The thread that was linked in Treadwells thread about his blaster was evidently lost in the change over of the RPF. Does anyone have info on taking apart the blaster or is there any way to retrieve that thread? Any info is appreciated. I just got the MR blaster and am considering doing mods to it. Thanks!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone have info on taking apart the MR trooper blaster?

- Thread starter Betamin

- Start date

The more I think about it, that thread was more about trying to figure out stuff than actual info about doing it. Someone did state that they got the forward cap off by melting silicone holding it on, but mine was welded on with no silicone.

User winnstudio once made a great thread about getting the grip assembly off and making the trigger workable. Maybe you could purty-please him into reposting. We'll archive this time, promise!

User winnstudio once made a great thread about getting the grip assembly off and making the trigger workable. Maybe you could purty-please him into reposting. We'll archive this time, promise!

Fortunately the version I posted at the Blaster Builder's Club is still there.

Repost!

-real Hengstler (mounted via bracket fastened under front scope mount)

-real Sterling grip

-real M47 scope (w/ Bobadebt/Corellian Exports bolts)

-custom rail

-RPF cylinders

-working trigger

-working stock

-new paint (slightly crinkled)

-mild weathering

Of great help with the trigger mod was an old RPF thread by wynnstudio that is now gone.

Also this other MR mod thread: [also gone]

I would've put SaberFreak T-Track on it, with a slight ANH bow, but lookie what's under the MR T-Track:

Slots instead of holes! :confused

Repost!

-real Hengstler (mounted via bracket fastened under front scope mount)

-real Sterling grip

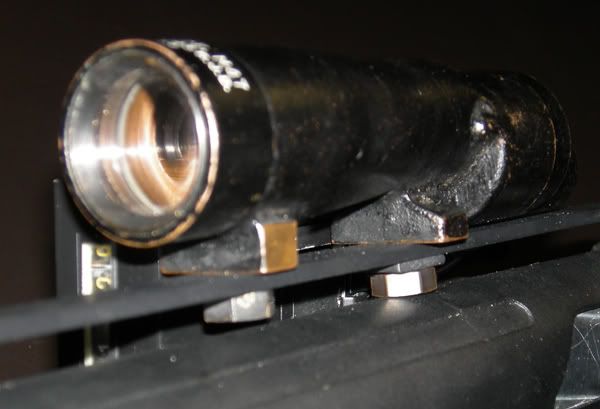

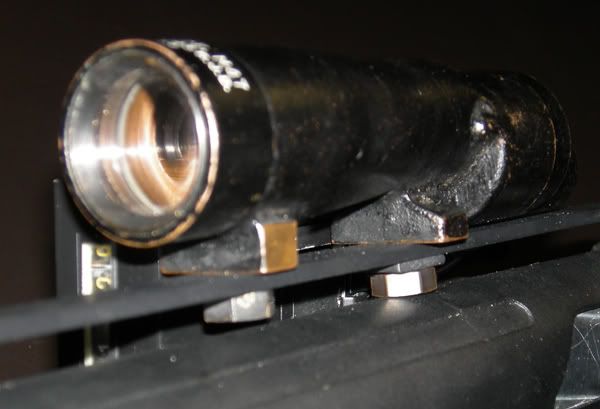

-real M47 scope (w/ Bobadebt/Corellian Exports bolts)

-custom rail

-RPF cylinders

-working trigger

-working stock

-new paint (slightly crinkled)

-mild weathering

Of great help with the trigger mod was an old RPF thread by wynnstudio that is now gone.

Also this other MR mod thread: [also gone]

I would've put SaberFreak T-Track on it, with a slight ANH bow, but lookie what's under the MR T-Track:

Slots instead of holes! :confused

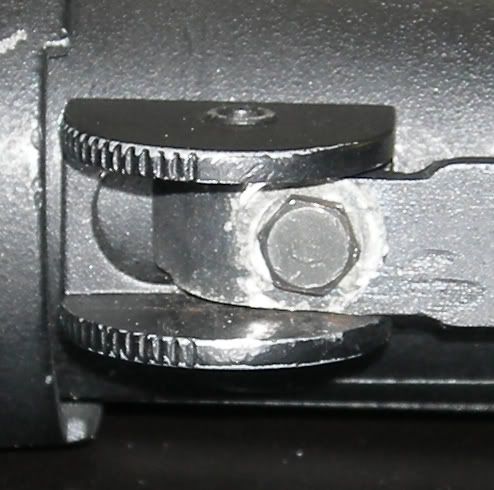

All three allen bolts were stripped of paint and then blacked/blued with some stuff from Brownells. Also the brass hex bolts.

Paint: bulk of it is satin black, with semi-flat for that plate on the trigger assembly, and flat for the magazine. I gave it somewhat of a krinkly texture by sputtering spraypaint at it from about 3 feet away (a tip BobaDebt posted years ago). Note I also painted that rectangular area around the slot for the trigger, which was left silver on the MR.

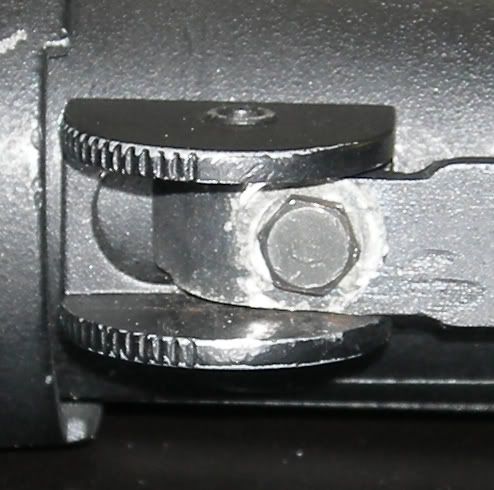

The scope rail is just 1/2" aluminum bar, bent by hand with pliers and dremeled as needed to hook it into the vent hole and the sight. I used the same screw hole in the sight that MR used, but needed to replace the screw itself since I needed it to be longer. Found a hex bolt of the correct size and threading (and can dig up the package for that info if anyone needs it). There is a spacer under the rail in the rear sight, as tightening the bolt tended to bend the aluminum. I tried using aluminum black on the rail but I never have much luck getting even finishes with that. So I painted over it.

There was nothing wrong with the MR grip, but I had a real Sterling one, so why not? Plus, the real ones have a different look and feel, being a lighter colored bakelite (I think), as opposed to the glossy black ABS of the MR. The Sterling grip did require modification to fit. I had to remove material at the top and in the inside. As it is, the retaining pin is still a little off-center.

The stock was a bit of a PITA. It is screwed on from the inside of the shroud, and access to that screw is blocked by the barrel. Contrary to reports from others who apparently were able to get the front endcap off the shroud, mine was quite soundly welded and wouldn't come off, not even after being heated with a propane torch.

So I had to get the barrel out of the way. To do that, you have to remove the allen screw at the bottom of the grip, which enables you to remove the trigger assembly (at which time you can make the trigger workable). Inside the area where that assembly goes, is a little screw that goes through the reciever and keeps the "bolt" in place. Remove that, and you can slide the bolt, and the attached barrel, back into the reciever and allow yourself access to that screw keeping the stock in place. Be careful as you slide the bolt around, as there are screws going into the receiver from the magazine well, and they will scratch the bolt. (As they did mine.)

A rectangular piece on the stock sticks up into the receiver, and as I recall I had to dremel that down to size to get the stock loose.

The stock will now unfold somewhat, but not all the way without dremeling away some material. Hard to describe, but you'll see what's in the way when you get there. In the end, unfolding it into a shoulder stock is a little clunky (a real Sterling has a spring that helps the process) but you can do it.

When you flip it around to the rear of the blaster, the arms will not fit around the endcap as they should. I simply dremeled some material off the lower sisides of the endcap, as well as bent the arms somewhat. Now it locks in snugly.

But then I faced a problem: to free up the stock I'd had to destroy the means to keep it stuck to the shroud when folded all back up! A real Sterling (and even the Asahi airsoft version) has a spring/latch thingie that I had no idea how to create from scratch. After failed attempts at using magnets and homemade clips, I finally settled on using a snap fastener. Not particularly elegant but it works.

I wanted to be able to remove the magazine so the blaster would fit in a padded gun case. This took some doing.

Ignore the big thumscrew on top of the magwell. Ignore the little oval insert on the bottom of it. What makes the magazine non-removable is a little screw hidden behind the cylindrical piece that sticks out to the left on the back end of the mag well. That piece has a hole in it--almost. It doesn't go all the way through, which is too bad, because that would make access to the screw easier.

I did it the hard way, by trying to unscrew that cylinder. Turns out a screw is attached to it from the inside of the magwell, and instead of unscrewing I broke the thing off! But hey, this allowed access to the screw.

But the proper way would be to loosen the bolt as described above, then, accessing through the eject port, remove a couple of screws on the inside of the reciever that attach the magwell. Once the magwell's off, you could access the screw inside that attaches the cylinder thing.

Either way, though, once the cylinder is off, and then the screw into the magazine is removed, you'll find that the magazine might still not come out. This is because there is a ton of silicone sealer inside this thing. Ultimately I used a blowtorch to heat up the metal and subsequently soften the silicone. All the parts are metal and can take the heat EXCEPT at the very end of the magazine. See the hole and the little round nub? That nub is ABS plastic. Keep the fire away from it and you'll be fine.

I did not reinsert that screw into the mag, and I made a peg for the cylinder and epoxied it back on. Now my mag was removable, but it did have a wee bit of play. So when I attached the plate with the cylinders (both epoxy and a screw), I drilled the screw hole through both the mag well and the mag. So to remove the magazine I will have to remove that screw, but that's fine, as it is easily accessible unlike the one hidden behind the cylinder thing.

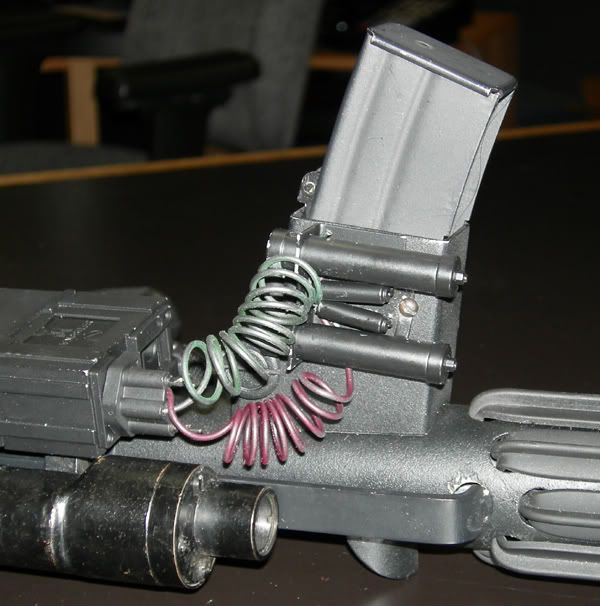

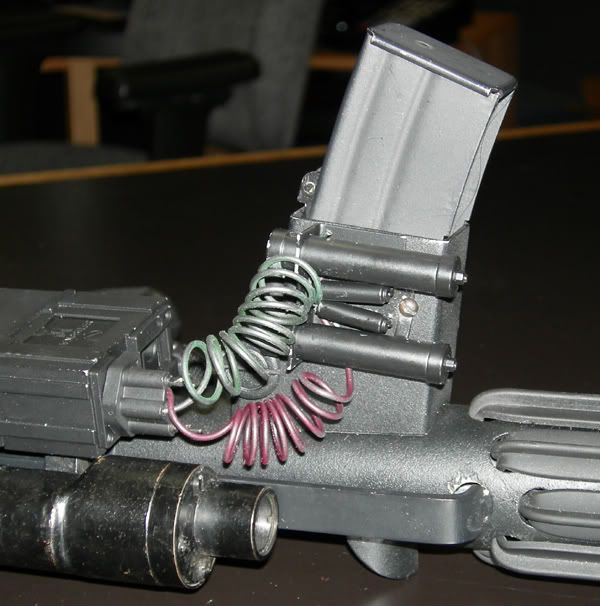

I was asked about the coiled wires.

I used 16-guage metal wire I got at either Lowe's or Home Depot. Comes wrapped around a square plastic rod. I comes black, and I spraypainted the colors only lightly, as I didn't want the colors to be too bright. Bright would be accurate, but looked gaudy to me.

I made the coils by tightly and neatly wrapping the wire around an aluminum tube. The ends of the wires are just bent around the cylinders and just crammed into the Hengstler. They do come loose on occasion.

Paint: bulk of it is satin black, with semi-flat for that plate on the trigger assembly, and flat for the magazine. I gave it somewhat of a krinkly texture by sputtering spraypaint at it from about 3 feet away (a tip BobaDebt posted years ago). Note I also painted that rectangular area around the slot for the trigger, which was left silver on the MR.

The scope rail is just 1/2" aluminum bar, bent by hand with pliers and dremeled as needed to hook it into the vent hole and the sight. I used the same screw hole in the sight that MR used, but needed to replace the screw itself since I needed it to be longer. Found a hex bolt of the correct size and threading (and can dig up the package for that info if anyone needs it). There is a spacer under the rail in the rear sight, as tightening the bolt tended to bend the aluminum. I tried using aluminum black on the rail but I never have much luck getting even finishes with that. So I painted over it.

There was nothing wrong with the MR grip, but I had a real Sterling one, so why not? Plus, the real ones have a different look and feel, being a lighter colored bakelite (I think), as opposed to the glossy black ABS of the MR. The Sterling grip did require modification to fit. I had to remove material at the top and in the inside. As it is, the retaining pin is still a little off-center.

The stock was a bit of a PITA. It is screwed on from the inside of the shroud, and access to that screw is blocked by the barrel. Contrary to reports from others who apparently were able to get the front endcap off the shroud, mine was quite soundly welded and wouldn't come off, not even after being heated with a propane torch.

So I had to get the barrel out of the way. To do that, you have to remove the allen screw at the bottom of the grip, which enables you to remove the trigger assembly (at which time you can make the trigger workable). Inside the area where that assembly goes, is a little screw that goes through the reciever and keeps the "bolt" in place. Remove that, and you can slide the bolt, and the attached barrel, back into the reciever and allow yourself access to that screw keeping the stock in place. Be careful as you slide the bolt around, as there are screws going into the receiver from the magazine well, and they will scratch the bolt. (As they did mine.)

A rectangular piece on the stock sticks up into the receiver, and as I recall I had to dremel that down to size to get the stock loose.

The stock will now unfold somewhat, but not all the way without dremeling away some material. Hard to describe, but you'll see what's in the way when you get there. In the end, unfolding it into a shoulder stock is a little clunky (a real Sterling has a spring that helps the process) but you can do it.

When you flip it around to the rear of the blaster, the arms will not fit around the endcap as they should. I simply dremeled some material off the lower sisides of the endcap, as well as bent the arms somewhat. Now it locks in snugly.

But then I faced a problem: to free up the stock I'd had to destroy the means to keep it stuck to the shroud when folded all back up! A real Sterling (and even the Asahi airsoft version) has a spring/latch thingie that I had no idea how to create from scratch. After failed attempts at using magnets and homemade clips, I finally settled on using a snap fastener. Not particularly elegant but it works.

I wanted to be able to remove the magazine so the blaster would fit in a padded gun case. This took some doing.

Ignore the big thumscrew on top of the magwell. Ignore the little oval insert on the bottom of it. What makes the magazine non-removable is a little screw hidden behind the cylindrical piece that sticks out to the left on the back end of the mag well. That piece has a hole in it--almost. It doesn't go all the way through, which is too bad, because that would make access to the screw easier.

I did it the hard way, by trying to unscrew that cylinder. Turns out a screw is attached to it from the inside of the magwell, and instead of unscrewing I broke the thing off! But hey, this allowed access to the screw.

But the proper way would be to loosen the bolt as described above, then, accessing through the eject port, remove a couple of screws on the inside of the reciever that attach the magwell. Once the magwell's off, you could access the screw inside that attaches the cylinder thing.

Either way, though, once the cylinder is off, and then the screw into the magazine is removed, you'll find that the magazine might still not come out. This is because there is a ton of silicone sealer inside this thing. Ultimately I used a blowtorch to heat up the metal and subsequently soften the silicone. All the parts are metal and can take the heat EXCEPT at the very end of the magazine. See the hole and the little round nub? That nub is ABS plastic. Keep the fire away from it and you'll be fine.

I did not reinsert that screw into the mag, and I made a peg for the cylinder and epoxied it back on. Now my mag was removable, but it did have a wee bit of play. So when I attached the plate with the cylinders (both epoxy and a screw), I drilled the screw hole through both the mag well and the mag. So to remove the magazine I will have to remove that screw, but that's fine, as it is easily accessible unlike the one hidden behind the cylinder thing.

I was asked about the coiled wires.

I used 16-guage metal wire I got at either Lowe's or Home Depot. Comes wrapped around a square plastic rod. I comes black, and I spraypainted the colors only lightly, as I didn't want the colors to be too bright. Bright would be accurate, but looked gaudy to me.

I made the coils by tightly and neatly wrapping the wire around an aluminum tube. The ends of the wires are just bent around the cylinders and just crammed into the Hengstler. They do come loose on occasion.

I'll probably mess with my blaster a bit this weekend and fiddle with it to see what I can take apart without destroying anything. What is needed to get that orange plug out of the barrel? Drilling it out? Or is it something that can be taken out from behind the barrel front piece?

I took the allen bolts off the front of my blaster, and saw that mine has the solid metal end with the "barrel" inside. I popped off the end cap and was glad to see that it's not a thick tube, so I'll be drilling and cutting out the slide slot at some point. Anyone know what the pull back lever looks like on the original Sterling? Robstyle, is the plug solid and far enough back that a hole could be drilled and a lever could be added on?

I was lucky to see that so far, the only glue I've encountered is in the trigger area. The end cap popped right off after I took out the tiny screws under that lever on the bottom.

Anyone have any ideas where to get a proper looking large spring to put inside the tube if I cut the slot so you can see it like the real Sterling?

I was lucky to see that so far, the only glue I've encountered is in the trigger area. The end cap popped right off after I took out the tiny screws under that lever on the bottom.

Anyone have any ideas where to get a proper looking large spring to put inside the tube if I cut the slot so you can see it like the real Sterling?

Woohoo!! Thanks to Treadwells info about taking his blaster apart, I was able to, in a very short amount of time, remove the bolt, slide it out the back, take out the incredibly tiny screws (I still can't believe that's all they used to hold that mag section on with!) and was soon holding the magazine assembly in my hands. Mine too had a ton of clear silicone in it...... which popped out in two solid chunks thanks to barely prying at it with my pocket knife. :lol They must have used the cheap stuff on mine. Following Treads info, I soon had the small black tube off, exposing the screw that held on the clip, and voila, it now pops out and will be removable! It slides back in and holds in place easily, and will stay in just fine. My once static prop now has an actual removable part! I don't know if I will tackle the stock for awhile though, it sounds like a major pain in the butt. Thanks for the info, Treadwell!

robstyle

Master Member

I honestly dont remember much since its been a couple years since I had seen that thing cut up like that. I just remember it seems someone went through some pains to make sure simple things like the trigger, clip and stock didnt function yet they would have been very simple to convert/make functional for sale.

I honestly dont remember much since its been a couple years since I had seen that thing cut up like that. I just remember it seems someone went through some pains to make sure simple things like the trigger, clip and stock didnt function yet they would have been very simple to convert/make functional for sale.

Rob, I remember seeing the thread you spoke of where they showed the way to make the trigger move. I can pop out one of the metal rods holding it in place and I believe they put a spring in there to make it work. I may try that next, but I can't see how to get the stock off, because of the clip that is inside the front that is holding it in place. You can see it in your parts pic, but I didn't see any way other than snapping it off or removing the hinge pins at the back (which I couldn't figure out how to do" to get it to release so you could swing it down.

One thing I noticed while just taking parts off is how easily the finish flakes off if you're not careful. A small spot where the mag assembly touched flaked off, and it looks like it wouldn't take much to really flake off more. I can see this getting "distressed" easily if you beat it around a bit. While looking at the body tube and thinking about drilling and cutting out the slide slot, I wondered if I'd have to end up repainting it if it flaked badly from drilling and cutting. Probably so. :unsure

robstyle

Master Member

I dont think the paint flake thing is intentional. It may be more a factor of contaminants on the metal surface not being properly cleand prior to painting. You would be amazed at how quickly you can disassemble the MR E11. Just grad your tools and start going at it. Some peices are simply glued in while others are held with set screws.

You're right about it actually being pretty easy. I had it all the way down to just the body tube with the stock and grips being all that was left on it. I would have had the stock off if I could have figured out how to get it loose without breaking that clip up in the nose of the tube. How did you get yours off of the gun?

Similar threads

- Replies

- 2

- Views

- 324

- Replies

- 0

- Views

- 182

- Replies

- 11

- Views

- 647