DW Design Studios

Sr Member

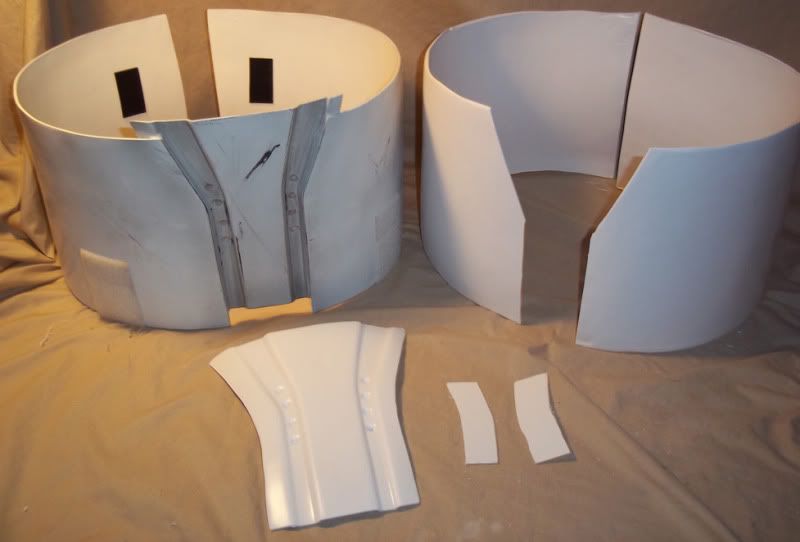

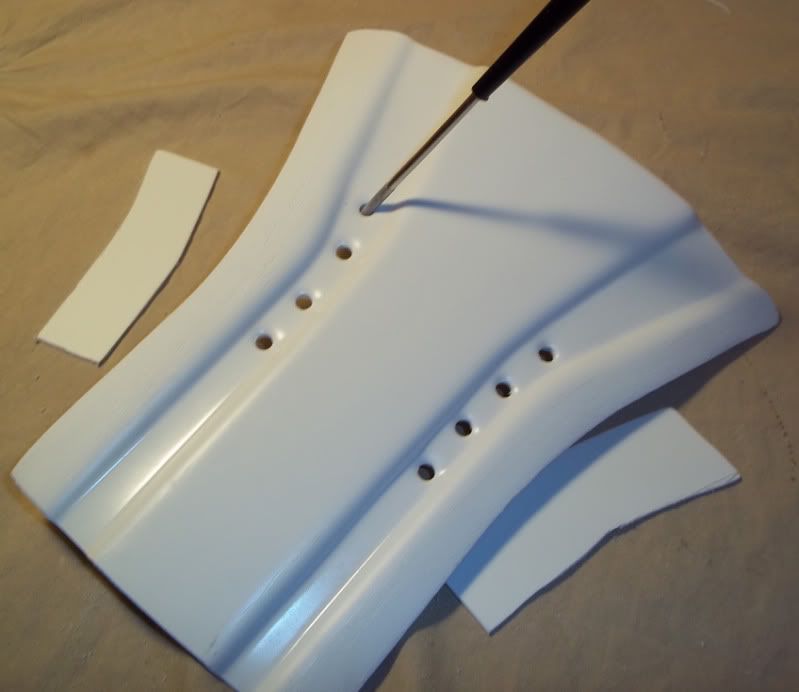

Hello Clonetrooper friends. I have completed my Clone Pilot tutorial and am moving onto

a Clonetrooper suit tutorial. I have been building these suits since 2005 and plan to share

some of my tips and tricks with you here. I have build around 10 suits for myself, friends and

local 501st members. Hopefully this tutorial can help you with your build. Maybe I can also

learn some new tricks and ideas from fellow board members.

Once the tutorial if finished the suit will be for sale. Please contact me if you are interested.

Please feel free to add to the discussion.

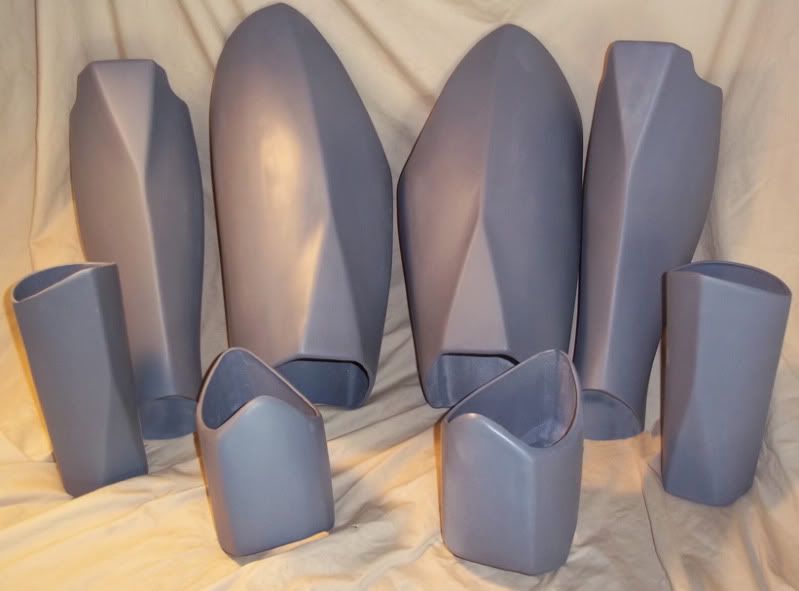

We are going to take a pile of plastic, reins and rubber and turn it into something like this!

These photos were taken a few weeks ago at Wonder Con in San Francisco.

As you can see, the suit can be made to fit troopers big and small.

The bigger troopers in these photo’s are around 6’1” and the smaller ones are around 5’8”.

a Clonetrooper suit tutorial. I have been building these suits since 2005 and plan to share

some of my tips and tricks with you here. I have build around 10 suits for myself, friends and

local 501st members. Hopefully this tutorial can help you with your build. Maybe I can also

learn some new tricks and ideas from fellow board members.

Once the tutorial if finished the suit will be for sale. Please contact me if you are interested.

Please feel free to add to the discussion.

We are going to take a pile of plastic, reins and rubber and turn it into something like this!

These photos were taken a few weeks ago at Wonder Con in San Francisco.

As you can see, the suit can be made to fit troopers big and small.

The bigger troopers in these photo’s are around 6’1” and the smaller ones are around 5’8”.