Snowflake

Well-Known Member

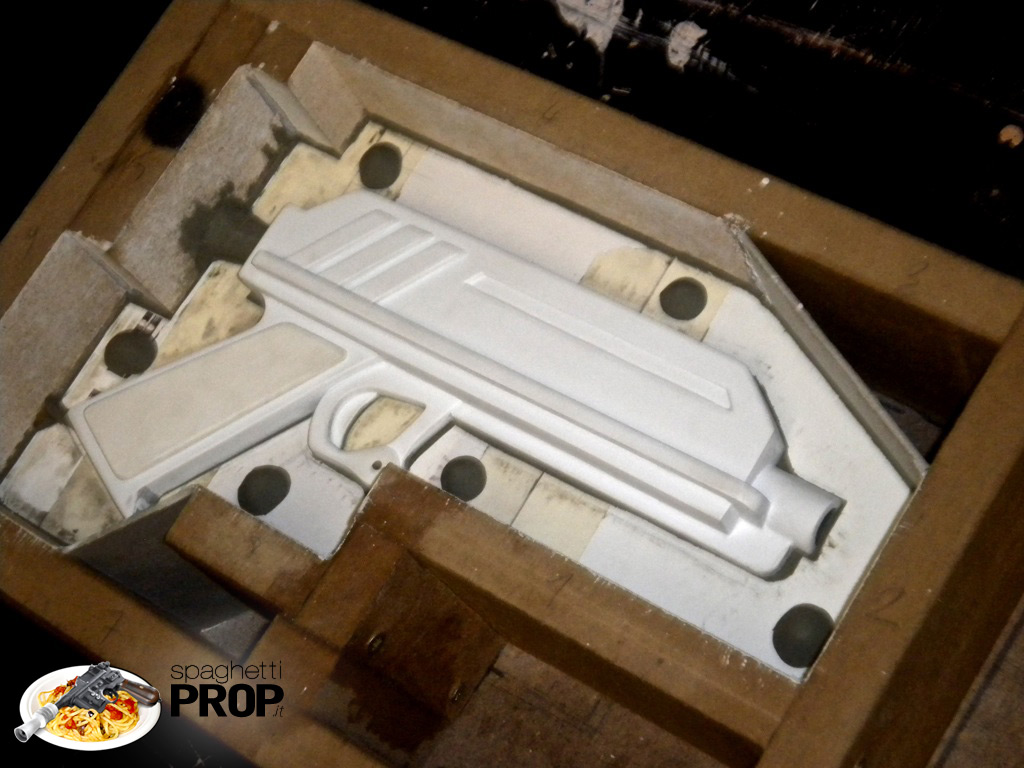

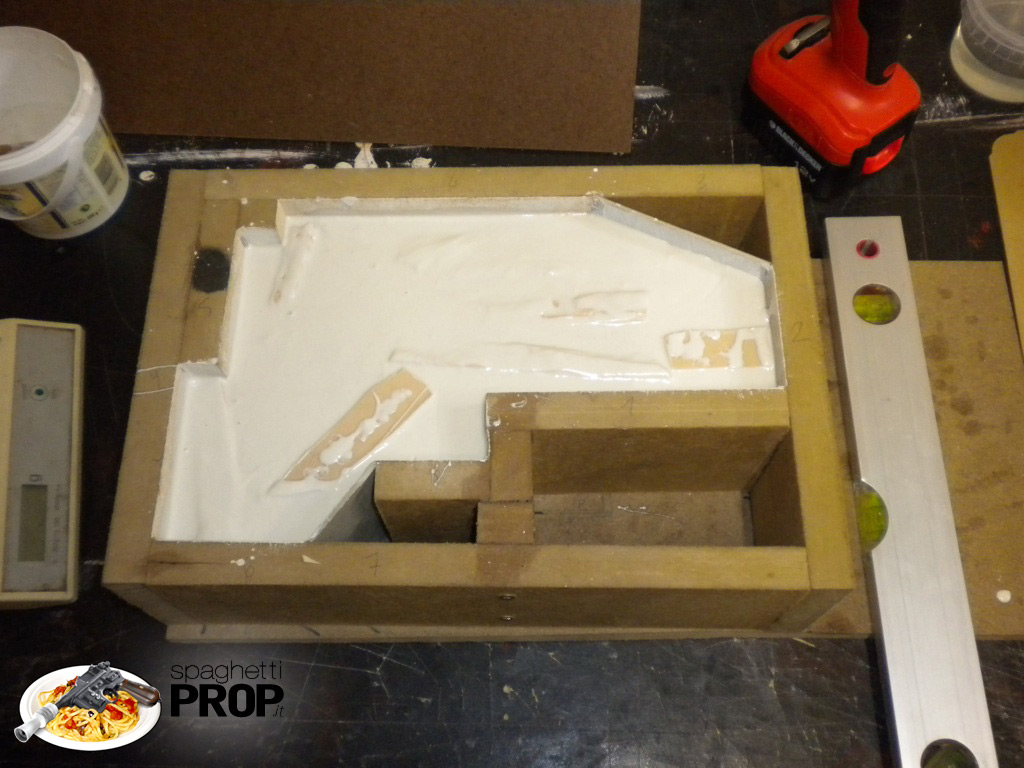

Here's my new work... this is a very fun project, right now i finished the main structure (out of MDF, wood and sintra) and in the next day i'll finish filling and sanding.

Any suggestion how to make the silicone mold? I was thinking of using the hammer side as the main hole to pour resin and adding another little hole on the back of the grip for air release. Also i'm concerned about the barrel, sholud i fill it to keep the mold simple and avoiding bubbles in the resin cast?

Any suggestion how to make the silicone mold? I was thinking of using the hammer side as the main hole to pour resin and adding another little hole on the back of the grip for air release. Also i'm concerned about the barrel, sholud i fill it to keep the mold simple and avoiding bubbles in the resin cast?