First things first...

Realize that this thing is going to get TRASHED, if you work on it a lot. So... and this is absolutely critical, as far as I'm concerned... make sure that you can easily replace the top surface. In my case, I have a top laminate sheet which is clamped down, around all edges, to the underlying substrate. The top layer is fine-surfaced euca-board (designed for wall paneling), and it's clamped by aluminum extrusions on all edges (with set-screws on the underside to allow clamping and unclamping.

This provides an easily replaceable top surface (which you'll likely want to do periodically... say, every two years... without having to totally rebuild!). The extrusion used to clamp it down provides a nice "rim" to the top surface, which prevents tiny parts from rolling off the surface.

The top should be a minimum of 24" deep. 30" or even 36" is not unreasonable if you have the space.

You want a power-strip mounted on the wall right behind the desktop... if you want jars and other part carriers along the rear edge, be sure to mount it high enough to clear those easily (my own is 8" above the top work surface). They make LARGE power strips, specifically intended for this purpose... ranging from 4' to 6' in length, usually. Get the biggest one which fits within the space you'll be using. Ideally, get one with "covers" over the unused plugs, and the highest total capacity you can get (you want your circuit breaker, not the power strip, to be the "point of failure" if you overload things!)

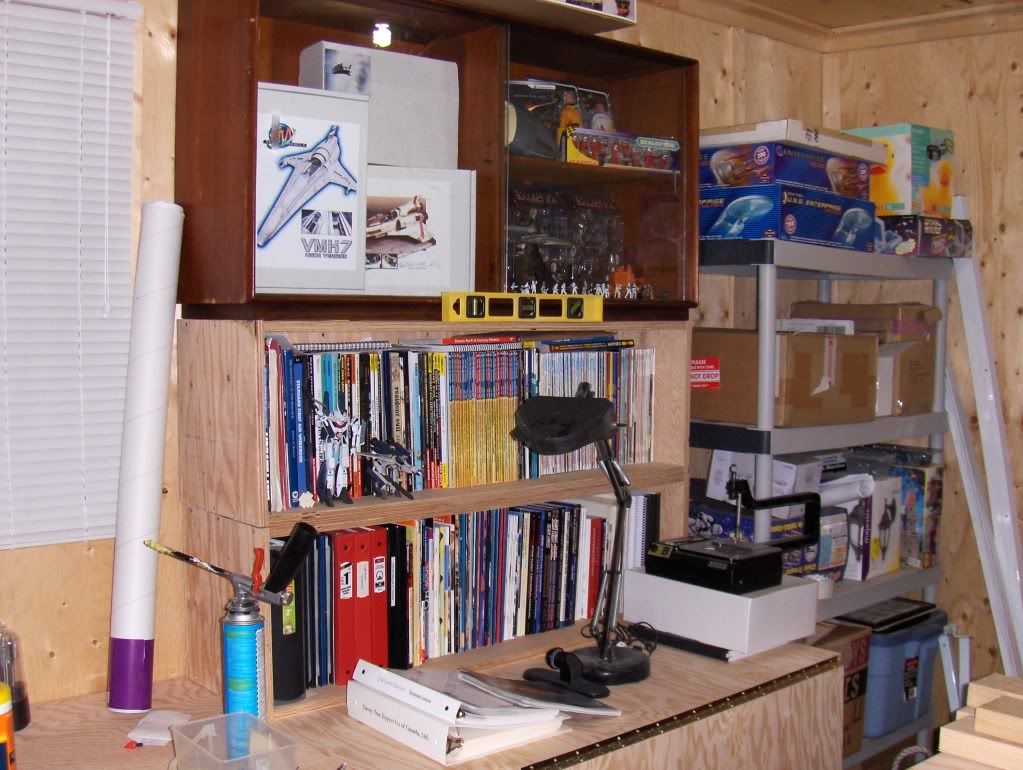

A pegboard is always useful... especially with little bins which can be mounted to the pegboard. My own goes from the top of the work surface (with the power strip mounted directly to it) My own is 2' tall, total.

Above that, I have wire-mesh shelves mounted to the wall. The deeper ones, not the little 12" ones. These are good for storing model boxes, boxes filled with sandpaper, etc. LARGE stuff which you don't need regular access to. I have two tiers of these 20" stuff above my working area, but 16" would probably have been good enough, in retrospect, for most purposes. This stuff is cheap, and very useful, if not "pretty" (as my wife likes to point out).

There should be one or two SHALLOW shelves underneath the workbench. 8" or 10" is normally fine. You want to be able to store your heavier stuff (power tools, etc) down there, without knocking your knees on them all the time. These are not going to be wire shelves, most likely... but rather wooden ones (or rather "pressed wood" if you buy your stuff at Home Depot, etc) Paints, thinner, etc. Whatever's too bulky to just leave on the bench, too heavy to want way up over your head, and which you (probably) want more frequent access to.

You need a COMFORTABLE seat. Trust me on this... DO NOT SKIMP on seating. I have a "Drafter's chair" with a very cushy seat. My feet don't touch the floor when I'm on that at its "normal" height. This allows me to sit while working, OR stand while working, with the bench at the proper height for either. If you use a regular chair, you won't be able to stand while working, or else you'll need to have a standing-height bench and won't be able to sit while working. The drafter's stool is the perfect solution to that. It has a back, it spins, but the base is stationary. And it has a "rung" on the main body at the proper height for my feet to rest on. (I also often rest my feet on one of the shelves underneath my workbench.)

You need good lighting. I recommend having a hanging lamp (there are some great LED-based "shop lamps" available these days), AND a "daylight lamp" clamped to your workbench surface, on a moveable arm. Many of these come with a magnifier included as well... something to consider. I don't have the magnifier, and instead use my magnifying goggles or loupe, but you may want to do differently. The hanging "shop lamp" is a necessity, but having a moveable light source to focus on whatever you're doing at the time is a huge help. "Daylight" lamps are my own personal preference... you don't want a lamp which puts out "blue" light (many standard flourescents) or "yellow" light (standard incandescents and tungsten lamps). LED "Daylight" lamps are really the best choice, I think.

Finally... if you're working there a LOT... give some consideration to having a little mini-fridge. I have one, which has cans of stuff to drink, and is also where I store my cyanoacrylate glues (to lengthen their shelf life). If you keep them in there, remember to take them back out and let them warm up before using them (otherwise they'll be too thick to work with most likely, and will cure slower than you might like). I keep mine in an airtight container, inside the fridge, to prevent any potential for cyanide-based gases from getting into anything else I might keep in there.

That's what I would consider to be a "perfect" workspace. My own is CLOSE, but because I used 20" shelving, my hanging lamp is a bit further back than I'd have preferred, making the clamped lamp much more necessary than it really needed to be.

And one last point... if you're doing "permanent" installation, that's one thing. But if you're in an apartment, or expect to move regularly, you may want to get "locking casters" for your bench rather than merely resting its legs on the floor.

And also, if you ever expect to move, make sure that you can get your bench, without disassembly, through the doors coming in and out of where you live (or wherever you might live in the future!)