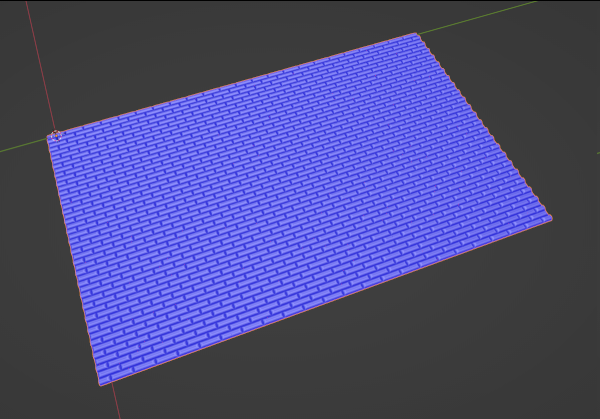

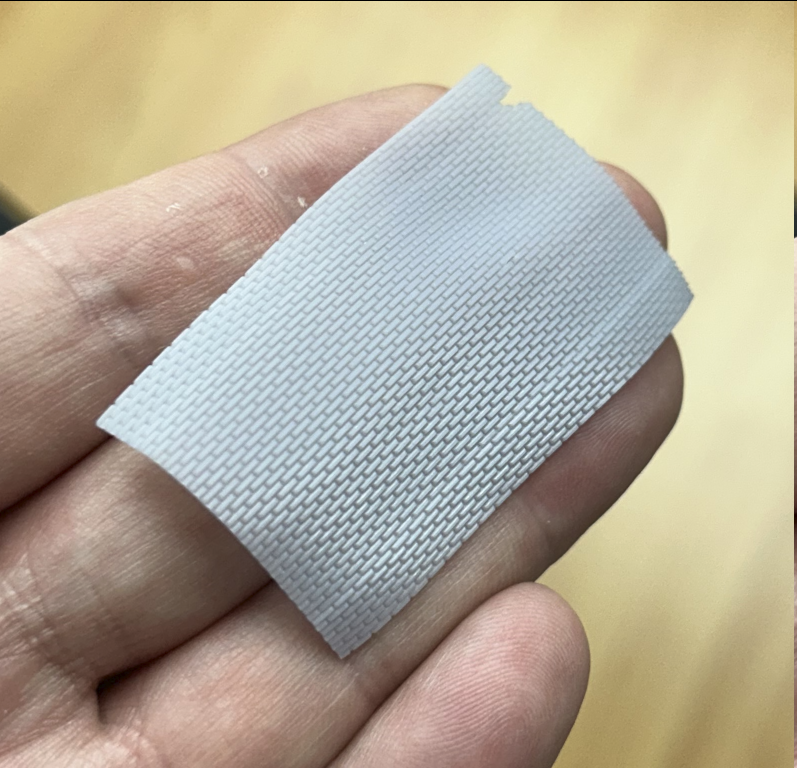

So thanks to t2sides I've updated my 3D model and printed new brick. It's too thin, but turned out pretty well. I will probably use standard resin for this rather than the flexible stuff. But for an experiment, I'm reasonably happy.

If you want to have a go at printing your own, the files are here -> H&R HO Brick 101

If you want to have a go at printing your own, the files are here -> H&R HO Brick 101