My son gave me this as a Father's Day gift last year, & it's pretty much just been lying around on the To-Do pile cause I just haven't had the time, but now, with my grandson starting preschool, I'm going to do something with it.

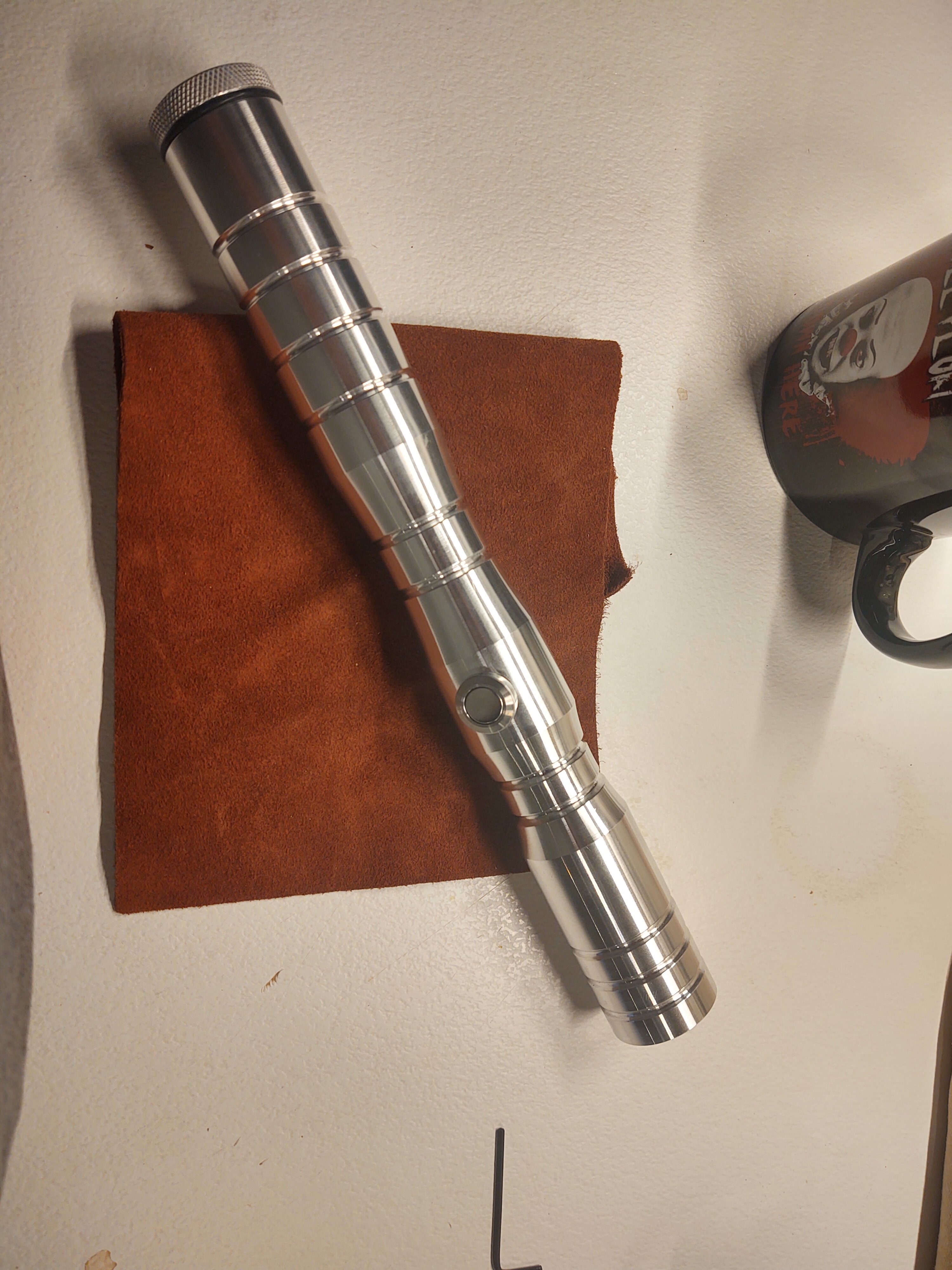

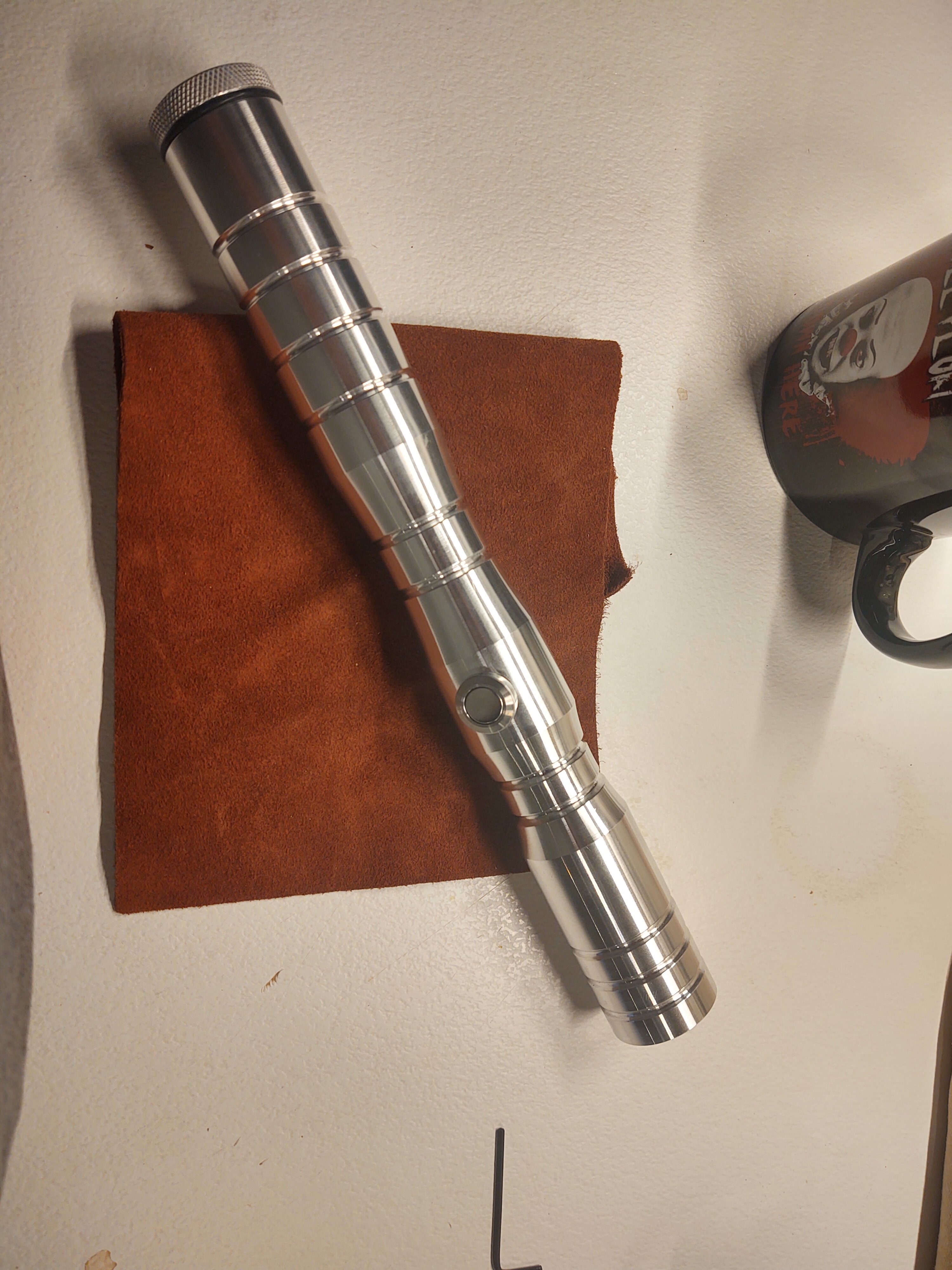

It's pretty much a plain aluminium hilt with a green light installed, no sound. I think it was a grab bag item from UltraSabers, so it'll be great for a base.

Even though my favorite designs are the thin necked V2s & Kenobi's, I've always liked the look of the older, EU, leather wrapped, beat up sabers.

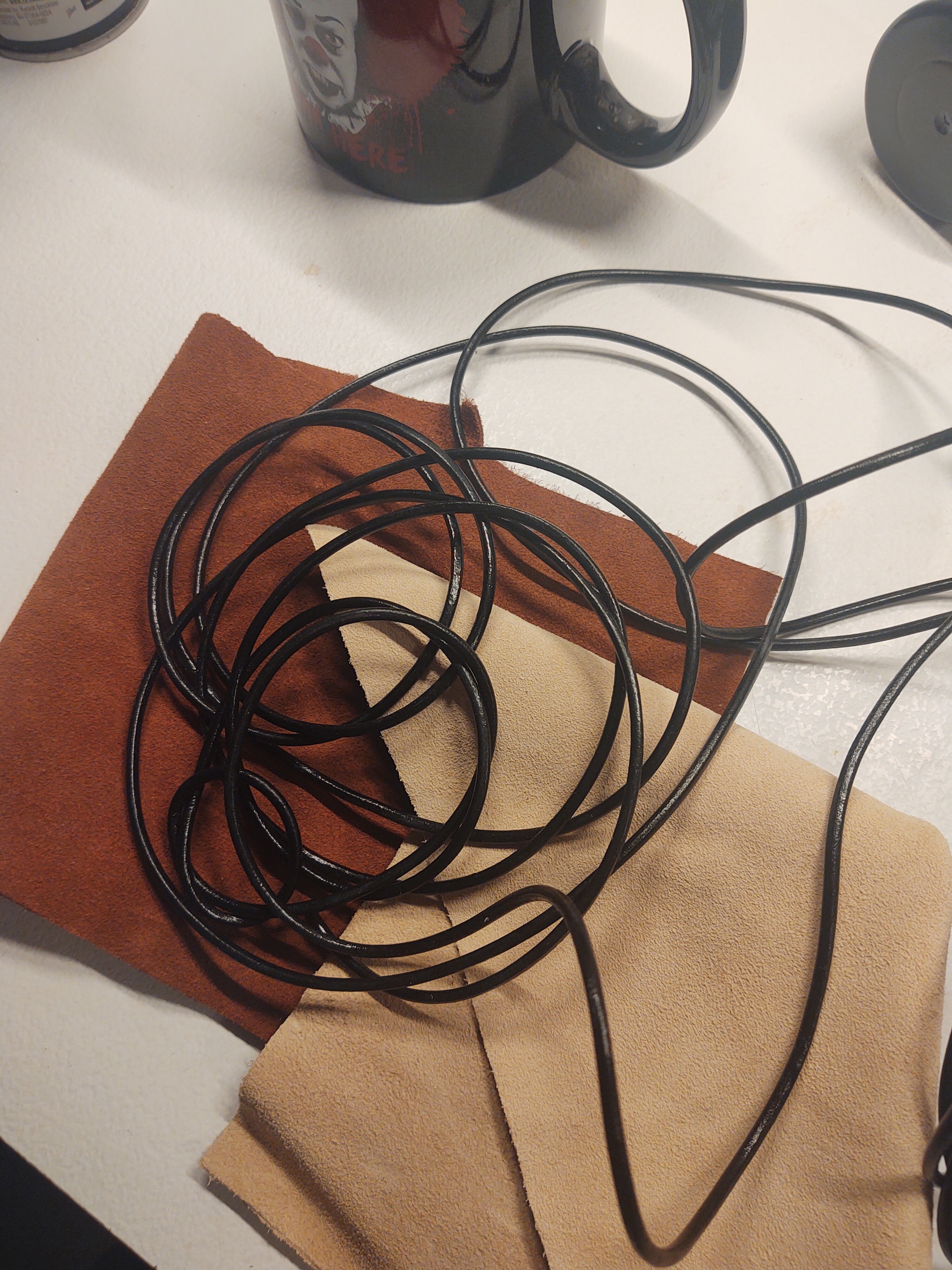

I bought a couple pieces of different colored suede & a length of twisted leather cord from Amazon for a few bucks, since I want this to be a budget build.

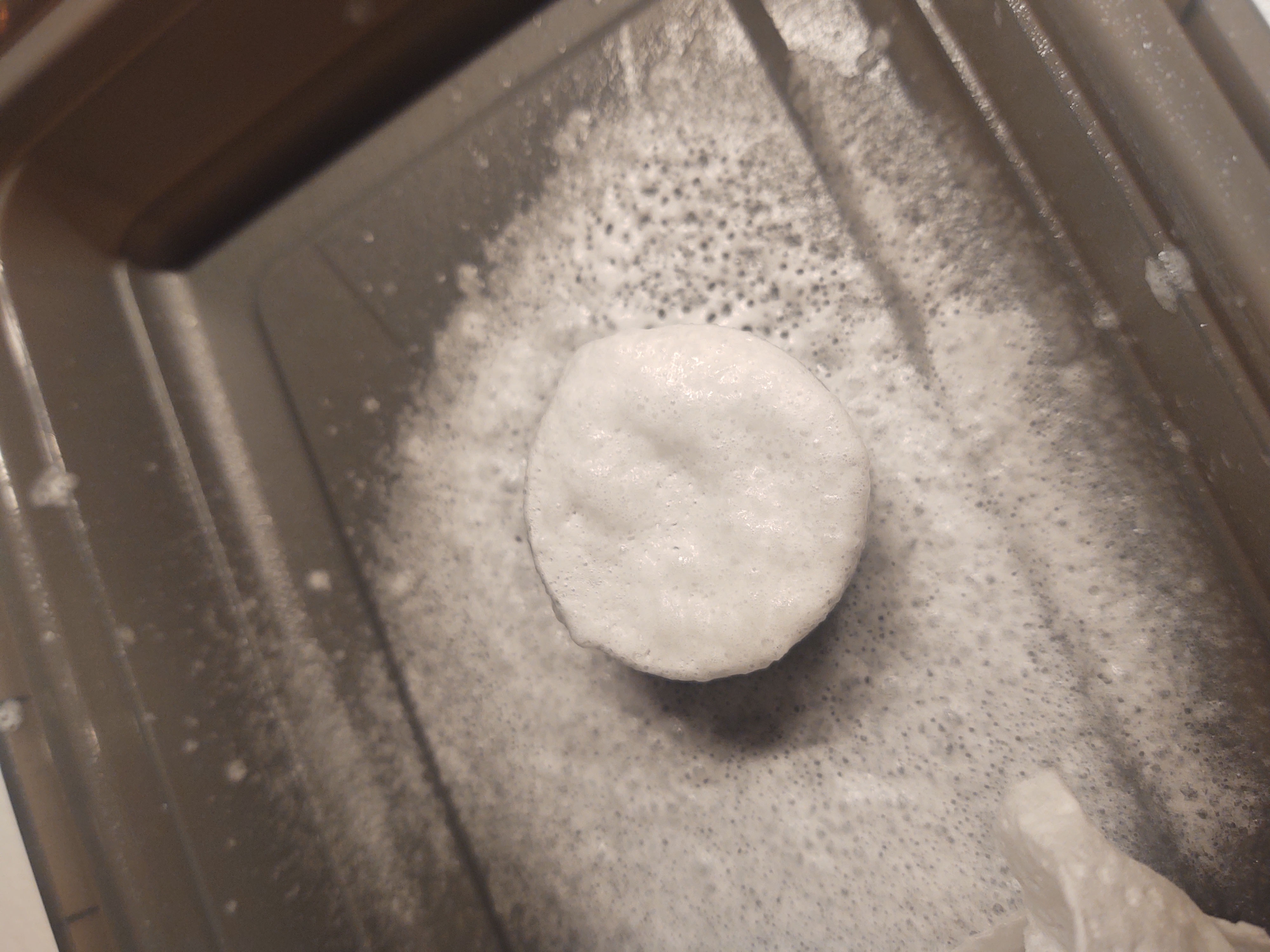

Before I get to that, though, I'm going to try & age the aluminum with oven cleaner. I decided to start with the pommel, so here it is before & during...

& since this will hopefully be a progress thread, I'll update later with the 'after'.

Only other thing I'm considering is to add some sort of shroud around the emitter end, but that'll probably just be simply cut from thin sheet metal & attached with JB WELD.

ANY thoughts or suggestions will be welcomed & appreciated. I like brainstorming with folks.

It's pretty much a plain aluminium hilt with a green light installed, no sound. I think it was a grab bag item from UltraSabers, so it'll be great for a base.

Even though my favorite designs are the thin necked V2s & Kenobi's, I've always liked the look of the older, EU, leather wrapped, beat up sabers.

I bought a couple pieces of different colored suede & a length of twisted leather cord from Amazon for a few bucks, since I want this to be a budget build.

Before I get to that, though, I'm going to try & age the aluminum with oven cleaner. I decided to start with the pommel, so here it is before & during...

& since this will hopefully be a progress thread, I'll update later with the 'after'.

Only other thing I'm considering is to add some sort of shroud around the emitter end, but that'll probably just be simply cut from thin sheet metal & attached with JB WELD.

ANY thoughts or suggestions will be welcomed & appreciated. I like brainstorming with folks.