You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/350 Polar Lights Enterprise Refit - Build log

- Thread starter JNordgren42

- Start date

Ryker606

New Member

I am currently building the refit and I frequently reference Ian's work/photos along with several YouTube channels. I am about at the same stage as you for the build. Agree the windows are slightly oversized on the model. On mine, the windows touch the sensor bands on the rim in some places, perhaps the age of the mold or wrongly sized to begin with. I just finished installing acrylic pieces (lazer fire) for the windows on the rim of the saucer. // Just bouncing some thoughts, to downsize the windows it would mean using canopy glue or similar or clear plastic behind the windows. If you fill/sand/ resize I wouldn't trust them to take any acrylic or plastic inside the diameter. I used canopy glue on the TOS 1/350 saucer and it was OK, but it is difficult to obtain a flush fit with the hull using that method and it doesn't dry clear (which is OK, but it is definitely more opaque that what I wanted). Smaller would be accurate, but thats a bullet I wouldn't bite. I would never be able to keep them all aligned and the same diameter when drilling in filled areas, etc. But, thinking like this is what makes your build unique, enjoying the progress and ideas.Thanks! I'm building on a lot of those that came before, especially the greatly missed Ian Laurence. I'm definitely hoping this improves the look of the windows. Checking my references more closely, I may actually bite the bullet and downsize them, they are TINY on the filming model. Because it's in a smaller scale, I probably can't match them exactly, but I think smaller will be better. I just have to decide if it's worth the extra work of thinning the hull, filling, sanding down and then redrilling. I'm also concerned about getting that many windows placed "just right" and making the long ones straight. Even a slight misalignment of the pilot holes will skew them.

division 6

Master Member

Just to throw it out there but what about using brass tubing to scale them down. ???

Ryker606

New Member

Not all of the windows are round and with the shape of the hull/saucer the brass would not set flush with exterior of the hull. Hull is curved.Just to throw it out there but what about using brass tubing to scale them down. ???

JNordgren42

Sr Member

I'm planning on using UV resin to fill the portholes, with a backing tape, I'm hoping to be able to get them flush and I'm hoping the resin is tenacious enough to stay in there. I just found some great reference photos from Bill Krause (the two I posted above are part of the set) and was able to scale the dorsal pic to determine they should be about 1.8 or 1.9 mm at 1/350. The existing portholes are 2.1mm, so it's not a huge difference and 1.8 mm definitely looks too small at this scale). The tiny little porthole masks in the Mask Design set are 2 mm, so I may just pop those over the resin filled 2.1mm portholes and call it a day.I am currently building the refit and I frequently reference Ian's work/photos along with several YouTube channels. I am about at the same stage as you for the build. Agree the windows are slightly oversized on the model. On mine, the windows touch the sensor bands on the rim in some places, perhaps the age of the mold or wrongly sized to begin with. I just finished installing acrylic pieces (lazer fire) for the windows on the rim of the saucer. // Just bouncing some thoughts, to downsize the windows it would mean using canopy glue or similar or clear plastic behind the windows. If you fill/sand/ resize I wouldn't trust them to take any acrylic or plastic inside the diameter. I used canopy glue on the TOS 1/350 saucer and it was OK, but it is difficult to obtain a flush fit with the hull using that method and it doesn't dry clear (which is OK, but it is definitely more opaque that what I wanted). Smaller would be accurate, but thats a bullet I wouldn't bite. I would never be able to keep them all aligned and the same diameter when drilling in filled areas, etc. But, thinking like this is what makes your build unique, enjoying the progress and ideas.

JNordgren42

Sr Member

Just to throw it out there but what about using brass tubing to scale them down. ???

Also not all of them are perpendicular (or at least close) to the hull curvature which distorts the shape of the porthole and contributes to the non scale appearance. Someone on FB suggested trying hollow plastic tube, but that would suffer from the same issue.Not all of the windows are round and with the shape of the hull/saucer the brass would not set flush with exterior of the hull. Hull is curved.

JNordgren42

Sr Member

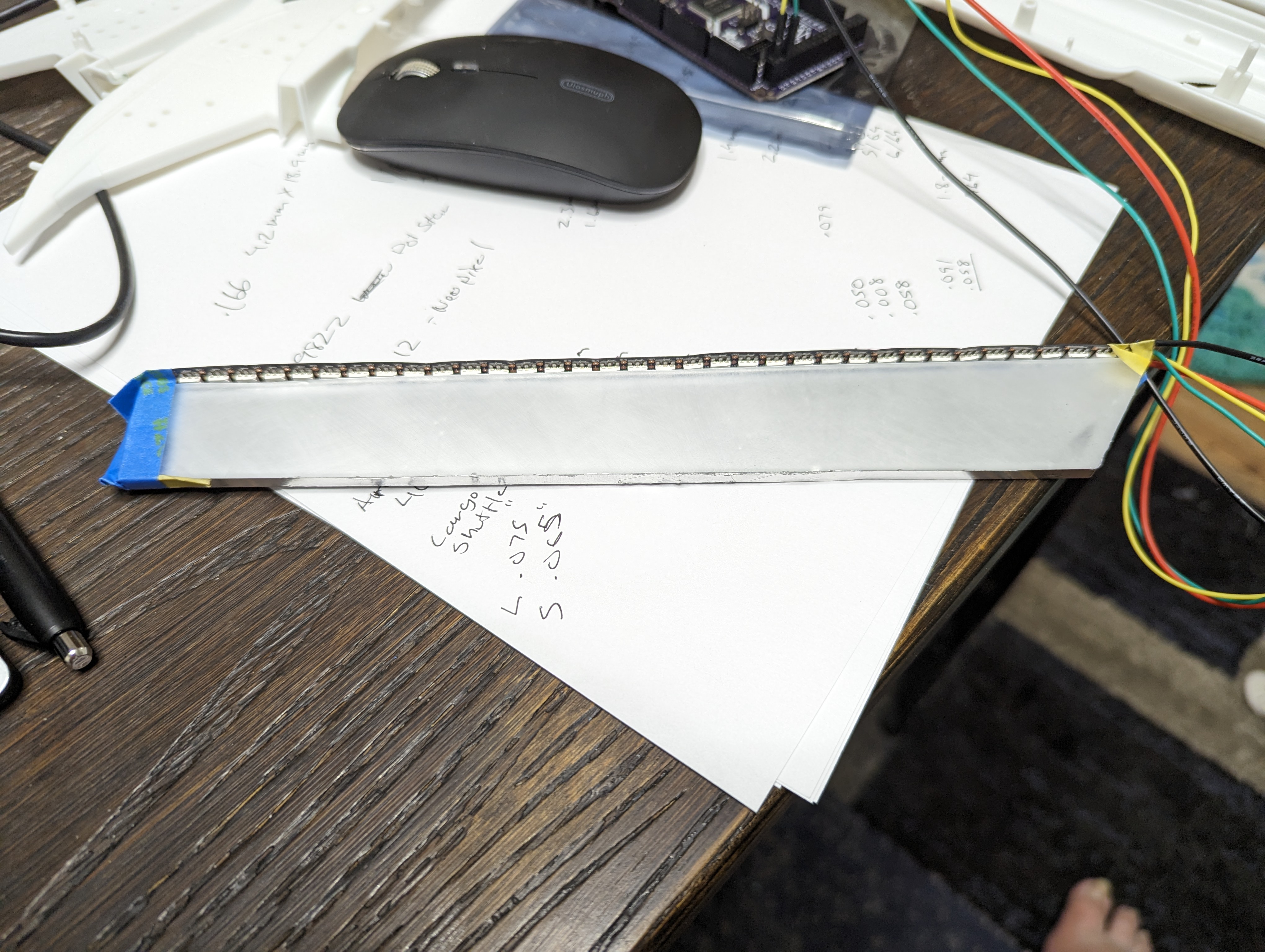

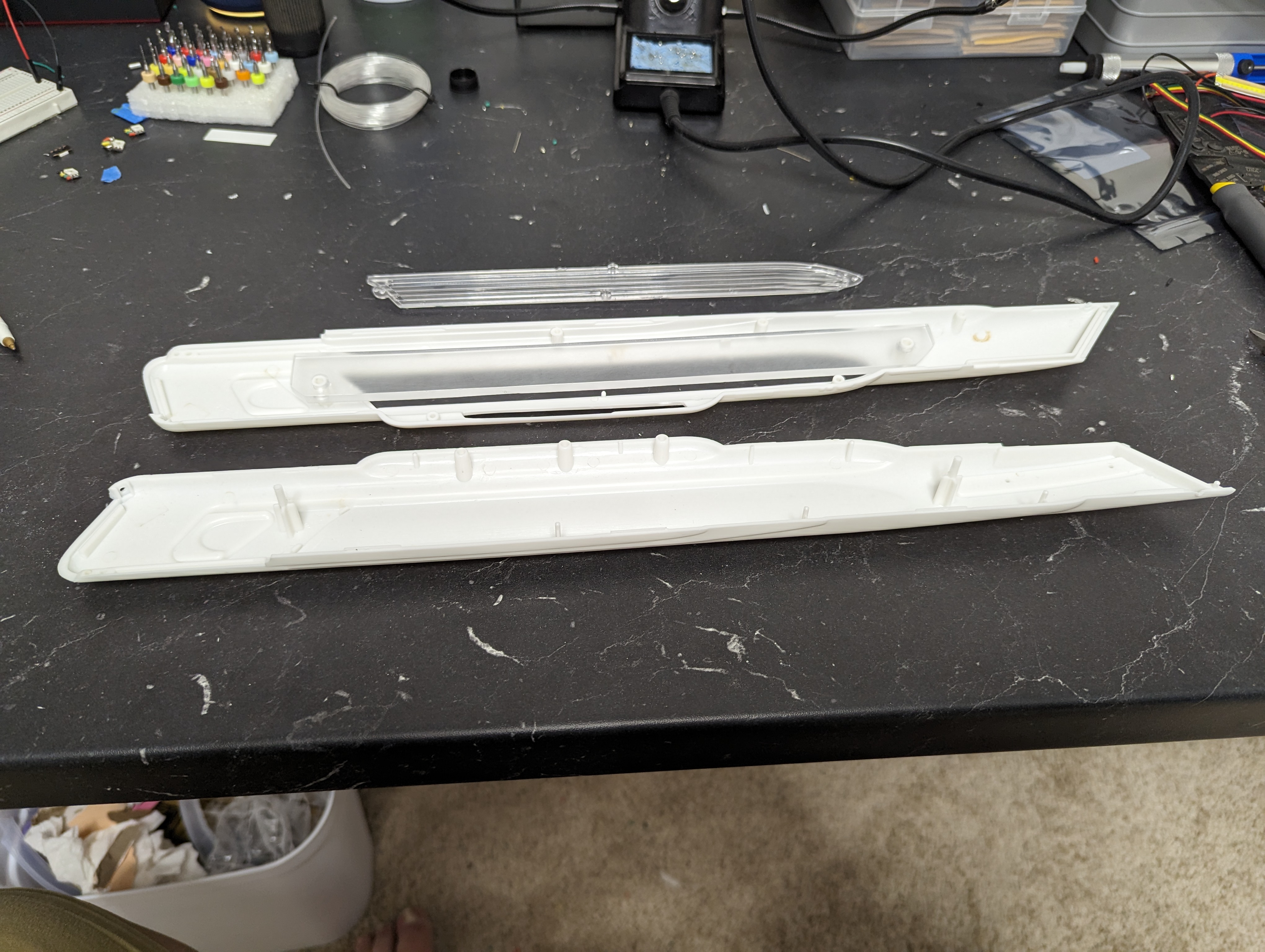

I've been kind of jumping all over the last week. I sanded down the exterior of the secondary hull sides and top and got the walls behind the windows thinned down on one side. I then turned my attention to the warp nacelle lighting. I did a quick test of an acrylic diffuser and the DotStar LED strip, and it worked amazingly well, even considering the fabrication of the test article was extremely rough. I started on the "production" diffusers and got one of them knocked out. I need to pick up some more aluminum tape and decide how I'm going to permanently attach the LED strip.

I also experimented with filling in the grid lines on my test mule secondary hull bottom. I used Perfect Plastic Putty and it was not robust enough to hold up to the scribing. I may give it one more shot with some epoxy putty, or I may just leave the grid lines alone (the softness bugs me, but it may be more work than it's worth and the potential for disaster is high).

Finally, I played around with some of the secondary lighting systems, some things were a success and some were failures. On the success side, I bought some 1.2mm fiber optic strand which fits perfectly in the existing holes for the nav lights. When the ends are rounded and sanded, they make excellent "bulbs". On the failure side, I tried several different methods of lighting the shuttle bay and arboretum, none of which were entirely satisfying. I'm ditching 12V COB strip because I don't want the control and added power difficulties. The RGB DotStars have a light quality issues with white, the RGB mixing always looks a touch off and in places like the shuttle bay and arboretum, you can see the separate emitters, even with a hefty amount of diffusion. I also tried some small Adafruit backlight modules, but they're not bright enough for the shuttle bay (they work OK in the arboretum. Because of these problems, I'm ditching the DotStars for the window and interior lighting. I ordered some RGBW Neopixels, which should solve the white light problem while still giving me the programmability that I want. I will have to run one separate data line for the Neopixels, but they can use the same +5V and ground as the DotStars (and I have plenty of GPIO pins on the Arduino to control them). I'll run some more experiments when I receive them.

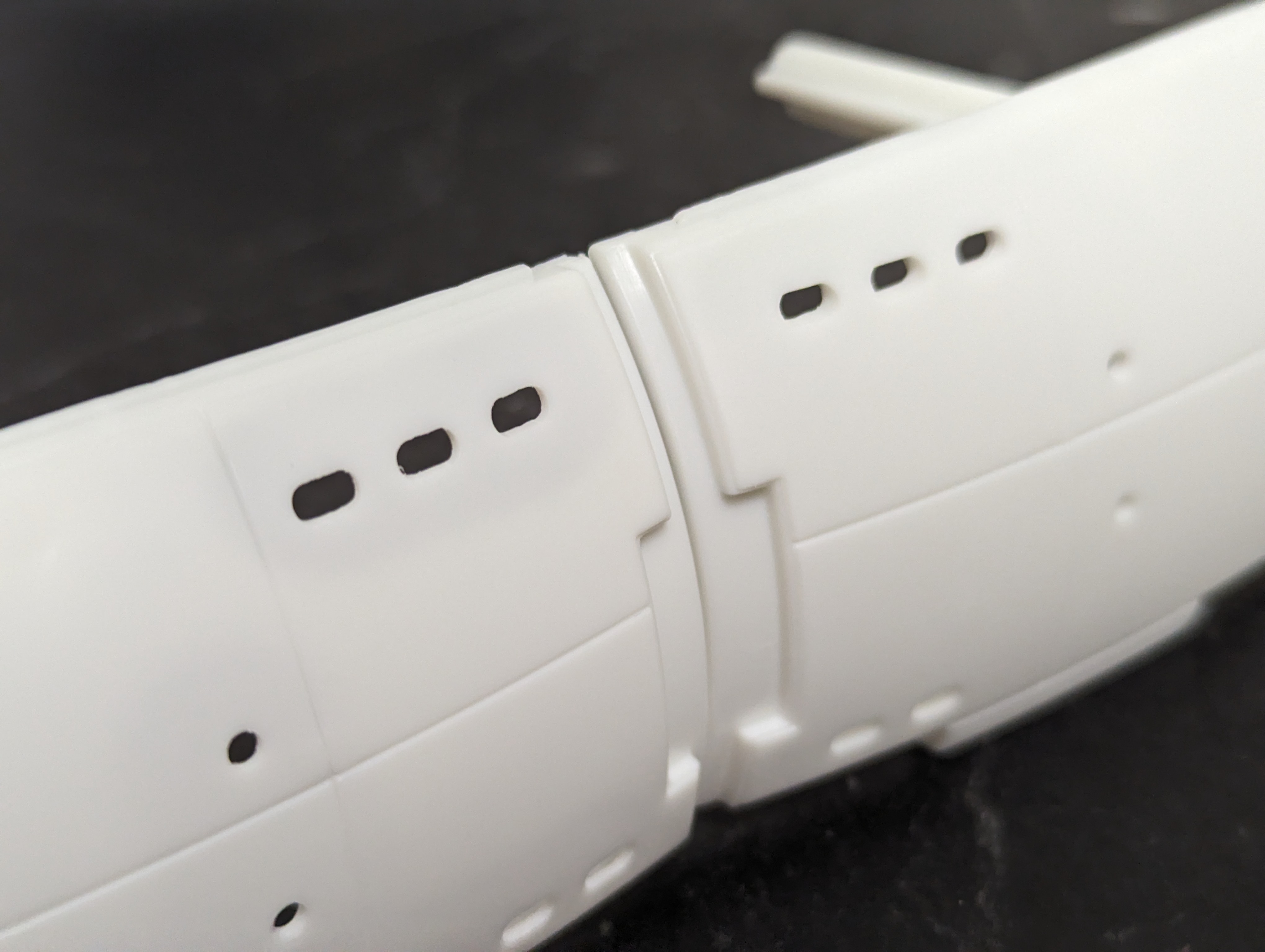

Starboard side (thinned) vs. port side (unthinned) secondary hull halves. This is a good example of the difference thinning the walls down makes.

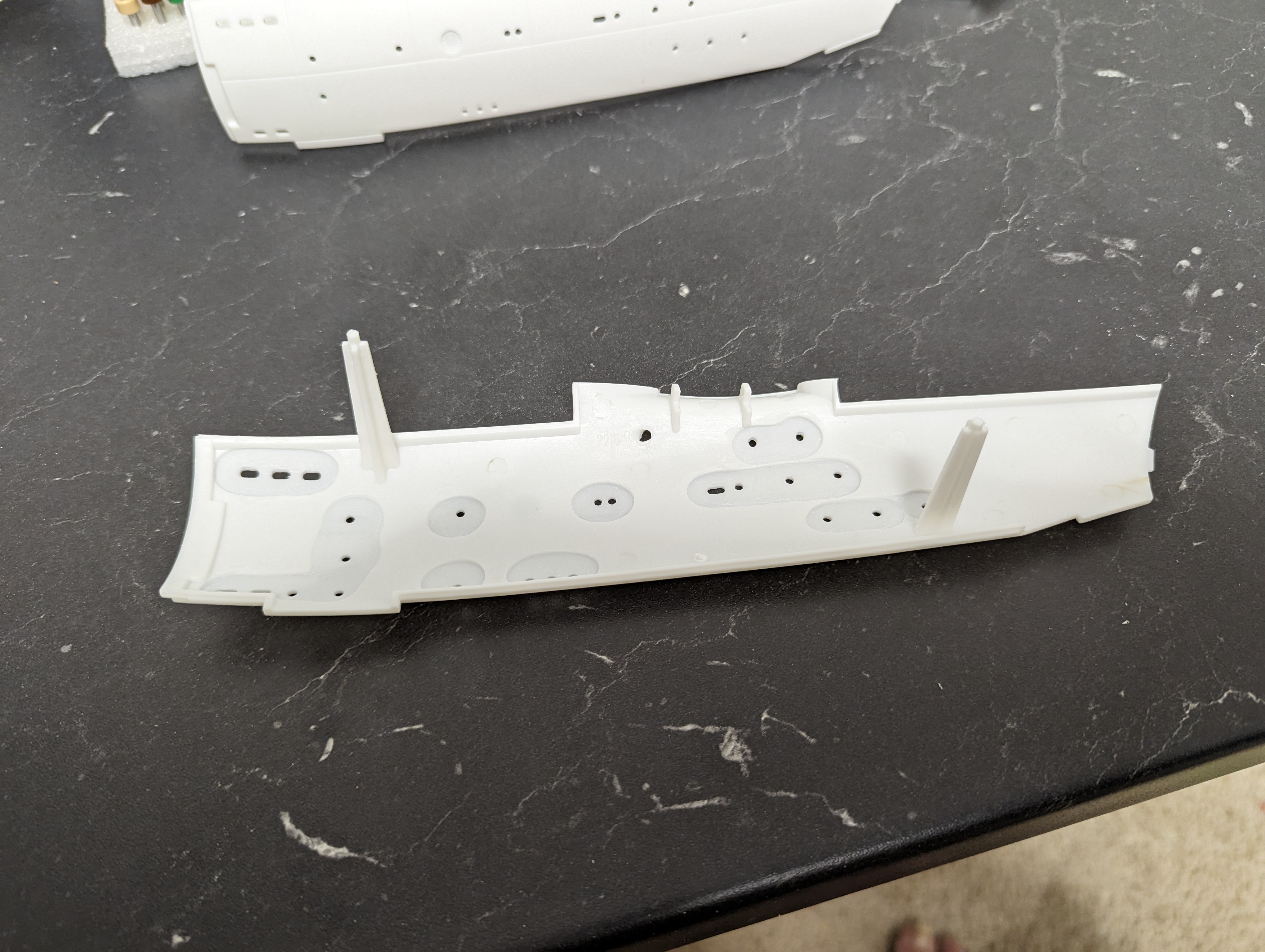

Back side of the starboard hull showing the ground out areas.

Diffuser test. Even with the unpainted grilles and no light blocking it looks really good and is more even to the eye than the picture shows.

Test light module. Again, it looks even better in person.

Test module with the light off. The back and edges are covered in metal foil.

"Production" version of the diffuser. I made them longer and drilled holes to use the glue posts to solidly mount them. I also sanded and polished the edges down to 7000 grit to help eliminate any hot spots from the rough edge tooling on my test. The diffusion side is sanded to 800 grit, and I may spray it with some glass frosting paint (Rustoleum from a rattle can).

Snug in place using the glue posts.

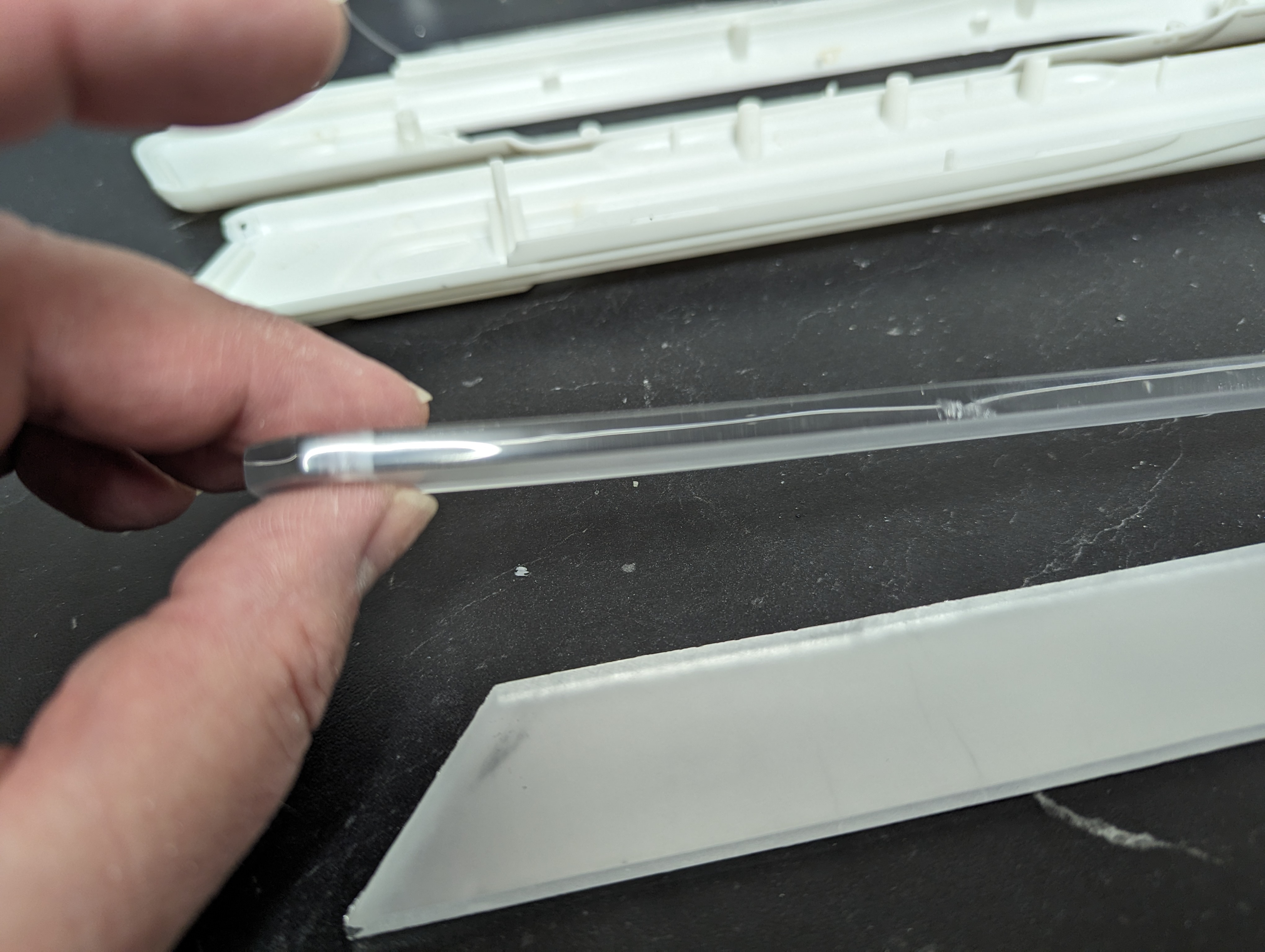

Close up of the polished edge. "Smoove"

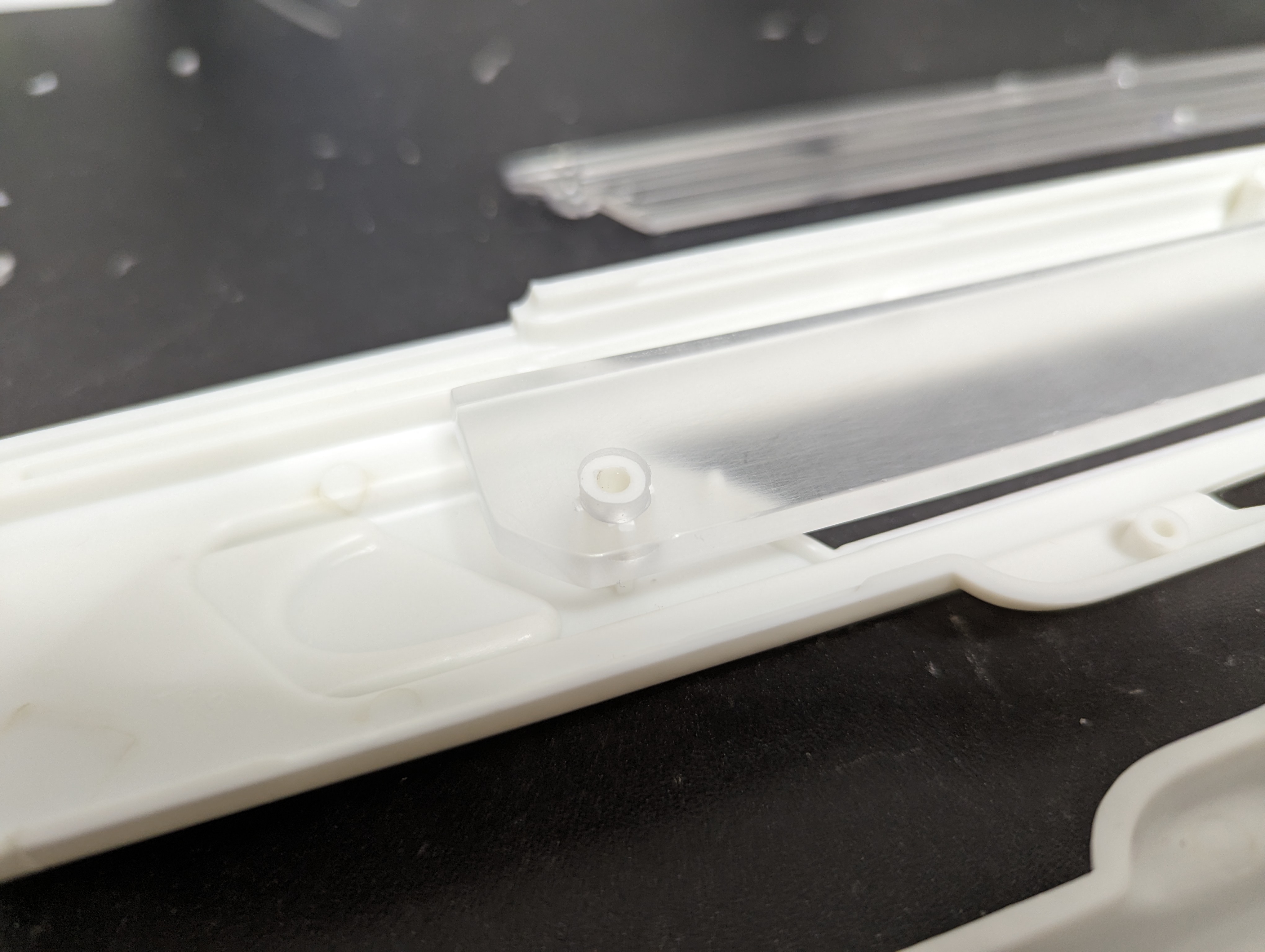

Close up of the mounting. I trimmed back the glue post gussets by the width of the diffuser, they make a nice solid stop to positively locate it. The gussets on the other pin sandwich the diffuser in.

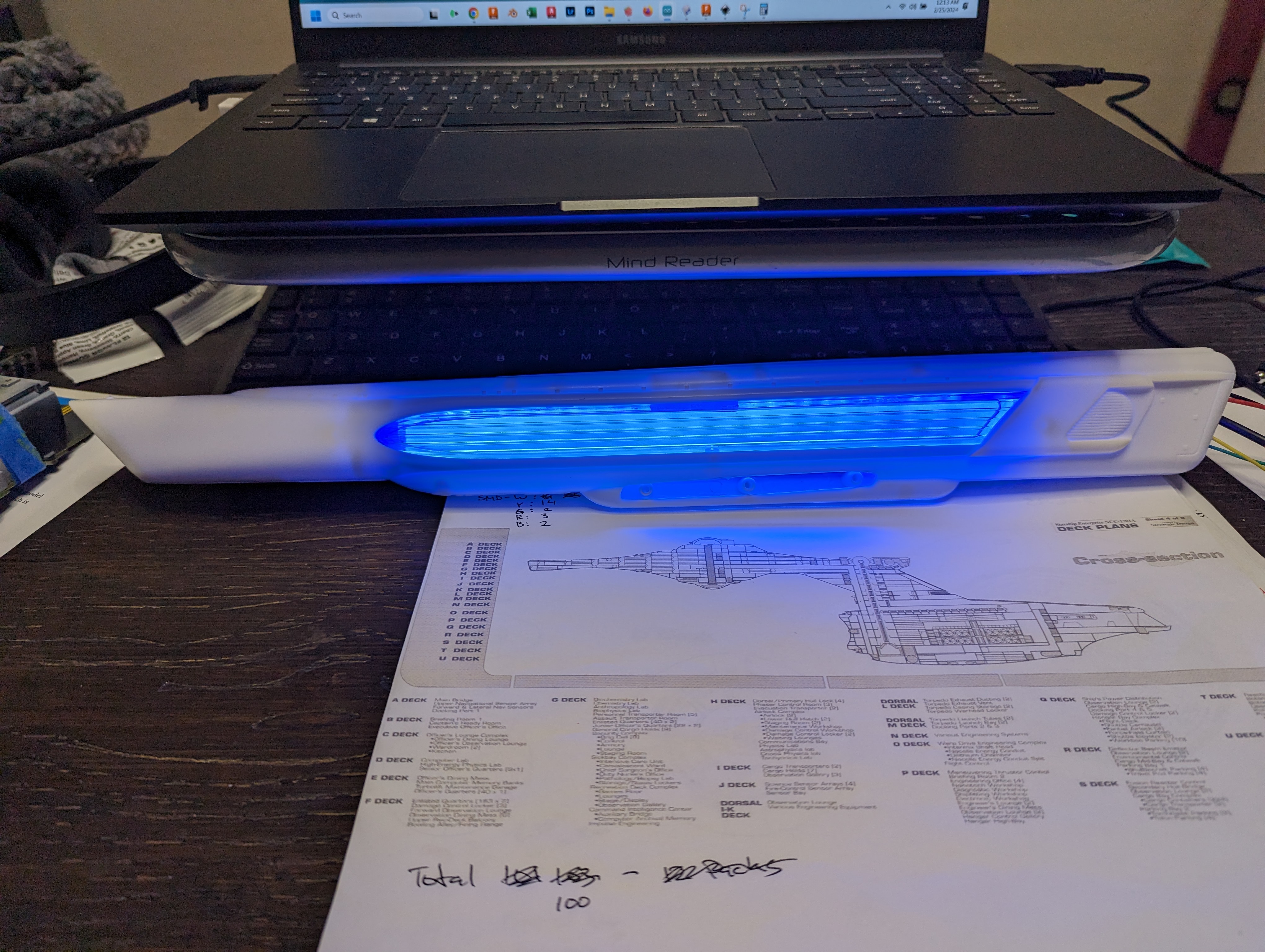

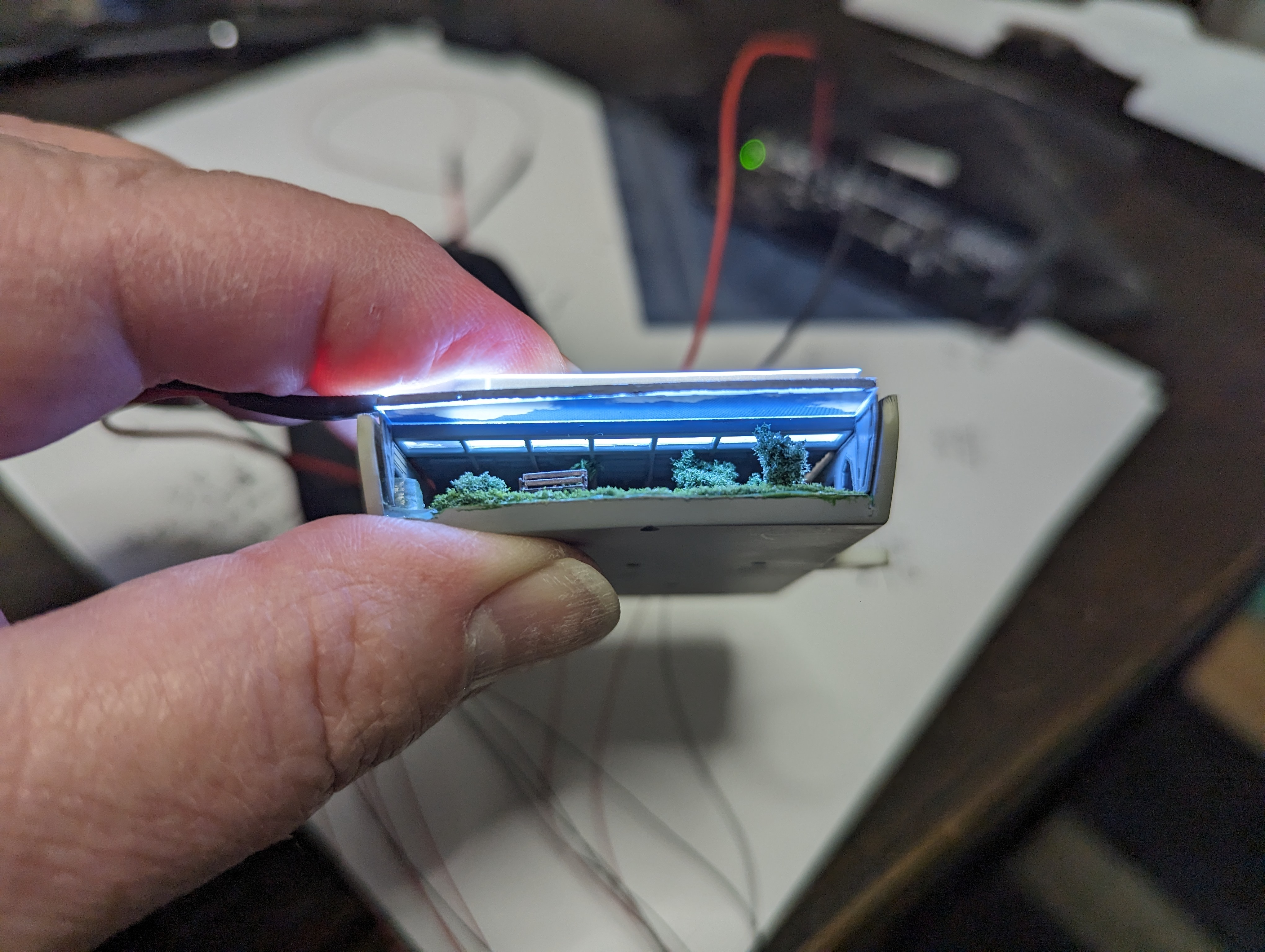

Test of the LED backlight module to light the arboretum. The brightness is acceptable here, but it's not enough in the shuttle bay, so I don't think it's worth the trouble to add in another new light type (plus it's not controllable other than PWM for brightness).

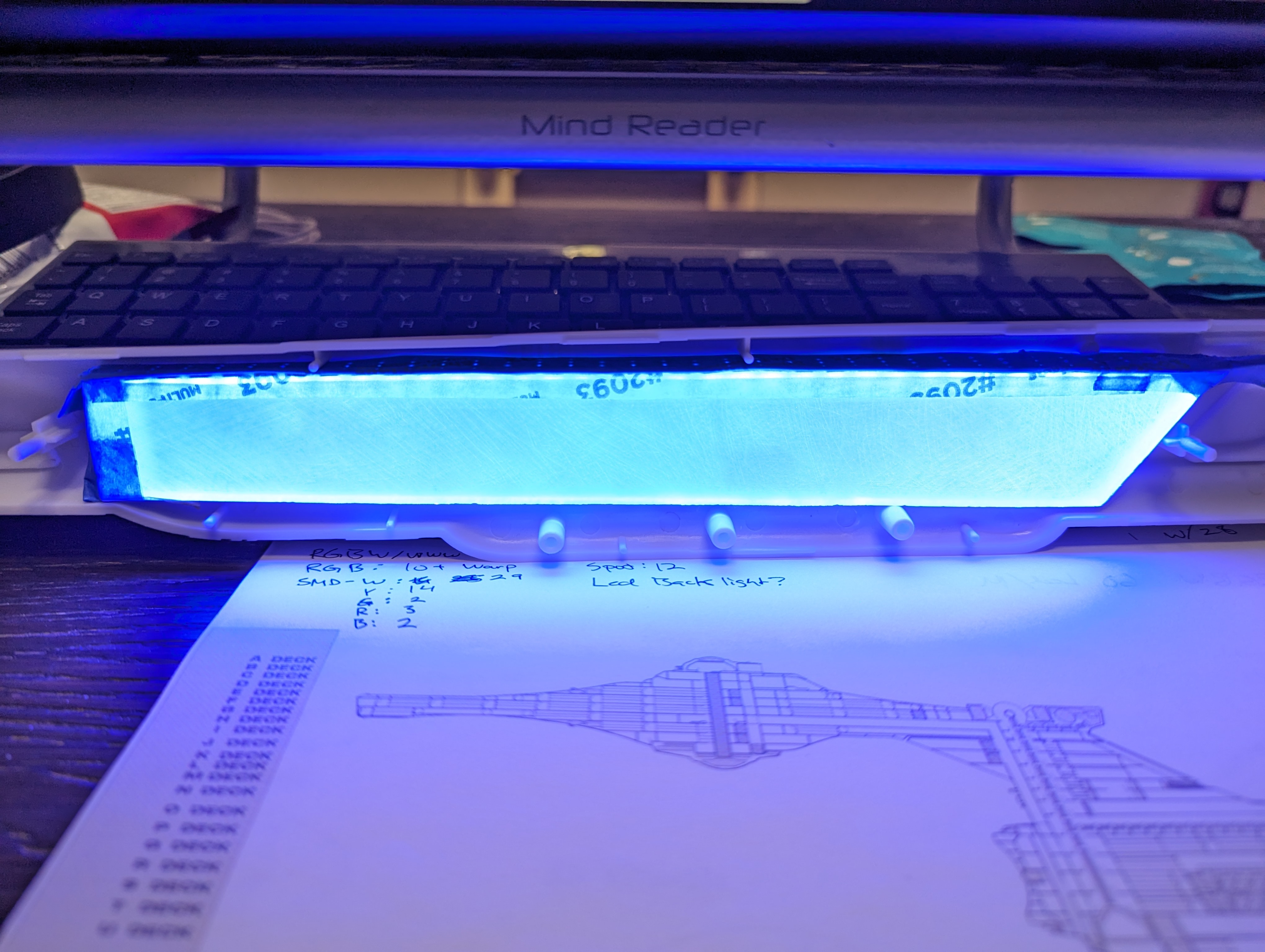

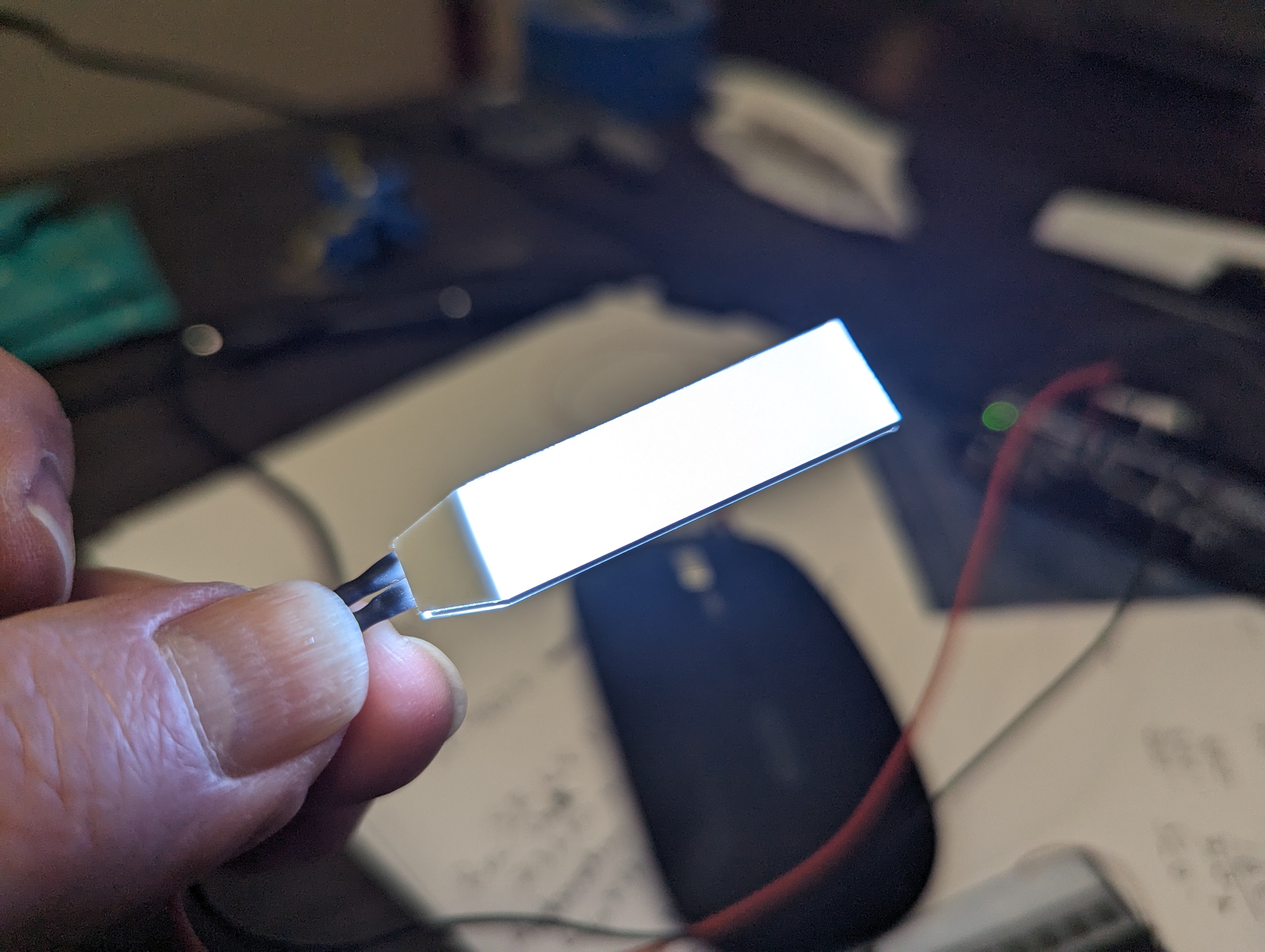

Bare backlight module. They come in a couple of larger sizes as well. Even though they don't work for me for this application, they'll stay in my stash and my brain for potential use in other projects.

I also experimented with filling in the grid lines on my test mule secondary hull bottom. I used Perfect Plastic Putty and it was not robust enough to hold up to the scribing. I may give it one more shot with some epoxy putty, or I may just leave the grid lines alone (the softness bugs me, but it may be more work than it's worth and the potential for disaster is high).

Finally, I played around with some of the secondary lighting systems, some things were a success and some were failures. On the success side, I bought some 1.2mm fiber optic strand which fits perfectly in the existing holes for the nav lights. When the ends are rounded and sanded, they make excellent "bulbs". On the failure side, I tried several different methods of lighting the shuttle bay and arboretum, none of which were entirely satisfying. I'm ditching 12V COB strip because I don't want the control and added power difficulties. The RGB DotStars have a light quality issues with white, the RGB mixing always looks a touch off and in places like the shuttle bay and arboretum, you can see the separate emitters, even with a hefty amount of diffusion. I also tried some small Adafruit backlight modules, but they're not bright enough for the shuttle bay (they work OK in the arboretum. Because of these problems, I'm ditching the DotStars for the window and interior lighting. I ordered some RGBW Neopixels, which should solve the white light problem while still giving me the programmability that I want. I will have to run one separate data line for the Neopixels, but they can use the same +5V and ground as the DotStars (and I have plenty of GPIO pins on the Arduino to control them). I'll run some more experiments when I receive them.

Starboard side (thinned) vs. port side (unthinned) secondary hull halves. This is a good example of the difference thinning the walls down makes.

Back side of the starboard hull showing the ground out areas.

Diffuser test. Even with the unpainted grilles and no light blocking it looks really good and is more even to the eye than the picture shows.

Test light module. Again, it looks even better in person.

Test module with the light off. The back and edges are covered in metal foil.

"Production" version of the diffuser. I made them longer and drilled holes to use the glue posts to solidly mount them. I also sanded and polished the edges down to 7000 grit to help eliminate any hot spots from the rough edge tooling on my test. The diffusion side is sanded to 800 grit, and I may spray it with some glass frosting paint (Rustoleum from a rattle can).

Snug in place using the glue posts.

Close up of the polished edge. "Smoove"

Close up of the mounting. I trimmed back the glue post gussets by the width of the diffuser, they make a nice solid stop to positively locate it. The gussets on the other pin sandwich the diffuser in.

Test of the LED backlight module to light the arboretum. The brightness is acceptable here, but it's not enough in the shuttle bay, so I don't think it's worth the trouble to add in another new light type (plus it's not controllable other than PWM for brightness).

Bare backlight module. They come in a couple of larger sizes as well. Even though they don't work for me for this application, they'll stay in my stash and my brain for potential use in other projects.

Similar threads

- Replies

- 11

- Views

- 1,451

- Replies

- 63

- Views

- 5,564

- Replies

- 1

- Views

- 1,003