I've gotten several messages lately asking about Starkiller. To help answer some of them, I thought I'd just transfer the WIP from my blog to here to share how the whole thing was made.

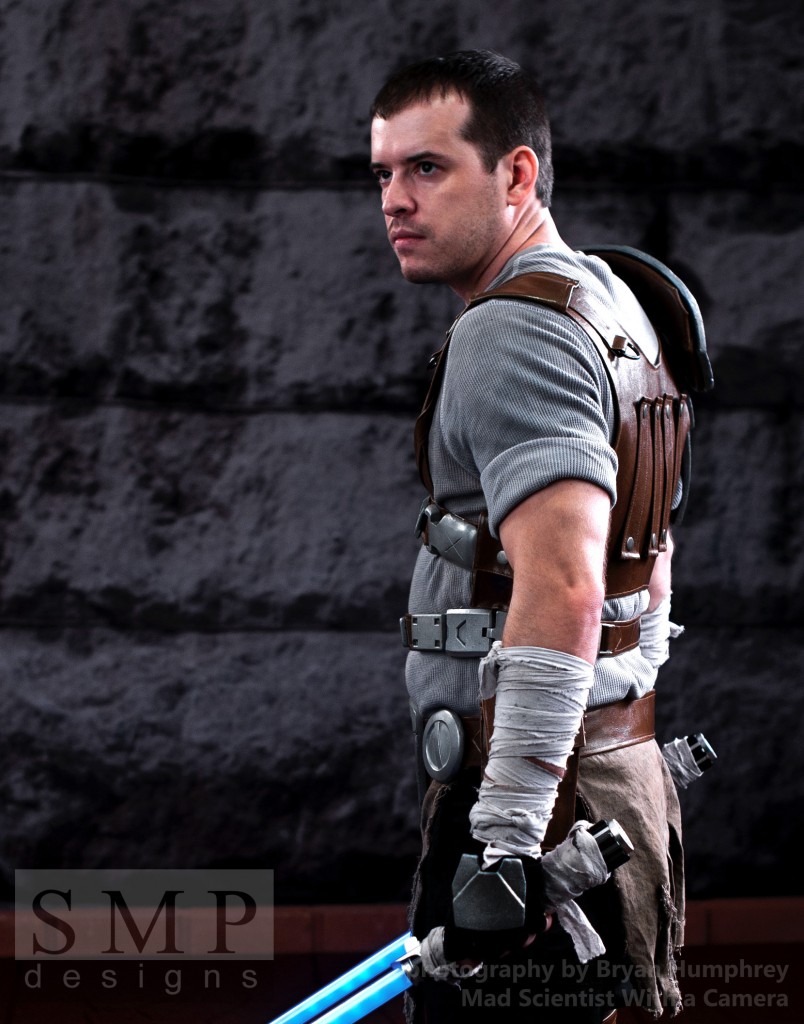

Some quick background: this costume was made for Dragon*Con 2013. It was made for a friend - who was Prince Dastan this year and some of you might recognize from my Captain America WIP as the body model for the patterns - and was also worn this year, where it got some love from Starkiller himself, Sam Witwer.

I also did a video of this build.

OK, so on to the WIP...

