I bought one of the recent qmx Mals pistols and when i got it it had a twisted barrel. I was going to send it back and QMX did offer to replace it but i have since decided to fix it myself. While fixing it i decided i might as well turn it into a project and upgrade it With working trigger and hammer and maybe some wood grips.

First thing was to cut the barrel off. I used an xacto saw and went around the barrel sawing a little on each flat until it was around 5/16 threw and the rest snapped off.

Then using a palm sander with 180 grit i flattened the ends down. This left a slightly rounded surface. To fix it i sanded it down on a flat file. Pull the gun in one direction only, from the tip of the file back to the handle turning it 90degrees after each pull untill its flat. Then i did the barrel, blurry friggin pictures..

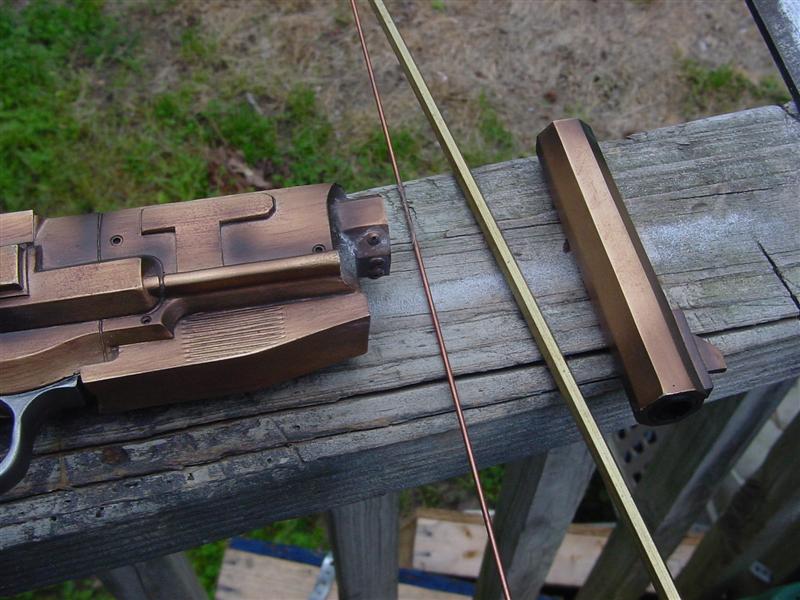

I then found some brass tube to give the barrel some support. I am guessing the prop is like this too but the finish is closer to copper color than brass. I know bronze has a tint but man thats copperish colored.

I then took this dremel bit and ground a hole into the end of the gun and barrel for the brass tube. I could have used a drill but i was worried that either piece could split or shatter.

.....and then i noticed that the barrel has slight upward bend to it too, i guess it wasn't noticable because the barrel was mounted twisted.

Take it inside and yup its bent.

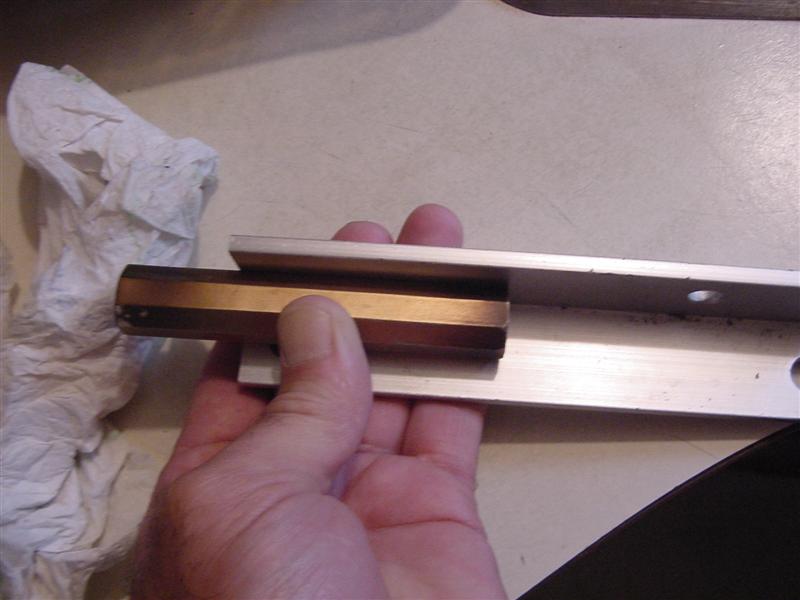

I tried hot water from the tap but that wasn't really working so i boiled some water, let it sit a few minutes and then poured it to this plastic cup with the barrel inside. I let it sit for awhile and then bent it back as best i could and held it against a piece of angle aluminum. This way you keep it straight on 2 angles. While i held it on the alum i held it under cold running water. It did take a few times to get it right. I didn't want to force it and bust it.

I used an angle to check it's squarness and now that it's straight the end is slightly crooked.

A little file work and its straightish again on both axis.

Did a check on the gun for squarness and it looked ok. You kinda have to eye it here as the receiver is not straight.

Just setting it up there and it looks OK, about as good as i can get it. Looks a little crooked in the pic but its because i was struggling to hold it and the camera all steady and straight. I failed.

For those wondering, the screws in the grip are just big setscrews. If yours are crooked just unscrew them, they came right out. May have to glue them back but i will probably go with some allen screws.

First thing was to cut the barrel off. I used an xacto saw and went around the barrel sawing a little on each flat until it was around 5/16 threw and the rest snapped off.

Then using a palm sander with 180 grit i flattened the ends down. This left a slightly rounded surface. To fix it i sanded it down on a flat file. Pull the gun in one direction only, from the tip of the file back to the handle turning it 90degrees after each pull untill its flat. Then i did the barrel, blurry friggin pictures..

I then found some brass tube to give the barrel some support. I am guessing the prop is like this too but the finish is closer to copper color than brass. I know bronze has a tint but man thats copperish colored.

I then took this dremel bit and ground a hole into the end of the gun and barrel for the brass tube. I could have used a drill but i was worried that either piece could split or shatter.

.....and then i noticed that the barrel has slight upward bend to it too, i guess it wasn't noticable because the barrel was mounted twisted.

Take it inside and yup its bent.

I tried hot water from the tap but that wasn't really working so i boiled some water, let it sit a few minutes and then poured it to this plastic cup with the barrel inside. I let it sit for awhile and then bent it back as best i could and held it against a piece of angle aluminum. This way you keep it straight on 2 angles. While i held it on the alum i held it under cold running water. It did take a few times to get it right. I didn't want to force it and bust it.

I used an angle to check it's squarness and now that it's straight the end is slightly crooked.

A little file work and its straightish again on both axis.

Did a check on the gun for squarness and it looked ok. You kinda have to eye it here as the receiver is not straight.

Just setting it up there and it looks OK, about as good as i can get it. Looks a little crooked in the pic but its because i was struggling to hold it and the camera all steady and straight. I failed.

For those wondering, the screws in the grip are just big setscrews. If yours are crooked just unscrew them, they came right out. May have to glue them back but i will probably go with some allen screws.

Last edited: