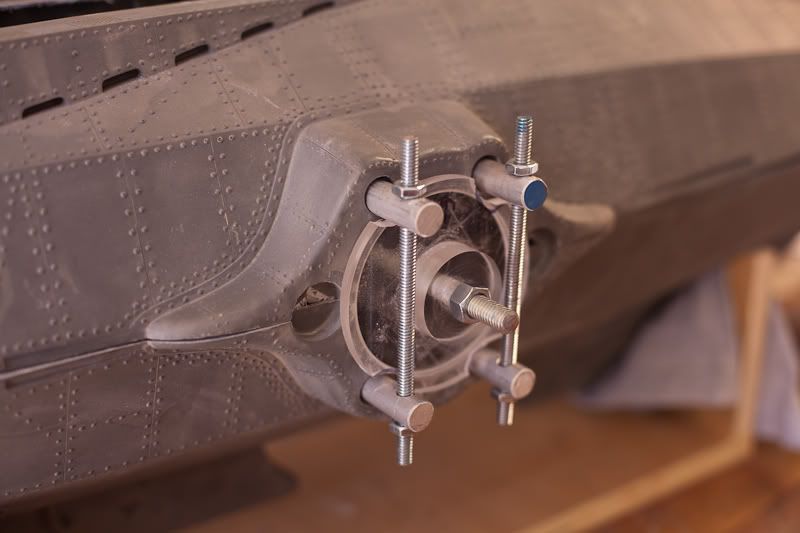

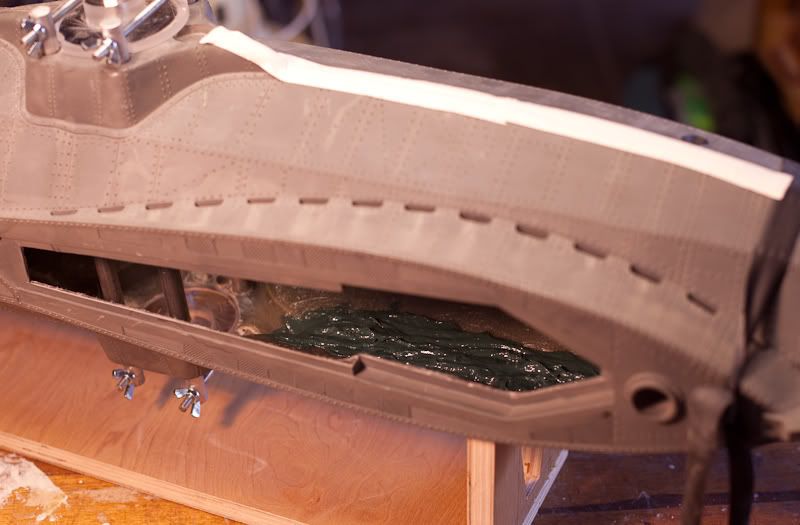

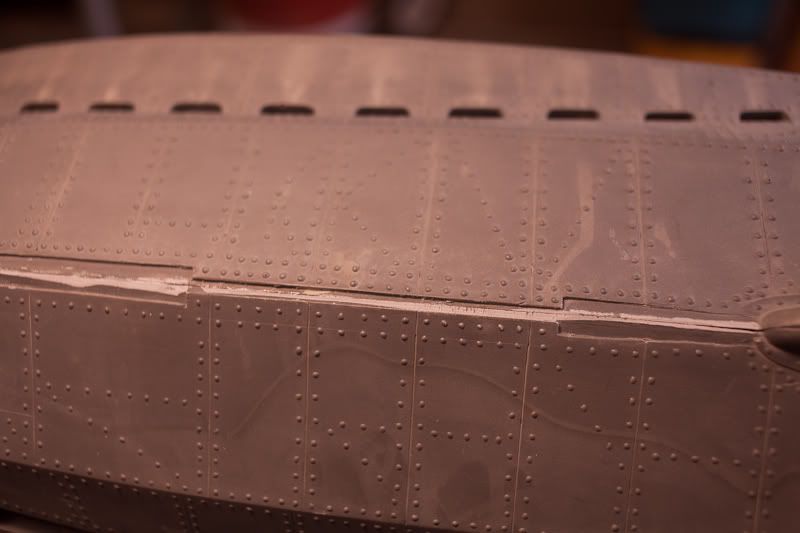

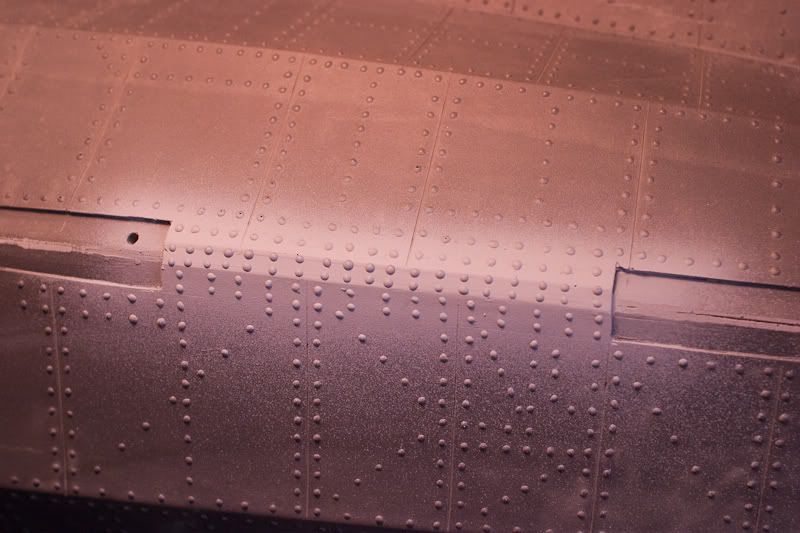

This thread wil chronicle my build of Custom Replicas 1/32 scale Nautilus from Disney's 20,000 Leagues Under the Sea. This kit is from the first generation run of parts and is about ten years old. Considering that CR recently anounced that they have discontinued production of this kit I feel very fortunate to have been able to pick this one up. When finished, the model measures 66 inches long and makes a spectacular display piece.

the model is going to be displayed in my Nautilus Home Theater which you can see here:

http://www.goldbergarts.com/nautilusscreeningroom/

The Nautilus model seen in the pictures on my site was borrowed for the photoshoot.

Here are the parts;

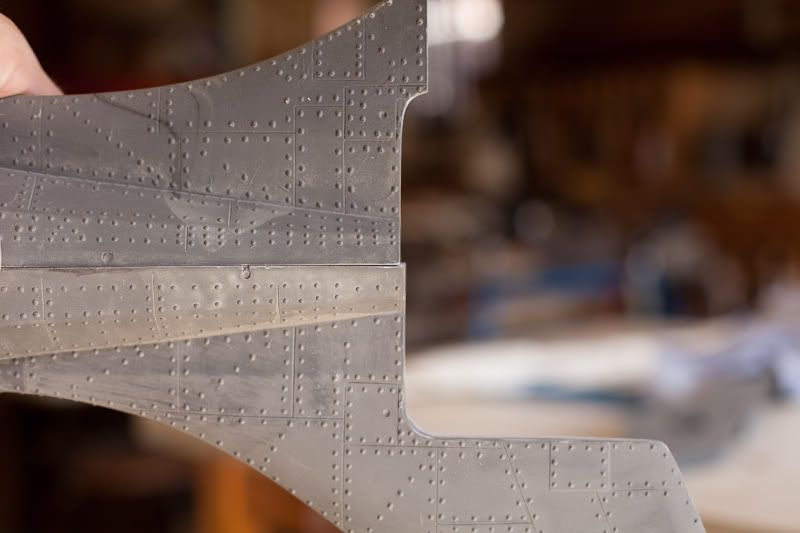

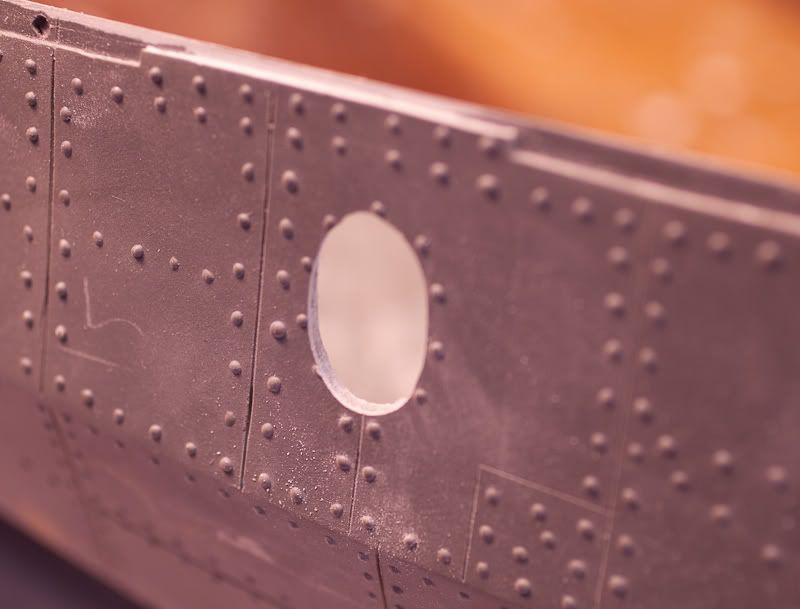

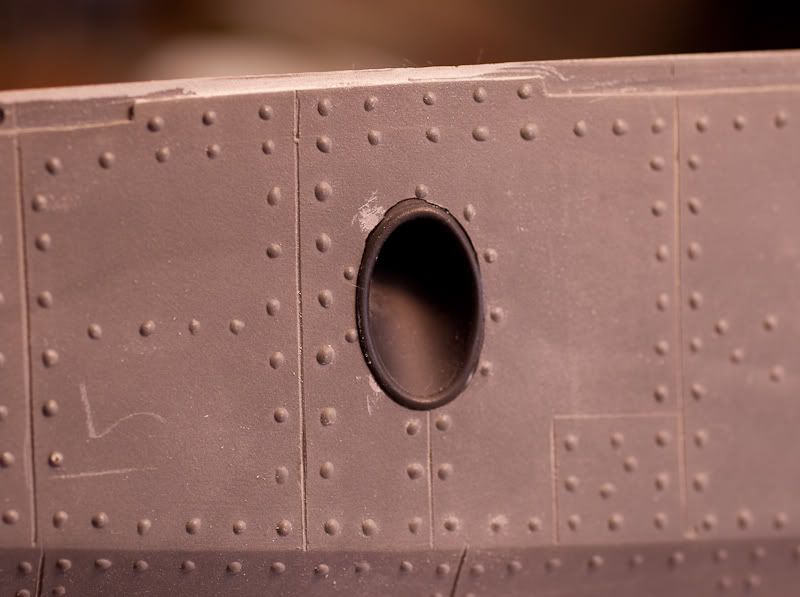

Overall, the castings are pretty clean. A bit of clean up required at the mold seams but nothing too bad. The hulls are warped just a tiny bit but should come together no problem. Some of the larger parts like the side fins and rackers are also warped, but again, I should be able to soften them in a hot box and straighten them out.

the model is going to be displayed in my Nautilus Home Theater which you can see here:

http://www.goldbergarts.com/nautilusscreeningroom/

The Nautilus model seen in the pictures on my site was borrowed for the photoshoot.

Here are the parts;

Overall, the castings are pretty clean. A bit of clean up required at the mold seams but nothing too bad. The hulls are warped just a tiny bit but should come together no problem. Some of the larger parts like the side fins and rackers are also warped, but again, I should be able to soften them in a hot box and straighten them out.