XenoMorpheus

New Member

Hi everyone!

I'd like to share with you how I made a practical Chirugai prop for my Kurtis Trent cosplay. I am really pleased with how it turned out as I really wanted to have the blades retract just like they do in the game without changing the dimensions of things too much.

I sourced this image for reference as the game is quite old now and the in game model doesn't have much detail.

Image credit http://jeanettesworld.blog.cz/1107/zadneho-muze-jste-tolik-nemilovali-a-nenavideli-zaroven

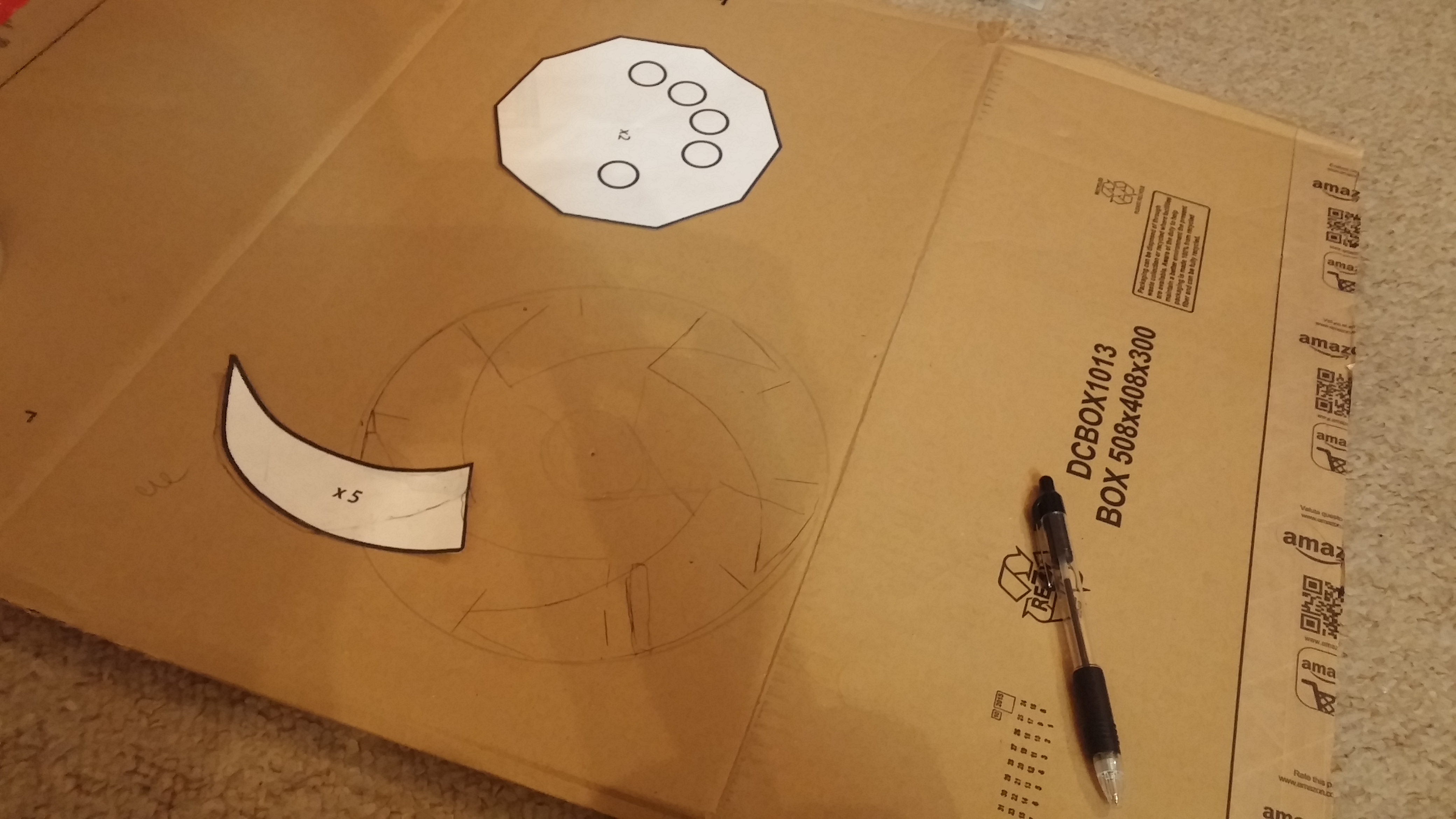

I began by working out on a cardboard box how everything would fit together using the template downloaded from Tomb Raider Cosplay.com. I took a little artistic licence with the shape and size as I wanted the blades to fold away neatly and I guessed had the game been made today the developers would have probably made it circular anyway.

