Darth Pinhead

Active Member

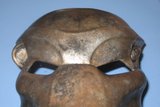

I am also the proud owner of one of the P1 Stunt Bios that George graciously casts. I have to say, since this is my first Bio project, I was quite intimidated to even touch the damn thing. I just sat and stared at it for a good week or so. At any rate, I've finally begun cleaning it up. My goal is not to necessarily get this guy smooth as glass. In fact, I plan on doing very little to the face of the Bio and intend upon keeping the major mold indentations. My major concern is cleaning up the edge of the bio and strengthening it with JB Weld Plastic Epoxy Putty. As I have read more than enough times, dropping these guys can lead to horrible results. Not that I intend upon dropping it (Who does?) but I do want to do my best to protect the edge from chipping. This is not to say the edge was not strong enough, just that I am super paranoid/anal and would rather error on the side of precaution. Applying the putty along the inside of the lip has also allowed me to build it up in places so that I can go back and sand it all down to a more consistant height all the way around the crown.

At any rate, I have spent four hours, over the course of three days, trimming the flashing, sanding anything major, and strengthing the edge of the bio with the putty. The putty I am using works GREAT. The JB Weld version (The Off-white) definitely does not stink as badly as the previous brand I used (Grey). I'm applying it by cutting off 1/4" slices from the stick, creating 1/4 ropes, and then smoothing it out with wet fingertips. Once I am content with the amount of putty that I have built up, I intend upon sanding down the outside edge, getting it as symmetrical as possible, and then will sand the inside down to eliminate some of the weight added by the putty. And yes, I realize I am spending WAY MORE TIME on the inside of the helmet than the outside (Probably more than most people spend on the outside, alone),

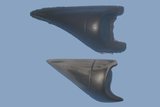

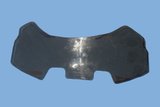

Laser Shroud & Air Tube References

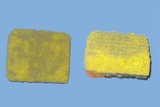

Putty & Sanding Supplies

Masking, Primer, & PlasttiDip

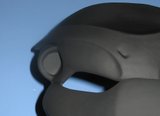

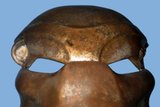

Bio Upon Arrival: 12.17.2010

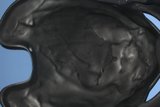

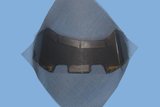

Post Initial Sanding & First Round of Putty: 12.27.2010 - 2 Hours

Second Round of Putty: 12.29.2010 - 1 Hour

Third Round of Putty: 12.29.2010 - 1 Hour

Sanding of the Rim & Cutting Out Eyes: 12.31.2010 - 3 Hours

Sanding of the Eyes & Detailing the Back Fin: 01.02.2011 - 4 Hours

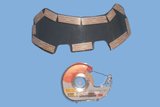

Sanding of the Shroud, Cutting hole in Bio for Laser access, Attaching of the Shroud: 01.04.2011 - 3 Hours

Casey (biohunter76) makes the kit with the shroud and hose connectors. He also sells the Pre-wired Tri Laser, however, I chose to use Jason's (PredatrHuntr) Super Bright Red LEDs.

Applying First Round of Epoxy Putty to Shroud: 01.06.2011 - 0.5 Hours

Sanding of the Shroud: 01.06.2011 - 4 Hours

Not So Final Sanding of the Shroud: 01.11.2011 - 1 Hours

Another Round of Putty To The Shroud & Eyes: 1.13.2010 - 3 Hour

Yet More Sanding of the Shroud: 01.14.2011 - 4 Hours

Reshaped the Shroud, Prepped for Hose Connector on Chin, Finished the eyes: 01.15.2011 - 8 Hours

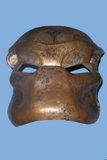

FINAL sanding of the Shroud, Casey's Kit affixed, Primer Coats Applied: 01.16.2011 - 5 Hours

I used Rust-oleum Auto Sandable Primer Spray

Masking Off & Application of PlastiDip Spray-4 coats: 01.18.2011 - 3 Hours

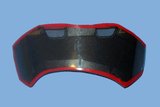

Peeling of PlastiShit, Etching of Shroud Line, and First Layer of Silver: 01.19.2011 - 2 Hours

Rustification of the Bio with Acrylics: 01.19.2011 - 2 Hours

Final Silver & Wet Sanding: 01.20.2011 - 1 Hour

I used a very fine thin sanding sponge to really knock down the metallic sheen and blend the silver in with the rust-job...

Blast Marks: 01.22.2011 - 1 Hour

Felting The Inside: 01.23.2011 - 3 Hours

Cutting of the Lens & Repaint: 01.24.2011 - 1 Hour Lens, 2 Hours Repainting

Lens Installation & Laser Plate Velcro: 01.26.2011 - 1 Hour Lens, 30 Minutes Laser Plate

At any rate, I have spent four hours, over the course of three days, trimming the flashing, sanding anything major, and strengthing the edge of the bio with the putty. The putty I am using works GREAT. The JB Weld version (The Off-white) definitely does not stink as badly as the previous brand I used (Grey). I'm applying it by cutting off 1/4" slices from the stick, creating 1/4 ropes, and then smoothing it out with wet fingertips. Once I am content with the amount of putty that I have built up, I intend upon sanding down the outside edge, getting it as symmetrical as possible, and then will sand the inside down to eliminate some of the weight added by the putty. And yes, I realize I am spending WAY MORE TIME on the inside of the helmet than the outside (Probably more than most people spend on the outside, alone),

Laser Shroud & Air Tube References

Putty & Sanding Supplies

Masking, Primer, & PlasttiDip

Bio Upon Arrival: 12.17.2010

Post Initial Sanding & First Round of Putty: 12.27.2010 - 2 Hours

Second Round of Putty: 12.29.2010 - 1 Hour

Third Round of Putty: 12.29.2010 - 1 Hour

Sanding of the Rim & Cutting Out Eyes: 12.31.2010 - 3 Hours

Sanding of the Eyes & Detailing the Back Fin: 01.02.2011 - 4 Hours

Sanding of the Shroud, Cutting hole in Bio for Laser access, Attaching of the Shroud: 01.04.2011 - 3 Hours

Casey (biohunter76) makes the kit with the shroud and hose connectors. He also sells the Pre-wired Tri Laser, however, I chose to use Jason's (PredatrHuntr) Super Bright Red LEDs.

Applying First Round of Epoxy Putty to Shroud: 01.06.2011 - 0.5 Hours

Sanding of the Shroud: 01.06.2011 - 4 Hours

Not So Final Sanding of the Shroud: 01.11.2011 - 1 Hours

Another Round of Putty To The Shroud & Eyes: 1.13.2010 - 3 Hour

Yet More Sanding of the Shroud: 01.14.2011 - 4 Hours

Reshaped the Shroud, Prepped for Hose Connector on Chin, Finished the eyes: 01.15.2011 - 8 Hours

FINAL sanding of the Shroud, Casey's Kit affixed, Primer Coats Applied: 01.16.2011 - 5 Hours

I used Rust-oleum Auto Sandable Primer Spray

Masking Off & Application of PlastiDip Spray-4 coats: 01.18.2011 - 3 Hours

Peeling of PlastiShit, Etching of Shroud Line, and First Layer of Silver: 01.19.2011 - 2 Hours

Rustification of the Bio with Acrylics: 01.19.2011 - 2 Hours

Final Silver & Wet Sanding: 01.20.2011 - 1 Hour

I used a very fine thin sanding sponge to really knock down the metallic sheen and blend the silver in with the rust-job...

Blast Marks: 01.22.2011 - 1 Hour

Felting The Inside: 01.23.2011 - 3 Hours

Cutting of the Lens & Repaint: 01.24.2011 - 1 Hour Lens, 2 Hours Repainting

Lens Installation & Laser Plate Velcro: 01.26.2011 - 1 Hour Lens, 30 Minutes Laser Plate