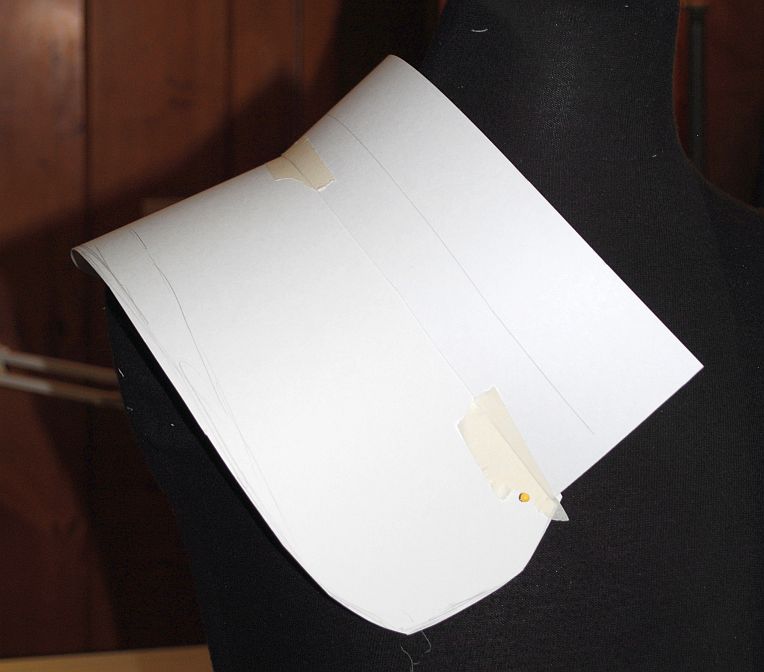

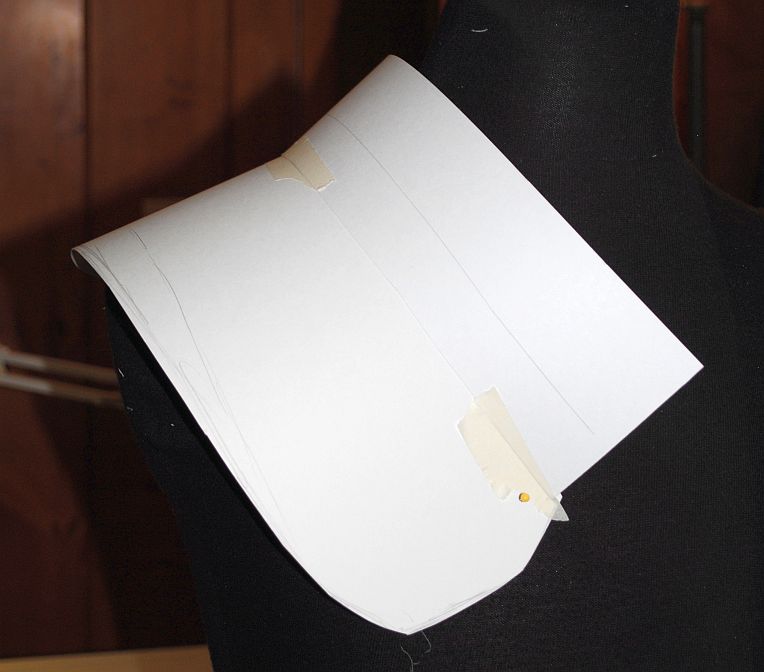

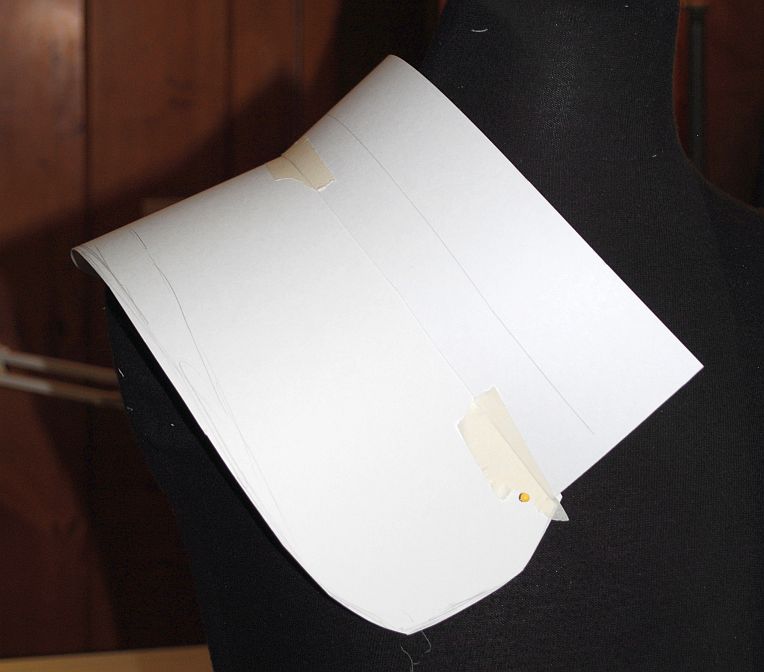

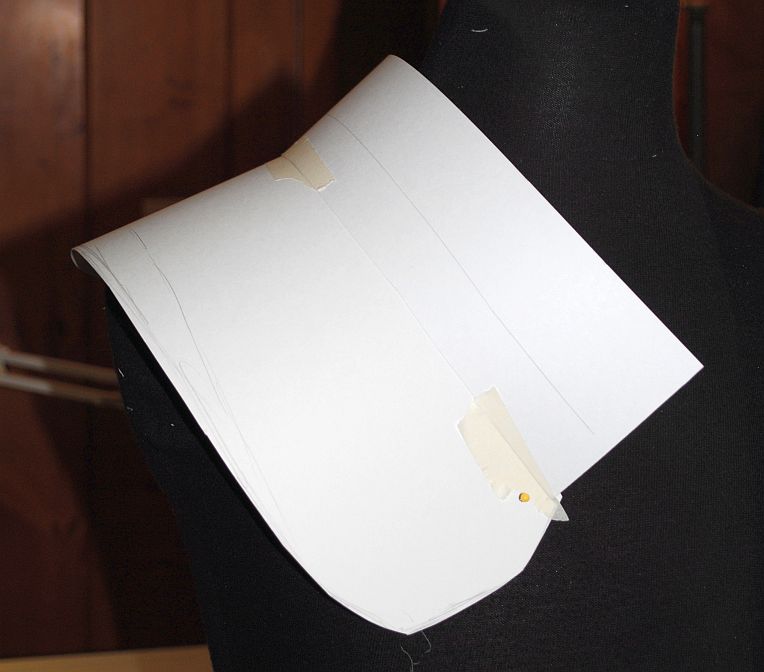

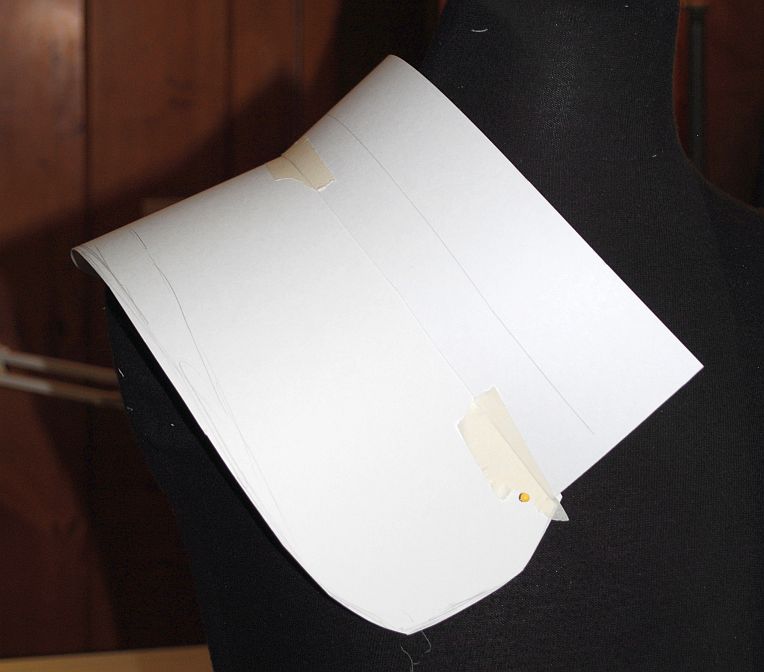

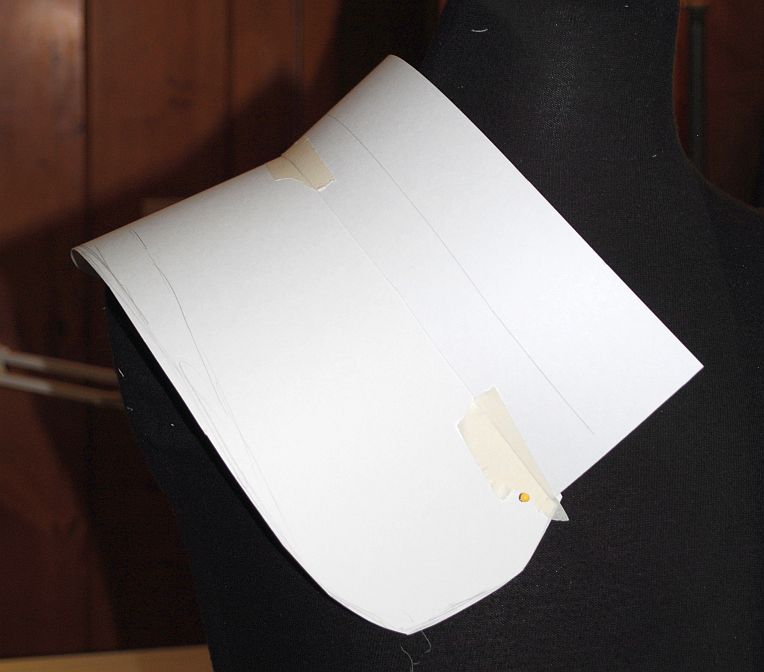

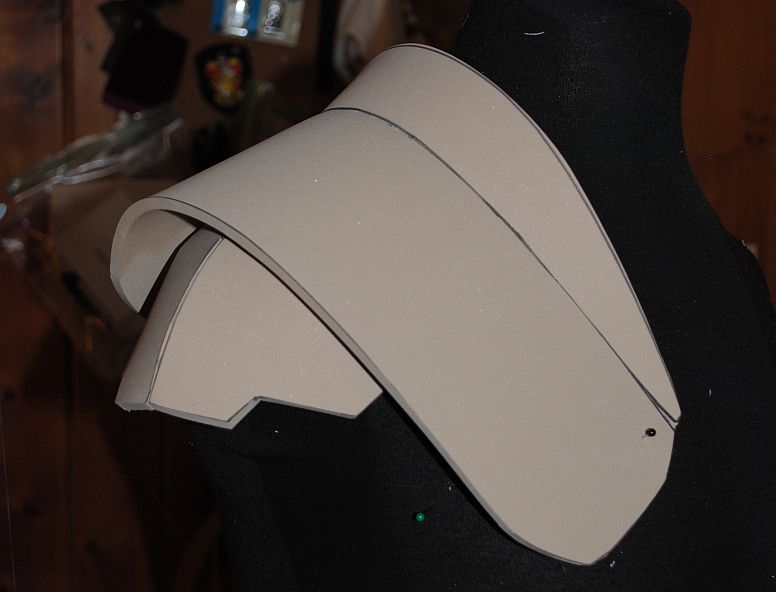

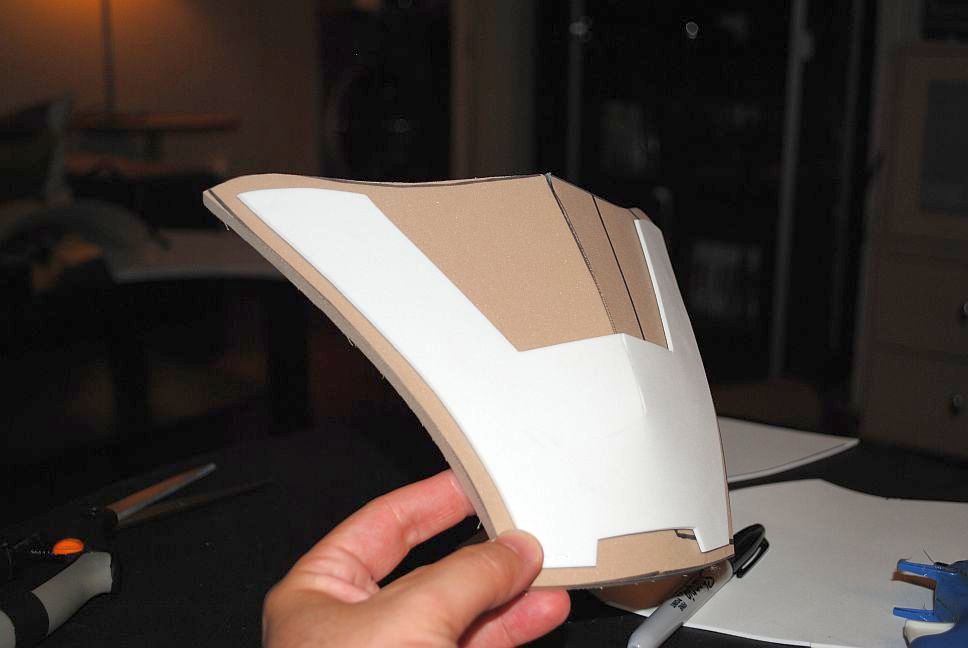

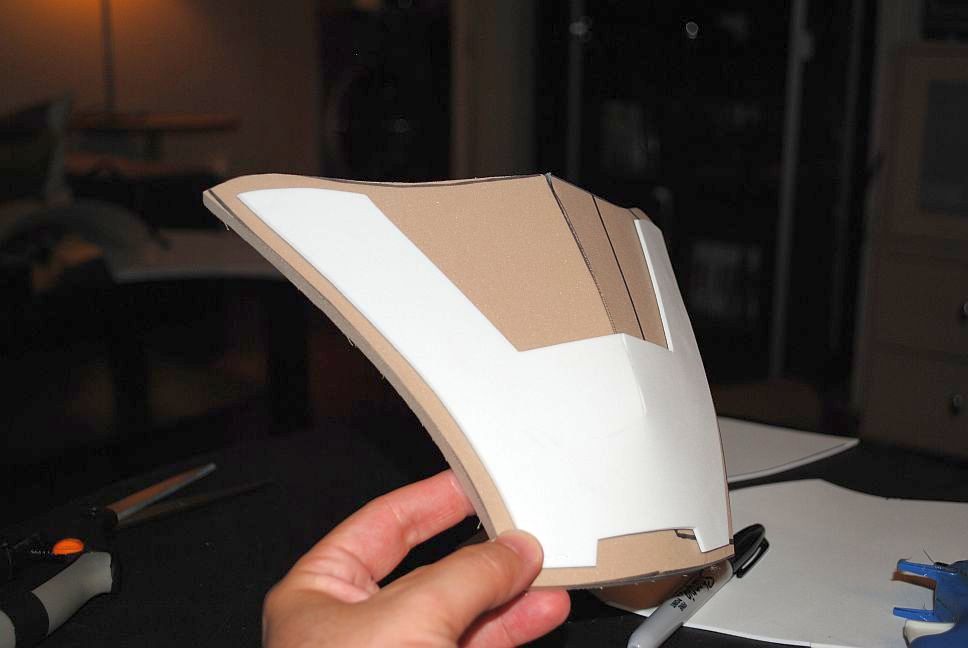

We began by working out a template for the armor. Starting with poster board, the general shape of the main shoulder armor was decided (to scale with the wearer) and then the collar piece was fitted to create the desired up-sweep.

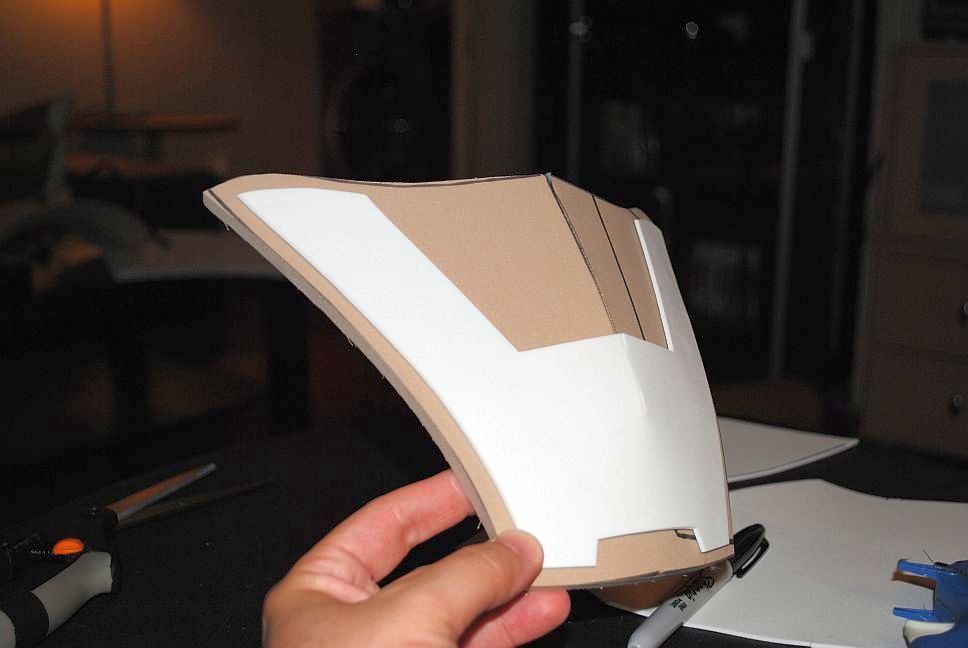

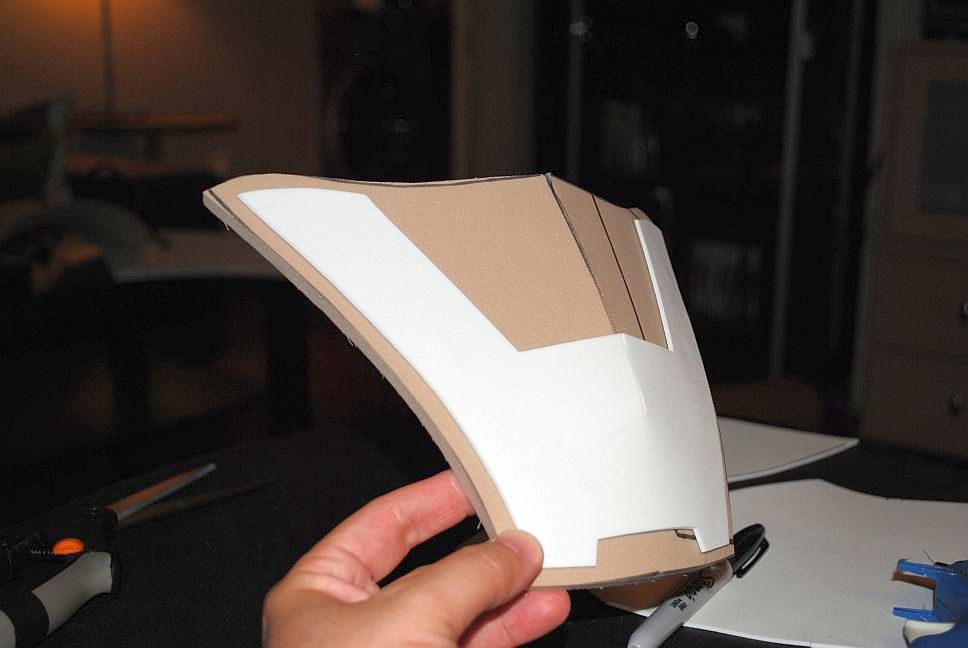

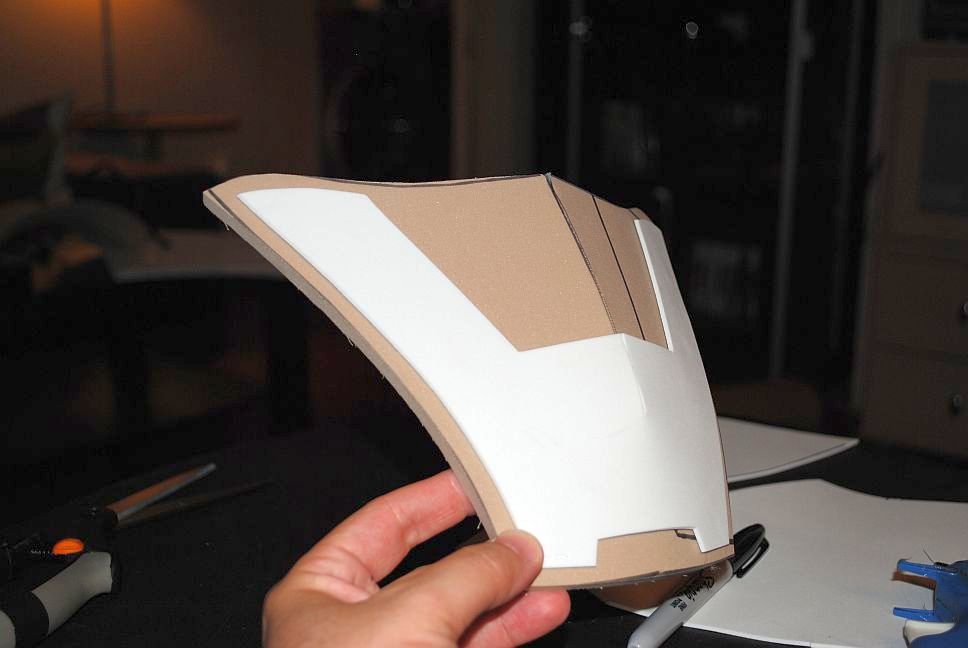

Next, the pieces were cut out of 6mm EVA foam and assembled. After, that the same process was used to create the bell for the shoulder and the bicep piece.

Next, the pieces were cut out of 6mm EVA foam and assembled. After, that the same process was used to create the bell for the shoulder and the bicep piece.

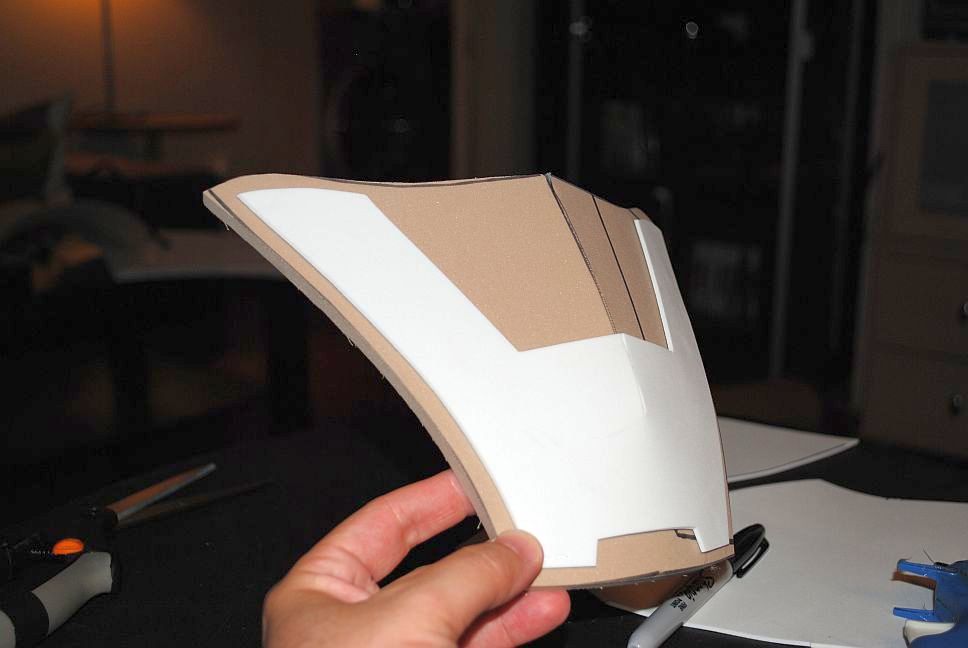

We taped all the foam test pieces together and tried them on to see how they fit and moved. After a little editing, we got the shapes and scale right and then began covering them with Worbla. Worbla is a thermoplastic that comes in sheets. When heated, it becomes pliable and elastic and can be shaped over forms. Then, as it cools, it re-hardens to its original strength. For more about Worbla, click here.I began with the bell. I started with adding the Worbla to the underside first to support the shape while adding it to the outside. Working around the shape, I heated and re-heated the Worbla until I was able to mold it around the entire piece and seal the edges.

We taped all the foam test pieces together and tried them on to see how they fit and moved. After a little editing, we got the shapes and scale right and then began covering them with Worbla. Worbla is a thermoplastic that comes in sheets. When heated, it becomes pliable and elastic and can be shaped over forms. Then, as it cools, it re-hardens to its original strength. For more about Worbla, click here.I began with the bell. I started with adding the Worbla to the underside first to support the shape while adding it to the outside. Working around the shape, I heated and re-heated the Worbla until I was able to mold it around the entire piece and seal the edges.

After the entire foam piece was encased in plastic, I used scissors and an X-Acto knife to trim the flange from around the shape. After trimming, I used my heat gun to reheat the edges and soften them slightly. Then, press the edges together to seal and smooth them and let it cool completely.

After the entire foam piece was encased in plastic, I used scissors and an X-Acto knife to trim the flange from around the shape. After trimming, I used my heat gun to reheat the edges and soften them slightly. Then, press the edges together to seal and smooth them and let it cool completely.

The bicep piece has some raised design elements - so to make those, I used a sheet of 2mm foam and cut the design from that. Then, that piece was tacked onto the main shape with hot glue and the same process as above was repeated. The inside of the piece was covered first to lend support and hold the shape. Then, working from the bottom up, the front was covered. Using my fingernails and the pocket clip from the cap of a Sharpie, I was able to press the soft Worbla into the layers of foam and create the dimension I needed.

The bicep piece has some raised design elements - so to make those, I used a sheet of 2mm foam and cut the design from that. Then, that piece was tacked onto the main shape with hot glue and the same process as above was repeated. The inside of the piece was covered first to lend support and hold the shape. Then, working from the bottom up, the front was covered. Using my fingernails and the pocket clip from the cap of a Sharpie, I was able to press the soft Worbla into the layers of foam and create the dimension I needed.

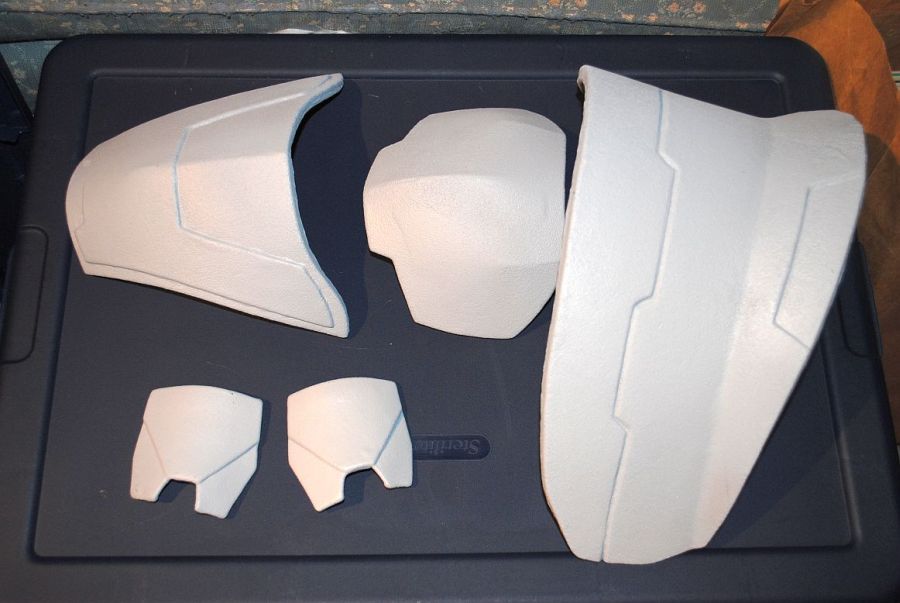

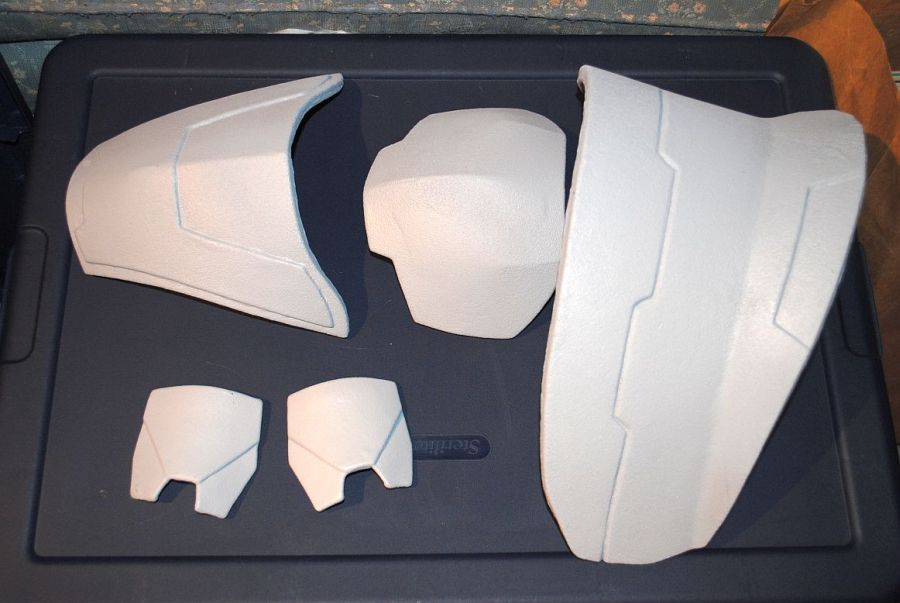

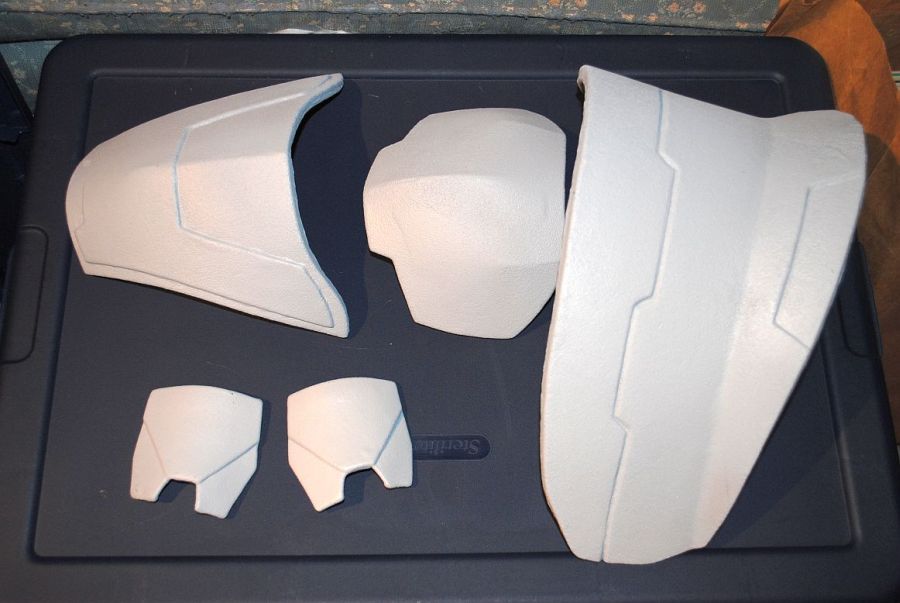

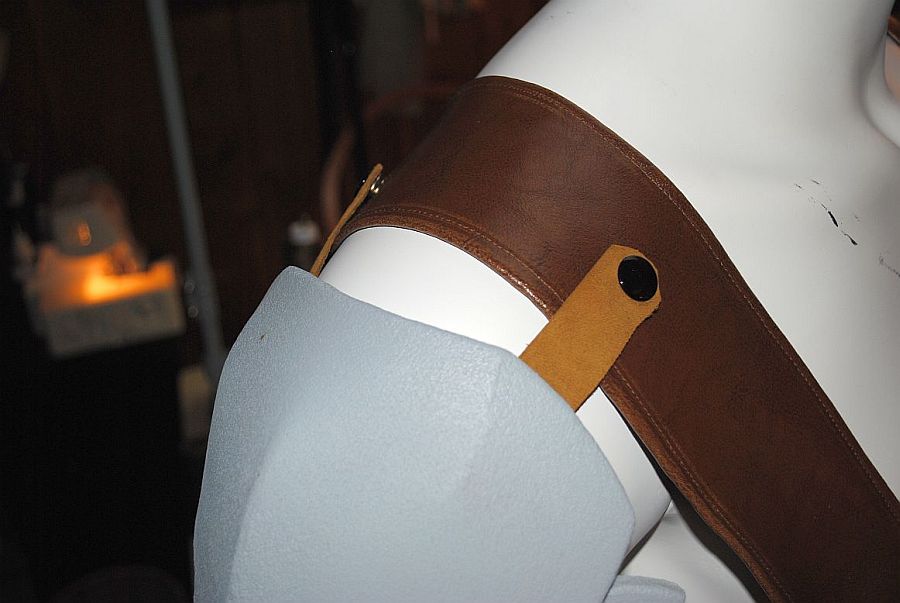

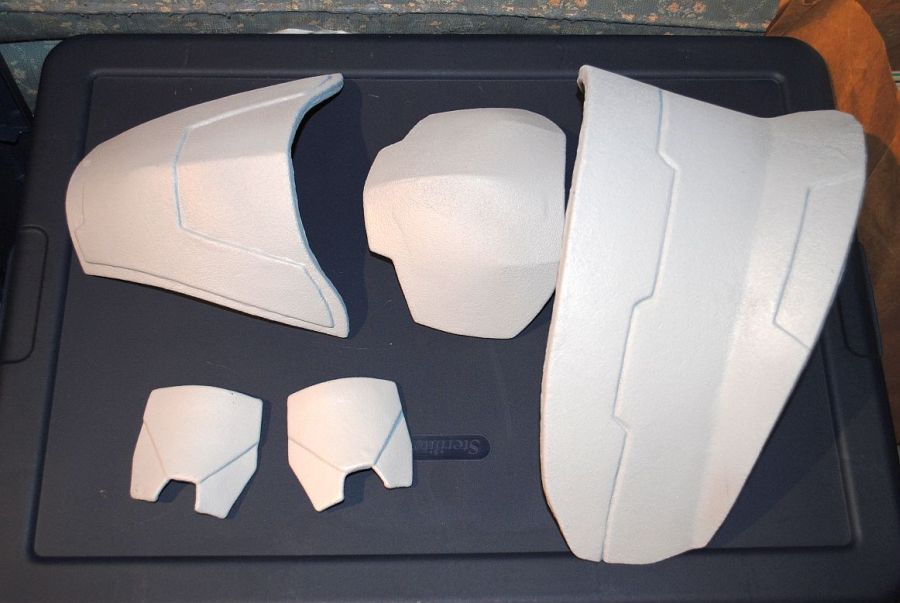

The recessed areas of the main collar were made the same way. To create the groove in the shoulder, I cut the collar piece out of 2mm foam and cut a 1/4" strip out of it and tacked it onto the main piece. Then, as I covered it with Worbla, pressed the soft plastic into the groove. Same with the section at the top of the collar. Here's a picture of all 3 pieces together (the main shoulder piece still needs to be trimmed and the edges finished).

The recessed areas of the main collar were made the same way. To create the groove in the shoulder, I cut the collar piece out of 2mm foam and cut a 1/4" strip out of it and tacked it onto the main piece. Then, as I covered it with Worbla, pressed the soft plastic into the groove. Same with the section at the top of the collar. Here's a picture of all 3 pieces together (the main shoulder piece still needs to be trimmed and the edges finished).

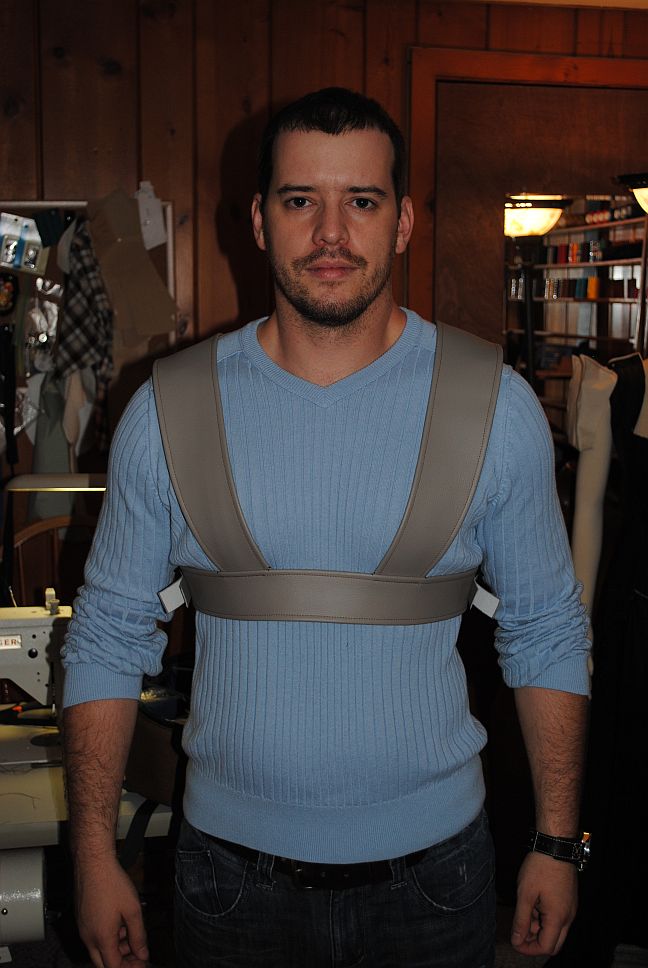

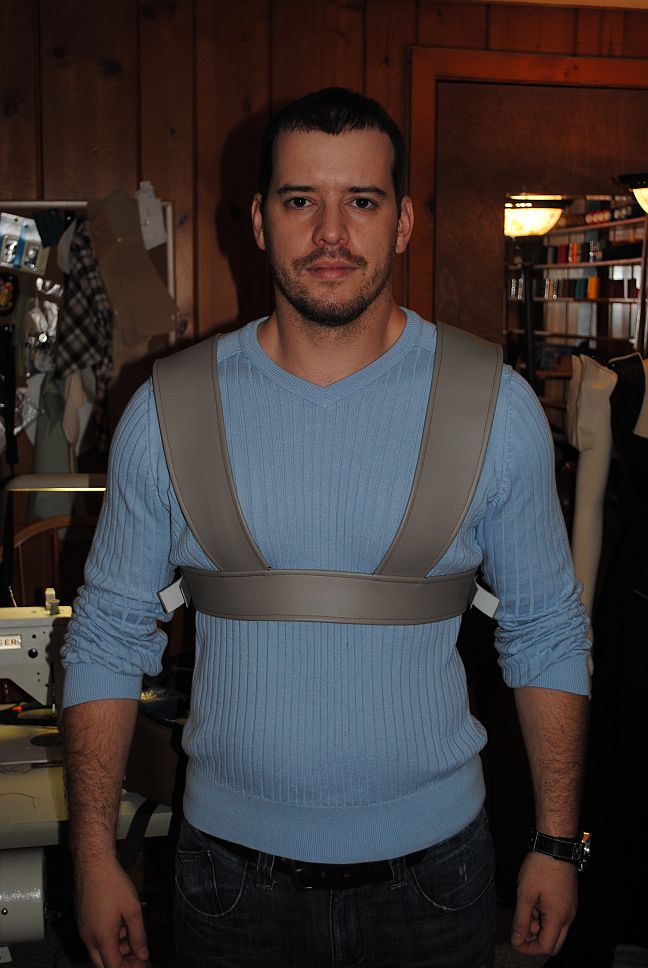

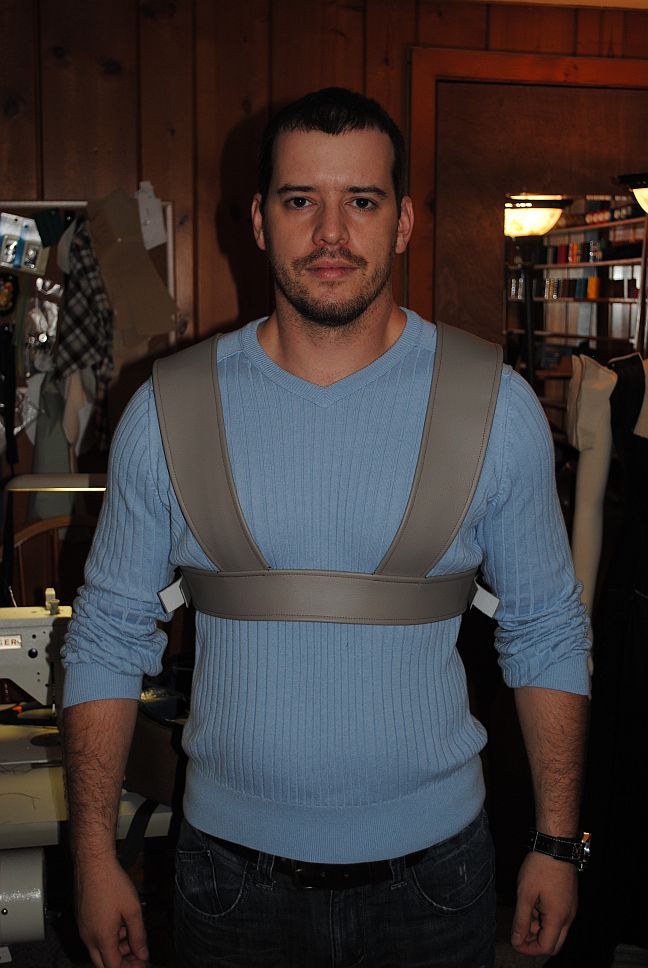

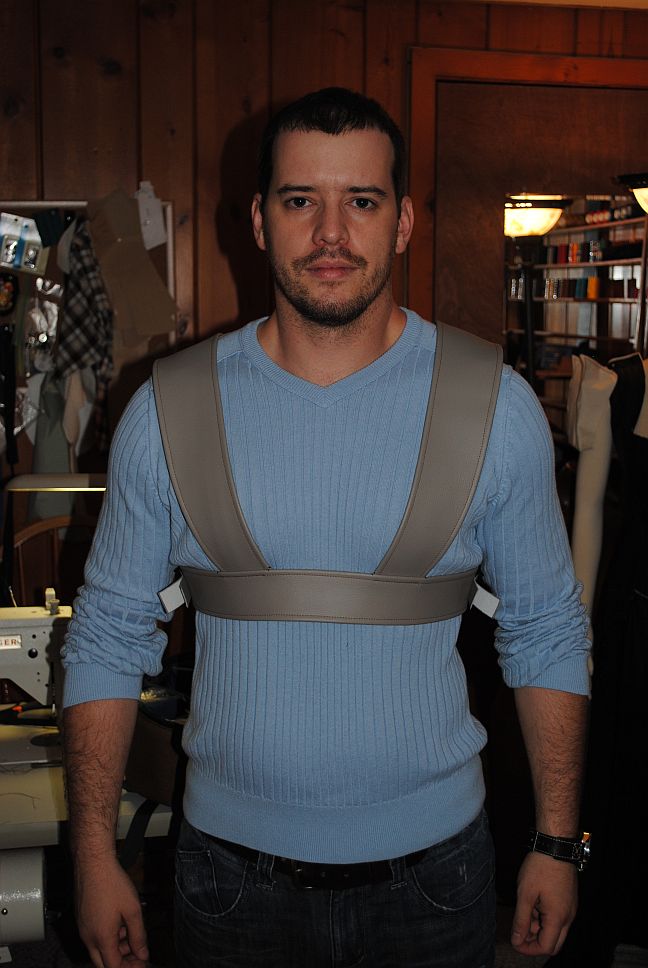

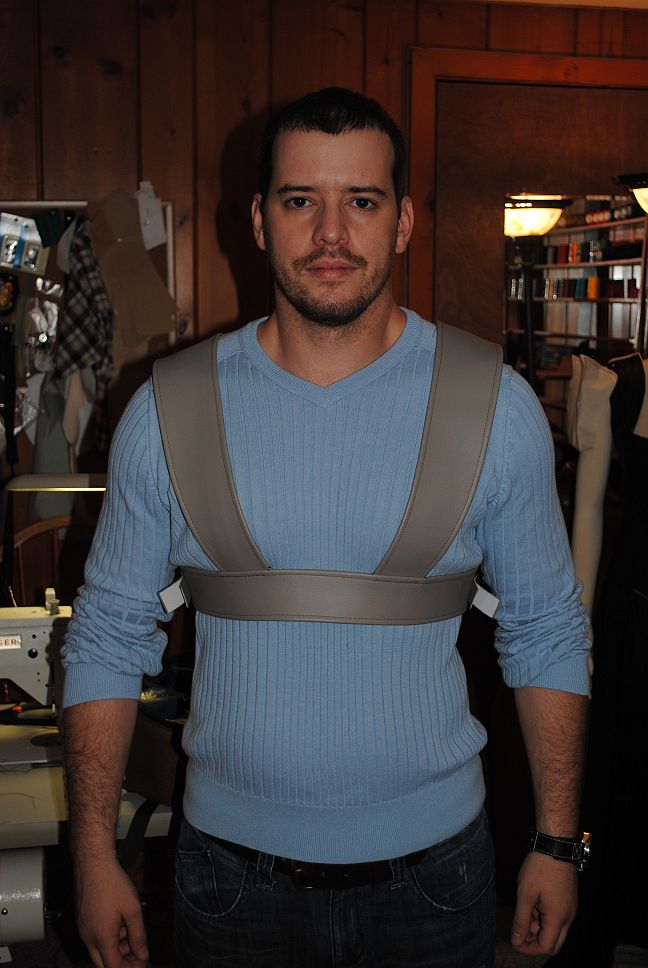

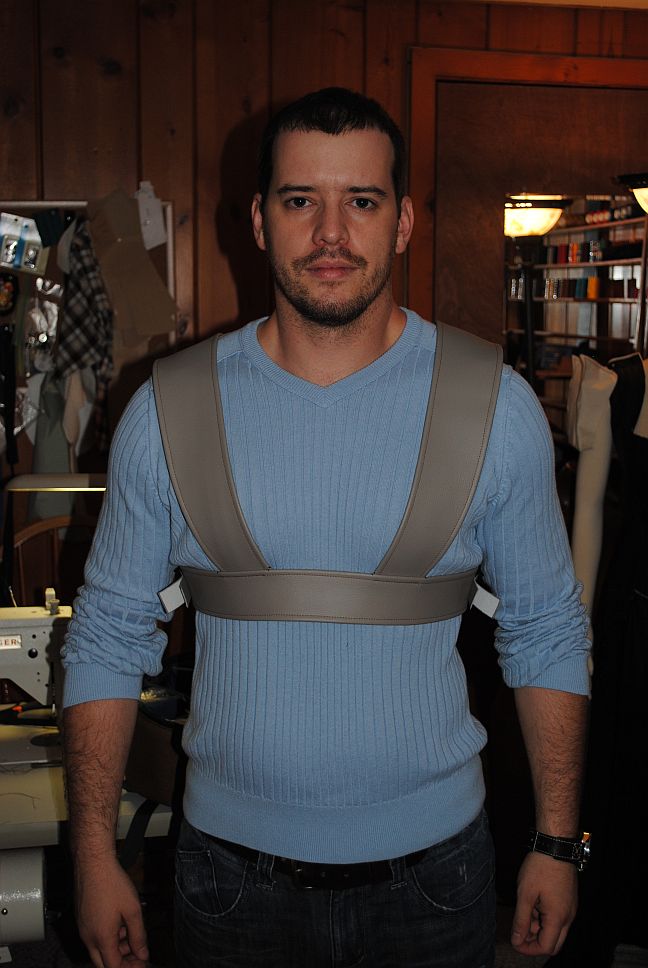

The client who's wearing the costume came by for a fitting and we tried on the base vest. The vest will be outfitted with the rest of the strapping and accessories and then get painted and distressed. The shirt will also get color-corrected, stained and distressed (and the sleeves shortened).

The client who's wearing the costume came by for a fitting and we tried on the base vest. The vest will be outfitted with the rest of the strapping and accessories and then get painted and distressed. The shirt will also get color-corrected, stained and distressed (and the sleeves shortened).

The next pieces I needed to make were the hand shields for the gloves. These were made using the same method as the rest of the armor pieces, except these were made of 2 layers of 2mm (rather than 1 layer of 6mm and 1 layer of 2mm) foam to keep the bulk down.

The next pieces I needed to make were the hand shields for the gloves. These were made using the same method as the rest of the armor pieces, except these were made of 2 layers of 2mm (rather than 1 layer of 6mm and 1 layer of 2mm) foam to keep the bulk down.

Next, it's time to start priming the pieces. I wanted to prime them before sanding so that I can see how much I'm taking off the surface as I sand. Since the material is fairly thin I want to make sure I don't get carried away and sand holes in the pieces which will be a pain to fill in.

Next, it's time to start priming the pieces. I wanted to prime them before sanding so that I can see how much I'm taking off the surface as I sand. Since the material is fairly thin I want to make sure I don't get carried away and sand holes in the pieces which will be a pain to fill in.

I linked the shoulder bell and the bicep pieces by embedding Chicago screws to the inside of the pieces. Then, I used leather strips to join them. Most of the reference materials I've seen for the costume looks like these are actually a single piece. However, we decided that we'd do them in two pieces for an increased range of motion and to add detail.

I linked the shoulder bell and the bicep pieces by embedding Chicago screws to the inside of the pieces. Then, I used leather strips to join them. Most of the reference materials I've seen for the costume looks like these are actually a single piece. However, we decided that we'd do them in two pieces for an increased range of motion and to add detail.

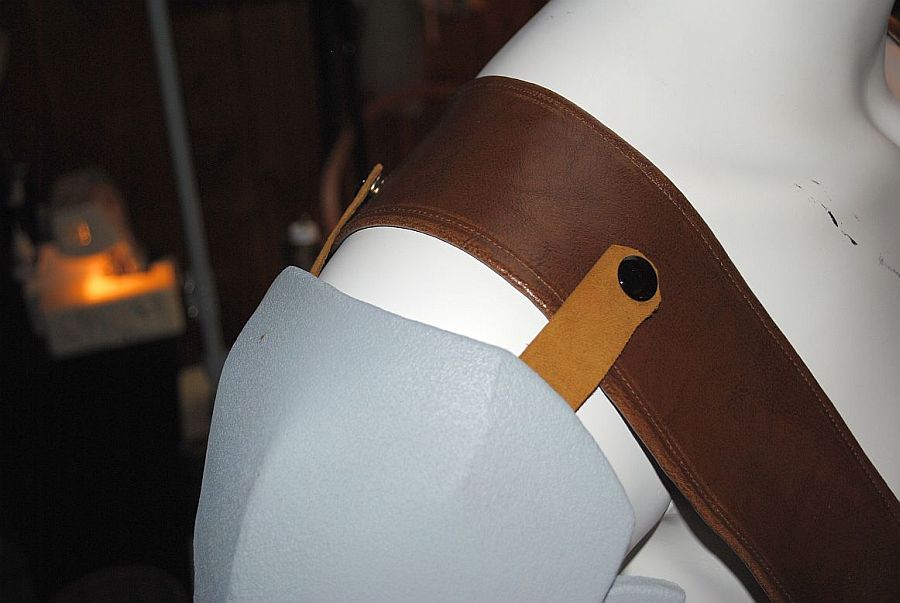

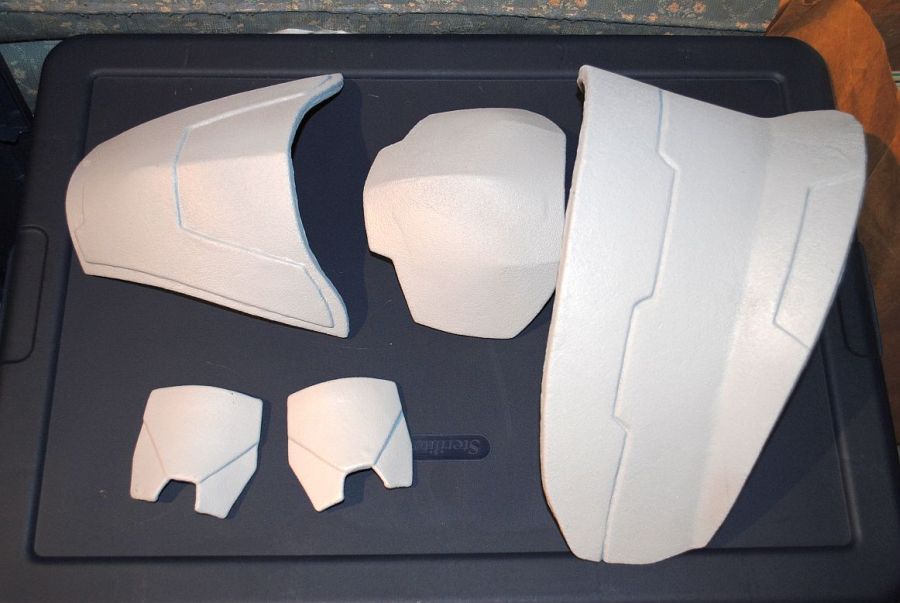

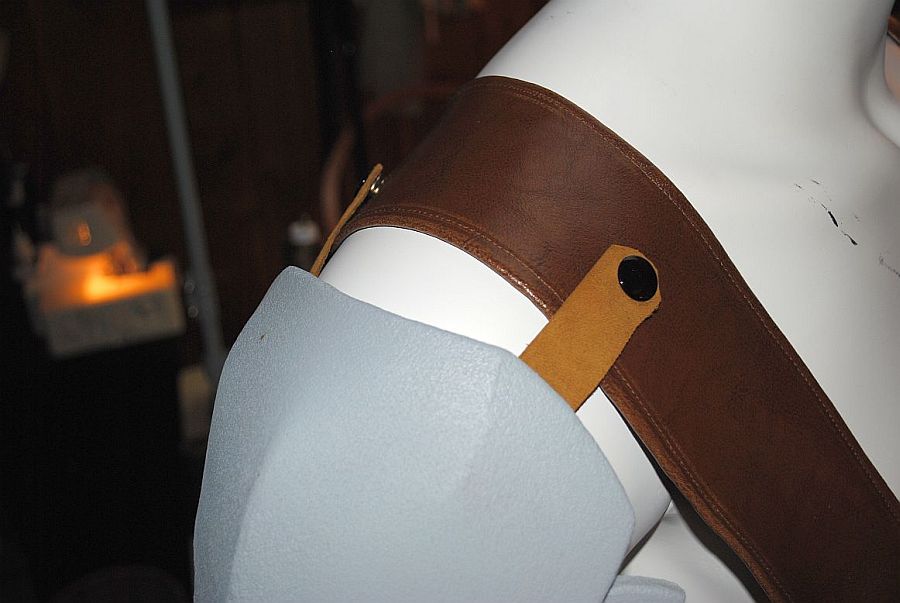

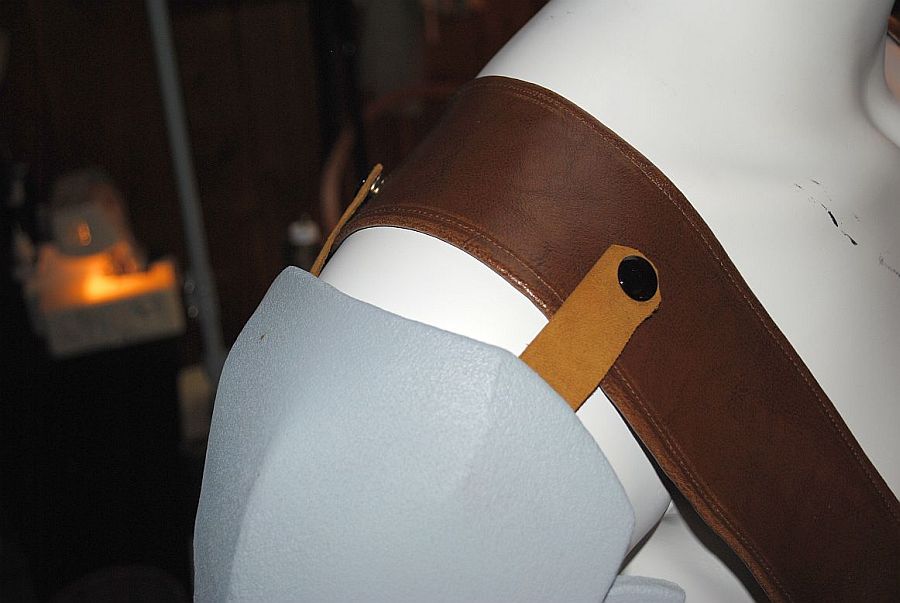

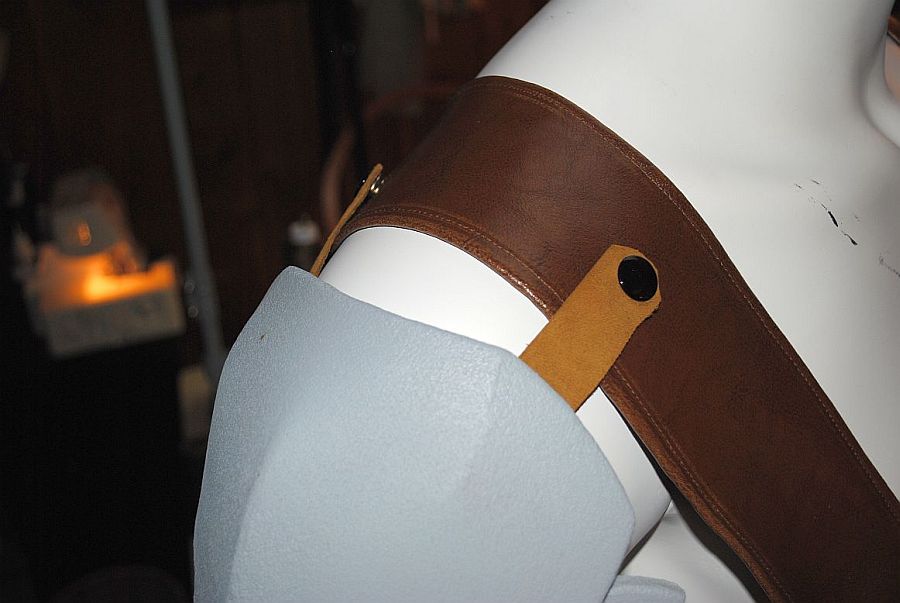

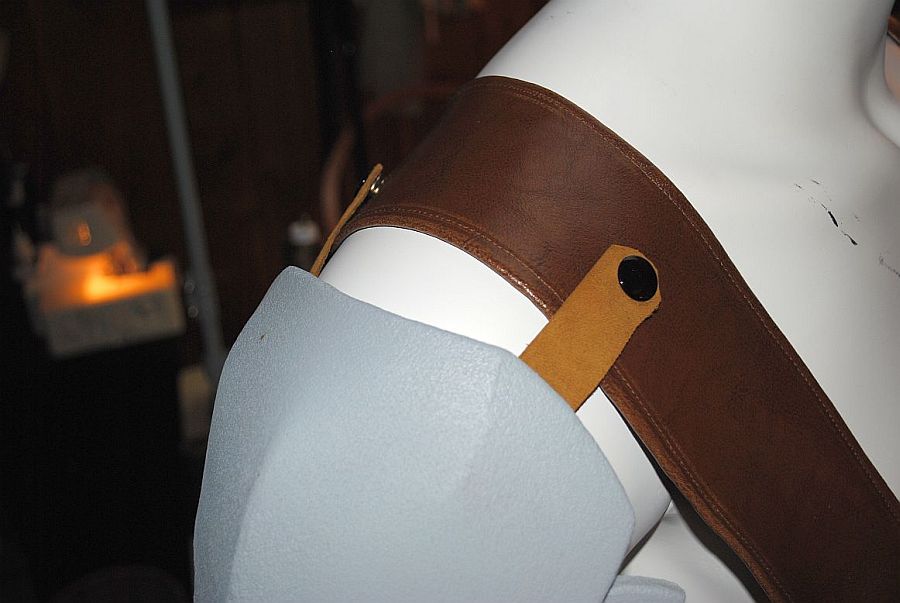

I then added additional straps to the top of the bell and used jean snaps to attach these pieces directly to the vest strap. I decided to attach these to the vest and not the shoulder piece so that the vest would take the weight and stress of movement of these parts and not the upper armor. I'm hoping this method will prevent the upper armor piece from being pulled out of position as the client poses in the costume.

I then added additional straps to the top of the bell and used jean snaps to attach these pieces directly to the vest strap. I decided to attach these to the vest and not the shoulder piece so that the vest would take the weight and stress of movement of these parts and not the upper armor. I'm hoping this method will prevent the upper armor piece from being pulled out of position as the client poses in the costume.

I also built the vest out of the actual material that all of the belting and pouches will be made in. This will also be given some paint and distressing treatments before the costume is finished.

I also built the vest out of the actual material that all of the belting and pouches will be made in. This will also be given some paint and distressing treatments before the costume is finished.

Here are front and back images of the armor and vest together so far. The shoulder and front detailing need to be added to the vest and the sanding and paint need to be applied to the armor. Then, all the distressing and detail paint will be applied once all of the hardware and belting is assembled.

Here are front and back images of the armor and vest together so far. The shoulder and front detailing need to be added to the vest and the sanding and paint need to be applied to the armor. Then, all the distressing and detail paint will be applied once all of the hardware and belting is assembled.

Chris (who is wearing this costume) came over to help out with the build because he wanted to learn more about how costumes are made. Be careful what you wish for! He was put to work in charge of sanding, paint on all the armor pieces and dye on the shirt and wraps (to be shown soon). He seemed to have a great time - he really bonded with the detail sander at any rate.

Chris (who is wearing this costume) came over to help out with the build because he wanted to learn more about how costumes are made. Be careful what you wish for! He was put to work in charge of sanding, paint on all the armor pieces and dye on the shirt and wraps (to be shown soon). He seemed to have a great time - he really bonded with the detail sander at any rate.

Huge thanks go out to Chris Donio at Lab604 for the amazing resin hardware pieces he cast for this project. He did all the small, specialty hardware pieces (of which there are more than a few) based on paper templates I gave him. The pieces were cast in resin and give a treatment of metal powder. The result being that, when rubbed with steel wool, the pieces took on an burnished, aged steel sheen.

Huge thanks go out to Chris Donio at Lab604 for the amazing resin hardware pieces he cast for this project. He did all the small, specialty hardware pieces (of which there are more than a few) based on paper templates I gave him. The pieces were cast in resin and give a treatment of metal powder. The result being that, when rubbed with steel wool, the pieces took on an burnished, aged steel sheen.

After laying out the resin casts on the in-progress belt pieces, the rest was really just a big jigsaw puzzle - figuring out what pieces went together in what order to maximize style and function. While Chris was around, it was easy to try things on him, test the fit and scale and adjust things as we went. It's very rare and fortunate for this type of project to have that kind of access to the client. Being able to just look around the corner and say, "I need you come stand in here while I build this costume on your body" is awesome.After the fittings and the layout was settled, the hardware on the middle belt was the first to deal with. The resin pieces were striated on the back and epoxy was the choice for setting them on the belt. However, there was concern that the semi-smooth surface of the belt would not grip with the epoxy. So, muslin strips were sewn into the surface to give the epoxy something to hold onto.

After laying out the resin casts on the in-progress belt pieces, the rest was really just a big jigsaw puzzle - figuring out what pieces went together in what order to maximize style and function. While Chris was around, it was easy to try things on him, test the fit and scale and adjust things as we went. It's very rare and fortunate for this type of project to have that kind of access to the client. Being able to just look around the corner and say, "I need you come stand in here while I build this costume on your body" is awesome.After the fittings and the layout was settled, the hardware on the middle belt was the first to deal with. The resin pieces were striated on the back and epoxy was the choice for setting them on the belt. However, there was concern that the semi-smooth surface of the belt would not grip with the epoxy. So, muslin strips were sewn into the surface to give the epoxy something to hold onto.

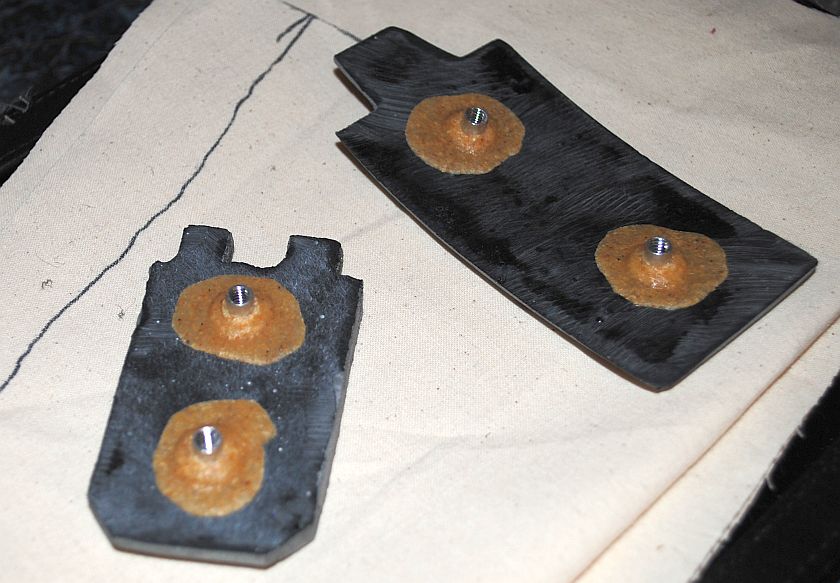

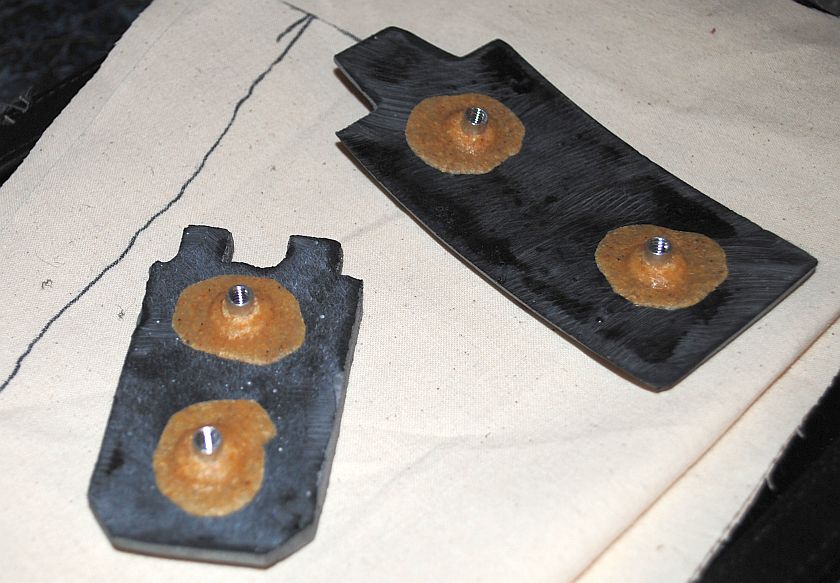

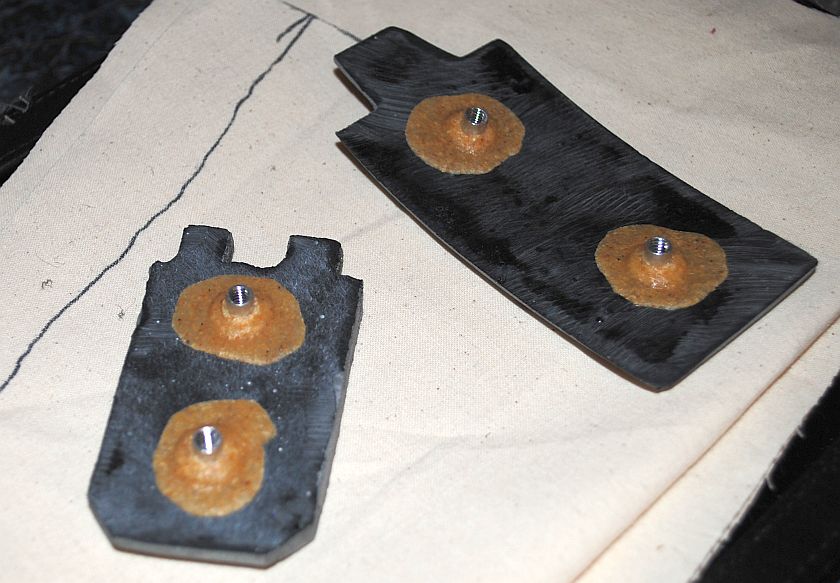

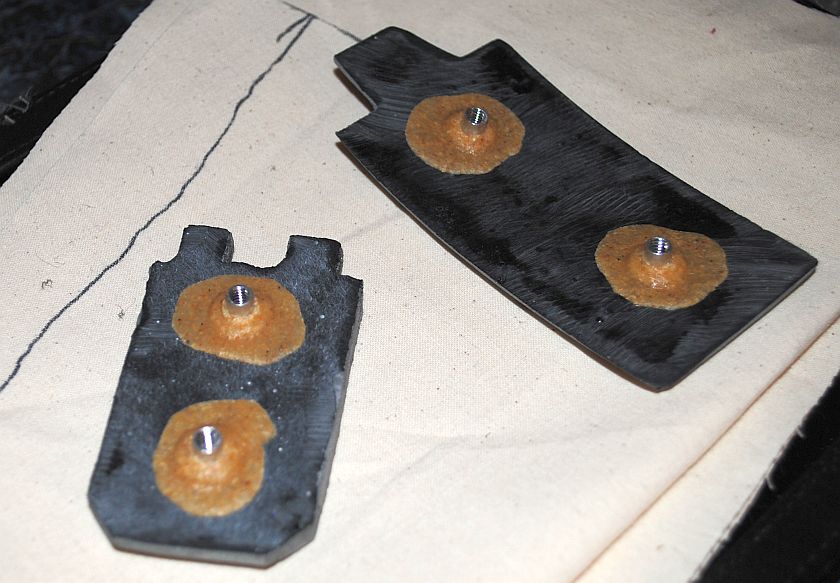

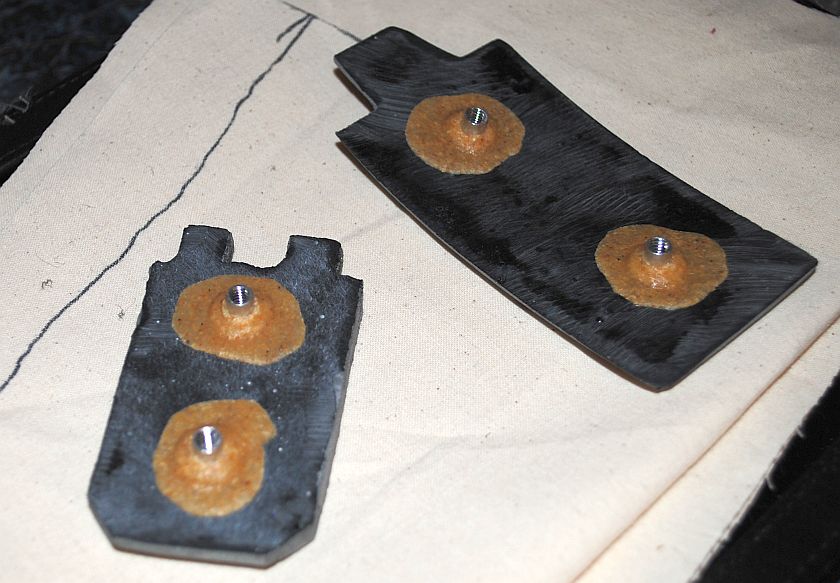

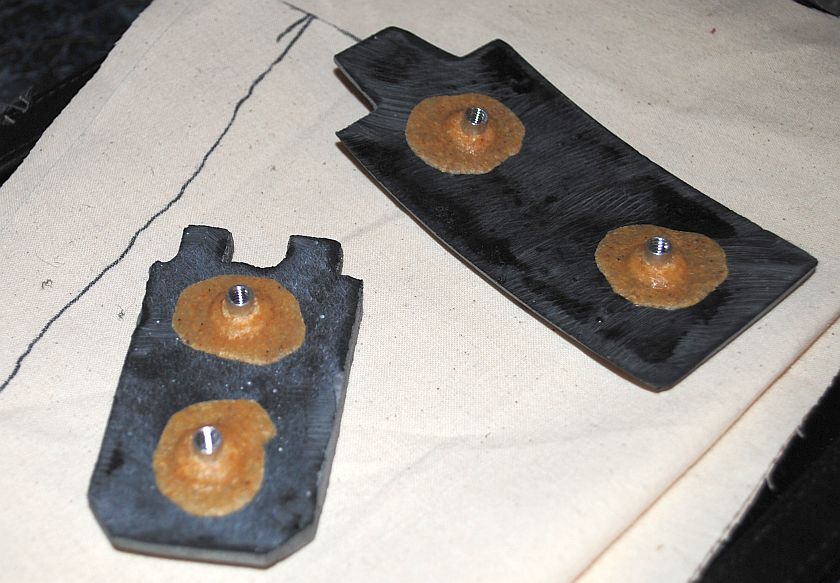

The resin pieces were glued into the muslin with epoxy and set aside to cure - we'll come back with pics of that in a bit. The main belt was tackled next. The buckle and side discs were secured with Chicago screws that were embedded into the resin during casting (once again - thank you, Chris Donio!). A couple of additional screws were added to the buckle to hold the lower straps.

The resin pieces were glued into the muslin with epoxy and set aside to cure - we'll come back with pics of that in a bit. The main belt was tackled next. The buckle and side discs were secured with Chicago screws that were embedded into the resin during casting (once again - thank you, Chris Donio!). A couple of additional screws were added to the buckle to hold the lower straps.

Once the main belt pieces were together, the pieces for the leg strapping were fitted, cut and assembled. For a number of the pieces of the lower belt and leg straps, Chicago screws were used to secure the resin pieces to the belts since they were going to take the most abuse from movement and stress. If you're not familiar with them, Chicago screws are insanely useful in costume projects are available at most hardware stores or online. I've linked them in this thread for easy searching.For pieces that did not already have the threaded posts embedded in the resin, I simply glued the posts to the back of the pieces with LocTite and then cut a worbla disc to encase the base of the post and seal it to the piece.

Once the main belt pieces were together, the pieces for the leg strapping were fitted, cut and assembled. For a number of the pieces of the lower belt and leg straps, Chicago screws were used to secure the resin pieces to the belts since they were going to take the most abuse from movement and stress. If you're not familiar with them, Chicago screws are insanely useful in costume projects are available at most hardware stores or online. I've linked them in this thread for easy searching.For pieces that did not already have the threaded posts embedded in the resin, I simply glued the posts to the back of the pieces with LocTite and then cut a worbla disc to encase the base of the post and seal it to the piece.

Then, holes are punched in the belt pieces and the resin pieces are screwed in place. Here's a pic of the belt and the leg straps all in place.

Then, holes are punched in the belt pieces and the resin pieces are screwed in place. Here's a pic of the belt and the leg straps all in place.

The whole costume is coming together and there are only a few details left to attend to. Here's how it looks at this point.

The whole costume is coming together and there are only a few details left to attend to. Here's how it looks at this point.

The last piece to assemble was the pad for under the shoulder armor. This piece needed to fit very snugly and smoothly, so I decided to create it from the same template that was used for the original piece. The pieces were cut out of EVA foam and glued together. Then, they were trimmed to be slightly smaller that the armor.

The last piece to assemble was the pad for under the shoulder armor. This piece needed to fit very snugly and smoothly, so I decided to create it from the same template that was used for the original piece. The pieces were cut out of EVA foam and glued together. Then, they were trimmed to be slightly smaller that the armor.

Once the foam base was complete, the lower surface was covered in thin foam to add padding.

Once the foam base was complete, the lower surface was covered in thin foam to add padding.

Finally, the cover and straps were made from the same material as the vest and belts and the pad was essentially upholstered with it. Then, the pad was glued to the bottom of the armor and corresponding snaps added to the vest.

Finally, the cover and straps were made from the same material as the vest and belts and the pad was essentially upholstered with it. Then, the pad was glued to the bottom of the armor and corresponding snaps added to the vest.

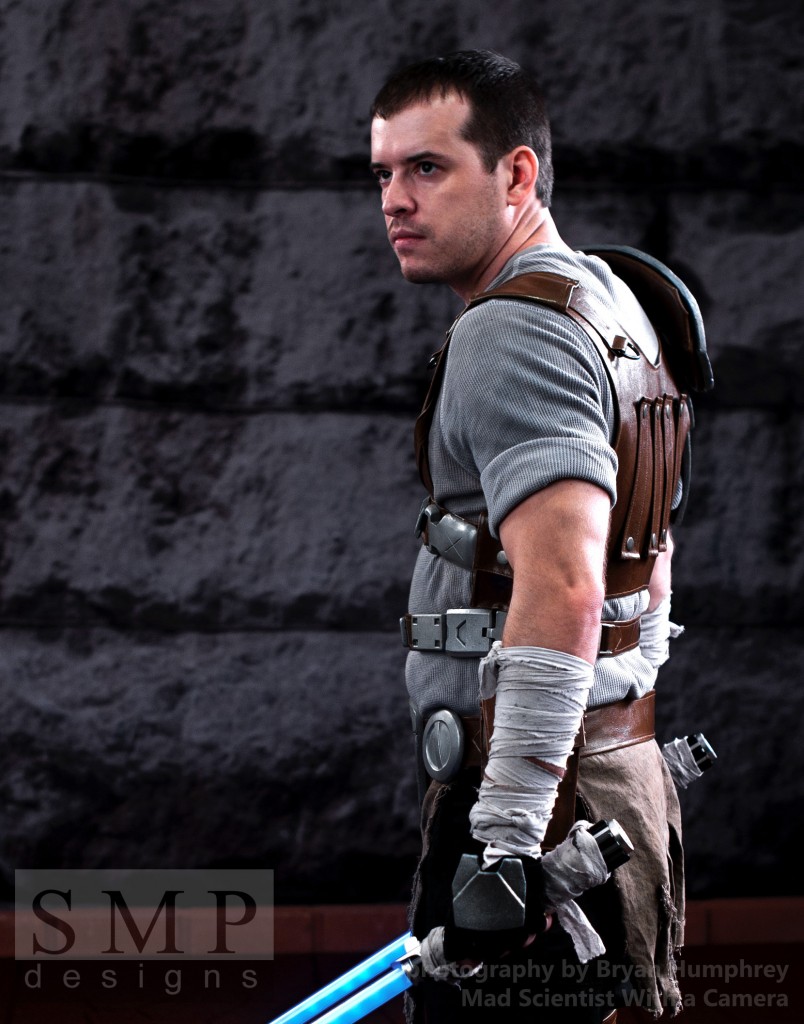

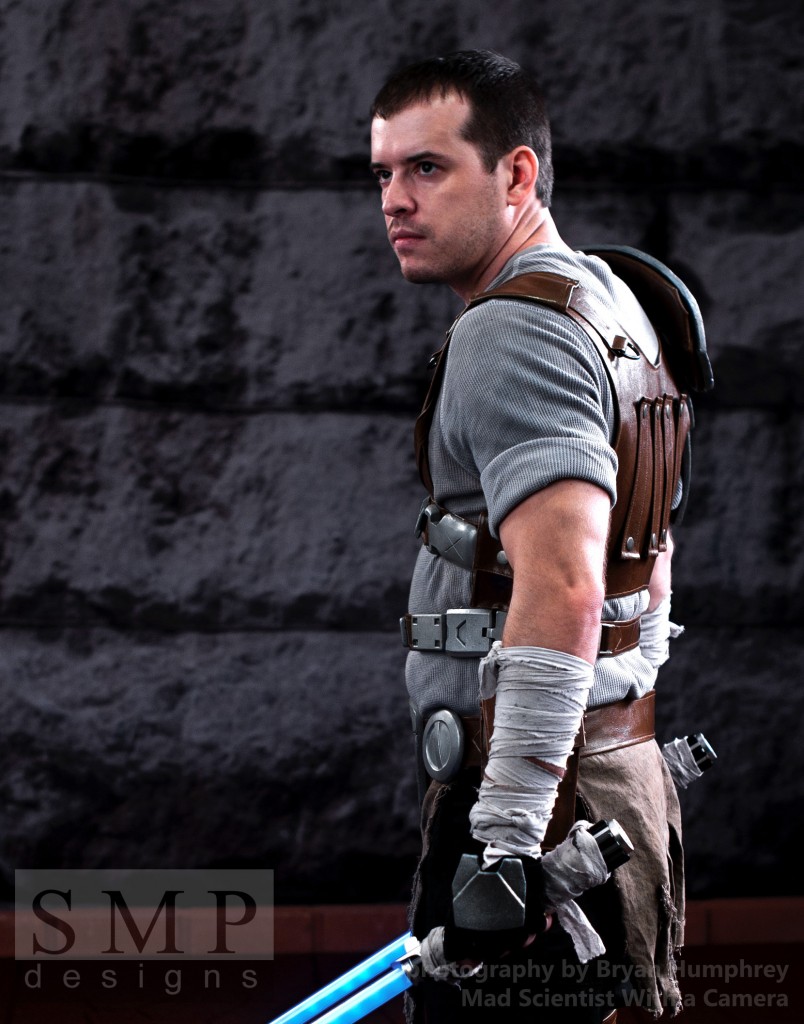

The last details were ripping linen and distressing it for the strapping and some final color correction. Here's the final costume:

The last details were ripping linen and distressing it for the strapping and some final color correction. Here's the final costume:

Some quick background: this costume was made for Dragon*Con 2013. It was made for a friend - who was Prince Dastan this year and some of you might recognize from my Captain America WIP as the body model for the patterns - and was also worn this year, where it got some love from Starkiller himself, Sam Witwer.

I also did a video of this build.

OK, so on to the WIP...

We began by working out a template for the armor. Starting with poster board, the general shape of the main shoulder armor was decided (to scale with the wearer) and then the collar piece was fitted to create the desired up-sweep.

Last edited by a moderator: