DEGASS RTV...

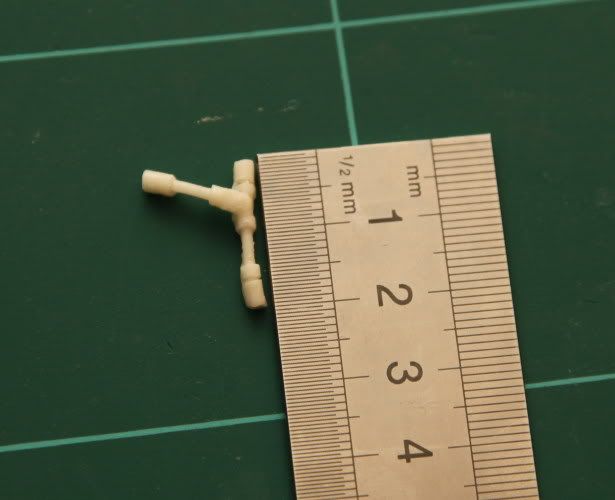

PRESSURE CAST..resin (cured mold for casting)....

Glue a TINY strip of styrene strip to the part..or...USE a TOOTH Pick to POP bubbles as you pour.

PRESSURE CAST..resin (cured mold for casting)....

Glue a TINY strip of styrene strip to the part..or...USE a TOOTH Pick to POP bubbles as you pour.