Template Link http://laracroftcosplay.com/HelpWithOutfits/kurtisweapon.html

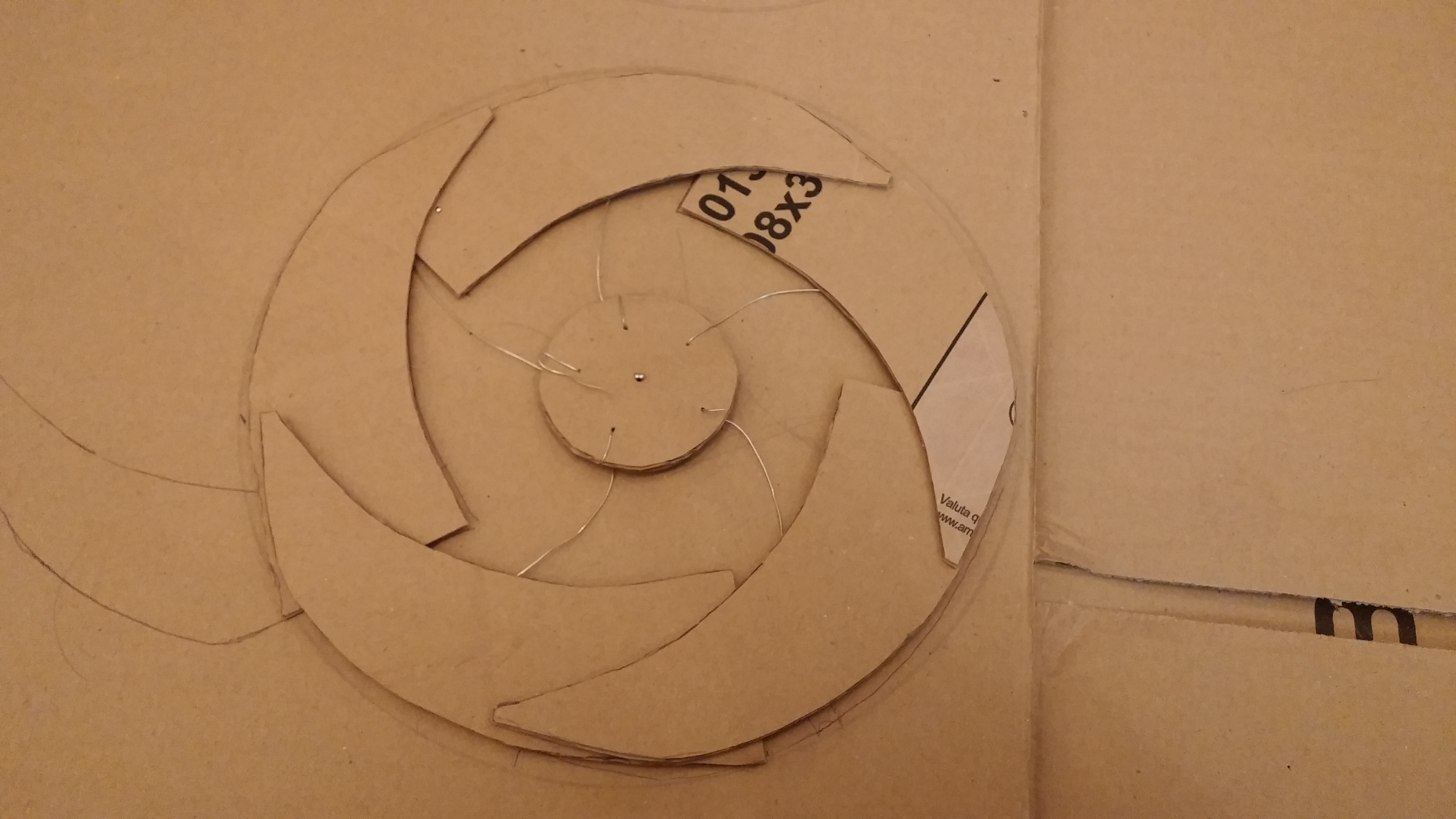

Next I began figuring out a mechanism for the blades to open and retract.

I used jewelry wire to link the pieces together

.

Here I used ordinary sewing pins as makeshift hinges. When the central disc is turned the wire would pull on the outer corner or the blade pieces and they all open out at once.

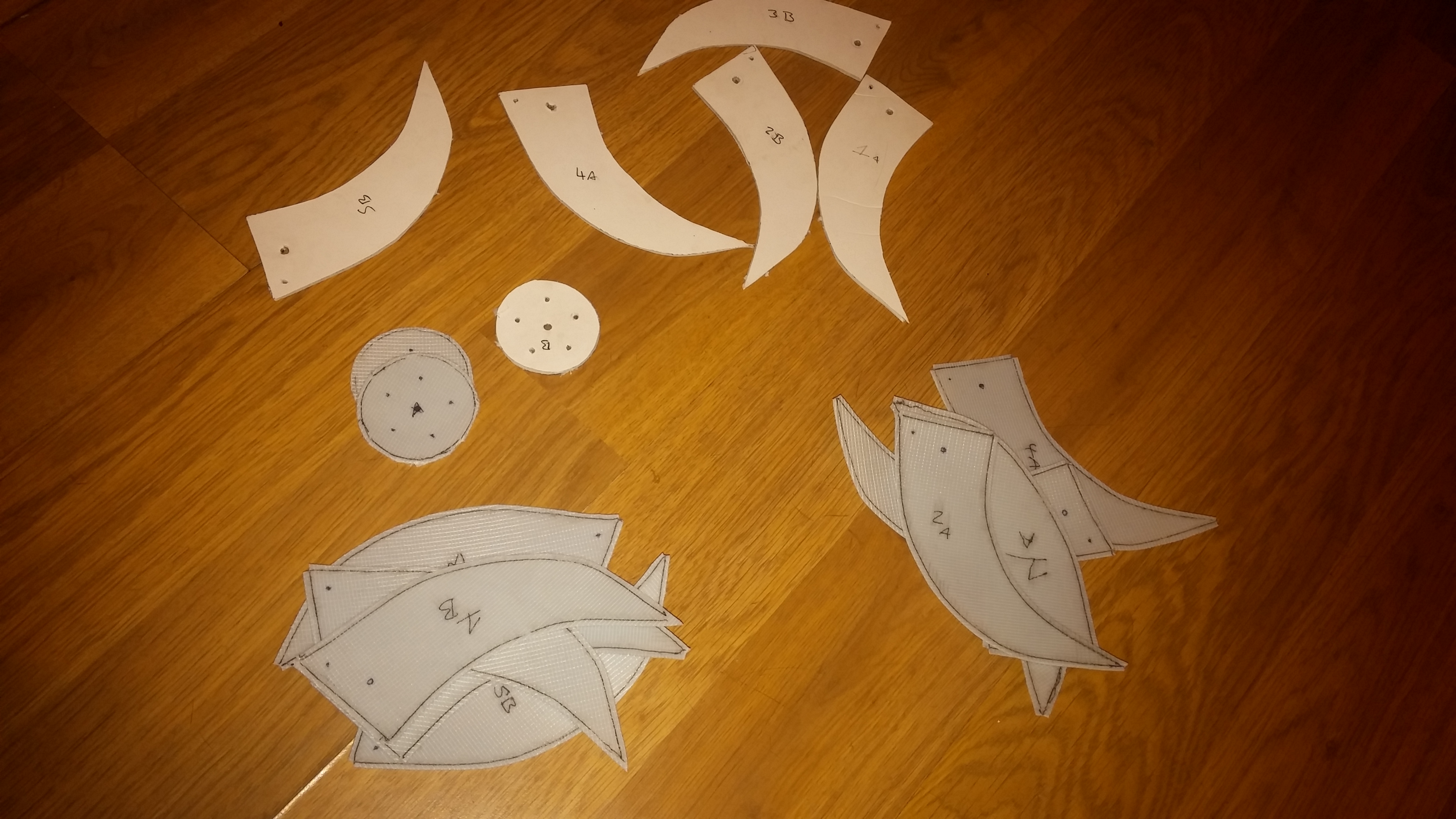

Next I traced out all the parts I'd need onto a piece of craft foam board. I originally planned to use pieces of foam board to link the blades to the central disc. however I soon realised it would be far too thick so ended up not using those pieces and decided to use wire instead. I also cut two discs for the centre part as the blades would be folding over one another, so the middle would need to be built up a bit.

I wanted to reinforce the foamboard to avoid it breaking and the whole thing having to be taken apart, so once I had cut out and labeled each individual piece, I drew around each onto a sheet of Wonderflex we already had (I wanted to get some Worbla for this but ended up buying a house instead), being sure to draw around and label each side. I also did this for one of the central discs to prevent the wire ripping through, but not for the two "faceplates" at this point.

It was at this point I realised how thick the whole thing could potentially end up being, so since I was reinforcing the blades anyway I decided to squash the blade pieces down with a rolling pin. You can see in the second picture how much I flattened it by. If I was to make another I'd probably use craft foam for these pieces instead.

Next I cut out the Wonderflex pieces, leaving a margin for folding over the edges. I also marked out where I would need to drill holes.

View attachment 20151104_165739A.jpg

I cut a small square from each corner to make it smooth once folded. Then I used an ordinary glue stick to help hold the parts together while I heated the Wonderflex with a heat gun. I did this for each piece, carefully molding the Wonderflex over the edges and smoothing them out before it completely cooled.

Once The Wonderflex had completely cooled I drilled the holes using a Dremel.

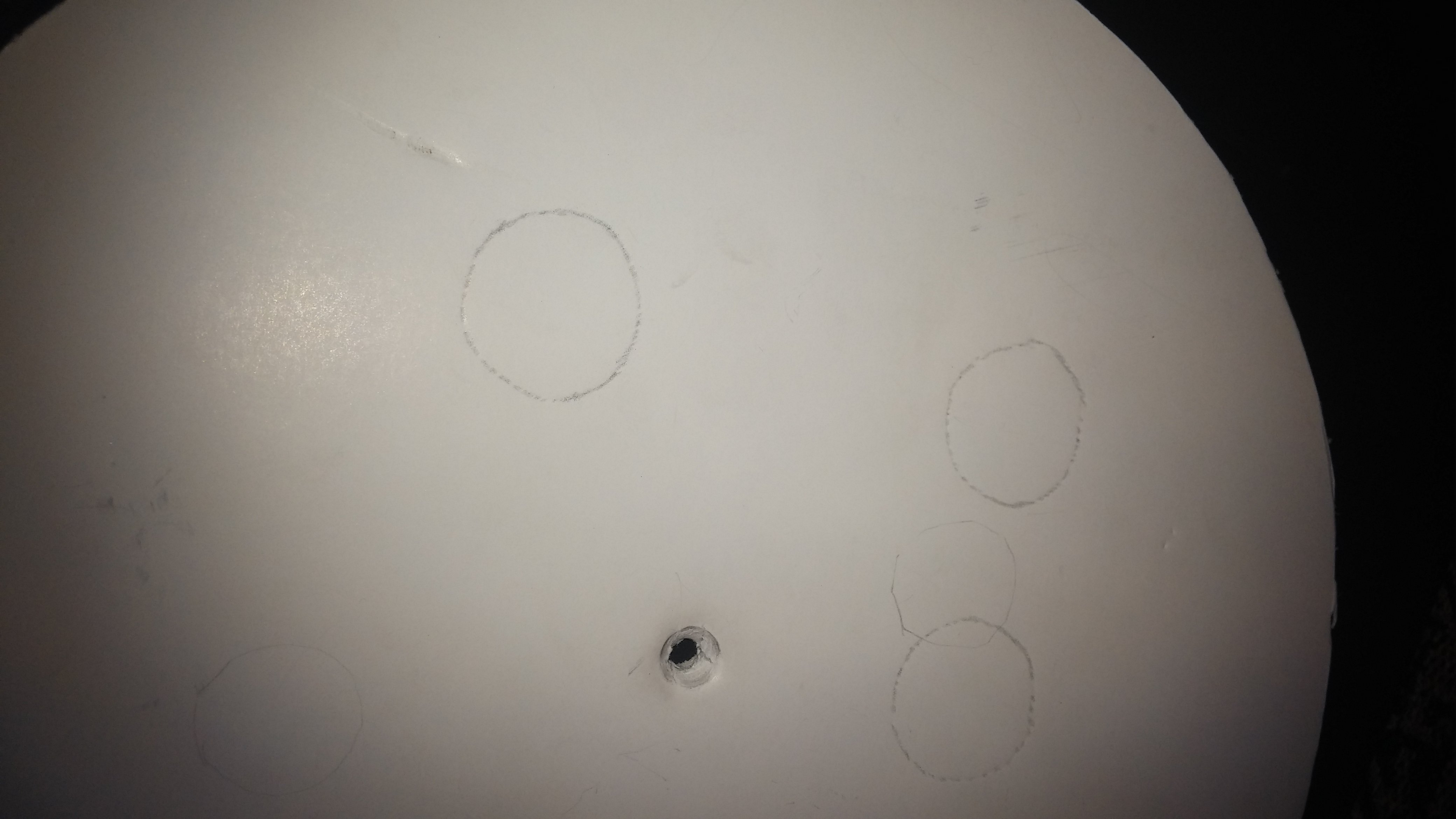

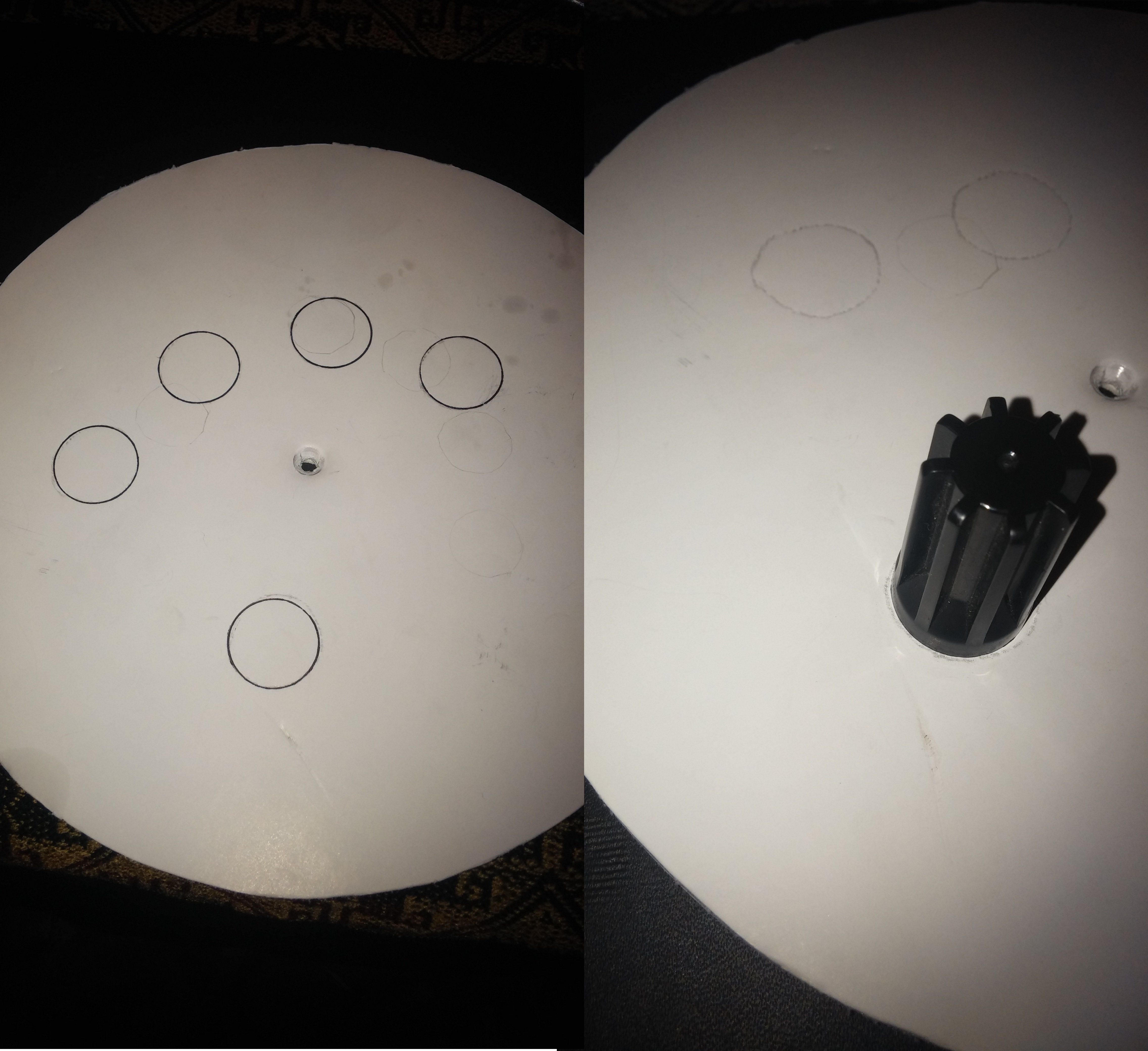

To plan out where to put the finger holes I roughly assembled everything I had so far onto the back piece to see where none of the blades would be in the way, and using the paper template from the beginning as a reference marked the position for each hole.

Then I drew around the outside onto a piece of grease-proof paper, then lining up the edge I traced the finger holes. Then I flipped the grease-proof paper over and scribbled over the finger holes with a HB pencil. This gave me a makeshift transfer.Turning the grease-proof back over, I then got the front piece, lined up the edge and applying a little pressure drew over the finger holes with a ball point pen. This left the outline for the holes in the exact same position as on the back piece.

I drew around a marker lid that was the right size to neaten it up.

To make a hinge that would pivot freely I used nuts and bolts with normal washers and spring washers. I needed 6 nuts and bolts and 11 of each washer.

I placed the normal washer on the outside and the spring washer on the inside. Then pushed it through the middle hole in each blade piece (you can see here I'd already painted the blade silver, this could be done at any point prior to final assembly). The washer configuration was then mirrored on the other side of the blade. Then I temporarily fixed each blade to the back piece.

View attachment 20151104_165739A.jpg

I'd like to share with you how I made a practical Chirugai prop for my Kurtis Trent cosplay. I am really pleased with how it turned out as I really wanted to have the blades retract just like they do in the game without changing the dimensions of things too much.

I sourced this image for reference as the game is quite old now and the in game model doesn't have much detail.

Image credit http://jeanettesworld.blog.cz/1107/zadneho-muze-jste-tolik-nemilovali-a-nenavideli-zaroven

I began by working out on a cardboard box how everything would fit together using the template downloaded from Tomb Raider Cosplay.com. I took a little artistic licence with the shape and size as I wanted the blades to fold away neatly and I guessed had the game been made today the developers would have probably made it circular anyway.

Template Link http://laracroftcosplay.com/HelpWithOutfits/kurtisweapon.html

Next I began figuring out a mechanism for the blades to open and retract.

I used jewelry wire to link the pieces together

.

Here I used ordinary sewing pins as makeshift hinges. When the central disc is turned the wire would pull on the outer corner or the blade pieces and they all open out at once.

Next I traced out all the parts I'd need onto a piece of craft foam board. I originally planned to use pieces of foam board to link the blades to the central disc. however I soon realised it would be far too thick so ended up not using those pieces and decided to use wire instead. I also cut two discs for the centre part as the blades would be folding over one another, so the middle would need to be built up a bit.

I wanted to reinforce the foamboard to avoid it breaking and the whole thing having to be taken apart, so once I had cut out and labeled each individual piece, I drew around each onto a sheet of Wonderflex we already had (I wanted to get some Worbla for this but ended up buying a house instead), being sure to draw around and label each side. I also did this for one of the central discs to prevent the wire ripping through, but not for the two "faceplates" at this point.

It was at this point I realised how thick the whole thing could potentially end up being, so since I was reinforcing the blades anyway I decided to squash the blade pieces down with a rolling pin. You can see in the second picture how much I flattened it by. If I was to make another I'd probably use craft foam for these pieces instead.

Next I cut out the Wonderflex pieces, leaving a margin for folding over the edges. I also marked out where I would need to drill holes.

View attachment 20151104_165739A.jpg

I cut a small square from each corner to make it smooth once folded. Then I used an ordinary glue stick to help hold the parts together while I heated the Wonderflex with a heat gun. I did this for each piece, carefully molding the Wonderflex over the edges and smoothing them out before it completely cooled.

Once The Wonderflex had completely cooled I drilled the holes using a Dremel.

To plan out where to put the finger holes I roughly assembled everything I had so far onto the back piece to see where none of the blades would be in the way, and using the paper template from the beginning as a reference marked the position for each hole.

Then I drew around the outside onto a piece of grease-proof paper, then lining up the edge I traced the finger holes. Then I flipped the grease-proof paper over and scribbled over the finger holes with a HB pencil. This gave me a makeshift transfer.Turning the grease-proof back over, I then got the front piece, lined up the edge and applying a little pressure drew over the finger holes with a ball point pen. This left the outline for the holes in the exact same position as on the back piece.

I drew around a marker lid that was the right size to neaten it up.

To make a hinge that would pivot freely I used nuts and bolts with normal washers and spring washers. I needed 6 nuts and bolts and 11 of each washer.

I placed the normal washer on the outside and the spring washer on the inside. Then pushed it through the middle hole in each blade piece (you can see here I'd already painted the blade silver, this could be done at any point prior to final assembly). The washer configuration was then mirrored on the other side of the blade. Then I temporarily fixed each blade to the back piece.

View attachment 20151104_165739A.jpg

Last edited by a moderator: