indiefilmgeek

Sr Member

Ok, so I need some help. I've been using Plasti-dip as my EVA foam sealer for over 8yrs now, and I've NEVER had any major issues... until today.

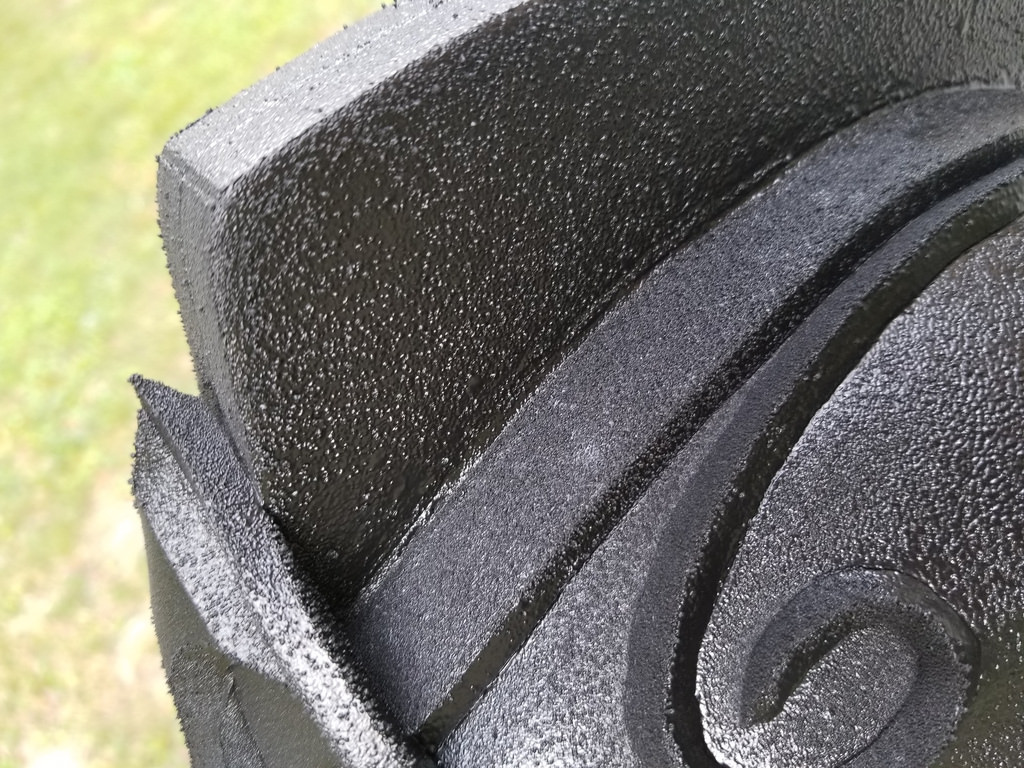

Today, I attempted to seal my EVA foam Red Knight Helmet from Fortnite (my daughter's Halloween costume). And the coat came out like coarse sandpaper. Absolutely horrible... 'Fuzzy' edges and very rough surfaces.

There are 4 different types of foam being used (all of which I've used before), and I switched Plasti-Dip cans to see if it was just a bad can of plasti-dip.

This basically ruined this piece. ANY ideas you have how WHY this happened or how I can recover this would be much appreciated!

Today, I attempted to seal my EVA foam Red Knight Helmet from Fortnite (my daughter's Halloween costume). And the coat came out like coarse sandpaper. Absolutely horrible... 'Fuzzy' edges and very rough surfaces.

There are 4 different types of foam being used (all of which I've used before), and I switched Plasti-Dip cans to see if it was just a bad can of plasti-dip.

This basically ruined this piece. ANY ideas you have how WHY this happened or how I can recover this would be much appreciated!