Dalex

Active Member

Hey guys,

This post is long overdue.

Last year I co-ordinated a project to build a replica of the Key to Time from Doctor Who:

The factory that built these replicas was kind enough to provide some behind-the-scenes photos of the production process, showing the work that was involved in hand-cutting these pieces out of Lucite.

I thought people here would appreciate seeing these photos, so I got permission from the factory to post them.....

- - - Updated - - -

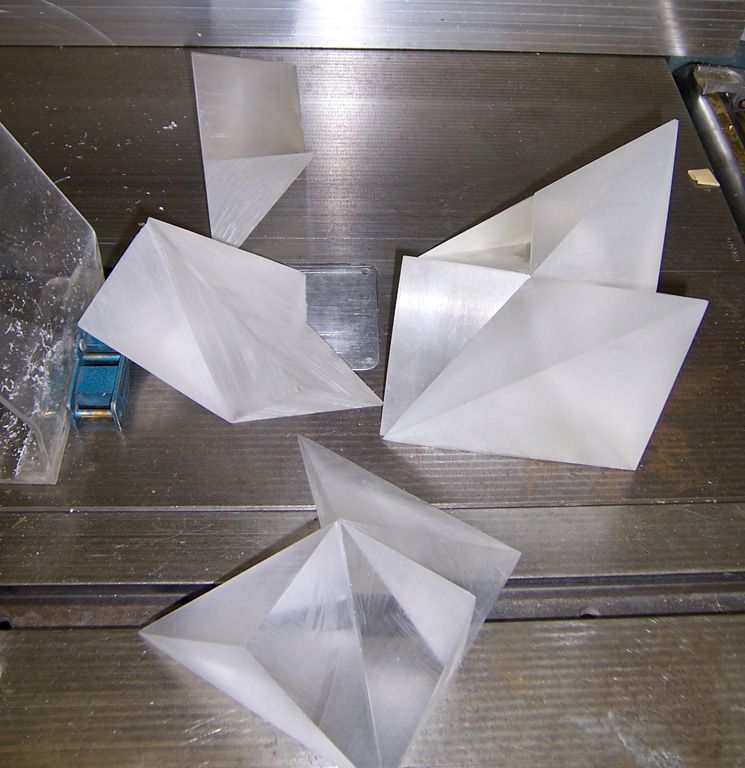

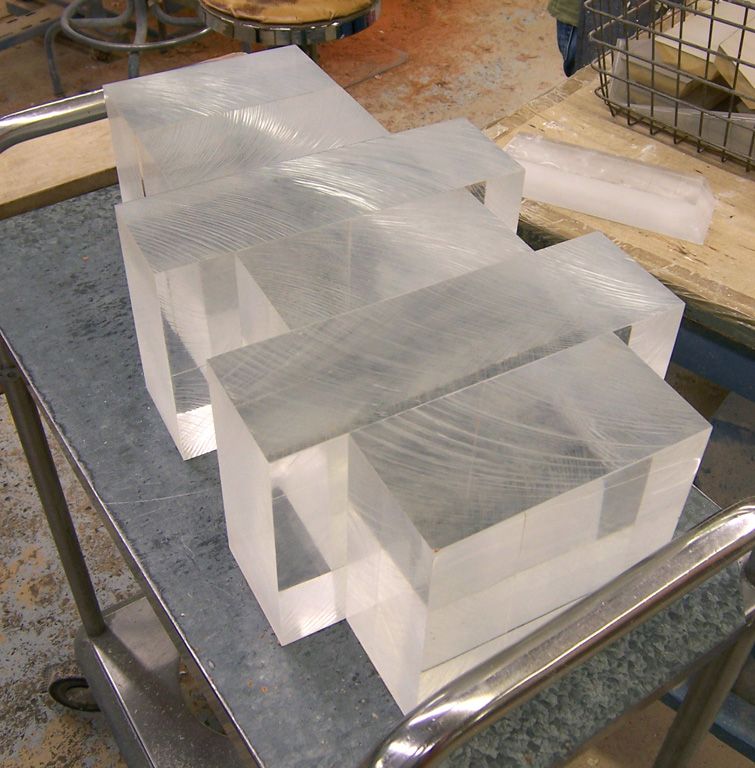

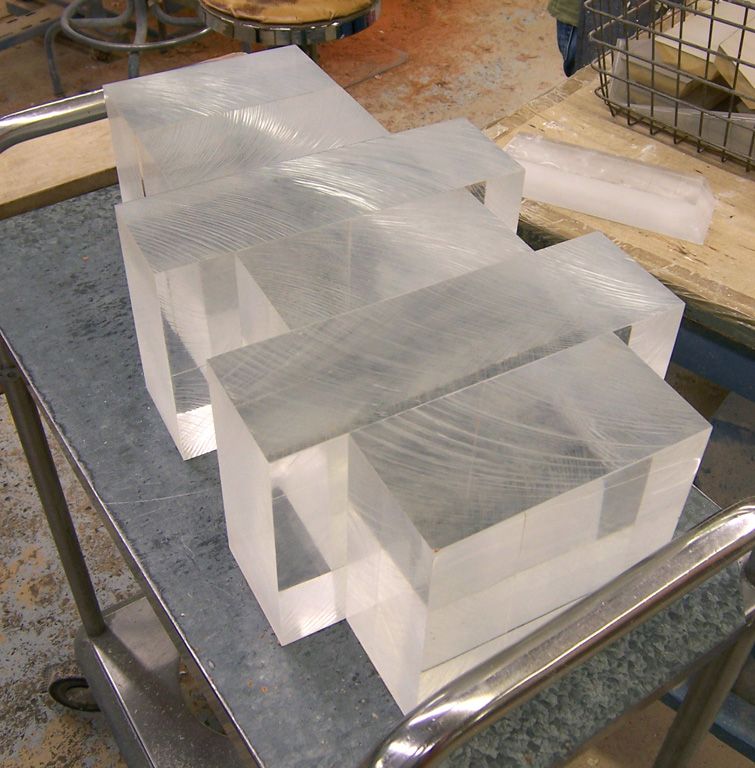

The Lucite used to make the Key to Time begins as a slurry, which is baked in an oven until it hardens into a solid block of Lucite. It is from these blocks of Lucite that the individual segments of the Key to Time are cut:

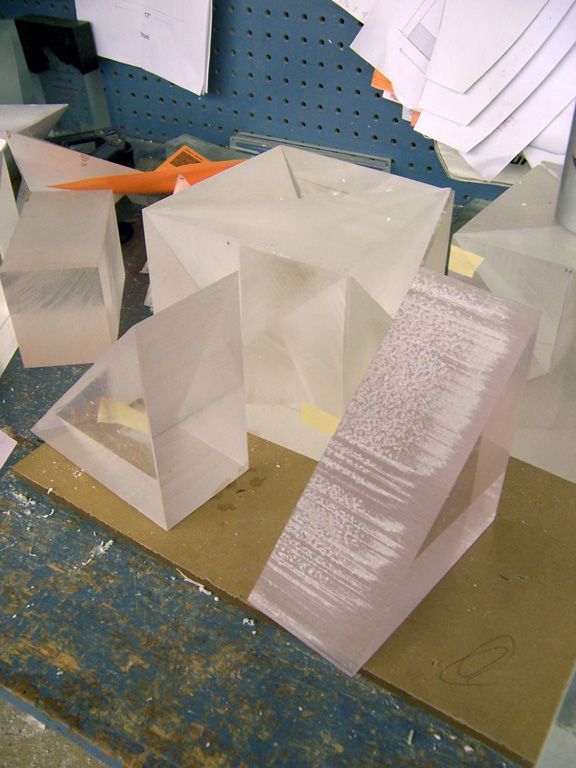

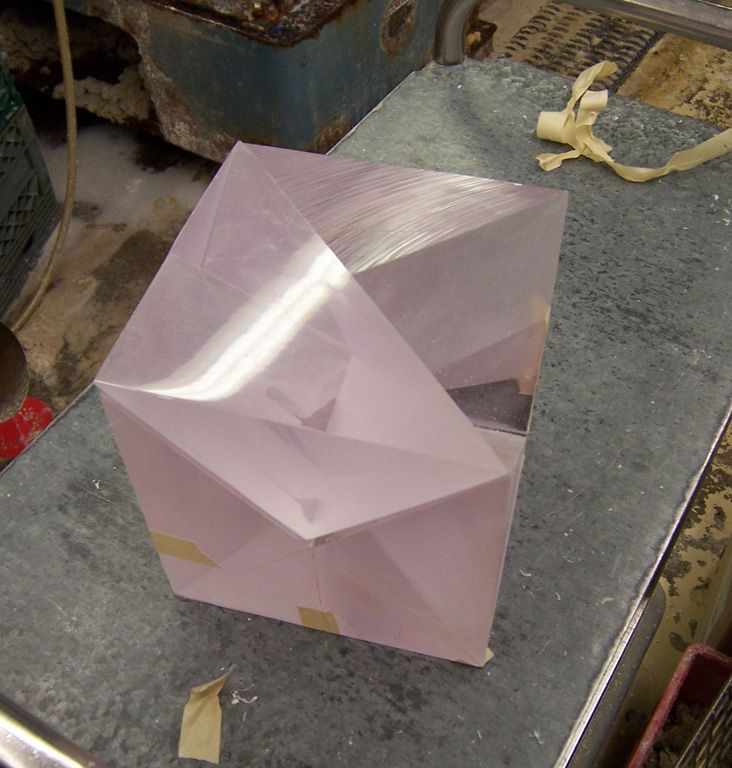

The Lucite can be tinted, so some people in our group had their Key to Time done with a pinkish-purplish hue:

Everything is precisely measured and marked in preparation for the cutting process. The blocks are mounted on a custom rig (itself made of Lucite) and a band saw is used to cut individual segments from the blocks:

This post is long overdue.

Last year I co-ordinated a project to build a replica of the Key to Time from Doctor Who:

The factory that built these replicas was kind enough to provide some behind-the-scenes photos of the production process, showing the work that was involved in hand-cutting these pieces out of Lucite.

I thought people here would appreciate seeing these photos, so I got permission from the factory to post them.....

- - - Updated - - -

The Lucite used to make the Key to Time begins as a slurry, which is baked in an oven until it hardens into a solid block of Lucite. It is from these blocks of Lucite that the individual segments of the Key to Time are cut:

The Lucite can be tinted, so some people in our group had their Key to Time done with a pinkish-purplish hue:

Everything is precisely measured and marked in preparation for the cutting process. The blocks are mounted on a custom rig (itself made of Lucite) and a band saw is used to cut individual segments from the blocks: