You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Attack on Titan/Shingeki no Kyojin gear build

- Thread starter DarkTime

- Start date

DarkTime

New Member

quote

The foamboard I used is standard 1/4" thick that you see typically used for science fairs. It can get fold damage if a really strong wind hits it on the side, but as long as you're mindful of that and where you wave/point it indoors (it can still poke people's eyes out), it's fine. How long and wide the blade should be on the other hand should be proportioned to your box size and body height; for 5'6" me and my box specs, it's 2.5" width, 30" long on the edge side, 26" long on the back side; so a 4" offset/slant for the snap-off lines. You get a total of 6 snap-off lines like in the anime.

As for the aluminum base/tang/strip, it's just there to endure the mechanism (otherwise it'd dig right into the foam). You can use anything as long as it's hard enough (plastic, hardwood, some other metal, etc.) to endure whatever mechanism you design, so you don't have to make a trip to get it/it doesn't have to be aluminum. The strip is the same length as the width of the blade (or more, if you prefer, but that limits space for the mechanism in an already super tight area), 3/4" height, and 1/8" thick.

Though this was a grey area thing in my major con because they specify there should be no metal on the blade; but since the metal is unexposed/inside the handle when mounted, they approved it.

The aluminum bar stock is only $5.72 at my hardware store for a 48" long flat:

Crown Bolt 3/4 in. x 48 in. Aluminum Flat Bar with 1/8 in. Thick-44650 at The Home Depot

But like said, it doesn't have to be that material as long as it meets your mechanism spec.

Good luck! Post your progress/finished product here! I had to make 3 sets also the first time, but my friends mostly did their own just using me for reference/prototyping.I am going to be starting three of these soon for friends...you're right there's not a whole lot on them here but this is a great thread for it!

Last edited:

Weapioneer

Active Member

I see, but my mechanism is pretty simple, by having a small nock in the tang of the blade, and a catch where the hammer is. My 3DMG is based off the manga, but I included the hammer. I just put a bit of CA glue in the nock to reinforce it in my short blades, which don't need a core due to their length, but making the full length blades necessitates a core of sorts to give it some strength. My handles work fine, but I don't want the blades to snap the instant I draw them.-quote-

Are there any other cores that can be cheaply found? I can use wood, but sanding the edge of a solid wood blade is a pain, and it isn't strong enough for just a core. Can I somehow flatten a threaded rod? or would repeated cold working result in it breaking? also, which would be stronger, sticking 3 layers of 3mm PVC FB together or using 1 layer of 9mm PVC FB? I use CA glue and epoxy for gluing things.

Thank you,

electraflier

Well-Known Member

Hmm, I was considering using aluminum strips with PVC foamboard on top, but I can't get aluminum easily,.

Thin aluminum bar stock 1/4 by 3/4, 3 feet long is at home depot by the threaded rods and steel pieces... they should have it.. if you can try Skycraft Orlando on line and they might ship? They have it too. its like 8$ maybe 10$

M

electraflier

Well-Known Member

So maybe i need to explain a few things, and please understand, that while this is text, it's not intended to be rude at all.

1. I'm the sole provider for my household at this time, wife lost her job and had a stroke earlier this year.

2. I have a 14 month old daughter, so you could guess that makes me more busy

3. i'm extremely busy running a normal job and a photo studio.

4. I've made two costumes, a Capt. Rex and a Biker Scout, i know the time it takes to make 1 costume.

So as you can see I just don't have the time to donate to creating anything right now. I actually am in NO rush at this time. and eventually i would most likely ask DarkTimes if he was interested to make me a set.

Anyway, hope you can see that i just can't donate even a few minutes. i need to get a new job! LOL

Fist on my heart Friend!

-River

You are doing something way more important and powerful. Taking care of your family first. The rewards to that are beyond count and the blessings will come with time. You and your family are in my thoughts and prayers! I salute you my friend!

M

third3ye

Sr Member

The one on the left really nailed Mikasa down to the hair and scarf. And the one on the right kinda looks like Annie. Good job!

Wilbur Walsh

New Member

You are great. Nice work.

Weapioneer

Active Member

Ok, finally finished the swords, and here are the pictures!

Photography is not my strong suit, and I will try to get better ones later. I used mostly PVC foamboard in this build, which is a new material i recently acquired. I didn't have enough to make the normal blades, nor did I have aluminum strips. I may make them later, but short blades are good for filling in the spaces in the sheath and for testing. The short blades were done pretty roughly, since I made them before the handles and I did not realize how easily FB got damaged. I think I posted a build log higher in the thread, but feel free to ask questions. I may make the rest of the gear to complete my ultimate assassin cosplay, which consists of Ezio, Corvo, and a few others blended together into one scary mix. When you think about it, the AoT soldiers are essentially assassins, who dart about and aim for lethal strikes.

So what do you think?

Weapioneer

Photography is not my strong suit, and I will try to get better ones later. I used mostly PVC foamboard in this build, which is a new material i recently acquired. I didn't have enough to make the normal blades, nor did I have aluminum strips. I may make them later, but short blades are good for filling in the spaces in the sheath and for testing. The short blades were done pretty roughly, since I made them before the handles and I did not realize how easily FB got damaged. I think I posted a build log higher in the thread, but feel free to ask questions. I may make the rest of the gear to complete my ultimate assassin cosplay, which consists of Ezio, Corvo, and a few others blended together into one scary mix. When you think about it, the AoT soldiers are essentially assassins, who dart about and aim for lethal strikes.

So what do you think?

Weapioneer

DarkTime

New Member

^Definitely manga accurate!

I'm not sure but is PVC foam board essentially sintra also?

Where did you get yours?

I know you said earlier the blade is held in by a notch using the hammer, but how is the hammer locked/keeping the blade from falling out? Is there a spring?

I think if you sand/better surface prep, that paint job would look even better!

I'm not sure but is PVC foam board essentially sintra also?

Where did you get yours?

I know you said earlier the blade is held in by a notch using the hammer, but how is the hammer locked/keeping the blade from falling out? Is there a spring?

I think if you sand/better surface prep, that paint job would look even better!

Weapioneer

Active Member

Sorry for the late reply, and Thanks

PVC foamboard is closed cell PVC foam, so I think it should be the same, though different recipes may exist for the same thing. I bought mine at a local aeromodeling store, around 5$ for 8sq ft of 3mm PVC FB. The hammer's at the back are just above the thumbs, and are just strips of metal glued together with a liberal amount of CA glue. I stuck a bit of 1mm thick wire between the strips(to be the fulcrum) and stuck them together to make the catch, and then stuck two bits of PVC FB onto the end to make the hammers. The strips are straight and extend into the central hollow, where they hold the blade nocks and prevent them from flying out when I prance about. The 1mm GI wire extends to either side of the catch, going into holes in the handle(covered by the grip) There is a small spring pushing the ends of the catches into the hollow, which allows me to just slide the handles onto the blades to lock them in. If i want to remove the blades, I simply press the hammers forwards with my thumbs to allow me to remove them. In an earlier attempt, I had included a small spring in the handle to push the blades out automatically, but they caused the blades to push into catch and would take a lot of effort to push the hammers. I decided that sending the blades flying was a bad idea anyway. My paint job was a bit shoddy since I was in a hurry, so I am redoing it on the blades, where it was worse. Also, would using a spray-on primer like krylon help fill in tiny scratches on the surface?

By the way, I have a bunch of 4mm acrylic which I was planning to use for the blades but decided against it. Would using it for the boxes be a good idea? my boxes are going to be around 72x9x14, so not exactly huge like the anime versions are. I plan on using some Styrofoam and cardboard on the inside for reinforcing it too. It would be either using 4mm acrylic I already have, or buying new MDF.

Hope this helps,

Weapioneer

PVC foamboard is closed cell PVC foam, so I think it should be the same, though different recipes may exist for the same thing. I bought mine at a local aeromodeling store, around 5$ for 8sq ft of 3mm PVC FB. The hammer's at the back are just above the thumbs, and are just strips of metal glued together with a liberal amount of CA glue. I stuck a bit of 1mm thick wire between the strips(to be the fulcrum) and stuck them together to make the catch, and then stuck two bits of PVC FB onto the end to make the hammers. The strips are straight and extend into the central hollow, where they hold the blade nocks and prevent them from flying out when I prance about. The 1mm GI wire extends to either side of the catch, going into holes in the handle(covered by the grip) There is a small spring pushing the ends of the catches into the hollow, which allows me to just slide the handles onto the blades to lock them in. If i want to remove the blades, I simply press the hammers forwards with my thumbs to allow me to remove them. In an earlier attempt, I had included a small spring in the handle to push the blades out automatically, but they caused the blades to push into catch and would take a lot of effort to push the hammers. I decided that sending the blades flying was a bad idea anyway. My paint job was a bit shoddy since I was in a hurry, so I am redoing it on the blades, where it was worse. Also, would using a spray-on primer like krylon help fill in tiny scratches on the surface?

By the way, I have a bunch of 4mm acrylic which I was planning to use for the blades but decided against it. Would using it for the boxes be a good idea? my boxes are going to be around 72x9x14, so not exactly huge like the anime versions are. I plan on using some Styrofoam and cardboard on the inside for reinforcing it too. It would be either using 4mm acrylic I already have, or buying new MDF.

Hope this helps,

Weapioneer

River

Member

Uploaded a high quality pic of me wearing the gear in its current version at a recent event in the first post! Hope it motivates a lot of you!

I know I get motivated looking at myself! :lol

River

I've actually been contemplating on selling some kits, and maybe even some completed sets at conventions!

(I'm not sure about selling completed sets online yet because shipping would be extremely cost prohibitive)

At the moment though, I'm working back to back on some props for the slew of summer conventions here in Southern California!

So sadly, I won't have time to set up something like that till after.

But I've recently gotten interest from this and other props, so I definitely am considering making things for sale in the near future.

If time is not an issue for you, I'll let you/this thread know if and when I do get around to making kits/full sets!

Of course, anyone can take the flag from me and make them for sale using info on this thread; I'm not for-profit, but for-enjoyment, so if someone else can deliver it faster, better, and hopefully cheaper than me, so be it! I'd rather not leave someone hanging from enjoying a set of these.

Weapioneer

For my blades, I used foam boards painted with Duplicolor Chrome, with automobile chrome vinyl on the edges, with an aluminum base/tang. The snap-off lines were made the same way I made the fake blade background behind my box's spring window--dents with a ruler. Check my updated OP post to see what my blades look like.

My blades are detachable, and I have spares (well, I used to on my manga version, but as you can see from the thread, my anime version gear only has dupes; now I just nab them off my friend's manga boxes, lol!). However, after spending a lot of time designing the handles and blades, it was either

1) Aesthetic/visual accuracy

2) Function

3) Cost

And we could only pick two (we--three of us--were all wearing manga gear at the time, so that meant having to make 36 blades! :eek), so we went with (2) and (3), lol. Though the blades don't have a slanted cutting edge, I decided not to because making a cutting edge with blades that thin would either be dangerous for cons (if the blade was a rigid material, as my cons are strict) and time-expensive/weight-expensive (36 blades?! lol). Hence I decided to just substitute the cutting edge with a shiny chrome vinyl to give the impression of an edge (just how it looks on snap-off utility knives), instead of having the same metallic finish all around. The handles are not visually accurate, but they worked! (and better looking than the barebones manga version imo)! The blades are released/inserted using the bike brake lever. Let me know if you or anyone wants info on it and I'll do a quick write-up.

Also, since they're foam board and easy to cut, if anything breaks mid-con, you can just sub it with a spare blade or... cut it down to a stub till the bent/damaged portion is gone! My friend particularly likes rocking his stub blade, lol.

http://img.photobucket.com/albums/1003/Saki_AFA/stub.jpg

electraflier

Wow, blades out of actual aluminum! I bet it was sort of a thrill carrying a semi-live blade around huh? :lol At least you were ready to save everyone from any titans!

And nothing beats a factory-made straight edge! I'm a proponent for factory-made anything; if you can buy something already factory cut straight for you, why re-invent the wheel (or in this case, the line)?

Greetings gang, Darktimes,

Thanks for reaching out to me, i'm actually contemplating making a lot of these items myself now, with a partner.

Originally i thought i would be alone in this. but my only thing now is

how are you guys making those amazing sword handles??!?! They look so gorgeous!

I'm reading this thread over and over, do you guys have patterns? I'm seeing one person use sintra and layering that. OMG, i'm just going cross-eyed!

-River

DarkTime

New Member

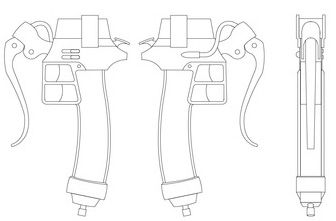

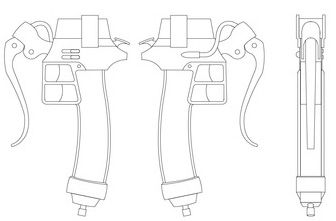

I haven't made updated, anime handles yet, but here's the template/pattern I plan to use!

Scale it to whatever width you want your blade to be, *while being mindful of your handle's thickness!*

For me, I ended up with a 2.25" width blade with a handle that fits comfortably in my hand (iirc; I'm currently away out of town so I can't check).

Stacking sintra and sanding/carving it to shape is one way. I plan to do the same, but with laminated MDF since it'll be way cheaper to stack/laminate, easier, and less noxious to sand (rapid sanding i.e. heating up sintra releases hydrocholoric acid!).

I also plan to checker the grips like on traditional M1911 pistol double-diamond grips.

Hope that gives you some ideas!

Scale it to whatever width you want your blade to be, *while being mindful of your handle's thickness!*

For me, I ended up with a 2.25" width blade with a handle that fits comfortably in my hand (iirc; I'm currently away out of town so I can't check).

Stacking sintra and sanding/carving it to shape is one way. I plan to do the same, but with laminated MDF since it'll be way cheaper to stack/laminate, easier, and less noxious to sand (rapid sanding i.e. heating up sintra releases hydrocholoric acid!).

I also plan to checker the grips like on traditional M1911 pistol double-diamond grips.

Hope that gives you some ideas!

iKillGiants

New Member

im such a loser, i got excited to see that i have the same metal yardstick as you hahaha. great job though.

Similar threads

- Replies

- 0

- Views

- 153