame with no jagged or irregular paint build-up due to masking.

Which leaves us with the issue of the black weather-stripping around the windows. I wish I had an easy solution, but I’m still pondering my options (as always, suggestions are welcome!).

This brings ya'll up to speed with my current progress. Next up: dealing with the aforementioned tail/ rudder irregularities. By the time of my next post an aftermarket solution will hopefully have presented itself (tick tock, Paul). Otherwise I suppose I’ll have to CAD up an accurate rudder assembly template and scratch a new tail from styrene.

Thanks for looking! And stay tuned!!

Having built a couple very fine Garage Kits of this subject I hafta say it’s WONDERFUL to finally be working in injection-moulded styrene!

The instructions are well laid-out, and are accompanied by pix of Moebius’s test build.

2 by Carson Dyle, on Flickr

2 by Carson Dyle, on FlickrSo let’s get started!

PHASE 1

The first order of business was making a few modifications to the upper and lower hull halves. It’s important to note that none of these tweaks are required, and the modeler is free to either emulate or ignore them. I should also note that this kit (which I’m building for a friend) will not be lit. I’ll save that ad-on for my own Proteus build.

The large intakes below the windows have always posed a bit of a dilemma for Proteus modelers. On both the full-scale mockup and hero FX miniature the intakes are simply a pair of scooped-out cavities painted to create an illusion of depth. In the film the area just goes dark, but for my purposes I decided to add a pair of scratch-built styrene inner-grills. This required me to Dremmel out two openings in the intake part to accommodate the grills (the model comes with the six outer-grills moulded in place. I removed these, and will replace them later with sections of styrene T-bar).

On my test shot the intake part did not seat well against the interior of the hull. The part has since been corrected, but the poor fit required a bit of puttying before it would blend seamlessly into the lower hull.

The custom grills, designed to be inserted after the hull is finished, are just dropped temporarily into place here, but you get the idea. The surrounding area will eventually be airbrushed in progressively darkening tones to recreate the transition from white to black seen in the film.

- - - Updated - - -

As with any model kit, certain inaccuracies crop up. In this case the factory in China failed to properly recreate the sub’s keel, and the goof wasn’t discovered in time to correct (I’ll take the heat for that one). On both the full-scale mock-up and hero miniature the bottom of the keel should be even with the bottom of the lower hull where the two areas meet just forward of the lower hatch. This is where putty comes in handy.

A strip of styrene was glued into place along the bottom of the keel. The sides were then built up with putty. It may seem like a lot of work, but it took less than an hour to complete (I use Evercoat sanding putty, which makes tasks like this a lot easier).

- - - Updated - - -

The model comes with ballast vents moulded into the hull. The detail is a little soft, so I removed the details in question. Eventually they’ll be replaced with either parts built from scratch, or aftermarket photo-etch (the etch shown here is just some stuff I had on hand).

The model comes with the rear windows sealed (which is how they appear in the film). I chose to open them up, and will add clear styrene windows later.

The sunken footholds looked a tad soft and shallow to me, so I opened them up, reshaped them, and fashioned simple backings, which were then bonded to the interior.

- - - Updated - - -

The next addition is more a matter of personal taste than screen accuracy; I added a thin strip of styrene to the leading edge of the prow. The intension is to create a more streamlined profile, but as you can see the effect is subtle.

The propulsion nozzles are, unfortunately, moulded into the upper and lower hull halves (a cost-cutting choice). To avoid alignment problems later, I decided to carefully saw the nozzles away from the hull halves and assemble them separately. The parts will eventually be filled with putty, the thruster openings will be drilled out, and small locator pins will be attached for bonding the parts to the completed hull.

Other than the issue with the keel, my biggest regret is the tail. Owing to another factory error that wasn’t caught in time (blame me) the shape of the inner rudder frame is off. As a result, the six slats which comprise the rudder are irregular in shape. It’s subtle, but it’s there. Hopefully this flaw will be corrected for later editions of the kit, and in any case some modelers will no doubt decide to live with tail the way it is. It’s one of those things that drives me crazy, so eventually I will either scratch an all new replacement tail, or modify the existing part to accommodate aftermarket photo-etch (hurry up, Paul!). (-:

- - - Updated - - -

On to the interior. I’m always surprised by how many parts there are inside the Proteus. I tend to think of the interior as being rather simple, but it’s actually filled with detail. Per my usual approach to this sort of assembly, I pre-painted all the parts.

The only reference we have for the interior color scheme of the Proteus comes from the film itself (the miniaturizer room sequence is the most helpful owing the the relatively neutral ambient lighting). Lunadude’s CMDF site is a great resource for frame grabs, for those who don’t have a DVD of Fantastic Voyage.

Please note that the images I’m posting here have not been color-timed, so the grays I used are reading much greener than they appear to the naked eye. For the most part I've attempted to recreate the look of the film, I did take some liberties here and there (blue-grey floor instead of slate green, and so forth). Point being, please don’t mistake the images here as being the last word in screen accuracy… I just went with what I thought would look good.

As I mentioned up-thread, this model will not be lit, so most of this detail will never be visible once the model is complete. My next Proteus model will be lit, so this was my opportunity to mess around with different techniques to see what worked. That said, here are a few paints that came in handy…

Model Master no longer makes Pontiac Engine Blue in lacquer (grrr), but I believe it’s still available in enamel and acylic. I mention it because that particular shade of silver-blue appears throughout Fantastic Voyage, as well as in many of Irwin Allen’s shows (it shows up inside the Planet of the Apes spaceship too). Fox must have had a ton of the stuff on hand, LOL.

A hole-punch came in handy for creating small paint masks for the chart table (I still need to find something suitable scale-wise to use as protruding charts; suggestions welcome!).

There are five reading lamps inside the Proteus. These are not included as parts, but they are easily recreated with a little wire and styrene chip. A drop of thick crazy glue promptly accompanied by a spritz of accelerator was used to fashion the shades.

- - - Updated - - -

Semi-accurate seat-belts were made from from Tamiya masking tape, along with bits of silver pin-striping tape. The circular air vents, accidentally omitted from the kit, were fashioned from aftermarket etch I had laying around. The vertical bar of “elevator lights” (also omitted from the kit) was similarly added, along with random print-outs, charts, file-folders, etc.

Test-fit of the interior assembly mated with the upper hull (the inner window frame is not yet attached, hence the gap between the inner bulkhead and the support braces).

The windows come moulded as a single piece, which, when mated with the inner window frame, nests perfectly against the inside of the upper hull. This will no doubt be completely acceptable for 90% of Proteus modelers. For those wishing a more scale-appropriate glass thickness, the clear styrene window part can be trimmed into four separate panes, which may then be used as scribing templates for the creation of replacement panes (I used a suitably thin gage of clear styrene sheet, carefully scribing around the edges of the template parts to get the correct shape).

The most visually important feature of this kit (IMO) is the window assembly. One's eye goes right to that area, so a crisp, clean look is highly desirable. Fortunately, because of the way the upper and lower hull halves are engineered to fit together (with the seam semi-hidden along the lower hull’s flange), it should be possible to completely paint the upper hull prior to installing the windows. Not only is this is a HUGE time saver in terms of window masking (none required!), it also means that if the builder takes his time to install the windows carefully, avoiding glue smears, the windows should set perfectly into to the surrounding hull and frame with no jagged or irregular paint build-up due to masking.

Which leaves us with the issue of the black weather-stripping around the windows. I wish I had an easy solution, but I’m still pondering my options (as always, suggestions are welcome!).

This brings ya'll up to speed with my current progress. Next up: dealing with the aforementioned tail/ rudder irregularities. By the time of my next post an aftermarket solution will hopefully have presented itself (tick tock, Paul). Otherwise I suppose I’ll have to CAD up an accurate rudder assembly template and scratch a new tail from styrene.

Thanks for looking! And stay tuned!!

Last edited: