mung

Sr Member

This is a very old project of mine started after I saw Star Wars Ep1 in 1999 and heavily inspired by the Radiant VII.

As is usual for me it was not a replica but my own take on it.

I never completed this unamed project as I was never very happy with how it was looking and over the years bits were hacked off and cannibalised for other models.

The front cockpit section, a bedside lamp housing, was chipped off and used for a different spaceship that was completed a long time ago.

I got quite carried away on this initially, and rented a welder to make up a steel spine with 6 mounting locations. The steel was 1" or 25mm square section with 1/2" whitworth nuts welded on at mounting locations top, bottom, left, right, front and back.

A section of figure eight electrical cable was then let out at each mounting point and carried back to the centre from which it then extended out to the cockpit area and the engines which I intended to light. It was mostly constructed of 2mm high impact styrene sheet ( HIPS).

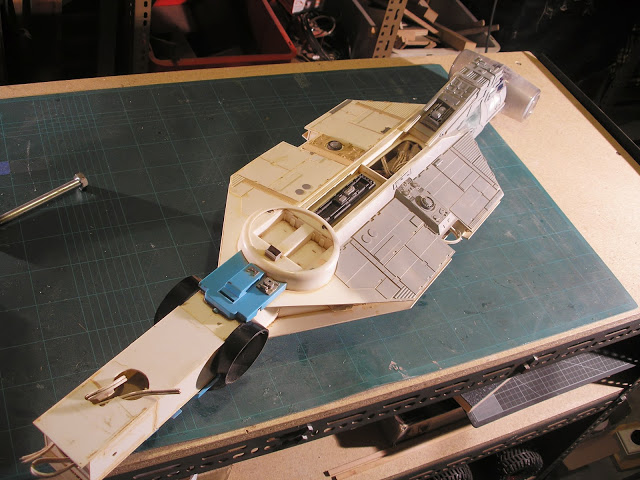

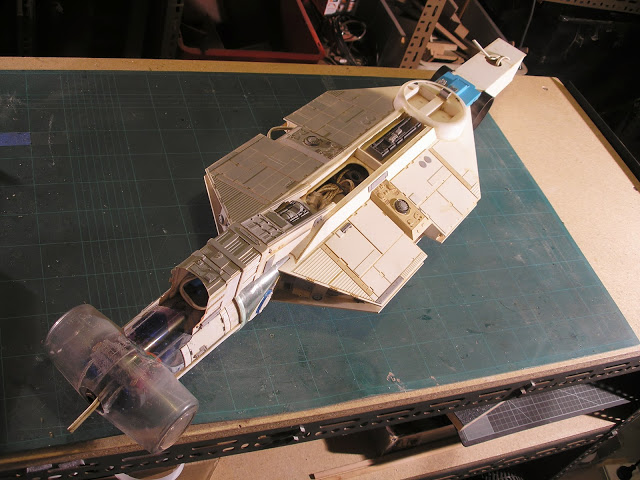

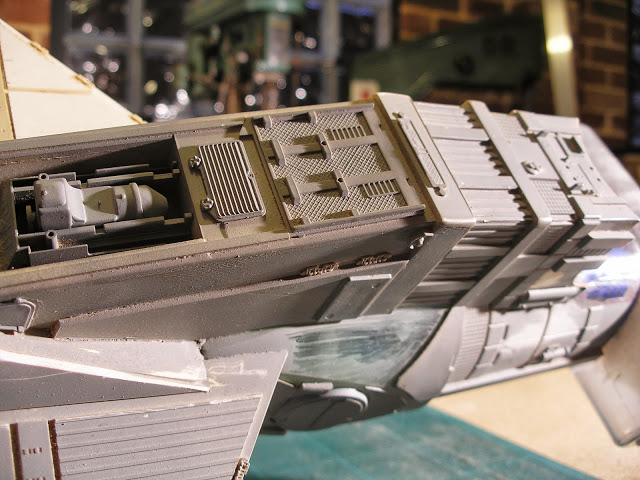

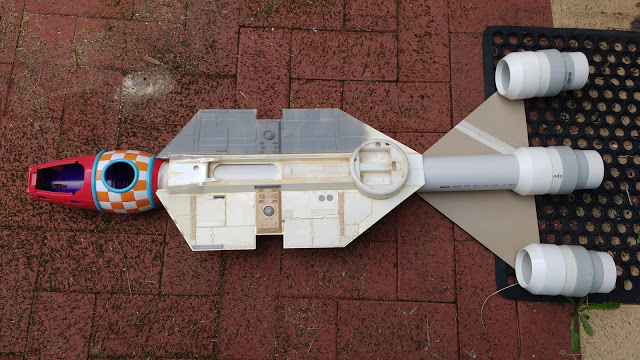

This was how the remains of the hull looked in 2013.

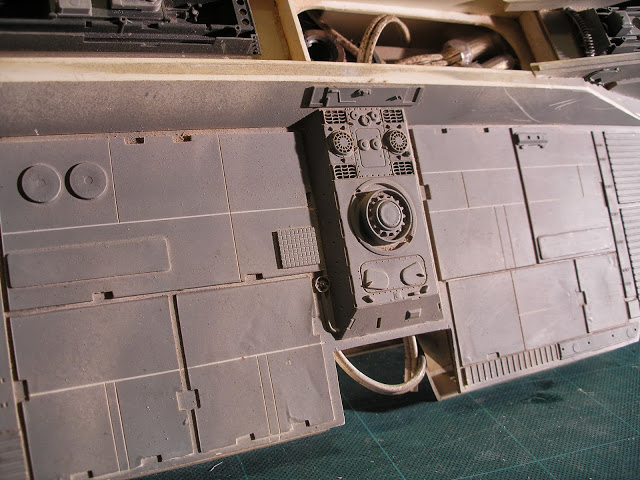

The front end was made from two plastic measuring cups joined to a longer plastic tumbler with a now mostly obscured basketball design on it.

That basketball tumbler was in turn glued to a green plastic cup which then blended back into the main hull structure.

Below is the void where the front rounded "bedside lamp" shape sat as the cockpit, later removed for reuse on the other model.

A 1/72 Matchbox Panzer kit hull is featured on the side,

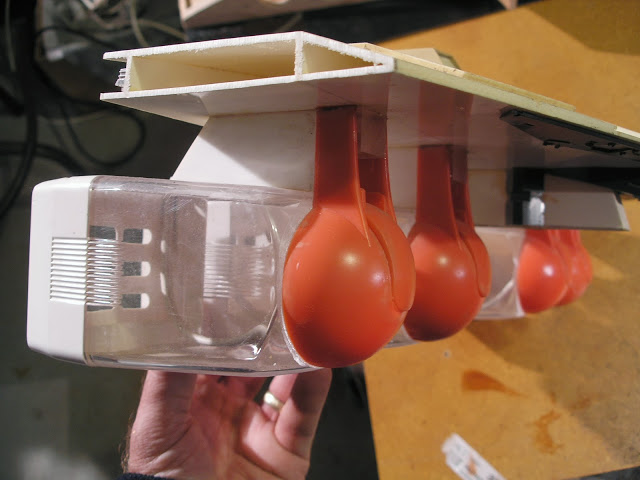

The engine section employed 6 plastic icecream scoops mated to 6 plastic Parmesan shakers in a very unwieldy six engine arrangement.

At some later stage I hacked of the two outer engines to see if it would improve it...it didn't.

That engine section made its way to an entirely different spaceship model some years ago that is still sitting on a shelf unfinished.

3 years later in 2016 I found myself unemployed with plenty of time on my hands but no money for modeling supplies and while cleaning up my shed and started to re-evaluate some old projects lying around.

This model in particular seemed to cry out for restoration and I started a build series on my blogsite rcscifi.blogspot.com.

This 2016 incomplete model page has become the second most popular page visited, a statistic which continues to baffle me.

At this point I named the model Resilient as it had bounced back from the scrap heap to live again.

I set to work and pulled the main surfaces apart, stripped out the heavy steel spine and laid out the major parts on the ground with a pvc pipe spine, PVC downpipe component engines, cardboard mockup engine mount shape and a toy rocket from a charity shop purchase.

Satisfied with the proportions I started the revised construction.

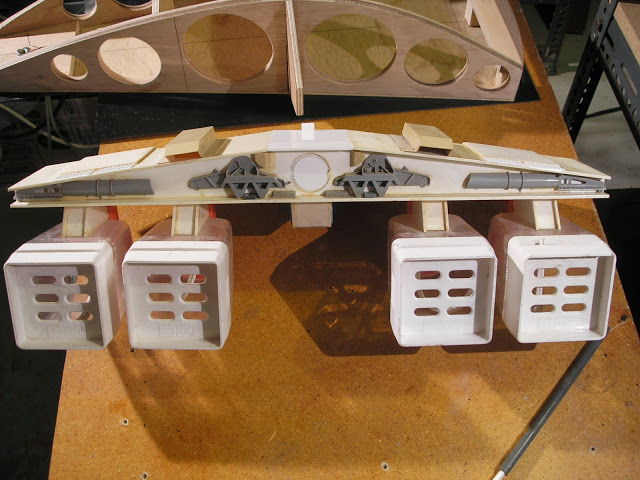

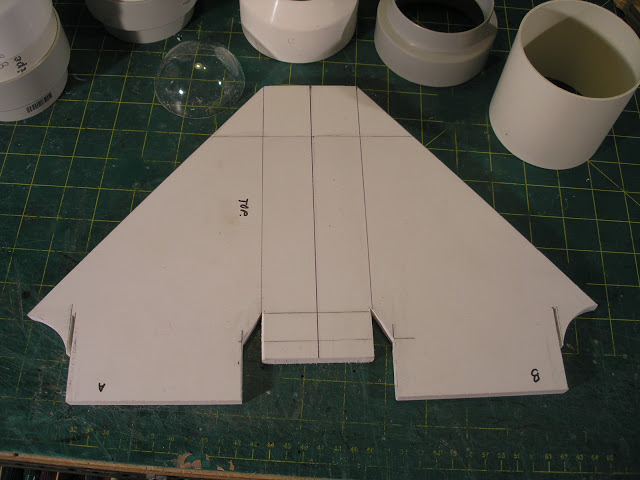

The engine mount wing was cut from 10mm thick foamed PVC sheet, lightweight easy to cut and relatively strong.

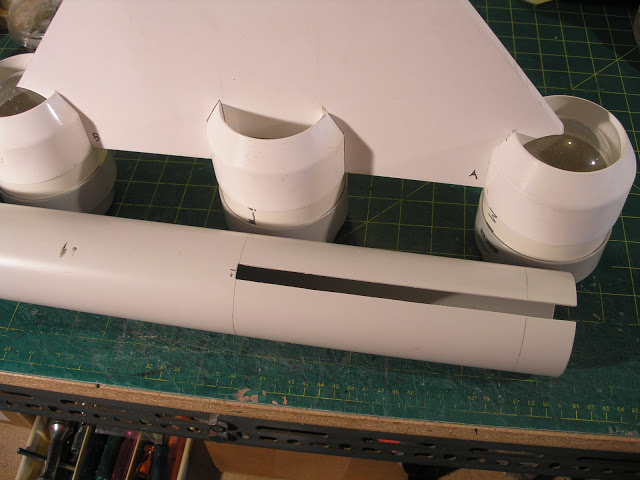

The 65mm (i.d.) PVC pipe spine was slotted to allow the engine section to slide into position and shaped to fit the engine pods.

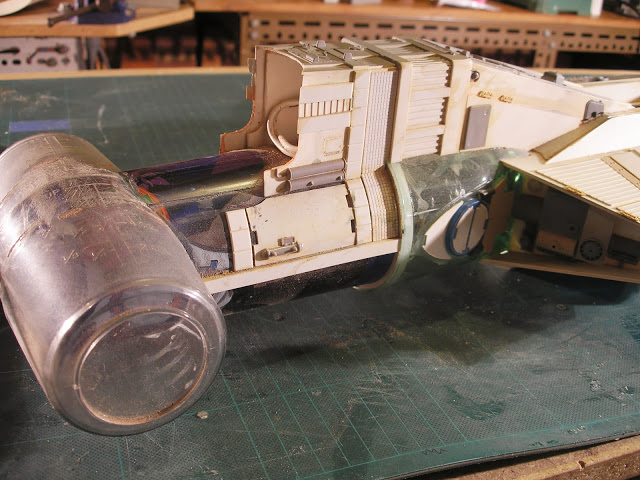

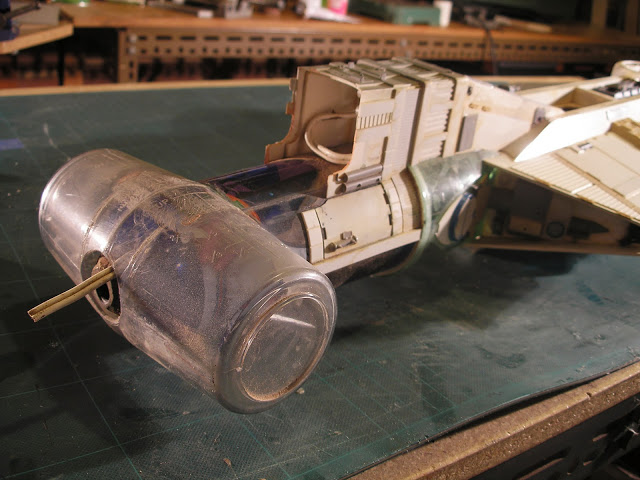

Each engine Pod is made from a 90 to 65mm PVC down pipe reducer, a short bit of 90mm storm water pipe and then a 90 to 75mm storm water reducer.

You can see in the pictures above I had a short piece of 75mm storm water pipe in the ends of the engine, this I decided was unnecessary as they made the engines too long so they were discarded.

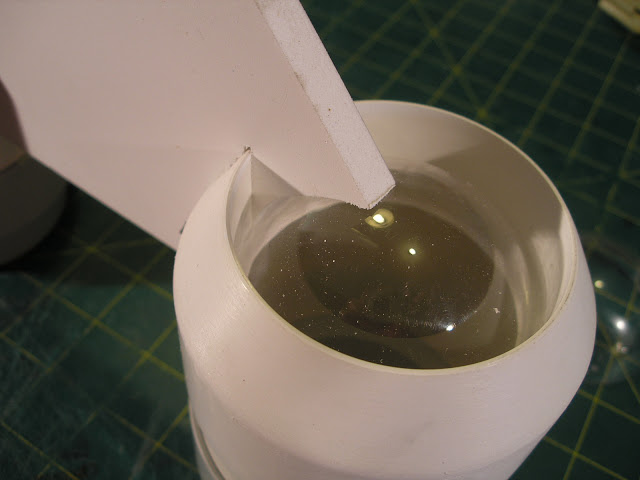

Inside the two outer pods a clear styrene dome was fitted inside the downpipe reducer.

These domes were cheap Christmas bauble decorations which come in two halves which you can put things inside.

The outer engine pods were also partly slotted to make a strong fixing to the wing, glued with thick super glue.

My engine arrangement is quite a bit smaller in proportion to the one on the Radiant.

Both the diameter of the engines is smaller and the spacing apart is less.

This is due to the sizes of PVC components I had handy but I think it looks fine.

When you look at the actual Radiant model from the top down (see the small picture in the Sculpting a galaxy book) the engines and their spacing is huge.

As is usual for me it was not a replica but my own take on it.

I never completed this unamed project as I was never very happy with how it was looking and over the years bits were hacked off and cannibalised for other models.

The front cockpit section, a bedside lamp housing, was chipped off and used for a different spaceship that was completed a long time ago.

I got quite carried away on this initially, and rented a welder to make up a steel spine with 6 mounting locations. The steel was 1" or 25mm square section with 1/2" whitworth nuts welded on at mounting locations top, bottom, left, right, front and back.

A section of figure eight electrical cable was then let out at each mounting point and carried back to the centre from which it then extended out to the cockpit area and the engines which I intended to light. It was mostly constructed of 2mm high impact styrene sheet ( HIPS).

This was how the remains of the hull looked in 2013.

The front end was made from two plastic measuring cups joined to a longer plastic tumbler with a now mostly obscured basketball design on it.

That basketball tumbler was in turn glued to a green plastic cup which then blended back into the main hull structure.

Below is the void where the front rounded "bedside lamp" shape sat as the cockpit, later removed for reuse on the other model.

A 1/72 Matchbox Panzer kit hull is featured on the side,

The engine section employed 6 plastic icecream scoops mated to 6 plastic Parmesan shakers in a very unwieldy six engine arrangement.

At some later stage I hacked of the two outer engines to see if it would improve it...it didn't.

That engine section made its way to an entirely different spaceship model some years ago that is still sitting on a shelf unfinished.

3 years later in 2016 I found myself unemployed with plenty of time on my hands but no money for modeling supplies and while cleaning up my shed and started to re-evaluate some old projects lying around.

This model in particular seemed to cry out for restoration and I started a build series on my blogsite rcscifi.blogspot.com.

This 2016 incomplete model page has become the second most popular page visited, a statistic which continues to baffle me.

At this point I named the model Resilient as it had bounced back from the scrap heap to live again.

I set to work and pulled the main surfaces apart, stripped out the heavy steel spine and laid out the major parts on the ground with a pvc pipe spine, PVC downpipe component engines, cardboard mockup engine mount shape and a toy rocket from a charity shop purchase.

Satisfied with the proportions I started the revised construction.

The engine mount wing was cut from 10mm thick foamed PVC sheet, lightweight easy to cut and relatively strong.

The 65mm (i.d.) PVC pipe spine was slotted to allow the engine section to slide into position and shaped to fit the engine pods.

Each engine Pod is made from a 90 to 65mm PVC down pipe reducer, a short bit of 90mm storm water pipe and then a 90 to 75mm storm water reducer.

You can see in the pictures above I had a short piece of 75mm storm water pipe in the ends of the engine, this I decided was unnecessary as they made the engines too long so they were discarded.

Inside the two outer pods a clear styrene dome was fitted inside the downpipe reducer.

These domes were cheap Christmas bauble decorations which come in two halves which you can put things inside.

The outer engine pods were also partly slotted to make a strong fixing to the wing, glued with thick super glue.

My engine arrangement is quite a bit smaller in proportion to the one on the Radiant.

Both the diameter of the engines is smaller and the spacing apart is less.

This is due to the sizes of PVC components I had handy but I think it looks fine.

When you look at the actual Radiant model from the top down (see the small picture in the Sculpting a galaxy book) the engines and their spacing is huge.