iconsunlimited

New Member

So this is the first time I have posted here on any of my own projects but have been a long time lurker. I found this site when I made my foam Iron Man build and have been on it far too often reading all the information and shared knowledge and positive comments for builds and thought it time to share what I am currently working upon. Two years ago my daughter asked why we don't make Stormtrooper suits which then led me to purchase the vacuum former plans over at build-stuff.com and over the course of a year complete a 2'X3' table. I can not recommend those plans enough.

So on to the first (probably over ambitious) project to begin with....

Deathstroke: The Terminator Arkham Edition

I have always had an interest in Deathstroke: the Terminator. I felt he was a very cool if underrated character in the DC Universe and really like his updated look for Batman Arkham Origins.

I started with simple Plasticine clay.

After working with this for a long while (sorry I didn't think to take pics once I had a finished sculpt) I opted to mold it using Polygel-35 after watching a lot of videos offered by Brickintheyard.com instead of silicone due to it being better for pouring Ultracal 30 which I intended on using to make the casting from in order to vacuum form a mask. I sprayed Pol -Ease 2300 over the whole thing including the life cast to insure the Polygel did not attach to the clay.

Here are some of the stages of coating the helmet. I was mixing about 6 oz. of Polygel A and B at this time and that seemed to give me adequate coverage.

At this point after the "print coat" and another two layers I added poly fiber to the mix in order to thicken the shell to fill in the eye socket and other areas to insure it was a good solid thickness.

Once I completed I made a mold jacket out of fiberglass resin and cloth (again forgot to document with pics). I then mixed up the Ultracal 30 and poured it in to the mold and within 30 minutes it was hard enough to pull out. The great thing about the Polygel-35 was that I needed no mold release. The plaster casting came out cleanly never sticking to the mold and leaving the original sculpt very much intact.

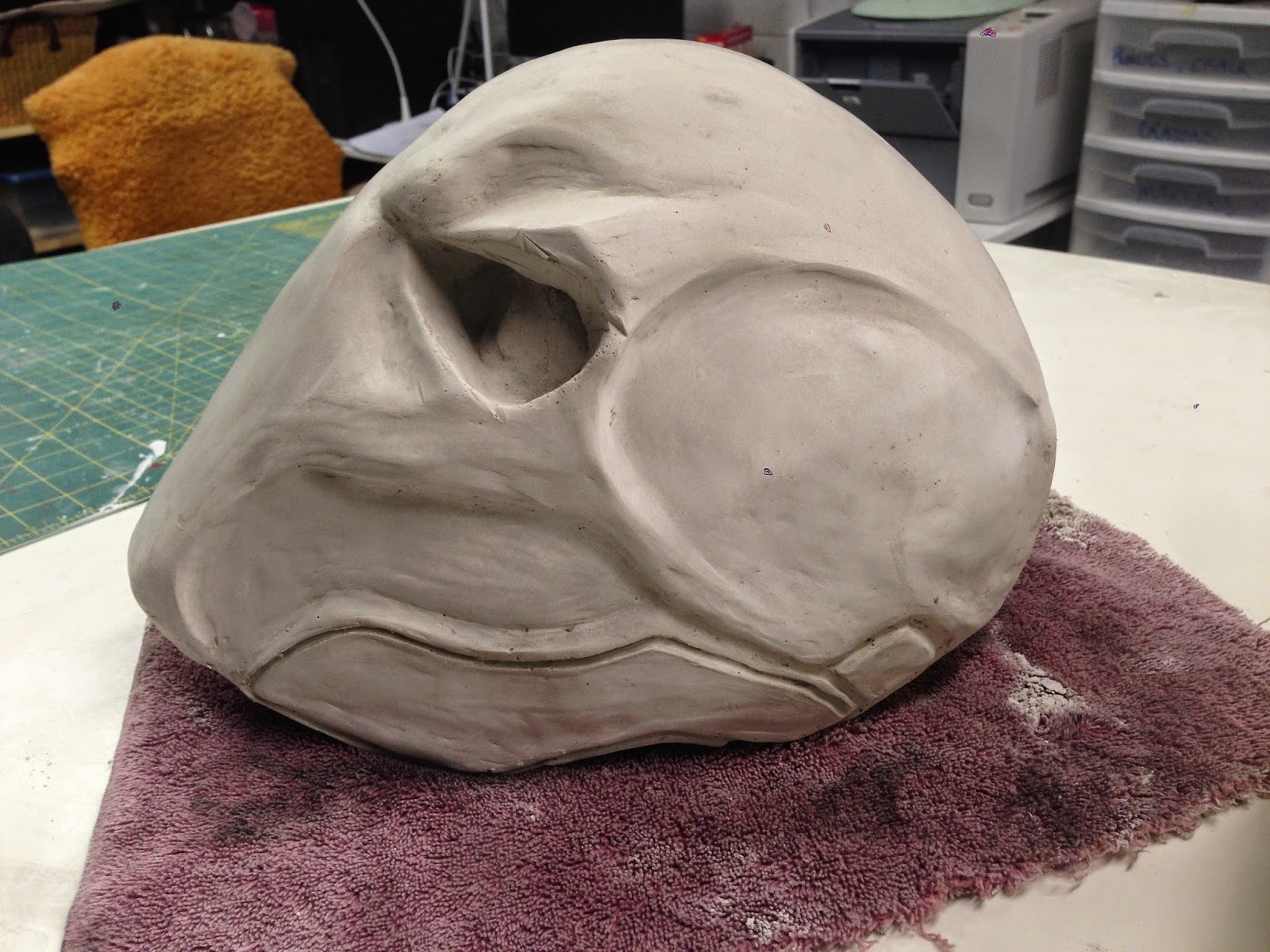

This is the stage I am currently at with this helmet. I will have to do more research to figure out how to avoid all the pitting I got around the eye and a few other areas but I am happy with my first attempt at anything like this. There is a lot sanding to do to clean up the surfaces and make the planes of the helm much more angular for the Deathstroke helm to look correct. I also have to begin sculpting the rear interlocking pieces so the helm has a complete front and back thanks to this site and specifically EyeofSauron with his thread regarding the separate pieces. http://www.therpf.com/f77/deathstroke-arkham-origins-helmet-research-now-accurate-pep-file-208480/

So on to the first (probably over ambitious) project to begin with....

Deathstroke: The Terminator Arkham Edition

I have always had an interest in Deathstroke: the Terminator. I felt he was a very cool if underrated character in the DC Universe and really like his updated look for Batman Arkham Origins.

I started with simple Plasticine clay.

After working with this for a long while (sorry I didn't think to take pics once I had a finished sculpt) I opted to mold it using Polygel-35 after watching a lot of videos offered by Brickintheyard.com instead of silicone due to it being better for pouring Ultracal 30 which I intended on using to make the casting from in order to vacuum form a mask. I sprayed Pol -Ease 2300 over the whole thing including the life cast to insure the Polygel did not attach to the clay.

Here are some of the stages of coating the helmet. I was mixing about 6 oz. of Polygel A and B at this time and that seemed to give me adequate coverage.

At this point after the "print coat" and another two layers I added poly fiber to the mix in order to thicken the shell to fill in the eye socket and other areas to insure it was a good solid thickness.

Once I completed I made a mold jacket out of fiberglass resin and cloth (again forgot to document with pics). I then mixed up the Ultracal 30 and poured it in to the mold and within 30 minutes it was hard enough to pull out. The great thing about the Polygel-35 was that I needed no mold release. The plaster casting came out cleanly never sticking to the mold and leaving the original sculpt very much intact.

This is the stage I am currently at with this helmet. I will have to do more research to figure out how to avoid all the pitting I got around the eye and a few other areas but I am happy with my first attempt at anything like this. There is a lot sanding to do to clean up the surfaces and make the planes of the helm much more angular for the Deathstroke helm to look correct. I also have to begin sculpting the rear interlocking pieces so the helm has a complete front and back thanks to this site and specifically EyeofSauron with his thread regarding the separate pieces. http://www.therpf.com/f77/deathstroke-arkham-origins-helmet-research-now-accurate-pep-file-208480/