tubachris85x

Master Member

I can't seem to find any real help on this, and it's kinda getting frustrating :unsure

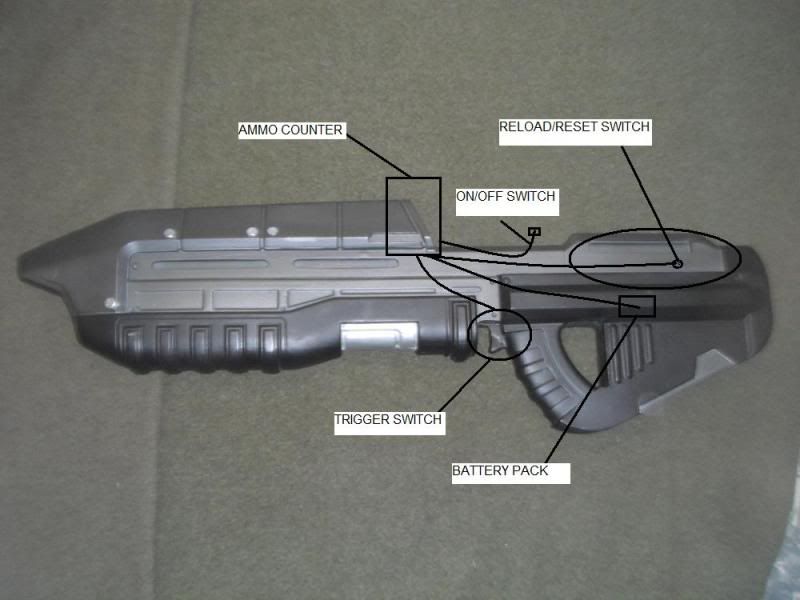

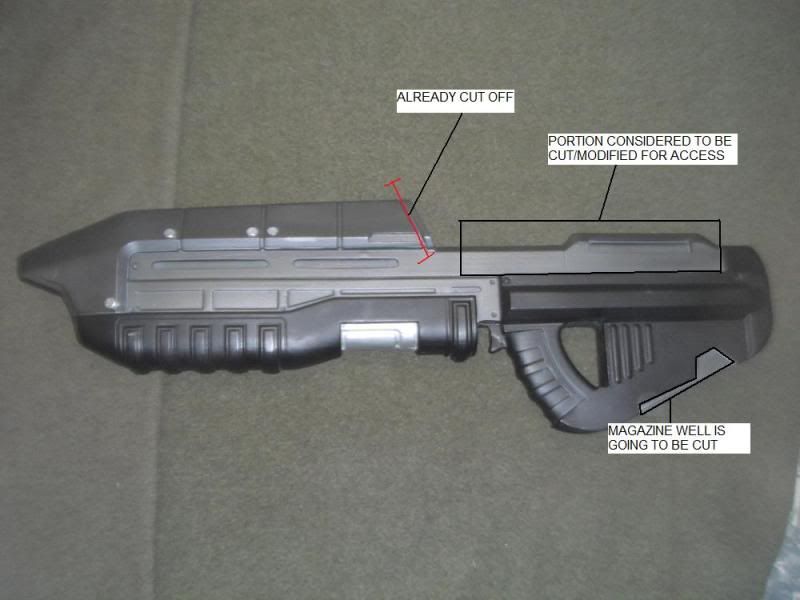

I am trying to get a series of electronics to fit into my halo AR. The issue being is that the rifle is a single piece cast. I have had many ideas, however, I am still loosing sleep on how to actually get the trigger switch and other components where it needs to be. I currently have cut out the main screen (where the counter will be placed) and that right now is my only real point of entry. I will be clearing out the magazine well as well, and that will be my 2nd point of entry.

My last resort however, is to cut a section off the top (where the bolt is, just behind the ammo counter screen, which would expose the entire rear inards. This though would be only as a last resort. :wacko

Any suggestions?

I am trying to get a series of electronics to fit into my halo AR. The issue being is that the rifle is a single piece cast. I have had many ideas, however, I am still loosing sleep on how to actually get the trigger switch and other components where it needs to be. I currently have cut out the main screen (where the counter will be placed) and that right now is my only real point of entry. I will be clearing out the magazine well as well, and that will be my 2nd point of entry.

My last resort however, is to cut a section off the top (where the bolt is, just behind the ammo counter screen, which would expose the entire rear inards. This though would be only as a last resort. :wacko

Any suggestions?

Last edited: