You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scratch Build- 2001 Space Odyssey- Clavius Moon Base

- Thread starter Carlb

- Start date

stevielewis

Sr Member

Jumped on the build thread late but what I have read and seen in the pictures is fantastic.

Carlb

Well-Known Member

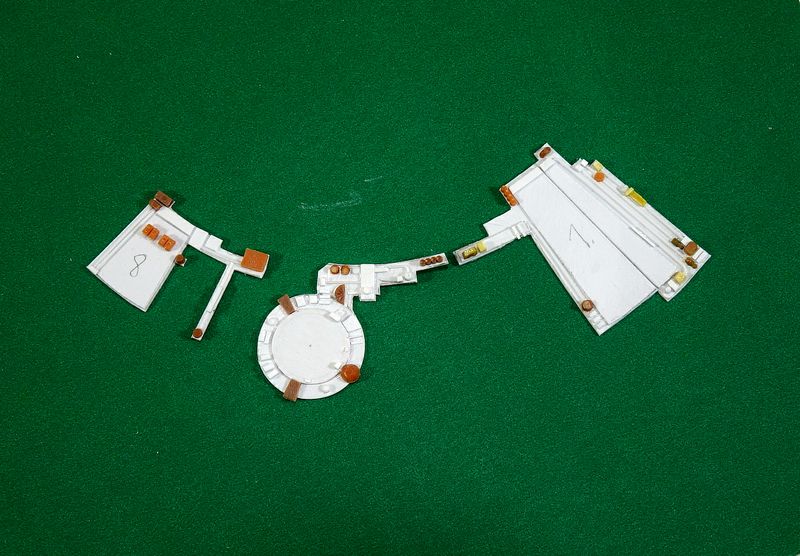

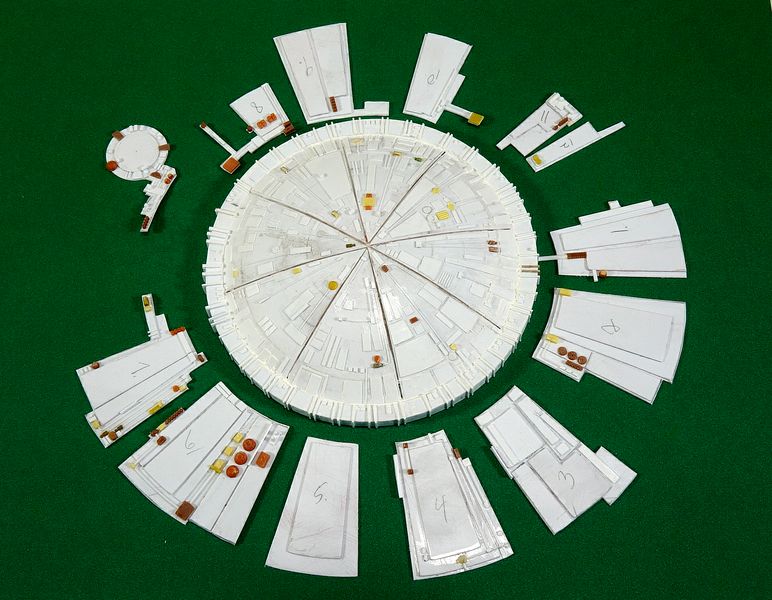

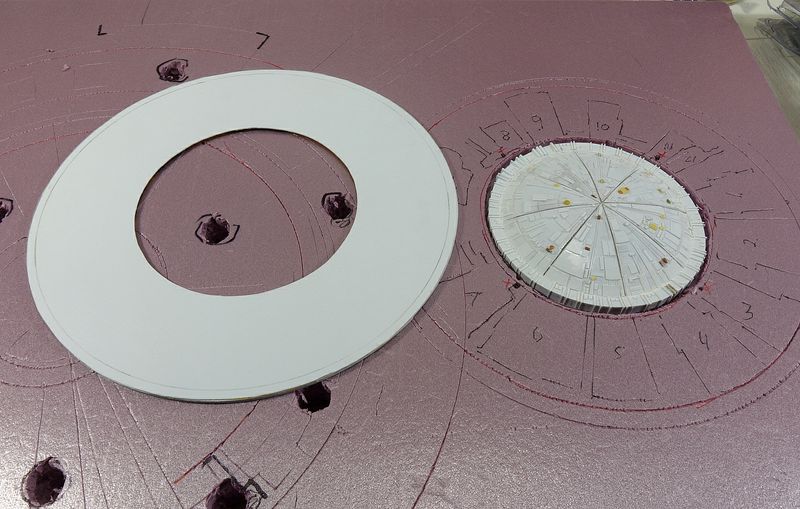

The small outer ring landing pads are positioned around the dome. Same technique as before... .02" styrene shapes,

and individual bits and pieces chopped up to randomly fill spaces.

Checking positions and sizes for the next steps.

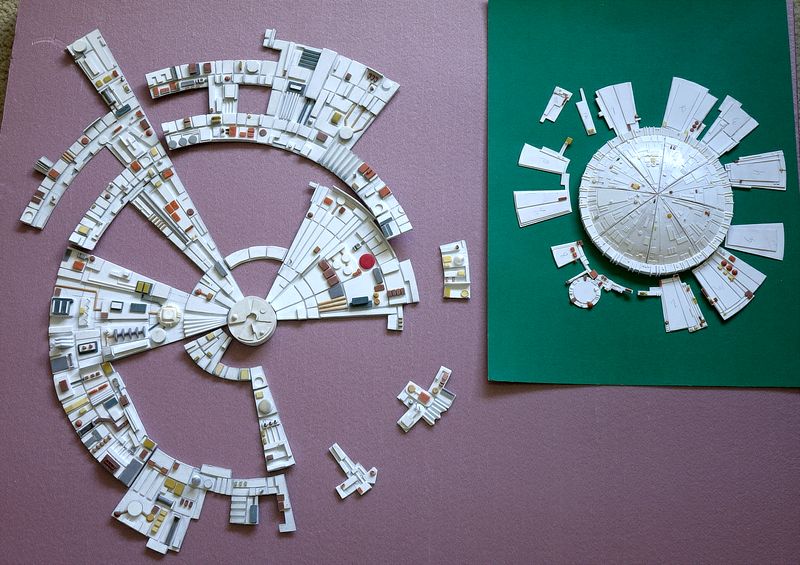

I'll be using "purple foam" (Owens Corning Foamular), a 1" (25mm) thick sheet sold in 24" (609mm) x 24" (609mm) as project panels,

for the moon surface base. To make the diorama as small & lightweight as possible, approximately 24" (609mm) wide

by 18" (457mm) tall. Testing the layout arrangement ....

Reminder: this model will be hung on a wall in a picture frame.....

Till next time....begin lights and wiring...

and individual bits and pieces chopped up to randomly fill spaces.

Checking positions and sizes for the next steps.

I'll be using "purple foam" (Owens Corning Foamular), a 1" (25mm) thick sheet sold in 24" (609mm) x 24" (609mm) as project panels,

for the moon surface base. To make the diorama as small & lightweight as possible, approximately 24" (609mm) wide

by 18" (457mm) tall. Testing the layout arrangement ....

Reminder: this model will be hung on a wall in a picture frame.....

Till next time....begin lights and wiring...

Lupano

New Member

You're welcome.Thanks for the thumbs up Lupano, and welcome to the thread.

Can't wait to see it finished.

Carlb

Well-Known Member

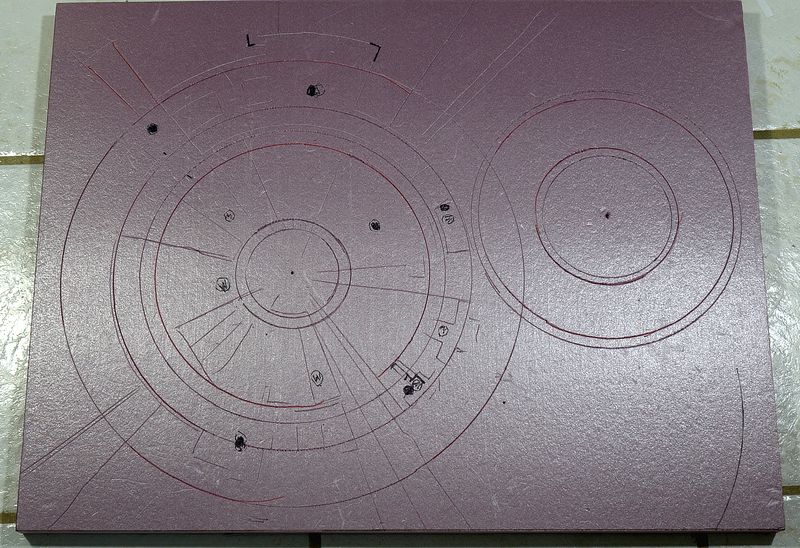

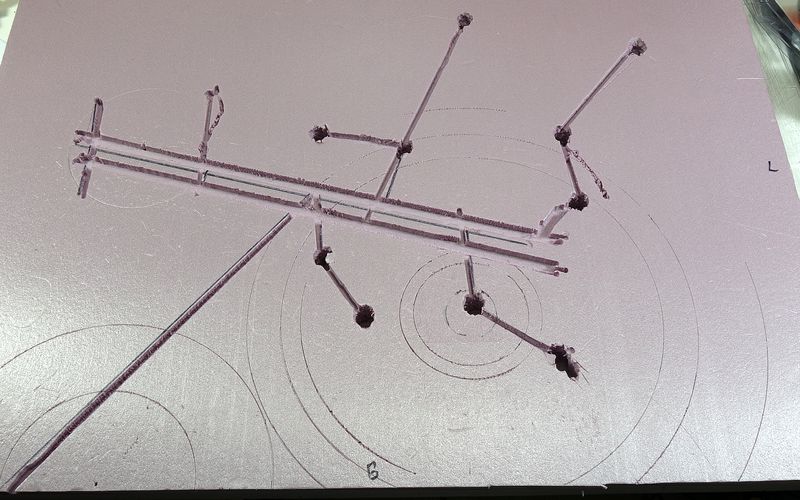

I marked the Foamular with some guidelines for future section placement....

To provide a sunken area in the lunar surface for the small dome- I cut out the foam with a Dremel 565 (router type) attachment , mounted on my vintage Dremel 395. Outdoors for fresh air....

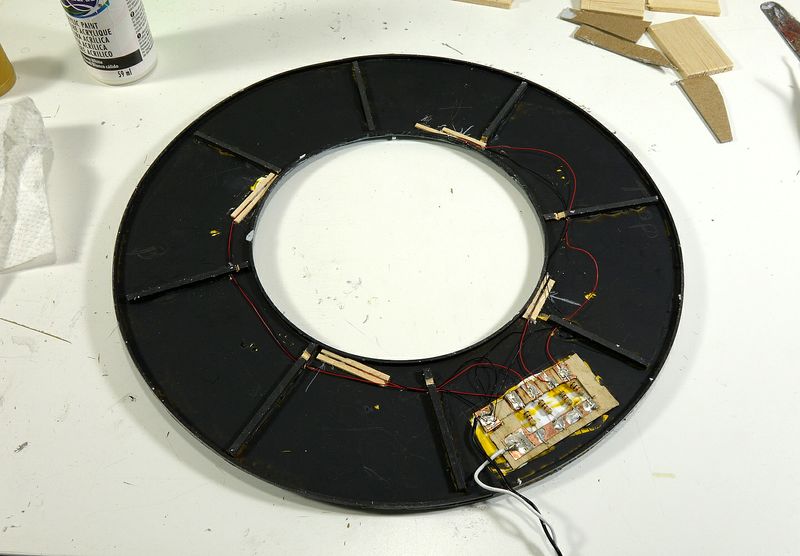

Test fit for the dome, along with a ring of styrene I built to mount the external landing pads, and provide mounting for four lights.

I mounted the 4 LED's underneath in place, with their companion resistors and power supply wires. All of it had to squeeze into an 1/8" (3.1 mm) wide space.

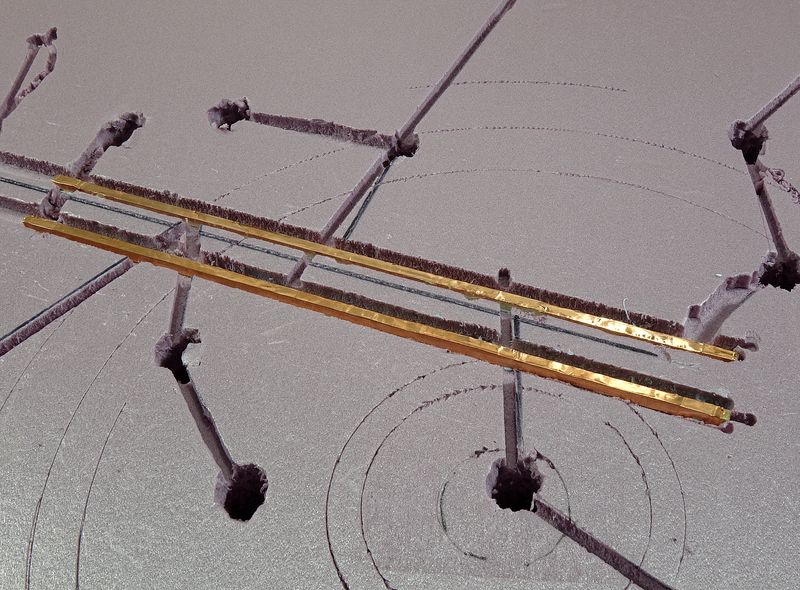

On the other side of the foam, I also cut out multiple channels to accommodate my copper tape clad DC power...12 volt plus & minus busses, & feeder wires for each section.

Glued the two power busses in place using Loctite PL300 adhesive, made especially for foam adhesion.

Till next time.... starting the lunar surface..

To provide a sunken area in the lunar surface for the small dome- I cut out the foam with a Dremel 565 (router type) attachment , mounted on my vintage Dremel 395. Outdoors for fresh air....

Test fit for the dome, along with a ring of styrene I built to mount the external landing pads, and provide mounting for four lights.

I mounted the 4 LED's underneath in place, with their companion resistors and power supply wires. All of it had to squeeze into an 1/8" (3.1 mm) wide space.

On the other side of the foam, I also cut out multiple channels to accommodate my copper tape clad DC power...12 volt plus & minus busses, & feeder wires for each section.

Glued the two power busses in place using Loctite PL300 adhesive, made especially for foam adhesion.

Till next time.... starting the lunar surface..

STEAMLOCODOG

New Member

Hi Carl, I guess you have branched out (to Space). I'll be following this tread. Jeff RThank you very much Analyzer.

Carlb

Well-Known Member

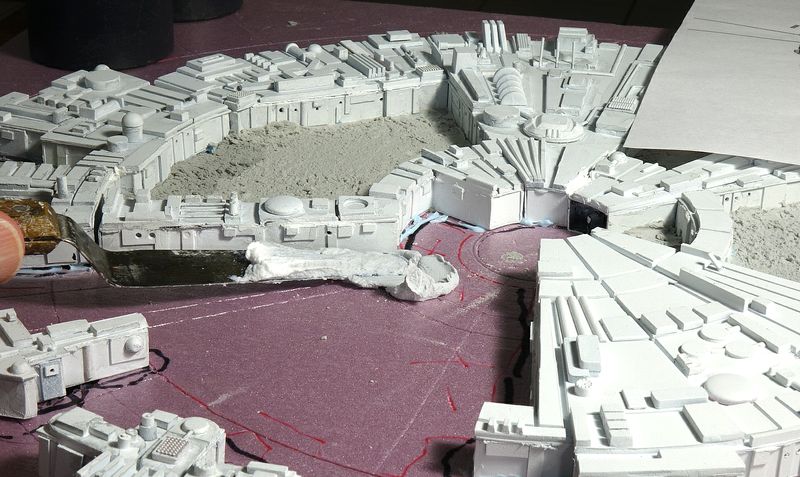

To create the moon surface, I chose a product called "Smooth Finish", that has amazing properties. It comes out of the tub like a thin toothpaste, and dries hard in 24 hours. It is paintable, sand-able and sticks to almost anything. Most importantly, it's water based & dries into an extremely lightweight texture.

I added a few drops of cheap acrylic gray to the "Smooth Finish" product and covered the ring with it, while leaving open spaces for the landing pads. Testing lights.

24 hours later dried, and glued down the pads.

I glued the dome in place with Loctite PL300, followed by the ring. More touch ups and fill-ins necessary.

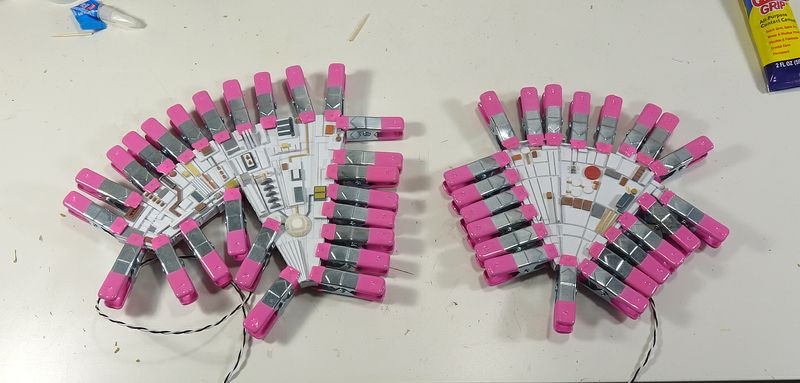

Started to get the main structures together, by gluing the "tops" of each unit to its proper lower sections.( Pink clamps are a "dollar" store item. 6 in a pack)

Glued down & clamped larger sections onto the proper positions onto foam board.

As each section was added, applied the "Smooth Finish" product to adjacent areas. In this way, I wouldn't be trapped by the next section trying to get into tight spaces.

A common open cell dry sponge was lightly dabbed onto the product. Plenty of open working time.

Till next time....

I added a few drops of cheap acrylic gray to the "Smooth Finish" product and covered the ring with it, while leaving open spaces for the landing pads. Testing lights.

24 hours later dried, and glued down the pads.

I glued the dome in place with Loctite PL300, followed by the ring. More touch ups and fill-ins necessary.

Started to get the main structures together, by gluing the "tops" of each unit to its proper lower sections.( Pink clamps are a "dollar" store item. 6 in a pack)

Glued down & clamped larger sections onto the proper positions onto foam board.

As each section was added, applied the "Smooth Finish" product to adjacent areas. In this way, I wouldn't be trapped by the next section trying to get into tight spaces.

A common open cell dry sponge was lightly dabbed onto the product. Plenty of open working time.

Till next time....

Similar threads

- Replies

- 47

- Views

- 2,147