Yep, new pictures needed, for technical/stupid reasons. I had lots of BTS pics of modeling up the gun muzzle, but I can't get to them so I will just describe it.

The laser cannon is a quad barrel, so I plan to model up one and cast it four times. I will do this in two sections: the barrel shaft and the muzzle. If my plan works out the barrels will be cast around a brass tube so the muzzle can mount to the end, and the whole piece can mount to the gun body with a nice solid rod.

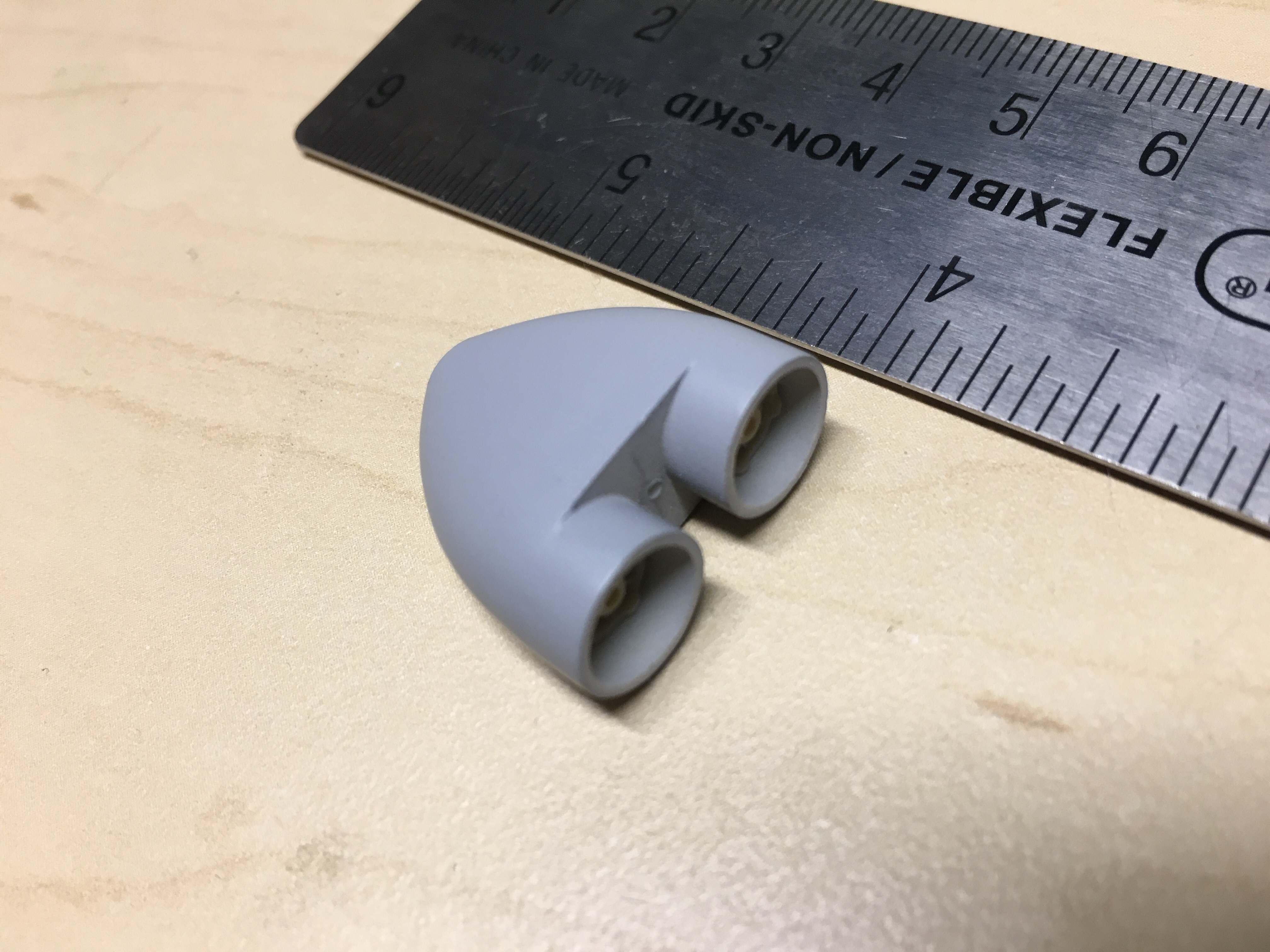

The muzzle is designed around a 1/4" brass tube, some flat styrene sheet, a couple of tank wheels, and some bondo (polyester fuller putty). It's about 1" by 1" by 3/8". Here are some pics:

I never figured out what the ILM guys used as the original piece on the 5-footer- I guess it is the engine pod from a jet powered bomber?

The barrel shaft model will have to be turned somehow. I don't have a lathe, so maybe I'll use a drill press? Working on it...

The laser cannon is a quad barrel, so I plan to model up one and cast it four times. I will do this in two sections: the barrel shaft and the muzzle. If my plan works out the barrels will be cast around a brass tube so the muzzle can mount to the end, and the whole piece can mount to the gun body with a nice solid rod.

The muzzle is designed around a 1/4" brass tube, some flat styrene sheet, a couple of tank wheels, and some bondo (polyester fuller putty). It's about 1" by 1" by 3/8". Here are some pics:

I never figured out what the ILM guys used as the original piece on the 5-footer- I guess it is the engine pod from a jet powered bomber?

The barrel shaft model will have to be turned somehow. I don't have a lathe, so maybe I'll use a drill press? Working on it...

Last edited: